Page 1

I & M Mark 58 Series

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve back pressure regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the

event of leakage or other malfunction, call a qualied service person; continued operation may cause system failure

or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disassembling a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

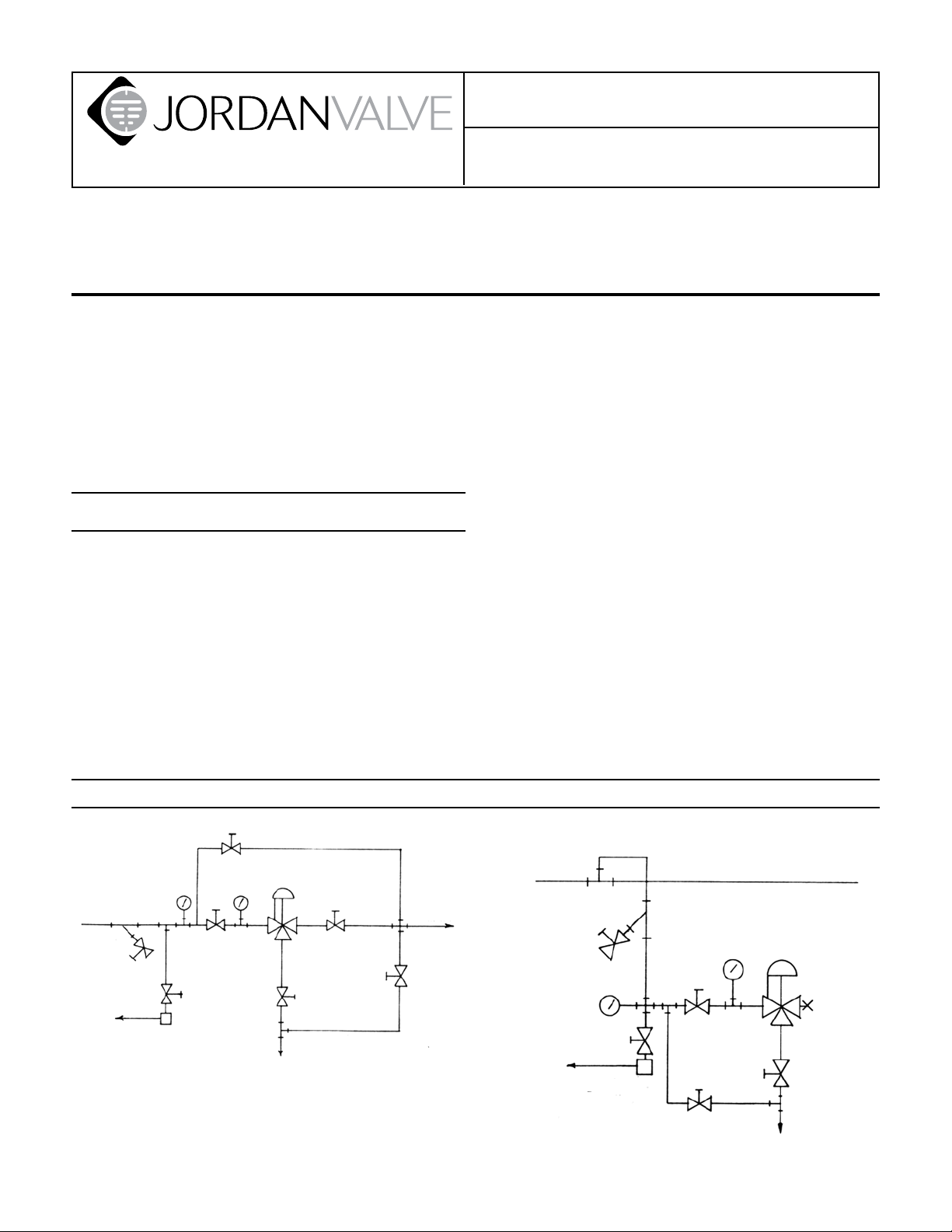

Ideal Installation

To protect the valve from grit, scale, thread chips, 1.

and other foreign matter, all pipe lines and piping

components should be blown out and thoroughly

cleaned before the valve is installed.

Shutoff valves, pressure gauges, and bypass piping 2.

should be installed as indicated in the diagram to

provide easier adjustment, operation, and testing.

A line strainer should be installed on the inlet side of 3.

the regulator to protect it from grit, scale and other

foreign matter. A 0.033 perforated screen is usually

suitable. Line strainers are available from Jordan Valve.

Installation & Maintenance Instructions for

Mark 58 Back Pressure Regulating & Relief Valve

For best control, 3’0” straight sections of pipe should 4.

be installed on either side of the valve.

Install the regulators in the highest horizontal line of 5.

piping to provide drainage for inlet and outlet piping, to prevent water hammer, and to obtain faster

regulation.

The regulator may be installed in a ow-through 6.

manner as in Figure 1 or into a tee off of the main

line (with one port plugged) as shown in Figure 2.

Flow may be in either direction through the body of

the regulator. Bypassed uid exits out of the bottom

bypass port.

In hot vapor lines, upstream and downstream piping 7.

near the regulator should be insulated to minimize

condensation.

Expand the outlet piping at least one pipe size if the 8.

outlet pressure (downstream) is 25% of the inlet

pressure or less. As standard tapered expander connected to the outlet of the regulator is recommended. Minimizing bypass piping length and number of

elbows will improve valve performance by reducing

pressure buildup.

Where surges are severe, a piping accumulator is 9.

recommended.

4

3

5

Condensate

Return

1 Inlet shut-off valve

2 MK 58 BPRV

3 Strainer and Drain Valve

4 Pressure Gauge

6

2

4

7

By Pass

5 Steam trap and valve

6 Manual bypass valve

7 Bypass shut-off valve

8 Pipe plug

Ideal Installation

Main Line

1

6

3

4

5

Condensate

Return

Main Line

1

6

4

2

8

7

By Pass

Page 2

Start-up Procedure

With the inlet and outlet shut-off valves closed:

Throttle the manual bypass valve so that the pres-1.

sure to be controlled is maintained near the set

point.

Slowly open the inlet shut-off valve.2.

Open the outlet shut-off valve.3.

Slowly close the bypass valve, but do not close it 4.

fully until you are certain that the regulator has control of the system.

To change the controlled pressure, turn the adjust-5.

ing screw clockwise to increase pressure, counterclockwise to decrease pressure.

WARNING:

6. Never substitute a longer length adjusting screw.

Personal injury and damage to the valve may result.

Troubleshooting

Erratic Control:

Oversizing causes cycling and hunting and reduces 1.

the rangeability of the valve. Make certain that your

sizing is correct.

Steam traps downstream may need attention.2.

Safety valve may be jammed open.3.

Excessive foreign matter on seats or plug (4*). Clean 4.

them. Inspect seating surface on plug for deterioration.

Valve plug may not be moving freely. Check cage 5.

bore (2).

Surges in piping system.6.

Check accumulator.7.

Will not operate:

Diaphragm ruptured. Replace.1.

Adjusting spring broken. Replace.2.

Improper spring setting. Reset.3.

Maintenance

Warning:

Be sure that there is no pressure in the valve before

loosening any ttings or joints. The following steps are

recommended.

Close the inlet shut-off valve.1.

Back off adjusting screw to allow inlet pressure to 2.

open seats.

Allow pressure to bleed off through downstream 3.

piping.

When inlet pressure gauge indicates no pressure in 4.

the line, close the outlet shut-off valve.

Valve may now be removed or serviced.5.

* Refer to the drawings for the proper orientation of the

parts and for proper nomenclature.

Plug Removal & Diaphragm

Replacement

Remove all pressure from the line as outlined under 1.

Warning.

Remove the compression of the adjusting spring (11) 2.

by rotating the adjusting screw (14) counterclockwise.

Remove the spring housing (9). Remove spring (11), 3.

spring seat (12) and ball bearing (13).

Remove the diaphragm assembly. The diaphragm 4.

assembly consists of the upper diaphragm plate (8),

diaphragm washer (7), washer (6), stem (5) and plug

(4). The plug is attached loosely to the stem. DO

NOT DROP.

Secure the upper diaphragm plate in a vise. Use a 5.

wrench on the stem and turn counter-clockwise to

remove.

Remove the diaphragm, clean the parts and install 6.

the new diaphragm in reverse order. The radius

edge of the washer goes against the diaphragm.

Clean and degrease the stem threads and apply one

drop of #290 Loctite to them before threading the

stem into the diaphragm plate. When an elastomer

diaphragm is used, thread the parts together hand

tight and then tighten 1/4 turn. When a metal diaphragm is used, pull the parts up together tight.

Clean the diaphragm seating surfaces on the spring 7.

housing (9) and on the body (1). Remove adjusting

screw (14).

Unscrew the cage (2) approximately two turns. Place 8.

the plug, diaphragm assembly, spring, spring seat

and ball bearing back into the valve body. (Metal

diaphragms nest into the counterbore in the body).

Do not lubricate the plug.

Install spring housing.9.

Check to see that ball is below the tapped hole for 10.

the adjusting screw and reinstall adjusting screw to

contact ball.

Tighten bolts (10) evenly per chart on next page.11.

Thread cage back into the body and pull up snug. 12.

Readjust adjusting screw.

Cage Removal

Remove all pressure from the line as outlined under 1.

Warning.

Remove the compression of the adjusting spring 2.

(11) by rotating the adjusting screw (14) counterclockwise.

Turn the hux end on the cage (2) counter-clockwise 3.

and remove it from the body. The o-ring (3) which is

used to seal the cage to the body main remain on

the cage or stay in the body when you remove the

cage.

Place the cage in a vise and grip it on the hex to 4.

prevent damage to machined surfaces. The plug will

Page 3

remain with the stem. To remove plug see preceding

section.

Inspect parts for wear and replace as required. It is 5.

recommended that the o-ring be replaced.

Clean all parts and the o-ring seating surfaces in the 6.

body and on the cage. Lightly lubricate these surfaces and the o-ring. Do not lubricate bore of cage

where the plug operates.

Check to see that the ball (13) is below the tapped 7.

hole for the adjusting screw and reinstall the adjusting screw to just contact the ball.

Install the cage o-ring and screw the cage into the 8.

body until it bottoms out and tighten. Readjust adjusting screw.

Torque Procedure

5

3

2

1

4

6

6 bolts (or multiples) 8 bolts (or multiples)

Install all bolts hand-tight.1.

Torque the bolts in order of the bolt pattern to a 2.

value equal to 1/4 of the recommended torque

valve.

Retorque each bolt to recommend value using the 3.

same bolt pattern as shown.

When ordering spare parts, rst make a note of the following information on the valve’s nameplate:

— Serial Number

— Model and Size

— Body Material and End Connections

— Range

3

7

5

2

1

6

8

4

-3-

Page 4

12

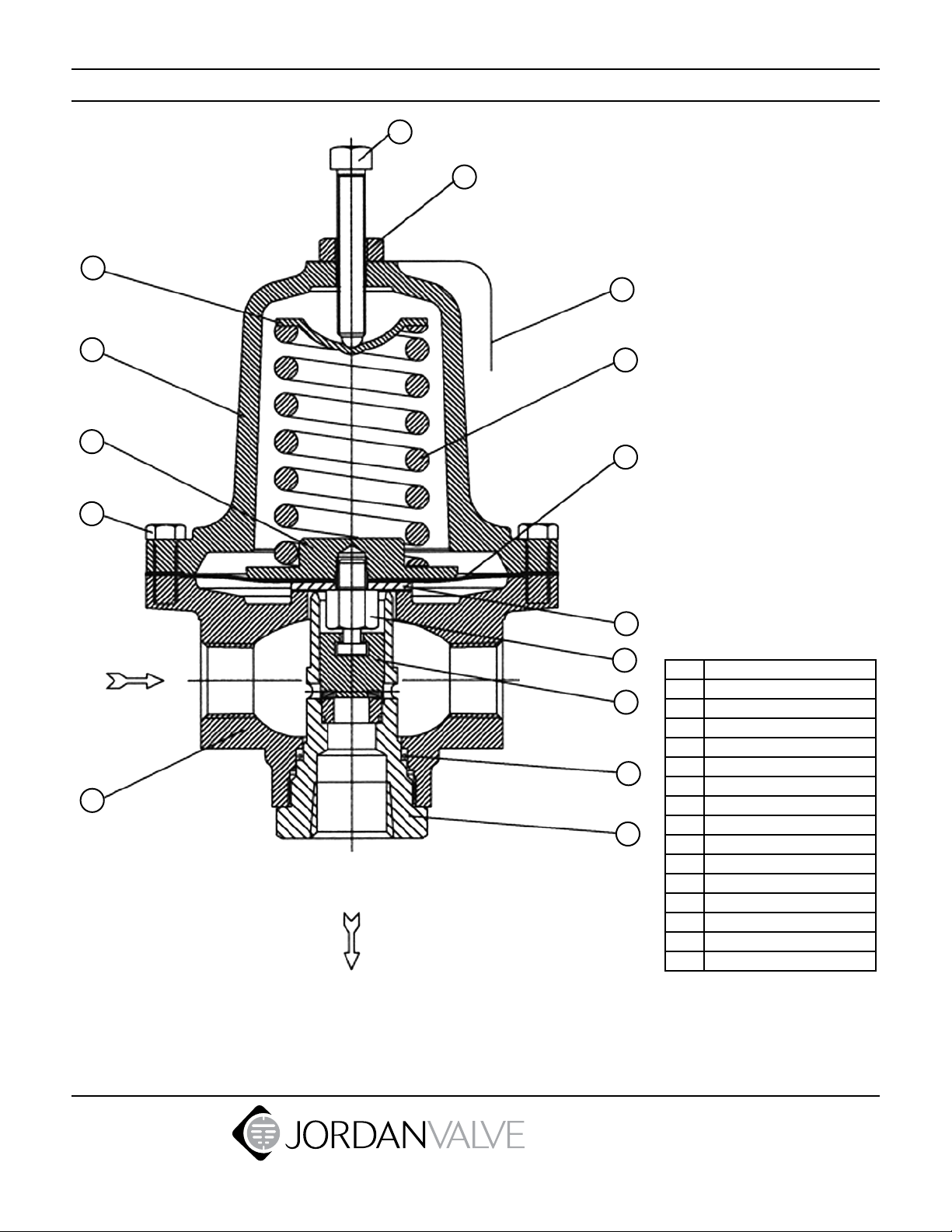

Cross Section View

14

15

16

9

8

10

11

7

6

5

4

1

2

1

By-Pass

Item Description

1 Body

2 Cage Sub-Assembly*

3 O-Ring

4 Plug

3

5 Stem

6 Washer

7 Diaphragm

8 Upper Diaphragm Plate

9 Spring Housing

10 Cap Screw

11 Range Spring

12 Spring Seat

14 Adjusting Screw

15 Jam Nut

16 Name Plate

Bulletin IM-MK58-0708

* Consists of seat, seat o-ring,

and cage

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...