I & M Mark 56

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve pressure regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the

event of leakage or other malfunction, call a qualified service person; continued operation may cause system failure

or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

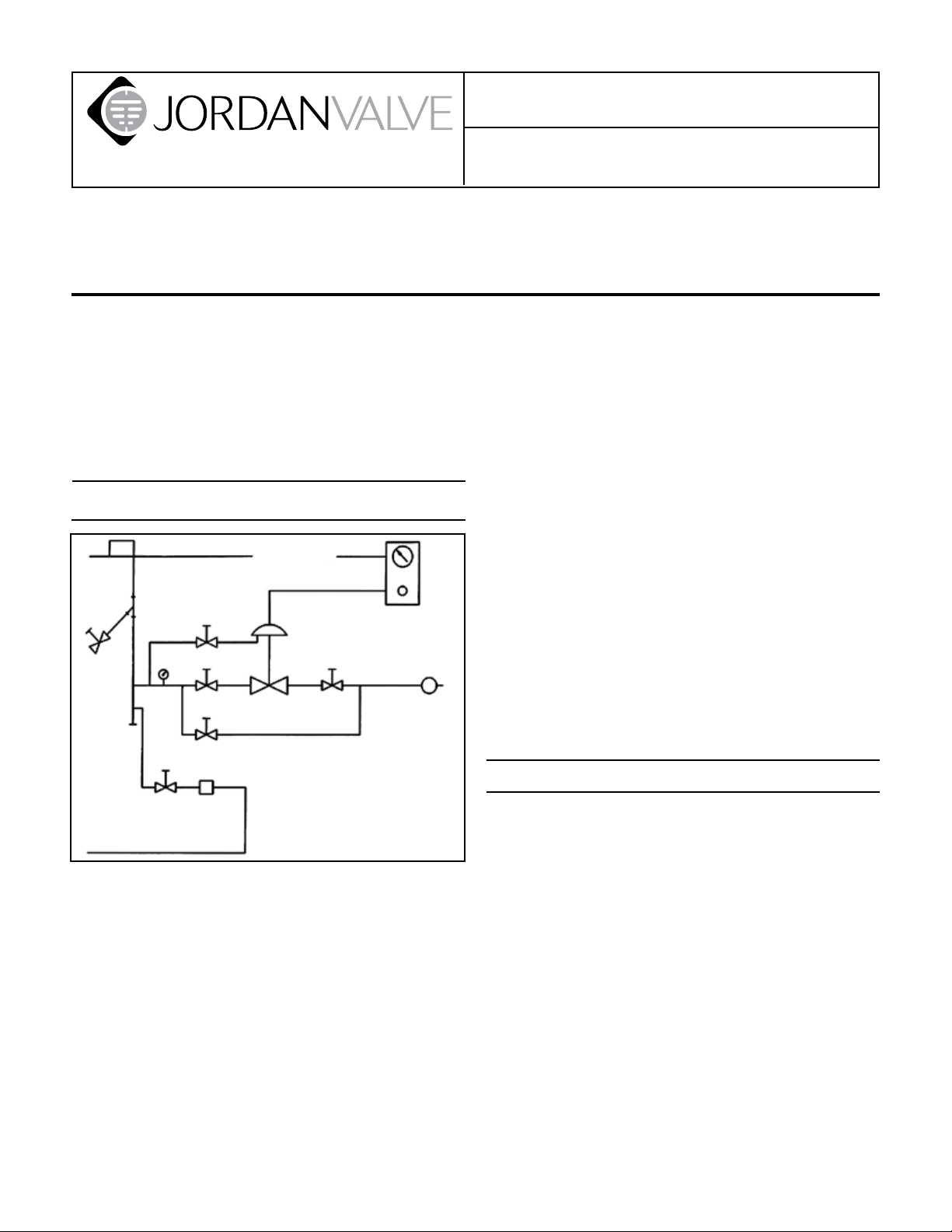

Ideal Installation

Main Steam Line

3

1

4

1

1

1

6

Condensate Return Line

1. Protect the regulator from grit, scale, thread chips

and other foreign matter, by blowing out and thoroughly cleaning all pipe lines and piping components before the regulator is installed.

2. Shutoff valves, pressure gauges, and by-pass piping should be installed as indicated in the diagram

above to provide easier adjustment, operation and

testing.

3. When preparing threaded pipe connections, care

should be exercised to prevent pipe sealing compound from getting into the pipe lines. Pipe sealing

compound should be used sparingly, leaving the

two lead threads clean.

4. A line strainer should be installed on the inlet side

of the regulator to protect it from grit, scale, and

Plant Air

2

1. Shut-Off Valve

2. Jordan Regulator

3. Strainer and Drain Valve

4. Pressure Gauge

5. Relief Valve

6. Steam Trap

7. Panel Loading Station

1

7

5

R

Installation & Maintenance Instructions for

Mark 56 Air Loaded Back Pressure Regulators

other foreign matter. A 0.033” perforated screen is

usually suitable. Line strainers are available from

Jordan Valve.

5. Install the regulator in the highest horizontal line of

piping to provide drainage for inlet and outlet piping, to prevent water hammer, and to obtain faster

regulation.

6. The flow arrow on the regulator body must be

pointed in the direction of flow. The regulator may

be installed in any direction, but damage to the

seating surfaces may occur if installed in a vertical

line with the flow upwards.

7. For best control, 3’0” straight sections of pipe

should be installed on either side of the regulator.

8. In hot vapor lines, upstream and downstream piping near the regulator should be insulated to minimize condensation.

9. Expand the outlet piping at least one pipe size if

the controlled pressure (downstream) is 25 percent

of the inlet pressure or less. A standard tapered

expander connected to the outlet of the regulator

is recommended.

10. Where surges are severe, a piping accumulator is

recommended.

Control Line

Install a control line as follows:

1. Connect 3/8” O.D. tubing to the fitting under the

diaphragm.

2. Connect the other end in a straight run of pipe

three to five feet upstream from the regulator.

3. DO NOT locate the control line tap in an elbow,

swage, or other changes in configuration of the

pipeline where turbulence or abnormal velocities

may occur. DO NOT locate the control line tap in

a vessel, such as a deaerator, located immediately

upstream of the regulator. Locate the tap in the

pipeline leading to the vessel.

4. The control line should be sloped away from the

regulator.

5. Install a shutoff valve (not a needle valve) in the

control line.

6. Install a pressure gauge in the control line or near

the inlet of the regulator to aid in setting the valve.

Start-Up Procedure

2”

With the inlet, outlet and bypass shutoff valves

closed, and no pressure in the downstream line:

1. Fully open the control line shutoff valve.

2. Fully open the outlet shutoff valve.

3. Slowly open the inlet valve just enough to start

flow through the regulator. Observe the upstream

pressure gauge. Increase the air-loading pressure

slowly to gradually close the regulator.

4. Do not fully open the inlet valve until you are sure

that the regulator has control of the system. Usually, the handwheel on the inlet valve will turn freely

when this point is reached.

5. To change the controlled pressure, adjust the loading pressure supplied to the top of the diaphragm.

Trouble Shooting

Erratic Control

• Oversizing causes cycling and hunting, and reduces the rangeability of the regulator. Check sizing calculations to be sure that you have the proper

size valve.

• Steam traps downstream may need attention and

could be causing erratic control.

• Safety valve may be jammed open, disrupting the

system. Repair as necessary.

• Excessive foreign matter on seats can cause erratic

operation. Clean them as outlined under Valve

Seats.

• Valve stroke may be out of adjustment. Readjust

stroke.

• Valve disc may not be moving freely. Check disc

guide clearance, and clearance of the stem to the

bushings.

Will Not Operate

• Diaphragm may be ruptured and need replace-

ment.

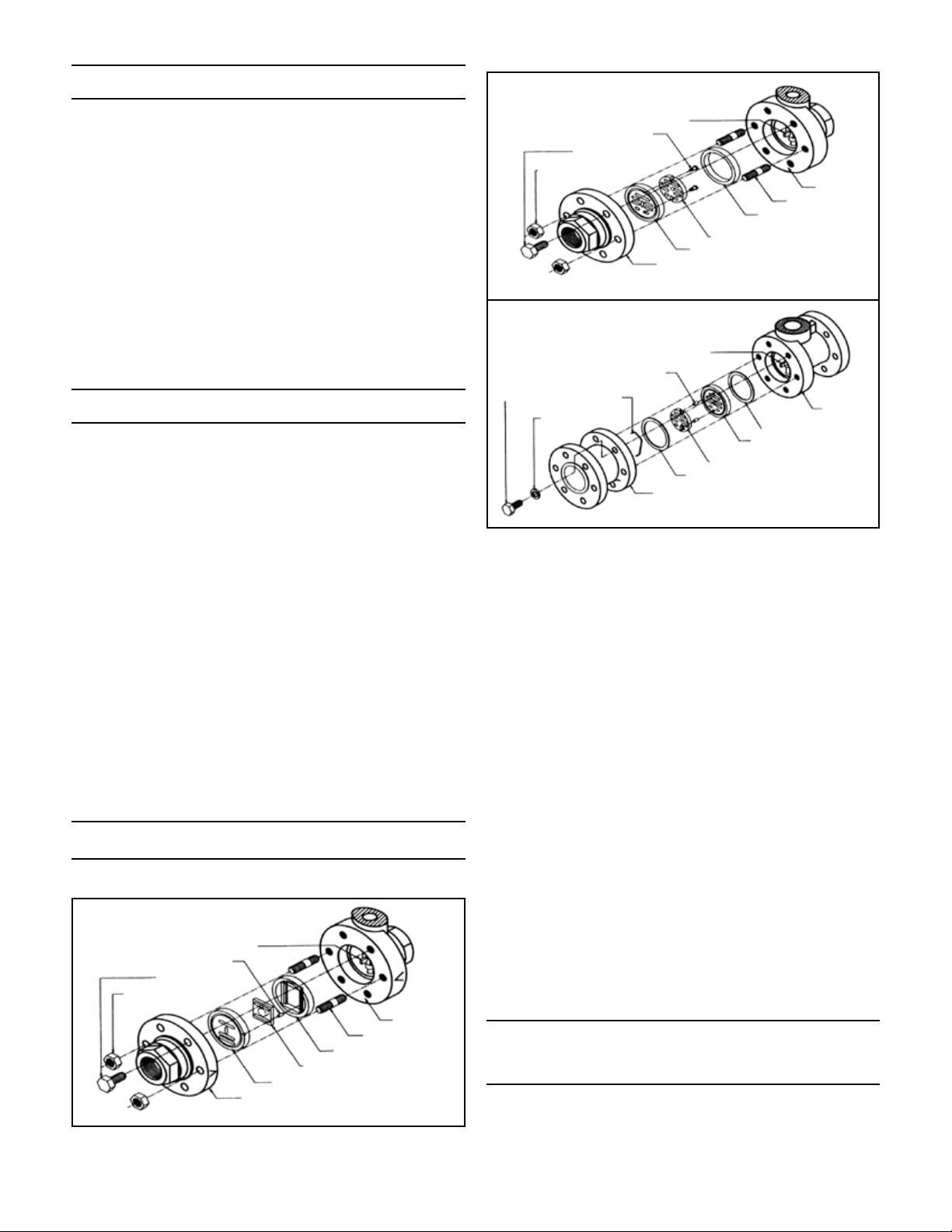

Valve Seats

1/2” to 1-1/2”

Disc Pin

Index Pin

Body Bolts

Stud Nuts (2)

Body

Studs (2)

Disc Guide

Disc

Plate

Cap

Disc Pin

Guide Screws (2)

Body Bolts

Stud Nuts (2)

Pressure Ring

Disc

Plate

Cap

Body

Studs (2)

2-1/2” to 6”

Disc Pin

Body

Bolts

Disc Guide (2)

Disc Spring

Lockwashers

Body

Gasket: Plate-Body

Plate

Disc

Gasket: Cap-Plate

Cap

Disassemby (All Sizes)

The sliding gate valve seat is the key to the excellent

control and tight shutoff provided by a Jordan valve.

Maintaining these seats in good condition is critical to

valve performance, so care in handling is imperative.

NEVER USE METALLIC OBJECTS IN REMOVING THE

SEATS. Improper handling can result in leakage and poor

control.

1. Close the shutoff valve on each side of the valve,

and remove the valve from the line.

2. Note scribed “<“ on the side of the body and cap

for 1/2” - 2” sizes. Secure the body in a vise. Remove the body bolts and stud nuts and lift the cap

straight up.

3. Before removing, note the locating pin that aligns

the plate with the disc guide on 1/2” to 1-1/2”

sizes. This pin should be on the same side as the

“<“ on the body and cap. Remove the plate and

disc (on 2” valves, the disc will be attached to the

plate, and the screws should now be removed to

separate the two parts; on 2-1/2” - 6” valves, place

the body on its side to remove the plate). Place the

disc on the bench with lapped surfaces facing up.

Protect the lapped surfaces on both sides of the

disc guide.

It is important that the disc pin is not rotated when

disassembling, cleaning, or reassembling, since this affects the stroke adjustment.

4. Lightly tap on the body to remove the disc guide (2”

valve uses a pressure ring instead of a disc guide).

Invert the body, let the disc guide drop out into

-2-

Loading...

Loading...