Page 1

I & M Mark 627

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Pressure Regulators must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualied service person; continued operation may cause system failure or a

general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disassembling

a valve, be sure to release all spring tension.

Note: This document is to be used in conjunction with

The Mark 627 Series Cut Sheet.

WARNING! Over-pressure of this regulator or

installation of the regulator in applications which

may see pressure levels beyond those for which

the regulator is designed may result in leakage

and/or catastrophic failure. This failure could

result in leaking gas, damage to surrounding

equipment, personal injury or death. To prevent

such damage / injury the regulator should be installed in a safe location and should be chosen

based upon the user’s specic application.

It is highly recommended that suitable pressure relieving

devices, as recommended by appropriate codes or standards, be installed in your system to assure that maximum rated pressures are not exceeded.

Installation

The Mark 627 should be chosen based upon the 1.

maximum, differential and outlet pressures as

described in Table 1. Flow capacities are listed in

Table 2. The operating temperature range is -20°F

to 180°F. When choosing and installing a regulator

one must ensure that the conditions do not exceed

these parameters. Furthermore, large differentials

in pressure across the regulator may result in the

formation of ice in the orice area. The resulting

decrease in orice area may affect the regulators

Installation & Maintenance Instructions for

Mark 627 High Pressure Regulator

ability to ow in sufcient volume for downstream

demand. Therefore, large pressure drop applications may require the use of more than one regulator.

Make sure that line pressure has been eliminated 2.

prior to the installation of any regulator. Prior to

installation the line should be inspected to ensure

that there is no debris that might damage the regulator.

The regulator should be installed with the ow ar-3.

row on the side of the body in the correct orientation to ow - i.e. higher pressure upstream, lower

regulated pressure downstream. As is true with

most regulators, the Mark 627 has an outlet pressure rating that is lower than the inlet pressure rating. Over-pressure protection is needed to avoid

over-pressure if the actual inlet pressure can exceed the outlet pressure rating.

The regulator may be installed in any orientation 4.

as long as the ow is in proper agreement with

the ow arrow on the side of the body. However,

the regulator should be positioned such that the

screened vent will not collect debris or moisture.

Vent Line Option

The Mark 627 includes a vent in the upper housing (24).

If there is concern about build-up of gas in a conned

location, the vent assembly (25) may be removed to allow installation of a remote vent line. With the vent assembly removed, a vent line may be installed into the ¾”

NPT port. This vent line should be as large a diameter as

possible and should utilize minimal bends and elbows.

Furthermore, the vent line opening should be protected

from weather or debris and should be checked regularly

for blockage.

Start-up Operation

WARNING! Release downstream pressure to

prevent a potential over-pressure of the diaphragm. Failure to do so may result in property

damage and/or personal injury. Always employ

upstream and downstream pressure gauges to

monitor startup pressures.

Page 2

Assuming that the regulator is isolated with shutoff

valves on both the upstream and downstream sides,

slowly open upstream valve followed by slowly opening

the downstream valve. Check all connections for leaks

and make necessary output adjustments by manipulating

the adjusting screw (29) per the adjustment procedures

below.

Adjustment

The range of adjustment for a particular regulator is

indicated on the nameplate. Different ranges can be

achieved by substituting a different spring (27).

IMPORTANT: If a new spring is installed the nameplate must be remarked to indicate the new pressure

range.

Refer to Tables 1 and 2 prior to adjustment for pres-1.

sure and ow information, assuring that the chosen

spring will facilitate the desired pressure regulation

and that the maximum pressure output does not

exceed the downstream system pressure limits.

Remove the cap (30) and loosen the jam nut (28). 2.

To INCREASE pressure:3. Turn adjustment screw

clockwise.

To DECREASE pressure:4. Turn adjustment screw

counterclockwise.

Once the desired pressure is achieved, hold adjust-5.

ment screw while securing the jam nut and replace

cap.

Shutdown

the ow will result in accelerated wear on the disc assembly (9) and seat (2).

Replacing the Disk Assembly and Seat

Remove cap screws (3), separating the diaphragm 1.

case (5) and upper housing (24) as a unit.

Inspect the seat (2) and remove / replace if neces-2.

sary. Apply general purpose lubricant to threads of

new seat prior to installation.

Inspect disc assembly (9) for wear / damage. 3.

Should replacement be necessary, remove the hair

pin clip (13) that holds the disc assembly to the

stem (10). Install new disc assembly by aligning the

hole in the disc assembly and stem and reinstalling

the hair pin clip.

Should stem maintenance be required proceed as 4.

follows:

Remove the boost body (6), stabilizer (7) and a.

stem guide (8) form the diaphragm case. Unhook and remove the stem from the lever (15)

and remove the diaphragm case.

Remove and inspect the diaphragm case o-ring b.

(4) and replace as necessary, being sure to liberally lubricate with a general purpose grease

prior to installation in the boost body.

To reassemble, insert the stem into the diaphragm 5.

case and hook into the lever. Be sure to position

the diaphragm case assembly such that the pilot

tube is inserted into the Outlet side of the body.

Secure the diaphragm case assembly to the body

with the two cap screws. Torque the cap screws to

25 ft.-lbs. (34 N•m).

WARNING! Downstream pressure must be released to prevent an over-pressurization of the

diaphragm. Failure to do so may result in property damage and/or personal injury.

Close the upstream block valve followed by closing 1.

the downstream block valve. Open the nearest vent

valve between the regulator and the downstream

block valve.

Maintenance

Routine maintenance should be expected due to normal

wear and tear, damage from external sources or debris.

The regulator components, especially the moving and

sealing parts, should be inspected periodically and replaced as necessary. Frequency of inspection/replacement depends upon severity of conditions, but may also

be required by local/state/federal law or industry standards.

Body Area Maintenance

Large pressure drops or large amounts of particulate in

Diaphragm Assembly and Upper Housing

Maintenance

IMPORTANT! Prior to accessing the spring (27) all

pressure must be released from the diaphragm case.

Remove the cap (30), loosen the jam nut (28) and 1.

turn the adjusting screw (29) counter-clockwise until all spring compression is relieved.

Remove the upper housing cap screws (31) and re-2.

move the upper housing. If changing the spring or

adjusting the upper housing position, do so at this

point and reinstall spring, upper spring seat (26)

and upper housing cap screws and readjust regulator per the instructions under Start-Up Operation

on page one.

If diaphragm assembly maintenance is required, re-3.

move the diaphragm assembly by tilting it such that

the post and pin assembly (19) slips off the lever

(15). If lever replacement is necessary, free it by

removing the lever cap screws (18). Install the new

lever into the lever retainer (16) by inserting the

lever pin (17). Secure the entire assembly into the

diaphragm case by reinstalling the lever cap screws

and torquing them to 7 ft.-lbs. (9 N•m).

-2-

Page 3

Diaphragm and Spring

Remove the diaphragm head cap screw (33), 1.

spring seat (23), diaphragm head (22) and separate

the diaphragm (21) from the post and pin assembly

(19).

After examination and / or replacement, reas-2.

semble by installing diaphragm on post and pin

assembly and reinstalling diaphragm head, spring

seat and cap screw.

Hook the post and pin assembly onto the lever, 3.

rotating the diaphragm assembly until holes match

up with threaded holes in diaphragm case.

Unhook the post and pin assembly from the lever 4.

and torque the diaphragm head cap screw to 7 ftlbs (9 N•m).

Re-hook the post and pin assembly to the lever and 5.

re-check diaphragm hole alignment, loosening and

adjusting as necessary, making sure to re-torque

the diaphragm head cap screw appropriately each

time.

Once proper hole alignment is achieved re-hook 6.

the post and pin assembly to the lever.

Apply lubricant to upper spring seat and install with 7.

the Spring.

Install the upper housing such that the screened 8.

vent assembly is in the preferred orientation.

Install the upper housing cap screws through the 9.

upper housing and diaphragm and screw into the

threaded holes in the diaphragm case nger tight.

Install the adjustment screw into the upper housing, 10.

putting slack into the diaphragm.

Finish tightening the upper housing cap screws, 11.

using a crisscross method, and tightening each to

7 ft.-lbs (9 N•m).

Re-adjust the regulator per the instructions on page 12.

one under Startup Operation.

Mark 627 Regulator Tips

Overpressure protection must always be installed 1.

to protect against overpressure of regulator, as

well as overpressure of downstream equipment in

the event of a regulator failure. Also, downstream

pressure that is substantially higher than the pressure setting may result in damage to the regulator

components.

When sizing regulator you should utilize the small-2.

est orice necessary to accommodate the desired

ow/pressure requirement. Pipe size should preferably be 1”, but no smaller than ¾”.

When picking spring range, if two available spring 3.

ranges will accommodate the preferred pressure

setting, utilize the lower range spring, as it will allow

ner adjustment of the setting.

ADJUSTING SET POINT: Prior to adjustment the 4.

regulator should be owing 5% or higher of the

normal operating ow.

Vent should be oriented such that it is protected 5.

from water and other material which might collect

in the Upper Housing.

It is not uncommon that a small amount of gas may 6.

migrate through the diaphragm material. Proper

venting should be installed to avoid dangerous gas

build up.

Downstream pressure will change to some degree 7.

if upstream pressure changes.

FREEZING: Freezing is a common issue where the 8.

ow of pressurized gas is concerned due to normal

refrigerative effects. It is expected that the user will

realize approximately 1°F in temperature drop for

each 15 psi of differential across the regulator. This

may be particularly problematic during cold weather, when temperatures drop below 45°F (7°C). It is

important that the system be designed to alleviate

this problem by utilizing one or more methods such

as:

Multiple regulated pressure drops

Application of heat to the gas

Removal of water from the gas

Utilizing antifreeze solutions in the ow

Failure to consider the temperature-drop aspect

may result in ice plugging of the orice or erratic

performance due to ice formation on other components within the regulator.

Noise can be generated in regulators with large 9.

pressure drops and high ow volumes, resulting in

premature wear of regulator components.

Regulators inability to maintain published ow rate 10.

may be as a result of inefcient piping on both the

upstream and downstream side of the regulator.

Upstream pressure should be checked at body

inlet.

Table 1

Maximum Spring & Diaphragm Housing Pressure

Maximum pressure to avoid leakage to

atmosphere or possible damage to internal

parts.

Maximum pressure to prevent burst or

possible damage to internal parts.

Maximum diaphragm housing over-pressure

(above set-point) to avoid damage to internal

parts.

Table 2 - Wide-Open Flow Coefcients

Orice Size C

g

C

v

3/32” 6.9 0.24 28.5

1/8” 12.5 0.43 29.4

3/16” 29 0.93 31.2

1/4” 50 1.71 29.3

3/8” 108 3.42 31.6

1/2” 190 5.29 35.9

-3-

250 psi

375 psi

60 psi

C

1

Page 4

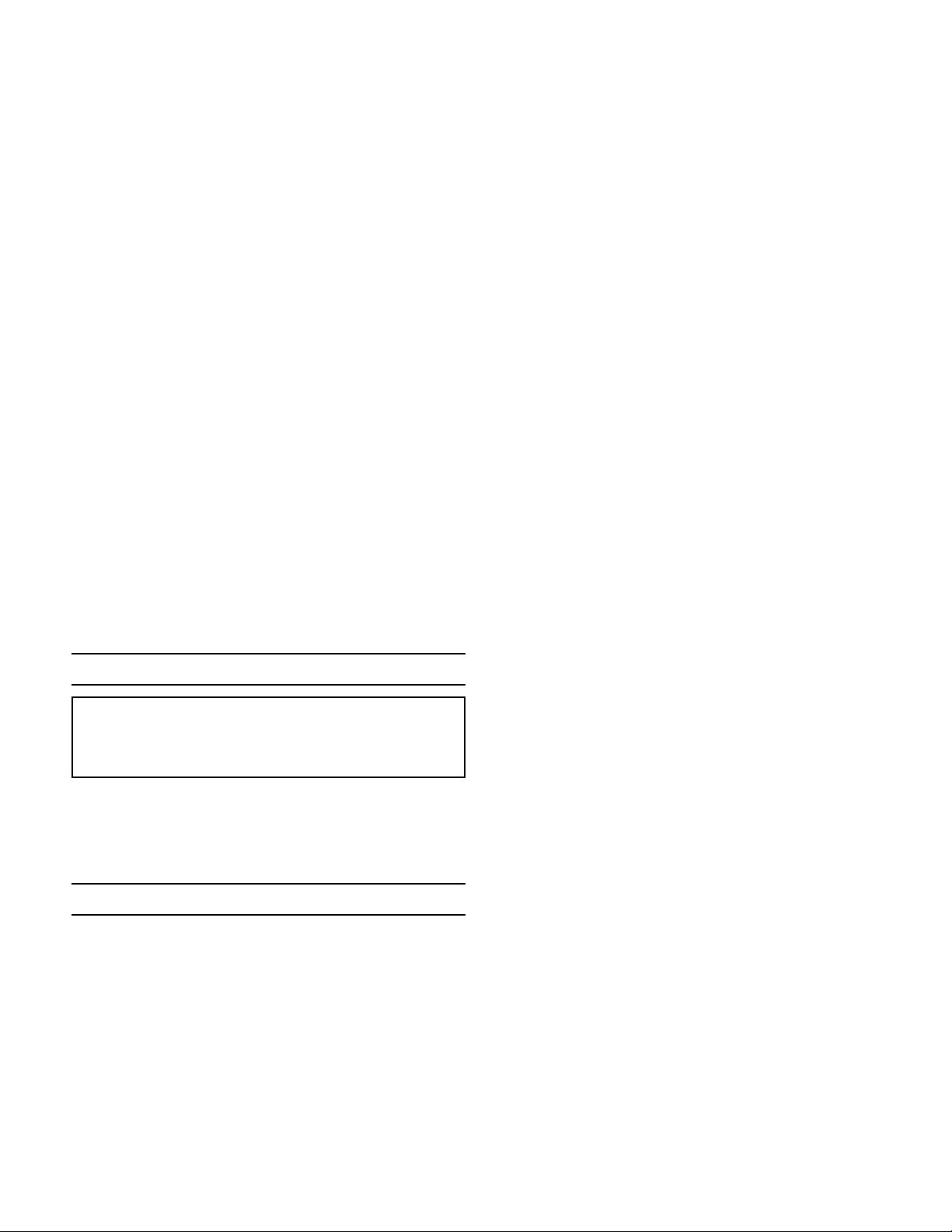

Illustration and Parts List

15

17

16

10

11

21

19

18

20

5

7

9

1

22

31

23

33 24

14

12

13

2

27

25 26

8

4

6

29 28

30

Item Description Qty. Item Description Qty.

1 Body 1 18 Lever Cap Screw 2

2* Seat 1 19 Post & Pin Assembly 1

3 Cap Screw (not shown) 2 20 Lock Washer 2

4* O-Ring 1 21* Diaphragm 1

5 Diaphragm Case 1 22 Diaphragm Head 1

6 Boost Body 1 23 Spring Seat 1

7 Stabilizer 1 24 Upper Housing 1

8 Stem Guide 1 25 Vent Assembly 1

9* Disc Assembly 1 26 Upper Spring Seat 1

10 Stem 1 27 Spring 1

11* O-Ring 1 28 Jam Nut 1

12 Back-Up Ring 2 29 Adjusting Screw 1

13 Hair Pin Clip 1 30 Cap 1

14 Pin 1 31 Cap Screw 8

15 Lever 1 32 Name Plate (not shown) 1

16 Lever Retainer 1 33 Cap Screw 1

17 Lever Pin 1 * Recommended Spare Parts

Bulletin IM-MK627-0310

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...