Jordan Valve Mark 608BP User Manual

I & M Mark 608BP

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Installation & Maintenance Instructions for

Mark 608BP Gas Pressure Regulators

Warning: Jordan Valve Pressure Regulators must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or a

general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling

a valve, be sure to release all spring tension.

Please read these instructions carefully!

available from Jordan Valve.

5. The flow arrow on the regulator body must be

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

pointed in the direction of flow. The regulator may

be installed in any position. The actuator may be

rotated to any position relative to the body (see sizing.) Loosen the union nut and position the actuator. Pull the union nut up hand-tight, then tighten ¼

turn. (The union nut is 8-sided and may be used as

a guide.)

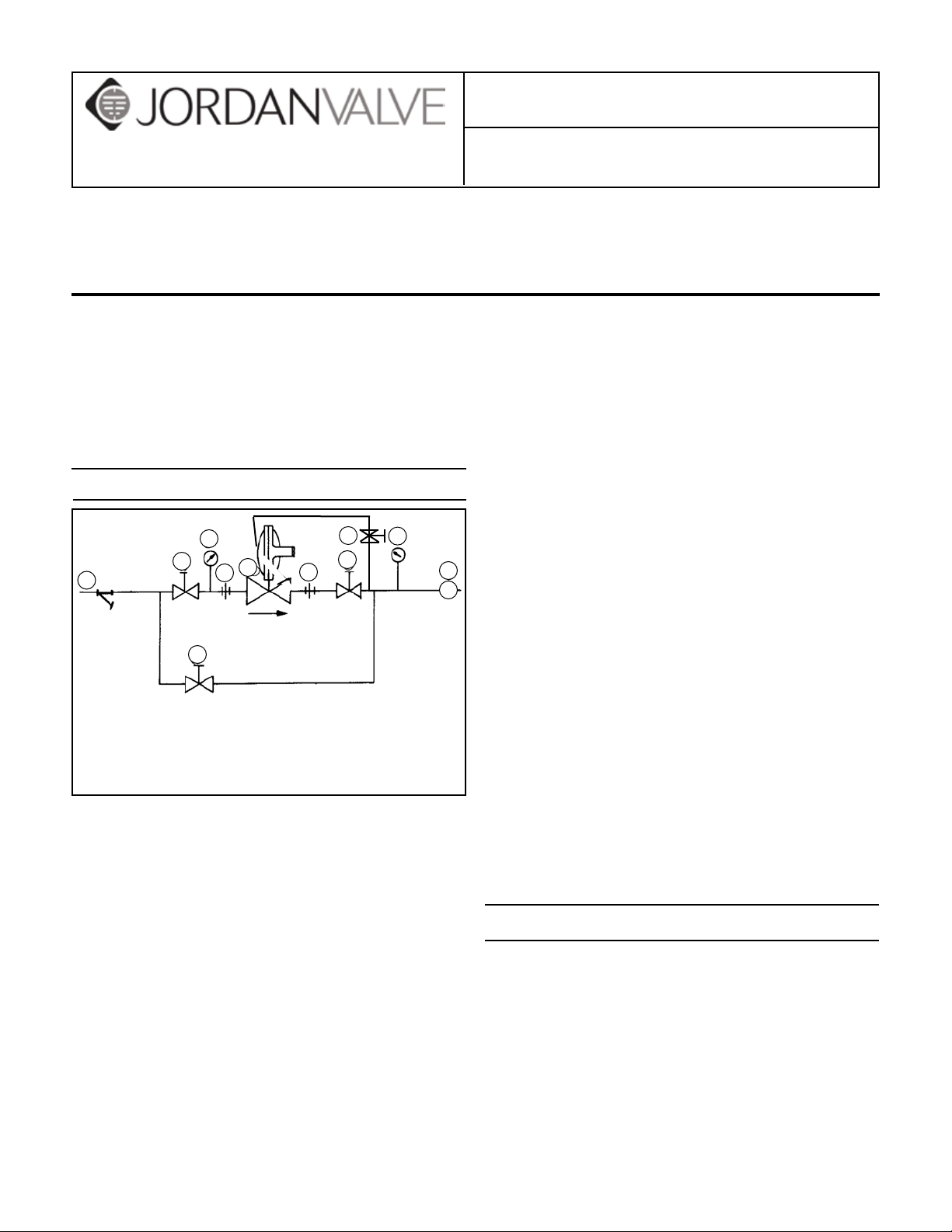

Ideal Installation

6. Provisions are provided to vent the case from the

top or bottom by a ¼” pipe tap opening. One open-

4

1

3

5

2

7

1

2

4

6

R

ing is plugged, the other has a screened (bug) vent.

Reverse these if it is desired open vents should

point downward; a street elbow can be used if

needed. Some installations will require that this

vent be piped to some location external to the

regulator. When remote piping is used, ¼” size is

adequate. NEVER BLOCK OFF THE VENT LINE. Fol-

1

By-Pass Line

1. Shut off Valve

2. Pipe Union

3. Strainer and Drain Valve

4. Pressure Gauge

5. Jordan Regulator

6. Relief Valve

7. Sensing Line

1. To protect the regulator from grit, scale, thread

chips and other foreign matter, ALL pipelines and

piping components should be blown out and thoroughly cleaned before the installation process begins.

low local regulations.

7. Install a relief valve downstream from the regulator

to protect downstream components from overpressurization. Generally, the setting of the relief

valve should be at least 20% greater than the regulator set point. It must have adequate flow capacity

to protect the downstream components should the

regulator fail to shut off.

8. Operate the regulator within its rated pressure and

temperature. The standard Mark 608BP is rated

at 150 psig max (inlet or outlet section) at -20 to

+200°F. Regulator ratings and materials of construction are listed on the valve name plate.

2. Shutoff valves, pressure gauges and by-pass piping

should be installed as indicated in the Installation

Sizing

Schematic to provide easier adjustment, operation,

and testing.

3. In preparing threaded pipe connections, care

Refer to the sizing charts for the flow capacity of the

regulator under various conditions.

should be exercised to prevent pipe sealing compound from getting into the pipe lines. Pipe sealing

compound should be used sparingly, leaving the

two end threads clean. Jordan recommends Teflon

tape.

4. A line strainer should be installed on the inlet side

of the regulator to protect pipe from grit, scale and

Because of the weight of the diaphragm assembly and

friction in the moving parts, there is a difference in the

lowest setpoint attainable when the actuator housing is

upright, or inverted. (Upright refers to the spring housing cap pointing vertically up.) Lower set points can be

achieved with the housing inverted.

other foreign matter. A 0.033 perforated screen is

usually suitable for this purpose. Line strainers are

With this information, refer to the flow capacity chart in

the Mark 608 Product Bulletin. Always use the smallest

orifice diameter possible to reduce outlet pressure variations caused by inlet pressure variations.

parts and for proper nomenclature.

A. DIAPHRAGM OR GASKET REPLACEMENT

Start-Up

1. Fully open the outlet shut-off valve.

2. Slowly open the inlet shut-off valve.

3. Slowly open and close the outlet shut-off valve

several times. This fully strokes the valve to insure

satisfactory operation.

4. With the outlet shut-off valve open and preferably

at a low flow, slowly turn the adjusting screw until

the desired pressure is shown on the outlet pressure gauge.

5. To change the controlled pressure, turn the adjusting screw clockwise to increase pressure, and

counterclockwise to decrease pressure.

Trouble Shooting

If You Experience Erratic Control:

Oversizing causes cycling and hunting and reduces

the rangeability of the valve. Make certain that your

sizing is correct.

Attempting to exceed flow capacity. Make certain

that your sizing is correct.

Blocked vent line or vent passage in spring hous-

ing. Clean.

Inlet pressure varying greatly. Stabilize or use sec-

ond regulator to control inlet pressure closer.

Aspirator blocked. Clean.

If You Cannot Set Outlet Pressure:

Orifice too large for inlet pressure. Refer to Sizing.

Improper spring.

If the Valve Will Not Operate:

Diaphragm ruptured. Replace.

Adjusting spring broken. Replace.

Improper spring setting. Reset.

Maintenance

WARNING: Be sure that there is no pressure in the

valve before loosening any fittings or joints. The following steps are recommended:

1. Close the inlet shut-off valve, and by-pass valve.

2. Back off adjusting screw to allow inlet pressure to

open seats.

3. Allow pressure to bleed off through downstream

piping.

4. When the inlet pressure gauge indicates no pressure in the line, close the outlet shut-off valve.

Refer to the drawings for the proper orientation of the

1. Remove all pressure from the line as outlined under WARNING.

2. Remove the compression of the adjusting spring

(22) by rotating the adjusting screw (19) counterclockwise.

3. Loosen the spring housing bolts (16) and remove

spring housing.

IF DIAPHRAGM IS NOT BEING REPLACED,

SKIP STEPS 4 THRU 8.

4. Remove diaphragm subassembly by sliding it away

from the valve body to disengage the lever arm (7).

5. Hold the lower diaphragm plate (5) and remove the

screw (6), separating the parts.

6. Clean the surfaces on the upper and lower diaphragm plates that the diaphragm (3) seats against.

Clean and degrease the threads on the lower diaphragm plate and the screw. (Degrease with Loctite primer T.)

7. Assemble the upper and lower diaphragm plates

to the new diaphragm with the screw. (Apply a few

drops of Loctite #290 to the screw threads to lock

the parts together.) The hole through the lower diaphragm plate must align with any pair of opposite

holes in the diaphragm so that it will properly engage the lever when reassembled into the valve.

8. Clean the flange surface on the diaphragm housing

and reinstall the diaphragm subassembly onto the

lever arm.

9. Clean the flange surface on the spring housing and

install a new gasket. The gasket may be temporarily

held in place using a few dabs of grease.

10. Set the spring housing on top of the diaphragm

housing. Using a 6” long screwdriver, or similar

tool, reach through the spring housing and push

the diaphragm down to align the diaphragm holes

with the housings’ holes.

11. Drop the bolts into place and attach the lockwashers and nuts, finger-right.

12. Continue to push the diaphragm down and snugup the bolts.

13. Evenly torque the bolts as described in the Torque

Procedure Section.

14. Install the spring and adjusting screw. (Adjusting

spring per start-up instructions and replace cap.)

B. SEAT INSERT, PLUG, OR ASPIRATOR REPLACEMENT

CAUTION: When replacing a plug or seat insert,

the lever must also be replaced to insure shutoff.

1. Remove all pressure from the line as outlined under WARNING.

-2-

Loading...

Loading...