I & M Mark 57

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Installation & Maintenance Instructions for

Mark 57 (1/2” to 6”) Pressure Regulators

Warning: Jordan Valve pressure regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the

event of leakage or other malfunction, call a qualified service person; continued operation may cause system failure

or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

should be exercised to prevent pipe-sealing compound from getting into pipelines. Pipe sealing

compound should be used sparingly, leaving the

two end threads clean. Jordan uses, and recommends, thread sealer Teflon ribbon.

6. The flow arrow on the valve body must be pointed

in the direction of the flow. Ideally the valve should

be installed in the highest horizontal line of pip-

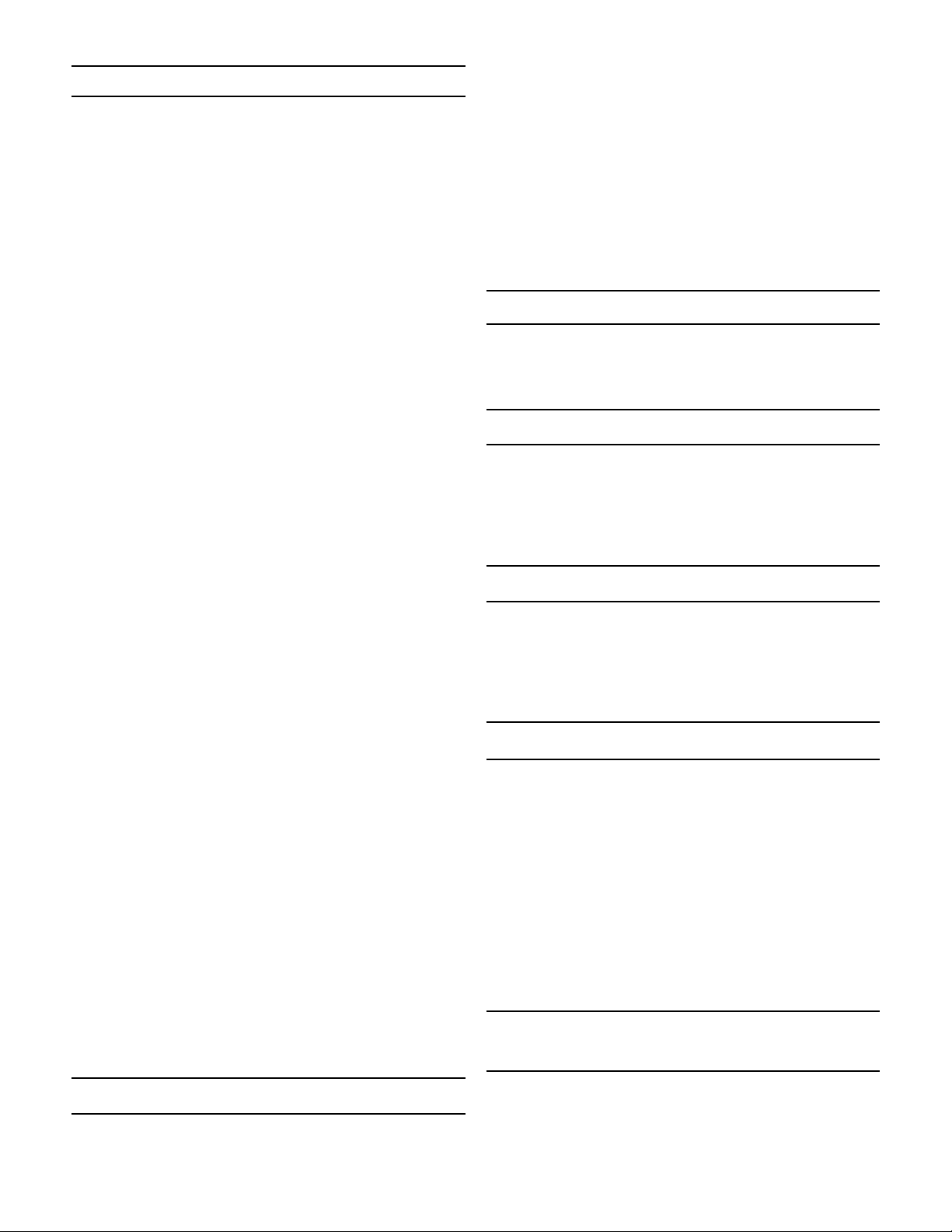

Ideal Installation

ing to provide drainage for inlet and outlet piping,

to prevent water hammer, and to obtain faster re-

Main Steam Line

sponse.

7. If possible, install a relief valve downstream from

the valve. Set at 15 psi above the control point of

3

4

1

2 1

5

R

the valve.

8. In hot vapor lines, upstream and downstream piping near the valve should be insulated to minimize

condensation.

9. In gas service, expand the outlet piping at least

one pipe size, if the control pressure (downstream)

1

1

6

Condensate Return Line

1 Shut-off Valve

2 Jordan Regulator

3 Strainer and Drain Valve

4 Pressure Gauge

5 Relief Valve

6 Steam Trap

is 25 percent of the inlet pressure or less. A standard tapered expander connected to the outlet of

the valve is recommended.

10. Where surges are severe, a piping accumulator is

recommended.

11. On steam control applications, install a steam trap

with sufficient capacity to drain the coil or condenser. Be sure to have a good fall to the trap, and no

backpressure. Best control is maintained if the coil

1. To protect the valve from grit, scale, thread chips

or condenser is kept dry.

and other foreign matter, ALL pipelines and piping

components should be blown out and thoroughly

Start-Up

cleaned before the installation process begins.

2. Shutoff valves, pressure gauges, and by-pass piping should be installed as indicated in the diagram

above to provide easier adjustment, operation and

testing.

3. A line strainer should be installed on the inlet side

of the valve to protect it from grit, scale, and other

foreign matter. A 0.033 perforated screen is usually suitable for this purpose. Line strainers are

available from Jordan Valve.

4. For best control, 3’0” straight sections of pipe

should be installed on either side of the valve.

1. Fully open the outlet shutoff valve.

2. Slowly open the inlet shutoff valve.

3. Slowly open and close the outlet shutoff valve several times. This fully strokes the valve to insure satisfactory operation.

4. With the outlet shutoff valve open, slowly screw

down the adjusting screw until the desired pressure is shown on the outlet pressure gauge.

5. To change the controlled pressure, turn the adjusting screw clockwise to increase the pressure,

counterclockwise to decrease pressure.

5. In preparing threaded pipe connections, care

Trouble Shooting

The first step in trouble-shooting a piloted back pressure

regulator is to classify the action of the controlled pressure into one of the following categories:

A. Over Pressure - Controlled pressure too high; not

enough flow or no flow through valve.

B. Under Pressure - Valve will not close or controlled

pressure decreases after valve closes.

C. Pressure Fluctuates - Controlled pressure rises and

falls, will not settle out under low relief loads.

The next step is to determine what could cause the trouble. The third step is to locate and remedy the cause by

the process of elimination. Make no assumptions and

check the easy ones first. The guide below lists the controlled pressure action, common causes and procedure

for checking each cause.

following steps are recommended:

1. Close the inlet shutoff valve.

2. Allow pressure to bleed off through the downstream piping. Do not attempt to reverse the flow

through the valve by bleeding pressure from the

upstream side of the valve.

3. When the pressure gauges indicate that all pressure has been removed from the system, close the

outlet shutoff valve, and the valve may be serviced.

Note: refer to the drawing at the end of this document for description and proper orientation of parts.

Pilot Valve

The pilot valve is a Jordan Mark 50 Back Pressure Regulator. For maintenance, refer to the Mark 50 Installation

& Maintenance sheet.

Main Valve

Controlled Pressure Action OVER PRESSURE

Valve undersized for application. Check capacity

required and valve capacity.

Line strainer screen clogged. Blow down strainer or

visually check that it is clear.

Incorrect setting on range spring. Vary the setting

and check response.

Main valve diaphragm ruptured. See section on

Main Valve Maintenance.

Controlled Pressure Action UNDER PRESSURE

Incorrect setting on range spring. Vary the setting

and check response.

Pilot Valve or main valve seats leaking. Close inlet

shut-off valve. Close outlet shut-off valve and remove loading pressure tubing. Both pilot valve and

main valve are closed. Barely open inlet shut-off

valve until fluid issues from pilot valve port, then

close inlet valve. Flow from pilot valve port should

cease. If it does not, the pilot seats are leaking. If

fluid issues from main valve port, the main valve

seats are leaking.

By-pass shut-off valve leaking. During period of

leakage, close inlet shut-off valve, observe pressure

gauge.

Bleed port in main valve clogged. Remove Upper

Bonnet to gain access bleed port and clean bleed

port. Follow instructions in section TO REMOVE

MAIN VALVE DIAPHRAGM.

It is necessary to remove the main valve from the line

only if the main valve seats must be replaced, inspected

or adjusted. All other operations can be performed with

the valve in the line and without disturbing the stroke

adjustment.

To Repair Main Valve

The sliding Gate Seats of Jordan Valves are lapped to

light band flatness. Maintaining such tolerances is of

paramount importance for your assurance of excellent

control and tight shutoff. DO NOT use metallic objects in

removing the seats. Care in handling is imperative.

To Remove Main Valve Seats

1. Remove the pilot tubing and the pilot valve with the

mounting nipple.

2. With the main valve out of the line, remove the

bolts securing the main valve cap to the main valve

body and lift the cap straight up.

3. Lift the disc from the plate and place on a clean

surface with the seating side up.

4. Place the valve body on a side. Hold one hand over

the plate to receive it and tap lightly on the back

of the plate with a soft, blunt object; push the pate

out evenly. Place the plate on a clean surface seating side up.

Controlled PRESSURE FLUCTUATES

Valve oversized. Check capacity required and valve

capacity.

Maintenance

Caution: Make certain that there in no pressure in

the valve before loosening any fittings or joints. The

To Remove Main Valve Diaphragm

and Disc Pin

1. Remove the bottom cap. The spring and spring

guide will come out with it.

2. Disconnect the loading pressure tubing from the

upper case, remove the case bolts and upper case.

-2-

Loading...

Loading...