Page 1

I & M Mark 53/54

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve pressure regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In

the event of leakage or other malfunction, call a qualified service person; continued operation may cause system

failure or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before

disassembling a valve, be sure to release all spring tension.

Note: The Mark 53 and Mark 54 Differential Regulators have the same valve body and seating construction as the

Mark 50 and Mark 60 respectively. This supplemental presents only those instructions necessary to maintain the

topworks, and is to be used in conjunction with the Installation and Maintenance Instructions for the Mark 50 and

Mark 60 for other maintenance procedures.

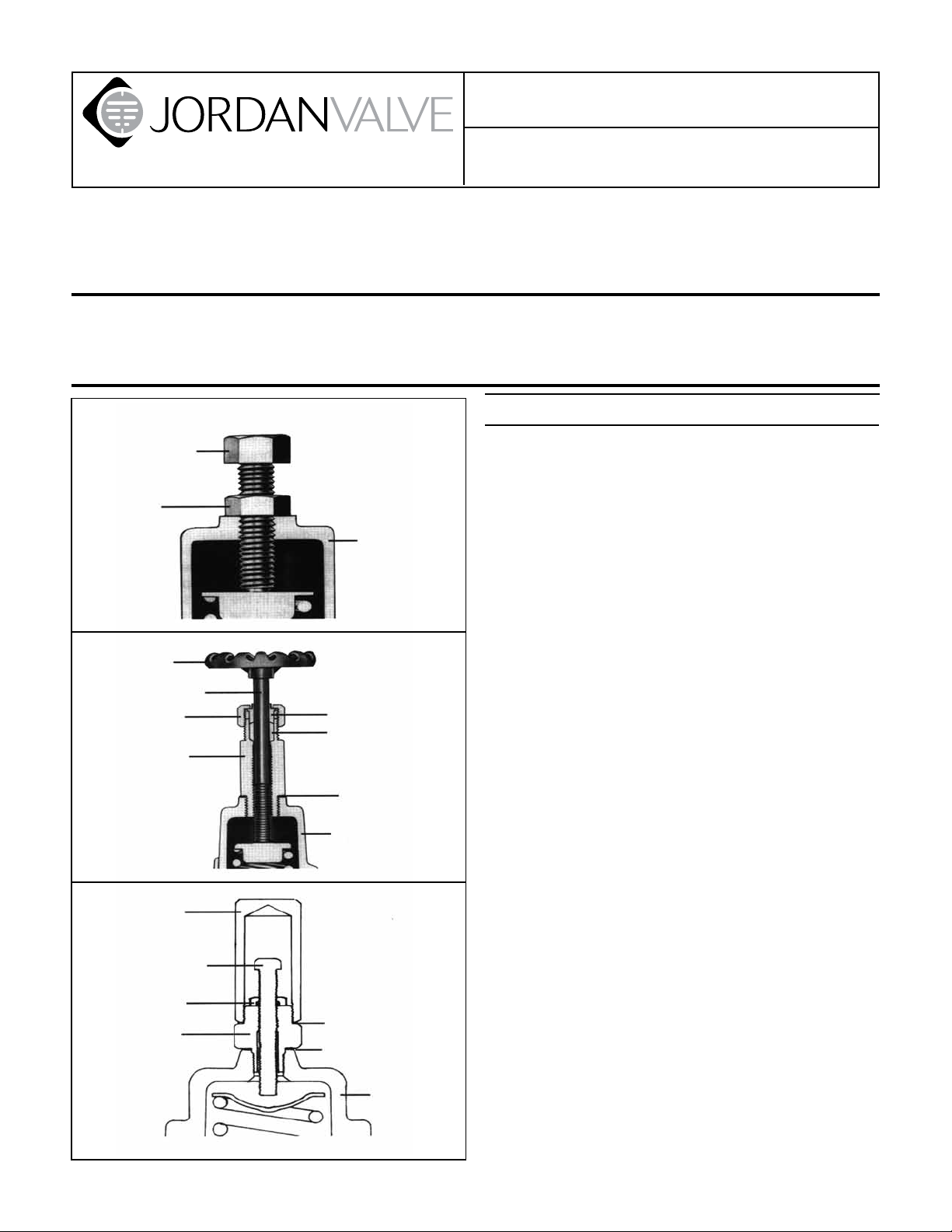

Seal Nut Type

Adjusting Screw

Seal Nut

Spring

Housing

Installation & Maintenance Instructions

Supplement for Mark 53 and Mark 54

Installation

The installation instructions for the Differential Regulator

are identical to the instructions for the Mark 50 and Mark

60 with the following additions:

Connect the reference pressure feedback line

to the threaded port in the spring housing. The

Flow-Thru Spring Housing has full size threaded

connections so that the reference fluid can be

piped directly through the Spring Housing.

Trapped air in the upper section of the Spring

Housing can be bled off by opening the Bleed Port

or Bleed Valve (if supplied) or by loosening the Seat

Nut on the Mark 53 and 53C or by loosening the

Handwheel

Adjusting Screw

Packing Nut

Packing Box

1.

Handwheel

Type

Packing Gland

Packing

Gasket

Packing Nut on the Mark 53H.

Seat Nut Type (Standard)

The seal Nut Type Differential Regulators are identical

in all respects to the Mark 50 or the Mark 60 with one

exception. The Seal Nut replaces the Lock Nut. Follow

the instructions in the Mark 50 or 60 I & M.

Handwheel Type

Closing Cap

Adjusting Screw

Lock Nut

Closing Cap

Bushing

Spring Housing

Closing Cap

Type

Gasket (Upper)

Gasket (Lower)

Spring

Housing

1. To remove the packing, remove the Handwheel

Screw and Washer from the Adjusting Screw.

2. Remove the Handwheel and then remove the

Packing Nut.

3. The Packing Gland and the Packing can now be

removed from the cavity of the Packing Box.

4. Teflon-impregnated, square-braided packing is

recommended, but other types may be used

depending upon your requirements.

5. Reassemble in reverse order.

Closing Cap Type

1. If your Differential Regulator is equipped with a

Closing Cap, the only maintenance that will likely

ever be required is the replacement of the gaskets.

2. To replace the gaskets, remove the Closing Cap.

Then remove the Adjusting Screw and Lock Nut.

The Closing Cap Bushing can then be removed.

Replace the gaskets as you reassemble the valve in

the reverse order.

Page 2

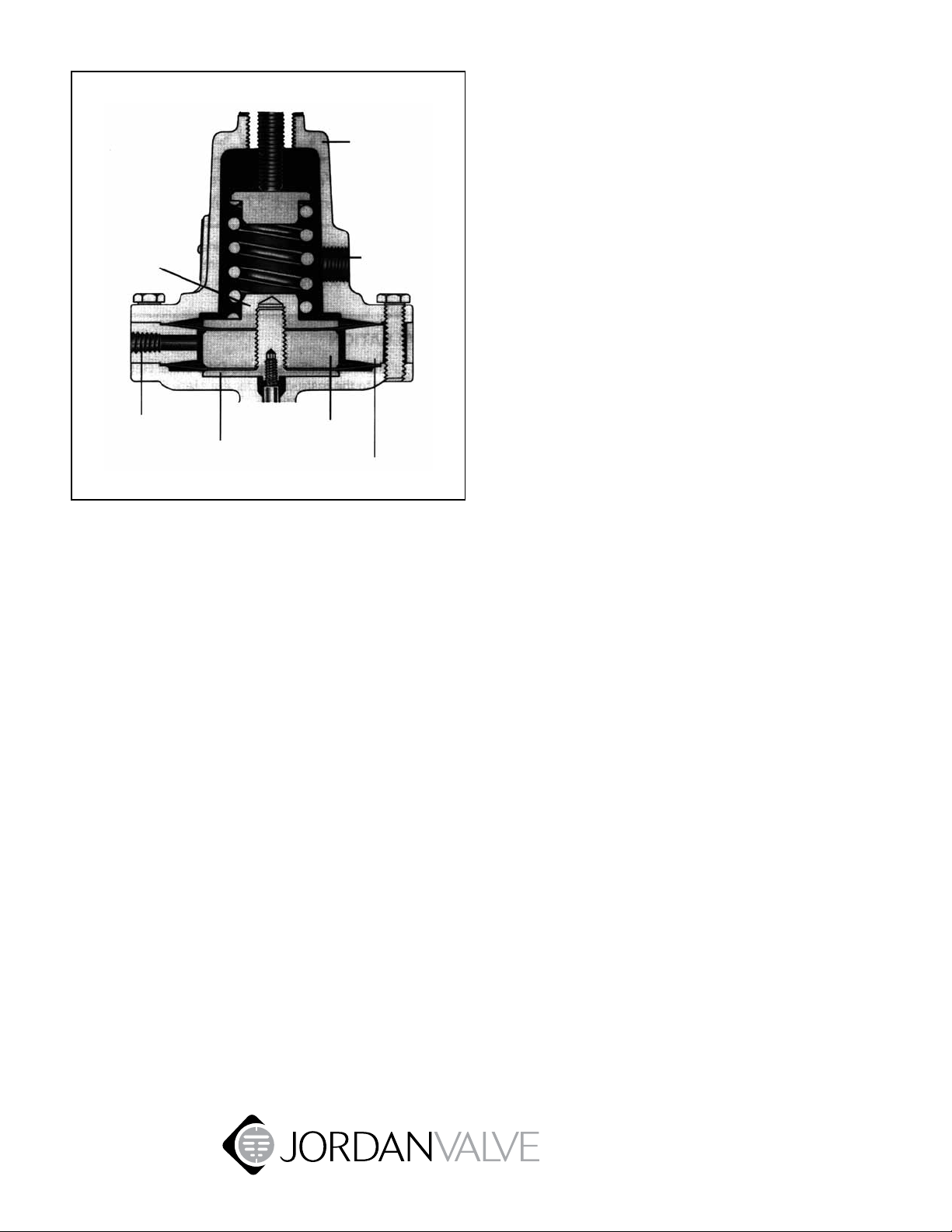

Upper

Diaphragm

Plate

Vent Port

Lower

Diaphragm

Plate

Spacer Plate

Spacer Ring

Spring

Housing

Flow-Thru

Connection

(both sides)

Separated Double Diaphragm

Diaphragm Replacement

1. REMOVE THE REGULATOR FROM THE LINE.

2. Release the compression of the spring by turning

the adjusting screw counter-clockwise.

3. Remove the SPRING HOUSING bolts and the

SPRING HOUSING, SPRING & SPRING SEAT.

4. Rotate the SPACER RING until the vent port aligns

with one of the holes in the side of the spacer

plate. Then bolt the spacer ring to the body with

two or three bolts. Insert a metal rod through the

vent port in the spacer ring and into the hole in the

spacer plate. Hold securely and loosen the upper

diaphragm plate with a pipe wrench.

5. Remove the upper diaphragm plate and the upper

diaphragm. Then remove the spacer ring.

6. Rotate the spacer plate and diaphragm counterclockwise and remove the assembly.

7. Fasten the spacer plate securely in a vise and then

remove the lower diaphragm plate with a pin face

spanner wrench. Use extreme caution, wear gloves

or tap the spanner wrench with a hammer in order

to avoid cutting your hands on the diaphragm.

8. Replace the diaphragm in the reverse order. Apply

sealant to the fluid side of the diaphragm around

the center hole and the outer seating edge. The

valve stroke must be adjusted. Refer to the Mark 60

or Mark 50 I & M for the proper instructions under

the heading: DIAPHRAGM REPLACEMENT - B.

ASSEMBLY AND STROKE ADJUSTMENT.

Bulletin IM-MK53-0909

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...