Page 1

I & M Mark 75 (1” – 2”)

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Installation & Maintenance Instructions for

Mark 75 Wafer Control Valve

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or a

general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling

a valve, be sure to release all spring tension.

Please read these instructions carefully!

should be installed on either side of the valve.

5. The disc in the valve body must be positioned

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

in the upstream portion of the flow, and the setscrews should be on the downstream side of the

valve. Ideally for steam applications, the valve

should be installed in the highest horizontal line of

piping to provide drainage for inlet and outlet piping, to prevent water hammer, and to obtain faster

response.

6. If possible, install a relief valve downstream from

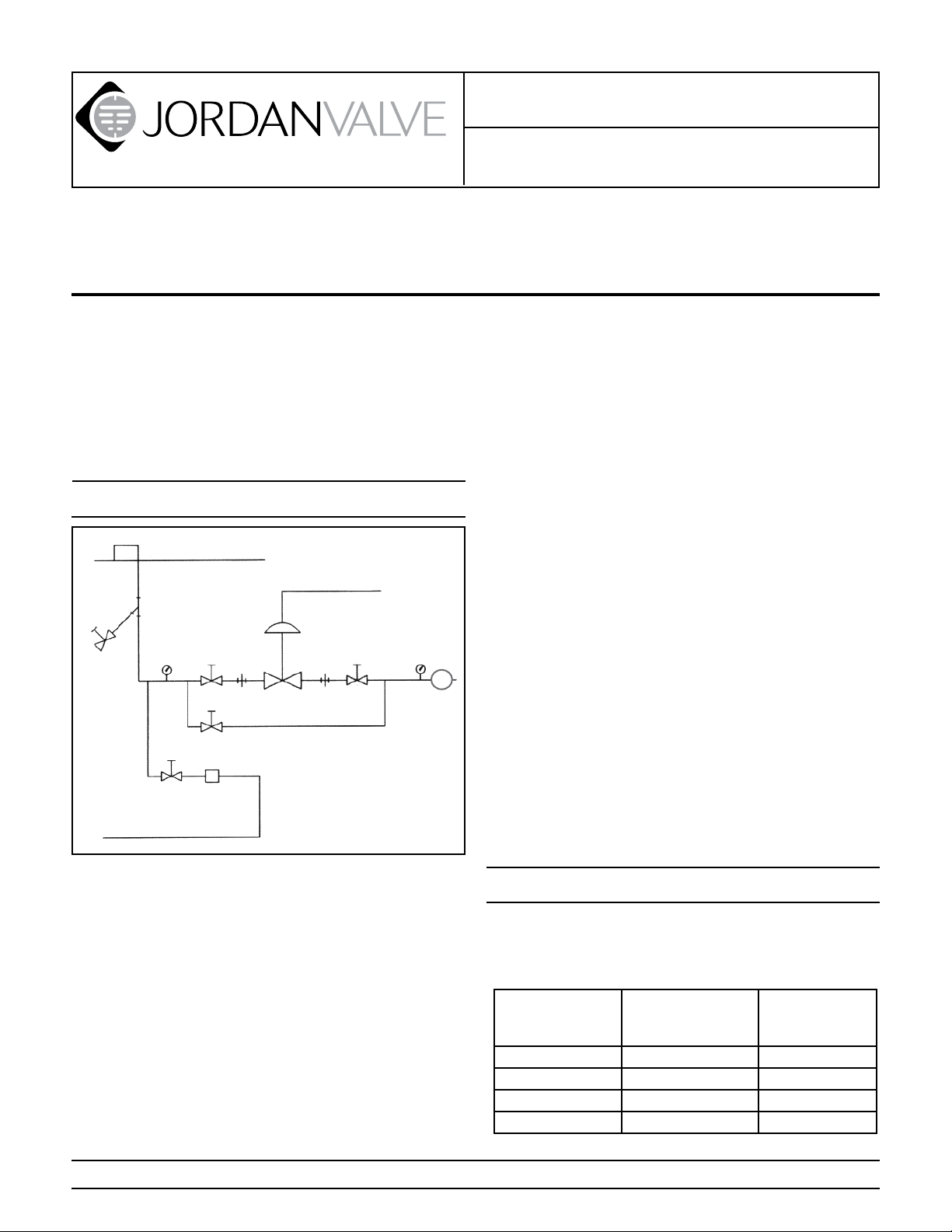

Ideal Installation

the valve. Set at 15 psi above the control point of

the valve.

Main Line

7. In hot vapor lines, upstream and downstream piping near the valve should be insulated to minimize

Control Air

condensation.

8. In gas service, expand the outlet piping at least

3

4

7

1

7

2

1

4

5

R

one pipe size, if the control pressure (downstream)

is 25 percent of the inlet pressure or less. A standard tapered expander connected to the outlet of

the valve is recommended.

9. Where surges are severe, a piping accumulator is

recommended.

1

1

6

Condensate Return Line

1. Shut off Valve

2. Jordan Control Valve

3. Strainer and Drain Valve

4. Pressure Gauge

5. Relief Valve

6. Steam Trap

7. Pipe Union

10. On steam control applications, install a steam trap

with sufficient capacity to drain the coil or condenser. Be sure to have a good fall to the trap, and no

backpressure. Best control is maintained if the coil

or condenser is kept dry.

11. Tighten pipe flange bolts just enough to effect a

good seal.

1. To protect the valve from grit, scale, thread chips

and other foreign matter, ALL pipelines and piping

components should be blown out and thoroughly

cleaned before the installation process begins.

2. Shutoff valves, pressure gauges and by-pass piping should be installed as indicated in the diagram

above to provide easier adjustment, operation, and

testing.

3. A line strainer should be installed on the inlet side

of the valve to protect it from grit, scale and other

foreign matter. A 0.033 perforated screen is usually

suitable for this purpose. Line strainers are available from Jordan Valve.

4. For best control, 3’ 0” straight sections of pipe

PROTECT VALVES WITH LINE STRAINERS

Start-Up Procedure

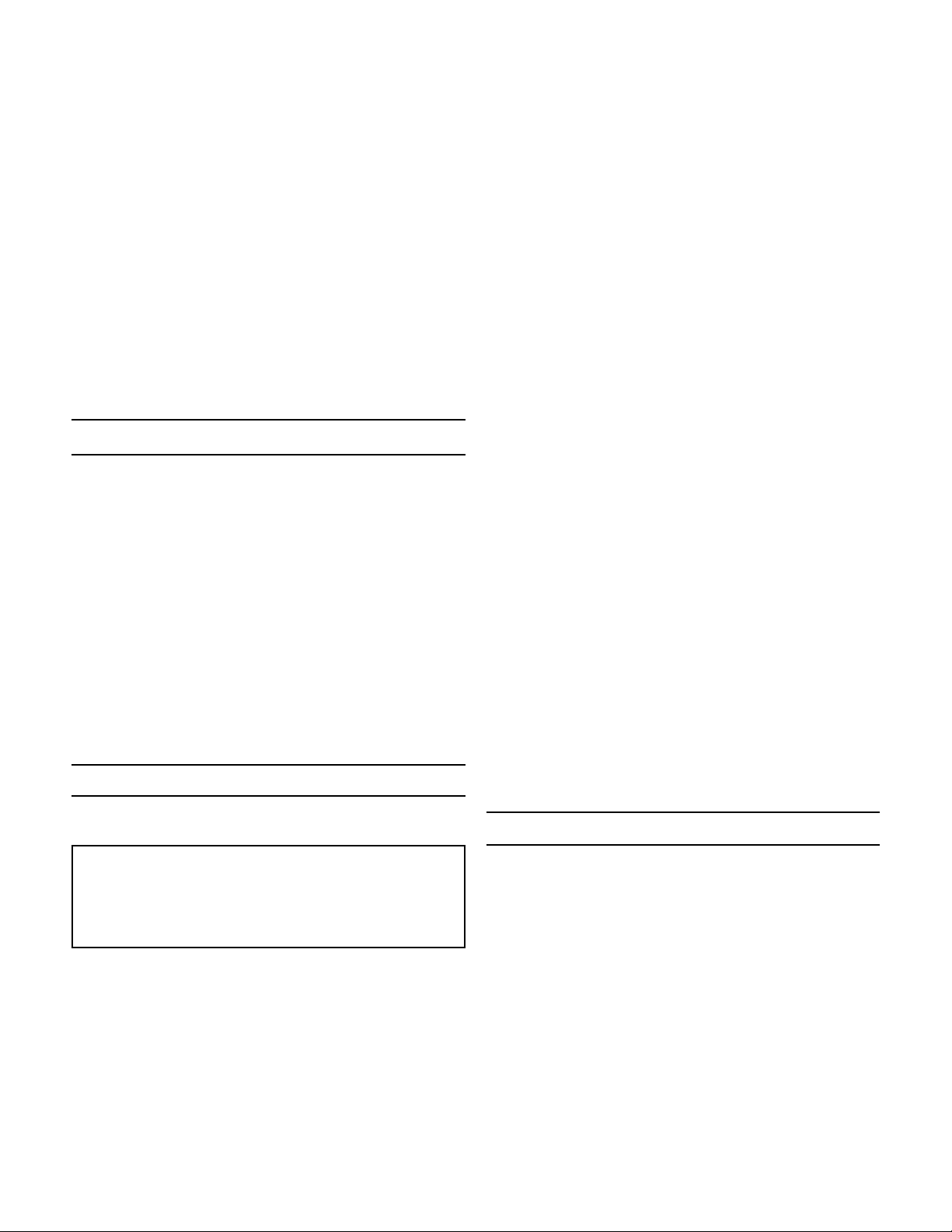

1. Be sure that the action of the control valve and of

the controller are such that you achieve the desired

results.

Increase in

pressure or

temperature must:

Close Valve Air to Close (Direct) Direct

Close Valve Air to Open (Reverse) Reverse

Close Valve Air to Close (Direct) Reverse

Close Valve Air to Open (Reverse) Direct

And the action of

the valve is:

Then the action

of the controller

must be:

Page 2

2. The control valve has been pre-set by Jordan Valve,

however, finer adjustment may be required to compensate for the system conditions of your application.

3. With inlet, outlet and bypass shutoff valves closed,

and no pressure in the downstream line, gradually

open the inlet valve enough to start flow through

the control valve. Increase the flow gradually by

slowly opening the inlet shutoff valve. Do not fully

open the inlet valve until you are sure that the

controller and control valve have control of the

system. Usually, the handwheel on the inlet valve

will turn freely when this point is reached.

4. To shut off the line fluid, close the inlet shutoff

valve first, and then close the outlet shutoff valve.

5. Loosen the body set screws (42).

6. It may be necessary to re-torque the pipe flange

bolts.

Maintenance

Caution: Make certain that there is no pressure in the

valve before loosening any fittings or joints. The following steps are recommended:

1. Close the inlet shutoff valve.

2. Allow pressure to bleed off through the downstream piping. Do not attempt to reverse the flow

through the valve by bleeding pressure from the

upstream side of the valve.

3. When the pressure gauges indicate that all pressure has been removed from the system, close the

outlet shutoff valve and the valve may be serviced.

Note: refer to the drawing at the end of this document

for description and proper orientation of parts.

Valve Seats

(28), Disc (27), and Gasket (36). Place the plate on

the bench with the lapped surface up.

5. Clean all parts of the Body (1) with a good quality

solvent. Remove Guide screws (35) and Guides

(34), the Disc (27) and Plate (28) can then be

cleaned. Place a piece of 4/0 polishing cloth or

jeweler’s cloth on a smooth flat surface such as a

surface plate and polish the Disc, and Plate lapped

surfaces using a figure “8” motion. If the parts are

scarred, do not attempt to re-lap them, but return

them to the factory for repair or replacement.

B. Reassembly

1. Place the plate (28) on a clean, flat work surface

with the lapped side up. The small single locator

hole should be towards you.

2. If the valve action is “air to open”, place the Disc

(27) on the Plate with the words “TOP REVERSE”

away from you. If the valve action is “air to close”,

the words “TOP DIRECT” should be away from you.

Move the Disc (27) until the slots are in perfect

alignment with those of the plate (28).

3. Place the Guides (34) on either side of the Disc

(27), and secure them with the Guide screws (35)

so that the Disc (27) can move freely up and down

but not side to side.

4. Lightly lubricate both side of the Body Gasket (36)

with an anti-seize compound. Place a new Body

Gasket (36) into the Body (1).

5. Hold the Plate / Disc assembly together and insert

it into the large end of the Body (1) with the slots

perpendicular to the stem (20), taking care that the

“T” slot in the Disc (27) engages the head of the

valve stem. The word ”TOP” should be towards the

actuator.

6. Replace the Set screws (42) in the Body (1).

7. Follow instructions under Installation & Start Up

Procedure when placing valve back in service.

A. Disassembly

The sliding Gate Seats of Jordan Valves are lapped to

light band flatness. Maintaining such tolerances is of

paramount importance for your assurance of excellent

control and tight shutoff. DO NOT use metallic objects

in removing the seats. Care in handling is imperative.

1. Tighten the body set screws (42). Follow instructions under the Maintenance section to remove

valve from line.

2. Disassemble the valve only as far as necessary to

do the required work.

3. When replacing seats it is recommended by Jordan

Valve that the packing be replaced if the valve is

older than one year. Follow the instructions under

Packing Replacement.

4. Remove the Set screws (42), and remove the Plate

Stem & Packing Replacement

1. Remove the Plate (28) and Disc (27), following the

procedure outlined under the Valve Seats section.

2. Loosen the Stem Connector Nut (31) and Bolt (30)

and remove Connector Halves.

3. Back out the Yoke SST Screws (29) and allow the

Body (1) to separate from the Yoke (3).

4. Remove the Packing Flange Nuts (43) and the

Packing Flange (24).

5. Before pulling the Stem (20) completely out of the

Body, you must remove the “7th” Stem T-Head (32)

by unscrewing it from the Stem (20). Remove the

Packing Assembly (37,38, & 40). The remaining

parts of the Packing Assembly can “fished” out with

a small screwdriver. (Be careful not to damage the

packing bore.)

6. Clean the packing bore in the Body with solvent

-2-

and blow dry.

Page 3

7. Clean the Stem (20) with solvent if it is to be reused.

8. Replace the Packing Spring (37) and Packing Retainer (38) in the packing bore.

9. Reassemble the new Packing (40) on the stem (20)

with the open part of the “V” downward (^). There

will be a flat on the top and bottom. Place the Packing Follower (23) on top of the Packing (40). (Coat

each piece of the packing set with a suitable lubricant.)

10. Gently push the Packing (40) into the packing bore

and place the Packing Flange (24) on the stem.

11. Put the Packing Flange Nuts (43) on the Packing

Studs (25) and partially tighten. At this point it is

recommended that you gently move the stem up

and down three or four times to align the assembly.

12. Tighten the Packing Flange nuts (43) until the Packing Follower (23) bottoms out on the top of the

body.

13. Reassemble Yoke (3) to the valve Body (1) with the

four Yoke Screws (29). Reassemble the Seats by

inserting in the body as outlined in Valve Assembly

Section.

Actuator

CAUTION: DO NOT apply more than 45 psi to the actuator.

The valve need not be removed from the line; however

before performing any maintenance on the actuator:

Since there will be no control of the valve available

it is recommended that the valve be isolated from

the service.

Shut off the control air supply and remove the con-

trol line from the actuator.

Remove the stem connector assembly (Stem

Adapter (22) to the Valve Stem (20) using the Stem

Connector Halves (21), the Stem Connector Bolt

(30) and Nut (31).

A. Actuator Disassembly

1. Remove the actuator assembly from the valve by

removing the four yoke Bolts (26), and lift the actuator assembly off the Yoke (3).

2. Place the actuator assembly on its top, (side with

the control line connection). Release the spring

compression, by threading the Actuator Stem (14)

out of the actuator, by turning it counterclockwise.

3. Remove the Actuator Bolts and Nuts (6,7) and

separate the two halves, (Upper Case [5] and Lower

Case [4]), of the actuator assembly. Remove the six

Range Springs (10) from the diaphragm plate (11).

4. Lift out the diaphragm assembly. Loosen and remove the two Actuator Jam Nuts (17) from the Actuator Bolt (16). Remove the Diaphragm Plate (11),

Diaphragm (15), Diaphragm Stop (13), and the Fastener Seal (18) from the Actuator Bolt (16) also.

5. Clean all parts with a good quality solvent. Remove

any encrusted material with crocus or very fine aluminum oxide cloth. Inspect all parts for excessive

wear and/or damage. Replace any worn or damaged parts. USE ONLY JORDAN REPLACEMENT

PARTS. The use of other than genuine JORDAN

parts may result in damage to the actuator, personal injury or property damage.

B. Actuator Reassembly

1. Place the Fastener Seal (18), Diaphragm Stop (13),

Diaphragm (15), and Diaphragm Plate (11) on the

Actuator Bolt (16) in order. Align the Diaphragm

(15) and Diaphragm Plate (11) such that one of the

formed bosses on the Diaphragm Plate is lined-up

with one of the boltholes in the Diaphragm. Assemble and tighten the two locknuts (17) on the

actuator bolt (16), taking care that they are locked

together, and that the alignment between the diaphragm and the plate is maintained.

2. Place the Diaphragm Assembly (from step 1) on

the Upper Actuator Case (5), (half with the control

line connection) with the Diaphragm Plate (11) up.

Place the six Range Springs (10) on the Diaphragm

Plate (11) so that they nest over the formed bosses.

Place the Lower Actuator Case (4), (half with the

Adaptor Plate (19)), so that the six bolts (12) nest in

the Range Springs. The Range Springs must also

remain nested over the bosses in the diaphragm

plate.

3. Replace four of the Actuator Bolts and Nuts (6,7) at

90° increments and tighten finger-tight. Thread the

Actuator Stem (14), (with the Stem Adapter (22) and

Stem Locknut (33)) onto the Actuator Bolt (16) until

the shoulder on the Actuator Stem (14) contacts

the Adapter Plate (19). Some spring compression

should be felt.

4. Replace the remaining Actuator Bolts and Nuts and

tighten evenly across the actuator case.

5. Reassemble the Actuator Assembly to the Yoke

(3) and adaptor plate (19) making sure that the

recessed area faces the actuator, using the four

stroke plate bolts (26).

6. Reconnect the Adaptor Stem (22) to the Valve Stem

(20) using the Stem Connector Halves (21), the

Stem Connector Bolt (30) and Nut (31).

7. Adjust the spring pre-load following the instructions in the Spring Adjustment section of this I&M.

Valve Stroke Adjustment

1. Loosen the Stem Connector Nut (31) only enough

to allow the Stem Adapter (22) to rotate. DO

NOT REMOVE the Stem Connector (21). Proper

positioning of the Valve Stem (20) and the Stem

Adaptor (22) must be maintained while adjusting

the seats.

-3-

Page 4

2. For Direct Acting (Air to Close) Valves; Turn the

Actuator Stem (14) counterclockwise until the

Range Springs (10) are slightly compressed. This

insures that the Actuator Stem is in its fully upward

position. To confirm that the Actuator Stem is fully

stroked up, check that it cannot be easily rotated

without a wrench.

3. For Reverse Acting (Air to Open) Valves; Apply an

air pressure of approximately 5 psi above the maximum range pressure (ex. 20 psi for 3-15 psi range)

to the actuator. This insures that the Actuator Stem

(14) is in its full downward position. To confirm that

the Actuator Stem (14) is fully stroked down, check

that it cannot be easily rotated without a wrench.

4. Check the alignment of the orifices in the Disc (27)

and Plate (28). The orifices must be in the open

position and in perfect alignment. If the orifices are

not in proper alignment, loosen the Stem Locknut

(31) and thread the Stem Adapter (22) into, or out

of, the Actuator Stem (14), which will move the Disc

(27) up, or down, on the Plate (28).

5. After the proper alignment has been obtained,

tighten the Stem Locknut (31) against the end of

the Actuator Stem (14). Recheck the seat adjustment. Repeat Step 4 if necessary.

6. Adjust the spring preload if necessary. See the

Spring Adjustment section.

Changing Valve Action

The action of a Sliding-Gate Valve may be changed from

DIRECT ACTING to REVERSE ACTING, or vice versa, by

rotating the Disc (27) on the Plate (28) 180°. Check the

valve stroke and orifice alignment and adjust, if required,

as outlined in the Valve Stroke Adjustment section.

Ordering Spare Parts

Use only genuine Jordan Valve parts to keep your valve

in good working order. So that we can supply the parts,

which were designed for your valve, we must know exactly which product you are using. The only guarantee to

getting the correct replacement parts is to provide your

Jordan Representative with the valve serial number. This

number is located on the valve identification tag. If the

serial number is not available, the parts needed for your

valve might be determined using the following information: Model Number, Valve Body Size, Seat Material and

Cv Rating, Spring Range and Set Point, Trim Material, Part

Name - Number and Quantity.

NOTE: Any parts ordered without a valve serial number

that are found to be incorrect are subject to up to a minimum 25% restock charge when returned.

Spring Adjustment

The signal range is preset by Jordan Valve; however,

when the valve is installed this range may shift slightly

due to pressure drops across the valve. Additionally,

preload adjustment may be required after one of the

previous maintenance procedures. Note: ATO 3 – 15

psig rated valves are bench set at the factory at 5 – 17

psig. Please insure that any I/P utilized with this control

valve is capable of 17-psig output to ensure full valve

travel. If desired, the range may be changed to suit your

needs by following the instructions bellow.

1. Remove the air signal line from the actuator and

replace with a pressure gauge and an air regulator.

2. Loosen, but do not remove the Stem Connector

Bolt and Nut (30,31).

3. Adjust the actuator air pressure to just below the

starting point of the range and rotate the Actuator

Stem (14) until the stem just starts to move. Continue to rotate the Actuator Stem about one-half turn.

4. Remove the air pressure. Gradually increase the

air pressure and check at what pressure the valve

stem starts to move. Repeat Actuator Stem Adjustment (step 3) if necessary and again check to see

if the stem starts to move at the desired pressure.

5. After the preload has been properly adjusted,

tighten the Stem Connector Bolt and Nut (30,31)

and reattach the control air signal line.

-4-

Page 5

Illustration and Parts List (1” - 2”)

16

17

20

27

26

23

13

14

11

5

12

3

21

24

33

30

38

10 18

22

31

29

40

37

32

15

6

7

4

19

43 25

35

34

1

36

42

28

Item Description Quantity Item Description Quantity

1 Body / Bonnet 1 23 Packing Follower 1

3 Yoke 1 24 Packing Flange 1

4 Lower Actuator Case 1 25 Packing Flange Studs 2

5 Upper Actuator Case 1 26 Yoke Bolts 4

6 Actuator Bolt 16 *27 Disc 1

7 Actuator Nut 16 *28 Plate 1

10 Range Spring 6 29 Yoke Set Screws 4

11 Diaphragm Plate 1 30 Stem Connector Bolt 1

12 Adaptor Plate Bolts 6 31 Stem Connector Nut 1

13 Diaphragm Stop 1 32 Stem T-Head 1

14 Actuator Stem 1 33 Stem Lock Nut 1

15 Diaphragm 1 *34 Guide 2

16 Actuator Bolt 1 35 Guide Screws 4

17 Actuator Nut 2 *36 Gasket 1

18 Fastener Seal 1 37 Packing Spring 1

19 Adaptor Plate 1 38 Packing Retainer 1

*20 Stem 1 *40 Packing Set 1

21 Stem Connector 2 42 Body Set Screws 3

22 Stem Adaptor 1 43 Packing Flange Nuts 2

* Recommended Spare Parts

Bulletin IM-MK75_1&2”-0211

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...