I & M Mark 87 Series

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve temperature regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the

event of leakage or other malfunction, call a qualied service person; continued operation may cause system failure

or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disassembling a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

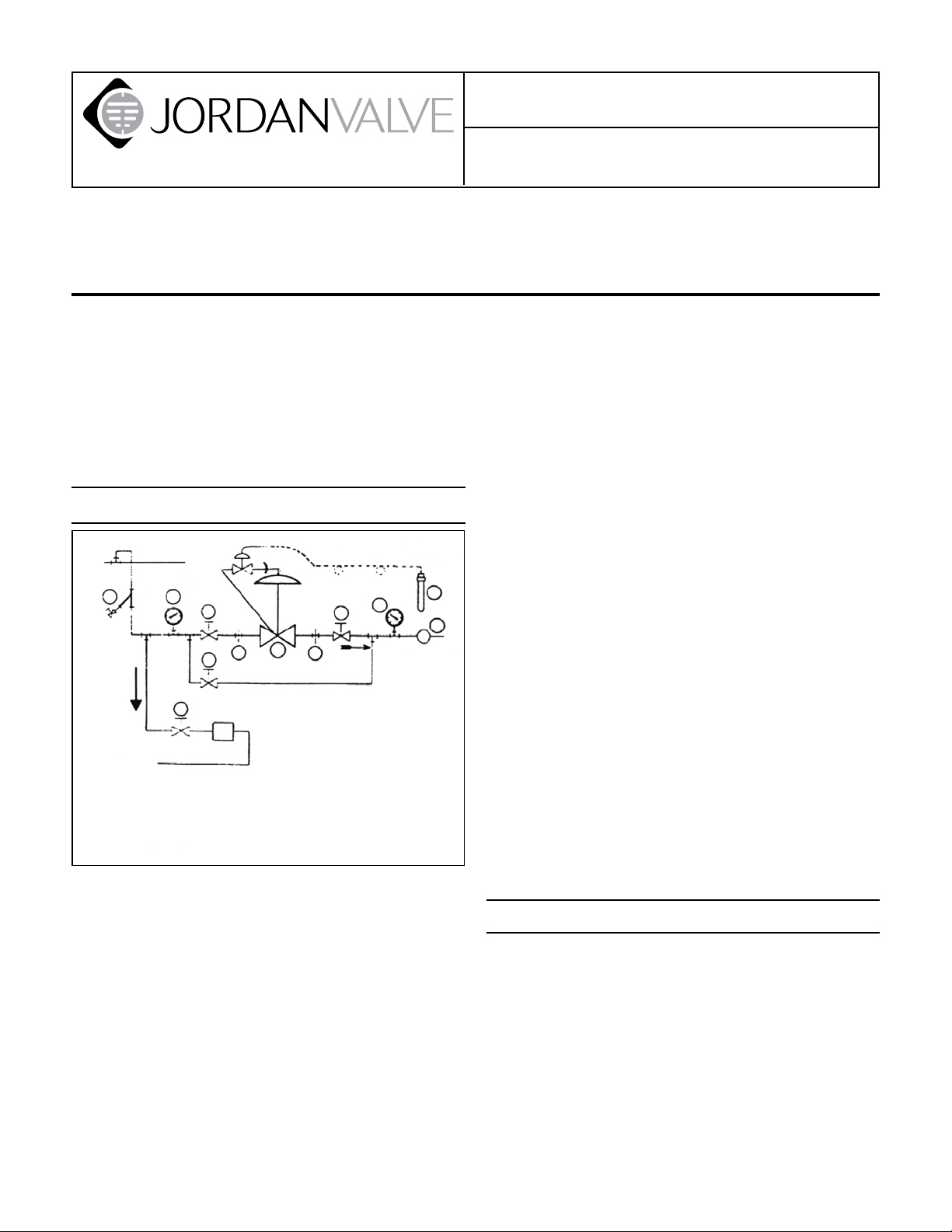

Ideal Installation

Main Steam

Line

3

To protect the regulator from grit, scale, thread chips, 1.

and other foreign matter, all pipe lines and piping

components should be blown out and thoroughly

cleaned before the valve is installed.

Shutoff valves, pressure gauges, and bypass piping 2.

should be installed as indicated in the diagram to

provide easier adjustment, operation, and testing.

In preparing threaded pipe connections, care 3.

should be taken to prevent pipe sealing compound

from getting into the pipe lines. Pipe sealing compound should be used sparingly, leaving the two

lead threads clean. Jordan uses, and recommends,

Seyco #2415 thread sealer Teon ribbon.

A line strainer should be installed on the inlet side of 4.

4

1

1

2

1

Steam

1

Trap

Condensate

Return Line

4

1

5

2

By-Pass Line

1. Shutoff Valve

2. Pipe Union

3. Strainer & Drain Valve

4. Pressure Gauge

5. Jordan Regulator

6. Relief Valve

7. Thermal Bulb

7

6

R

Installation & Maintenance Instructions for

Mark 87 Temperature Regulators (1/2” – 6”)

the regulator to protect it from grit, scale and other

foreign matter. A 0.033 perforated screen is usually

suitable. Line strainers are available from Jordan

Valve.

Install the regulator in the highest horizontal line of 5.

piping to provide drainage for inlet and outlet piping, to prevent water hammer, and to obtain faster

regulation.

The ow arrow on the regulator body must be 6.

pointed in the direction of ow. The valve may be

installed vertically or horizontally without affecting its

operation.

For best control, 3’0” straight sections of pipe should 7.

be installed on either side of the valve.

To minimize condensation in hot vapor lines, up-8.

stream and downstream piping near the regulator

should be insulated.

For injection heating applications, the regulator 9.

should be installed above the maximum water level

in the tank, or a check valve should be installed to

prevent water from backing up into the regulator.

For best regulation, the temperature regulator 10.

should be installed as closely as possible to the unit

in which the temperature is being controlled.

On steam control applications, install a steam trap 11.

of sufcient capacity to drain the coil or condenser.

Be sure to have a good fall to the trap, and no back

pressure. Best control is obtained when the coil or

condenser is kept dry.

Where surges are severed, a piping accumulator is 12.

recommended.

Operation

The direct acting pilot valve is normally open, allowing

the upstream pressure to force the main diaphragm

down to open the main valve seats. As the process

temperature approaches the desired setting, the uid

in the bulb vaporizes, creating the necessary pressure

on the pilot diaphragm to throttle the pilot valve toward

the closed position. This starves the pressure supply

to the main diaphragm and the lower spring beings to

close the main valve. The reverse acting pilot is normally

closed, and opens on an increase in temperature.

Start-Up Procedure

With the inlet, outlet and by-pass shut-off valves closed:

port. Follow instructions in section “To Remove Main

Diaphragm”.

Thermal System Failure. See Series 80 I & M Sheet.•

Fully open the outlet shut-off valve1.

Slowly open the inlet valve just enough to start ow 2.

through the regulator. Observe the downstream

pressure gauge. Increase the downstream pressure

slowly by gradually opening the inlet valve.

Do not fully open the inlet valve until you are sure 3.

that the regulator has control of the system. Usually, the handwheel on the inlet valve will turn freely

when this point is reached.

To change the controlled temperature, rotate the 4.

adjusting wheel on the pilot valve upward to increase the temperature, and downward to crease

the temperature.

Troubleshooting

Insufcient Heating (or Cooling)1.

A valve undersized for the application. Check capac-•

ity required and valve capacity.

Line strainer or pilot strainer screen could be •

clogged. Blow down strainers or visually check that

they are clear.

Incorrect setting on range spring. Vary the setting •

and check response.

Main valve diaphragm may be ruptured. See section •

on main valve maintenance.

Malfunction of other piping components. Check for •

leaking traps and safety valves, inadvertently opened

or closed valves.

Controlled Temperature Fluctuates

Valve oversized. Check capacity required and valve •

capacity.

Maintenance

WARNING: Be sure that there is no pressure in the

valve before loosening any ttings or joints. The following steps are recommended.

Close inlet shut-off valve.1.

Allow pressure to bleed off through downstream 2.

piping. Do not cause a reverse ow through valve by

bleeding pressure from upstream side of valve.

When downstream pressure gauge indicates no 3.

pressure in the line, close the outlet shut-off valve.

Close the control line shut-off valve.4.

Bulb Installation

The Thermal System is a hermetically sealed unit consisting of a sensing bulb, capillary tubing, protective armor,

and actuator assembly. This unit contains the thermostatic charge that operates the temperature regulator.

Please do not tamper with it. In case the charge is lost,

the thermal system must be replaced as a complete unit.

It is not repairable in the eld and must be returned to

the factory for repairs.

Overheating (or Cooling)2.

Incorrect setting on range spring. Vary the setting •

and check response.

Pilot valve or main valve seats leaking. Close inlet •

shut-off valve, allow downstream pressure to bleed

off, close outlet valve and remove loading pressure tubing. FOR HEATING APPLICATION: Heat the

sensing bulb to approximately 20° - 30°F above the

control point and/or reduce the compression of the

adjusting spring to guarantee that the pilot valve is

stroked closed. FOR COOLING APPLICATION: Cool

the sensing bulb to approximately 20° - 30°F below

the control point and /or increase the compression

of the adjusting spring to guarantee that the pilot

valve is stroked closed. Crack open inlet shut-off

valve - if uid issues from pilot valve point, the pilot

seats are leaking. If the uid issues from the main

valve port, the main valve seats are leaking.

By-pass shut-off valve leaking. During period of leak-•

age, close outlet shut-off valve, observe thermometer.

Bleed port in main valve clogged. Remove Upper •

Bonnet to gain access to bleed port and clean bleed

Correct Installation1. - For effective temperature control

installation of the sensing bulb is essential. For best

results, the bulb should be installed at a point of true

representative temperature and where there is good

circulation. A thermometer or other temperature

sensing device (if used) should be placed as close as

possible to the sensing bulb of the regulator.

Handle the capillary and armor carefully so they are 2.

not crushed, kinked or twisted. A bend of 4-1/2”

radius or larger is recommended.

Horizontal Mounting3. - When the bulb is to be

mounted horizontally, it must be turned so that the

word TOP and center punch mark (stamped on the

adapter) faces upward.

Vertical Mounting 4. - No special precaution is required

when the bulb is mounted vertically pointing down.

Inverted Mounting5. - A special capillary is required

if the tip of the bulb will be higher than the capillary end. The temperature regulator equipped with

-2-