Jordan Valve Mark 6127 User Manual

I & M Mark 6127 Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

The Jordan Valve Mark 6127 Pressure-Reducing/

Sustaining Valve is designed to perform the following

functions:

1. Reduce a higher upstream pressure into a lower,

constant downstream pressure.

2. Prevent upstream pressure from falling below

a predetermined minimum.

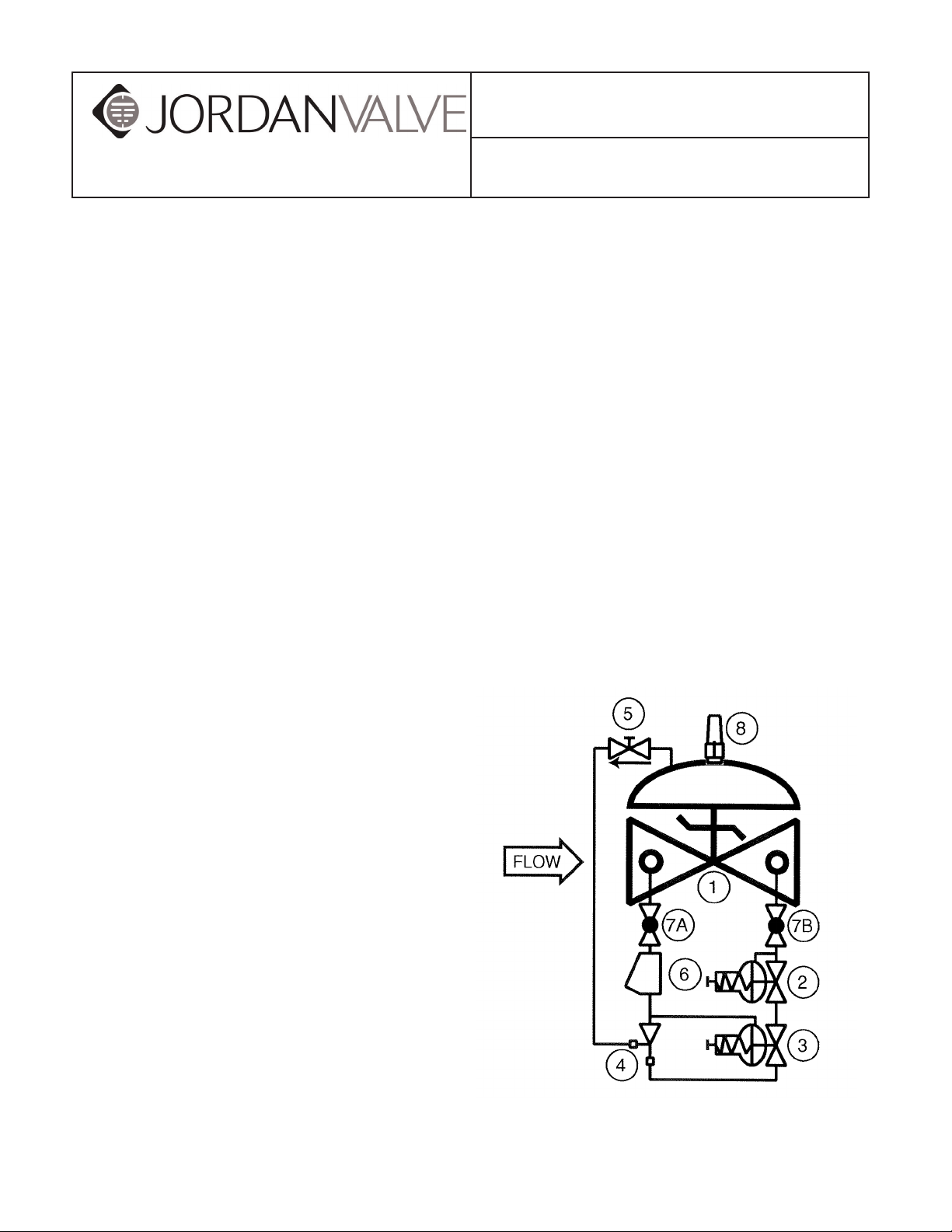

The 6127 consists of the following components:

1. Main Valve, a hydraulically-

operated, diaphragm-actuated globe or

angle valve which closes with an elastomer-on-

metal seal.

2. Pressure-Reducing Pilot, a two way, normally-

open pilot valve which senses downstream

pressure under its diaphragm and balances it

against an adjustable spring load. An increase

in downstream pressure tends to make the pilot

close.

3. Pressure Sustaining Pilot, a two way,

normally-closed pilot valve which senses

upstream pressure under its diaphragm and

balances it against an adjustable spring load.

An increase in upstream pressure tends to make

the pilot open.

4. Ejector, a simple "tee" fitting with a fixed orifice

in its upstream port. It provides the proper

pressure to the diaphragm chamber of the

main valve, depending on the position of the

pressure-reducing pilot.

5. Flow Control Valve, a needle type valve which

provides adjustable, restricted flow in one

direction and free flow in the opposite direction

On the 6127, the flow control valve is

connected as an opening speed control.

Installation & Maintenance Instructions for the

Mark 6127Pressure Regulating Valve

6. Y-Strainer (standard on water service valves)

or Inline Strainer (standard on fuel service

valves).The strainer protects the pilot system

from solid contaminants in the line fluid.

7 A/B. Two Ball Valves (standard on water service

valves, optional on fuel service valves),

useful for isolating the pilot system for

maintenance or troubleshooting.

At user option, the Mark 6127 may also be equipped

with the following:

1. Visual Indicator.

2. Limit Switch Assembly (includes visual

indicator).

3. Closing Speed Control

Mark 6127 SerieS PreSSure reducing ValVe

theory of operatIon

(Refer to Schematic Diagram)

A. Pressure- Reducing Action

To understand how the Mark 6127 operates, it is best

to start with the EJECTOR. Due to the orifice in its

upstreamport, the ejector creates a pressure drop

proportional to the flow through it. The flow through the

ejector is in turn controlled by the degree of opening

of the PRESSURE REDUCING PILOT. The wider the

pilot opens, the greater the flow through the ejector

and the lower the pressure downstream of the orifice.

Conversely, the more the pilot closes, the lower the

flow through the ejector and the greater the pressure

downstream of the orifice.

Now note that the diaphragm chamber of the MAIN

VALVE is connected to the branch port of the ejector

and is thus downstream of the orifice. In this manner,

the pressure in the diaphragm chamber of the main

valve is in fact controlled by the pressure-reducing

pilot. As the diaphragm pressure decreases, the main

valve opens; as the diaphragm pressure increases, the

main valve closes.

Putting it all together, as downstream pressure tends to

increase above the set point of the pressure-reducing

pilot, the pilot moves further closed. This results in an

increase in pressure in the diaphragm chamber of the

main valve. The main valve then closes slightly to

restore the downstream pressure to the set point.

Conversely, as downstream pressure tends to decrease

below the set point, the pilot moves further open. This

results in a decrease in pressure in the diaphragm

chamber of the main valve. The main valve then opens

wider to bring the downstream pressure back up to the

set point. The net result of all this is a constant

modulating action by the pilot and main valve and a

downstream pressure which remains constant despite

fluctuations in demand or inlet pressure.

B. Pressure- Sustaining Action

Action of the pressure-sustaining pilot is very similar

to that of the pressure-reducing, except that normally

upstream pressure is higher than the sustaining pilot's

set point. The pilot is therefore full open and has no

effect on the operation of the valve.

However, if demand should increase to such a point that

supply pressure should fall to the pilot's set point, the

pilot will begin to throttle, or modulate, and further close

the main valve to keep the pressure from falling any

further. Note that when this action occurs, downstream

pressure will necessarily fall below the set point of the

reducing pilot. Simply stated, the sustaining pilot is

there to protect the pump or supply system from too

low a pressure, and will come into effect only when

called upon to do so.

InstallatIon

The 6127 is furnished fully factory-assembled and

ready for installation at the appropriate point in the

system. The user is referred to the Main Valve section

of this manual for full installation details.

Startup and Adjustment

The following procedures should be followed in the

order presented in order to effect an initial startup of the

Mark 6127:

1. Install pressure gauges of the proper range

upstream and downstream of the Mark 6127.

2. Remove the plastic cap from the pressure

reducing pilot, and loosen the adjusting screw

jam nut. Turn the adjusting screw clockwise to

a full stop.

3. Remove the plastic cap from the pressure

sustaining pilot, and loosen the adjusting screw

jam nut. Turn the adjusting screw clockwise to

a full stop.

4. Turn the adjusting screw of the flow control

valve fully clockwise, then back it off three

full turns.

5. Start the pump, or otherwise start the system

flowing. The main valve will at this time be

either fully closed or open only a very small

amount.

6. Carefully loosen one of the pipe plugs in the

main valve bonnet until fluid appears around

the threads. When only clear fluid (no air) is

discharging, retighten the plug.

7. Open downstream valves to give as much

demand as possible.

8. Slowly turn the adjusting screw of the pressure sustaining pilot counterclockwise until

upstream pressure falls to the desired minimum.

9. Check downstream pressure. If it is lower than

desired, close downstream valves as required

to build pressure to a value higher than desired.

-2-

Loading...

Loading...