Jordan Valve Mark 608 User Manual

I & M Mark 608 (1-1/2” - 2”)

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Installation & Maintenance Instructions for

Mark 608 Gas Pressure Regulators

Warning: Jordan Valve Pressure Regulators must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or a

general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling

a valve, be sure to release all spring tension.

Please read these instructions carefully!

two end threads clean. Jordan uses, and recommends, thread sealer Teflon ribbon.

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

6. The flow arrow on the valve body must be pointed

in the direction of flow. Ideally, the valve should be

installed in the highest horizontal line of piping to

provide drainage for inlet and outlet piping, to prevent water hammer, and to obtain faster response.

7. If possible, install a relief valve downstream from

the valve. Set at 15 psi above the control point of

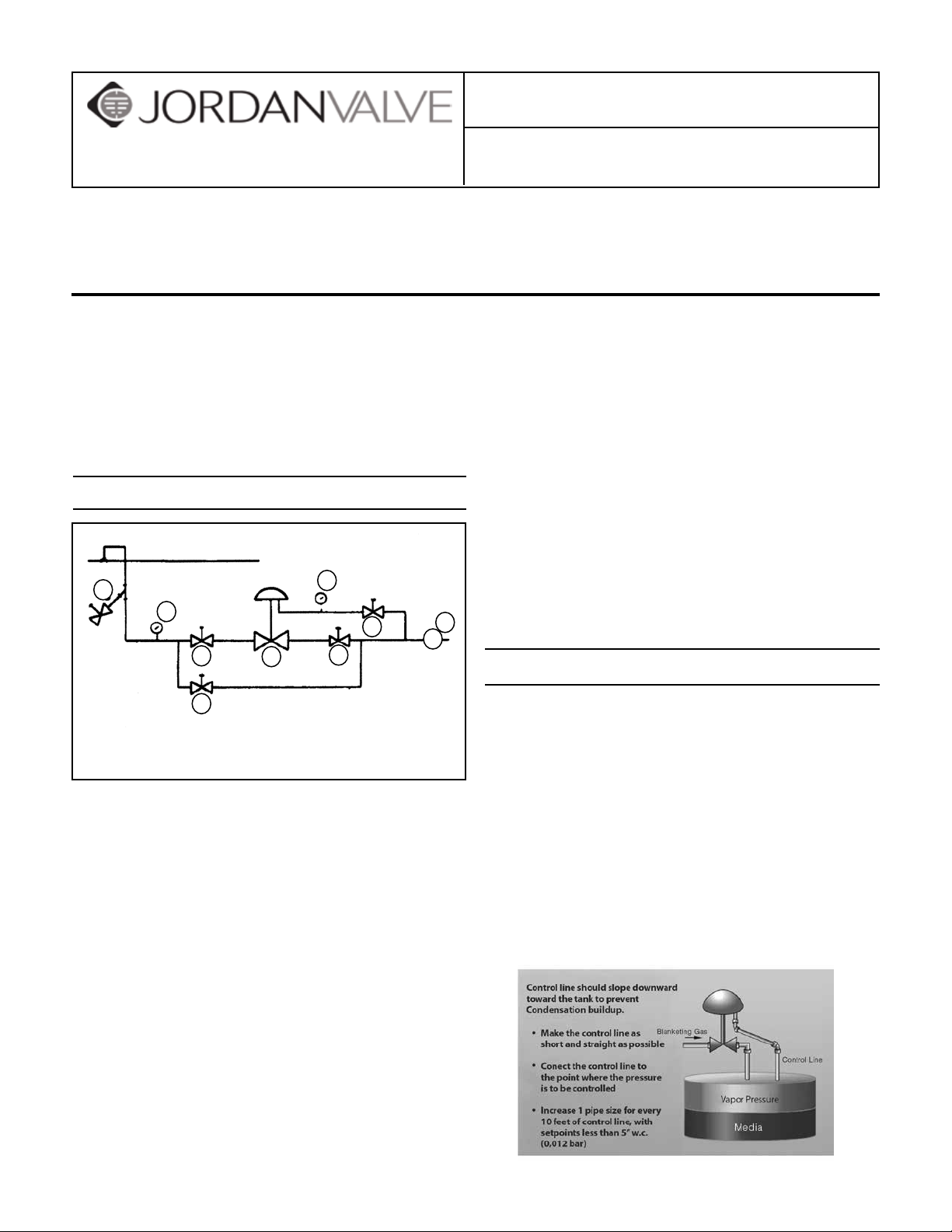

Ideal Installation

the valve.

8. In gas service, expand the outlet piping at least

one pipe size if the control pressure (downstream)

Main Line

3

4

1

2

4

1

1

5

R

is 25% of the inlet pressure or less. A standard

tapered expander connected to the outlet of the

valve is recommended.

9. Where surges are severe, a piping accumulator is

recommended.

Control Line

1

1. Shut off Valve

2. Jordan Regulator

3. Strainer and Drain Valve

4. Pressure Gauge

5. Relief Valve

1. To protect the valve from grit, scale, thread chips

and other foreign matter, ALL pipelines and piping

components should be blown out and thoroughly

cleaned before the installation process begins.

2. Shutoff valves, pressure gauges and by-pass piping

should be installed as indicated in the Ideal Installation Schematic to provide easier adjustment, operation, and testing.

3. A line strainer should be installed on the inlet side

of the valve to protect it from grit, scale and other

foreign matter. A 0.033 perforated screen is usually

suitable for this purpose. Line strainers are available from Jordan Valve.

4. For best control, 3’ 0” straight sections of pipe

should be installed on either side of the valve.

5. In preparing threaded pipe connections, care

should be exercised to prevent pipe-sealing compound from getting into pipelines. Pipe-sealing

compound should be used sparingly, leaving the

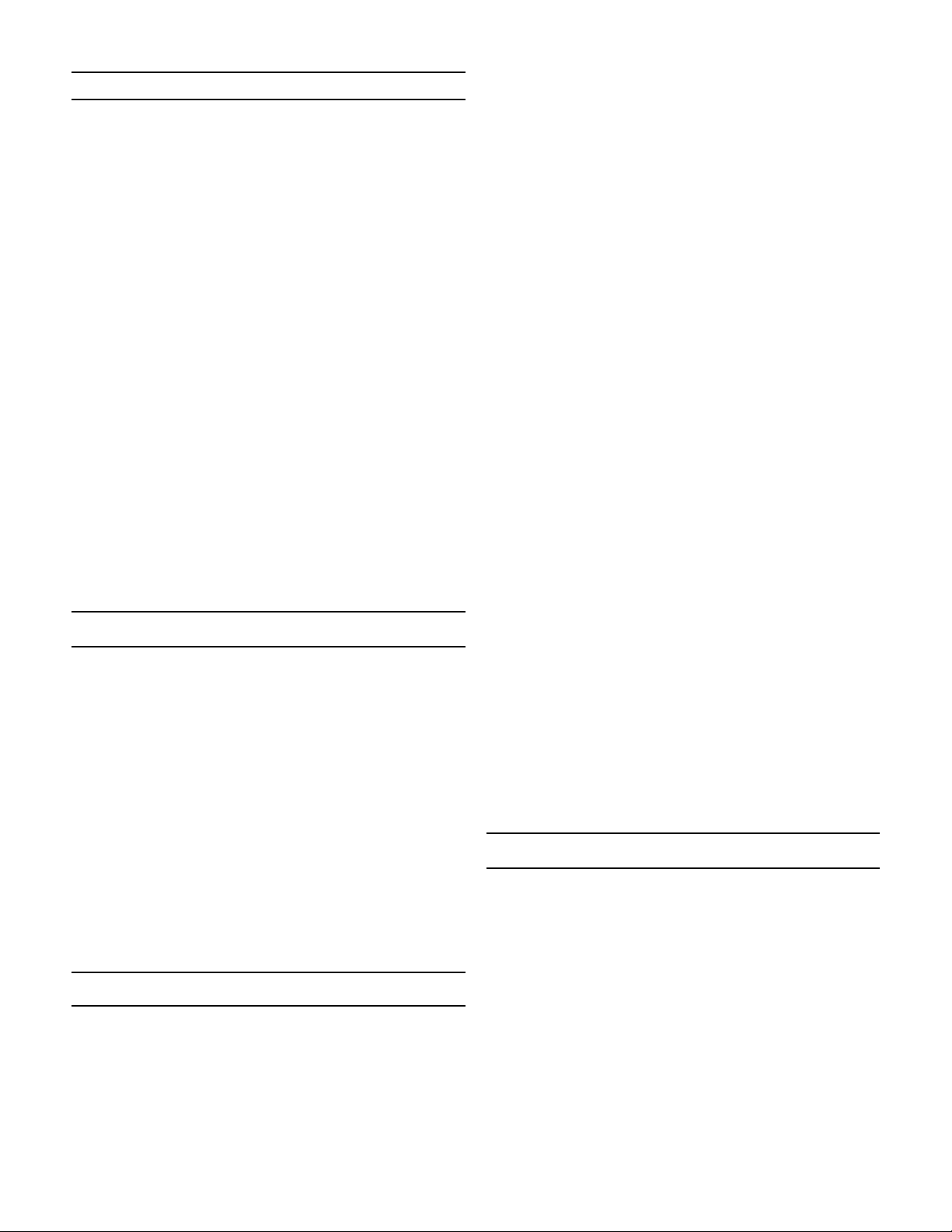

A control line must be installed as follows:

1. Connect one end of a ¾” pipe to the fitting under

the diaphragm.

2. Connect the other end to an appropriate fitting on

the tank.

3. DO NOT locate the control line tap in any location

where turbulence or abnormal velocities may occur.

4. The control line should be sloped away from the

valve.

5. Install a pressure gauge to measure pressure in the

tank itself, not in the outlet piping or the control line

to aid in setting the valve.

Control Line Piping Recommendation

Keep the regulator as close to the tank as possible

and as high as possible.

Minimize the length of the downstream pipe com-

ing from the valve.

NEVER reduce the pipe size on the valve outlet to

the tank. This line must always be as large as the

valve size, or one pipe size larger to assure it does

not act as a restriction.

Any downstream isolation valve after the regulator

must be a full port type. The isolation valve cannot

act as a restriction.

The sensing line must be a minimum of 3/4” pipe.

A sensing line isolation valve is recommended.

Again, must be full ported.

Slope the sensing line to the sensing port on the

tank.

Keep the sensing line as short and straight as pos-

sible.

For each 10 feet of sensing line, increase the line

size by one pipe diameter. (Especially important on

the blanket pressures of less than 5 inches of water

column).

Keep the sensing port on the tank as far removed

as possible from the downstream pipe outlet going

into the tank.

Start-Up

With the inlet, outlet, and bypass shutoff valves closed,

and no pressure in the downstream line:

1. Fully open the control line shut-off valve.

2. Fully open the outlet shut-off valve.

3. Slowly open the inlet shut-off valve.

4. Slowly open the inlet valve just enough to start flow

through the valve. Observe the downstream pressure gauge. Increase the downstream pressure

slowly by gradually opening the inlet valve.

5. Do not fully open the inlet valve until you are sure

that the regulator has control of the system. Usually, the handwheel on the inlet valve will turn freely

when this is achieved.

6. To change the controlled pressure, adjust the

controlled pressure supplied to the top of the diaphragm.

pressure increases after valve closes.

C. Pressure Fluctuates: Controlled pressure rises and

falls, will not settle out under low loads.

The next step is to determine what could cause the

trouble. The third step is to locate and remedy the cause

by the process of elimination. Make no assumptions and

check the easy ones first. The guide below lists the controlled pressure action, common causes and procedure

for checking each cause.

Controlled pressure action UNDER PRESSURE:

Valve undersized for application. Check capacity

required and valve capacity.

Line strainer screen clogged. Blow down strainers

or visually check that they are clear.

Incorrect setting on range spring. Vary the setting

and check response.

Main valve diaphragm or balance diaphragm rup-

tured. See action on valve maintenance.

Malfunction of other piping components. Check

for leaking safety valves, inadvertently opened or

closed valves.

Controlled pressure action OVER PRESSURE:

Incorrect setting on range spring. Vary the setting

and check response.

Main valve seats leaking. Close inlet shut-off valve,

allow downstream pressure to bleed off, close outlet valve and remove loading pressure tubing. Back

out adjusting screw on valve until free. Crack open

inlet shut-off valve - if the fluid issues from the main

valve port, the main valve seats are leaking.

By-pass shut-off leaking. During period of leakage

close outlet shut-off valve, observe downstream

pressure gauge.

Controlled Pressure Fluctuates:

Valve oversized. Check capacity required and valve

capacity.

Maintenance

Caution: Ensure that the valve is de-pressurized before loosening any fittings or joints. The following

steps are recommended before performing any maintenance on the valve:

Trouble Shooting

The first step in troubleshooting a piloted pressure regulator is to classify the action of the controlled pressure

into one of the following categories:

A. Under Pressure: Controlled pressure too low; not

enough flow or no flow through valve.

B. Over Pressure: Valve will not close or controlled

1. Allow pressure to bleed off through the downstream piping. Do not attempt to reverse the flow

through the valve by bleeding pressure from the

upstream from the upstream side of the valve.

2. When the pressure gauges indicate that all pressure has been removed from the system, close the

outlet shut-off valve and the valve may be serviced.

Note: Refer to the drawing at the end of this document for description and proper orientation of parts.

-2-

Loading...

Loading...