I & M Mark 52

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Installation & Maintenance Instructions for

Mark 52 Piloted Back Pressure Regulators

Warning: Jordan Valve Pressure Regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the

event of leakage or other malfunction, call a qualied service person; continued operation may cause system failure

or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disassembling a valve, be sure to release all spring tension.

Please read these instructions carefully!

should be installed as indicated in the diagram to

provide easier adjustment, operation and testing.

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

In preparing threaded pipe connections, care 3.

should be exercised to prevent pipe sealing compound from getting into the pipe lines. Pipe sealing

compound should be used sparingly, leaving the

two lead threads clean. Jordan uses, and recommends, Seyco #2415 thread sealer Teon ribbon.

A line strainer should be installed on the inlet side 4.

This pilot operated regulator was designed to handle

your more critical inlet pressure or relief applications.

It will accurately control pressure to 100% of its rated

ow capacity with only the slightest deviation from the

set point. This is comparable to controller operated

accuracy, and on most critical applications should be

considered before costly, more rened instruments. It is

designed to handle a wide range of control pressures.

of the regulator to protect it from grit, scale, and

other foreign matter. A 0.033 perforated screen is

usually suitable. Line strainers are available from

Jordan Valve.

Install the regulator in the highest horizontal line of 5.

piping to provide drainage for inlet and outlet piping, to prevent water hammer and to obtain faster

regulation.

The ow arrow on the regulator body must be 6.

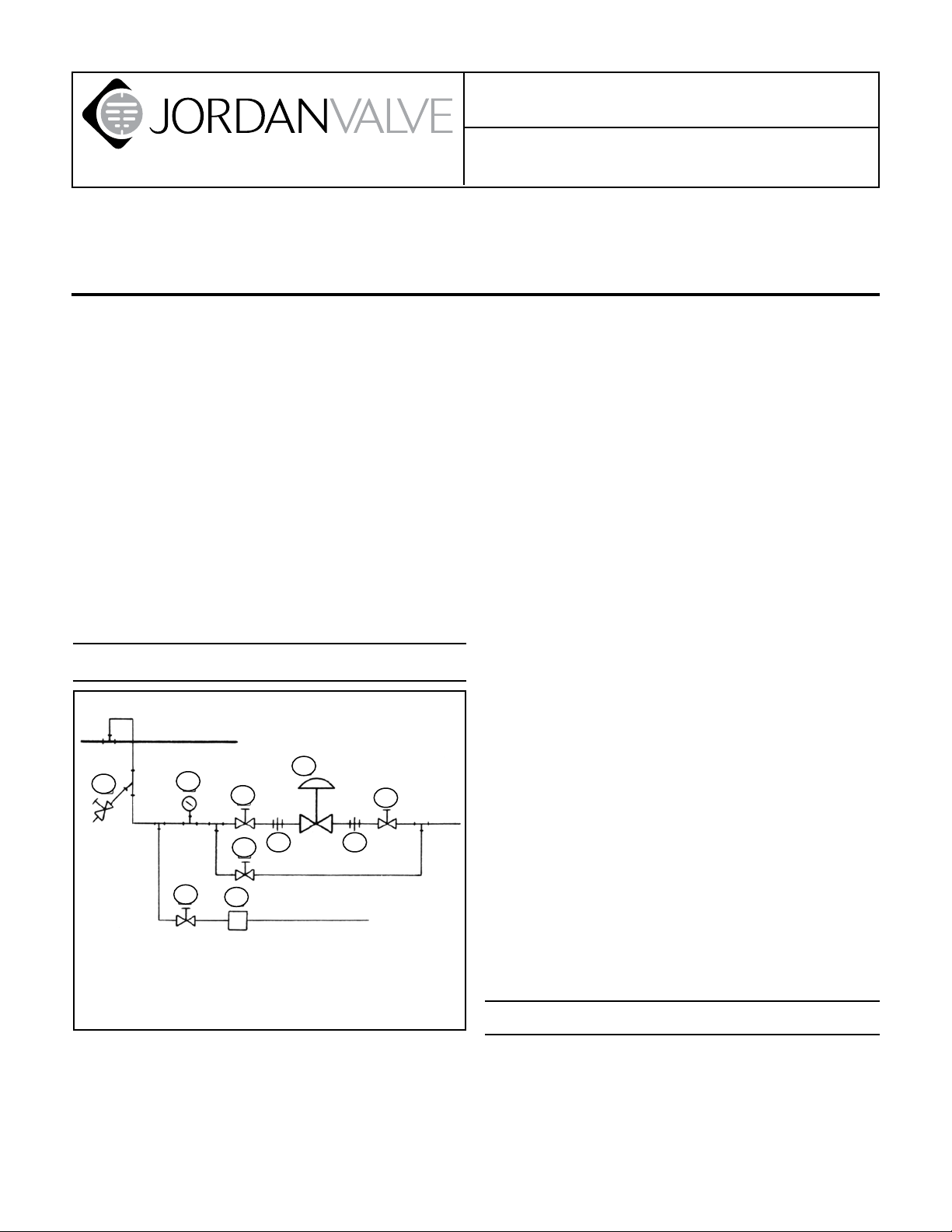

Ideal Installation

pointed in the direction of ow. The regulator may

be installed vertically or horizontally without affecting its operation.

For best control, 3’ 0” straight sections of pipe 7.

Main Line

should be installed on either side of the regulator.

To minimize condensation in hot vapor lines, up-8.

3

4

1

5

1

stream and downstream piping near the regulator

should be insulated.

If possible, install a relief valve upstream from the 9.

regulator. Seat at 15 psi above the control point of

2 2

1

the regulator.

Expand the outlet piping at least one pipe size if 10.

1

6

Condensate Return

1. Shut off Valve

2. Pipe Union

3. Strainer and Drain Valve

4. Pressure Gauge

5. Jordan Mark 52

6. Steam Trap

the downstream pressure is 25 percent of the inlet pressure or less. A standard tapered expander

connected to the outlet of the regulator is recommended.

Where surges are severe, a piping accumulator is 11.

recommended.

Operation

To protect the regulator from grit, scale, thread 1.

chips and other foreign matter, all pipe lines and

piping components should be blown out and thoroughly cleaned before the regulator is installed.

Shut-off valves, pressure gauges and by-pass piping 2.

The main valve and the pilot are normally closed. The

inlet pressure passes through the inlet pilot tubing beneath the pilot diaphragm. As the force of the adjusting

spring is overcome, the pilot valve opens allowing the

inlet pressure to enter the chamber above the main diaphragm, opening the main valve. When the set point is

reached, the adjusting spring overcomes the force of the

pressure beneath the pilot diaphragm and the pilot and

main valves close.

Start-Up Procedure

With the inlet and outlet shut-off valves closed:

Throttle the bypass valve so that the pressure to be 1.

controlled is maintained near the set point.

Slowly open the inlet shut-off valve. 2.

Open the outlet shut-off valve.3.

Slowly close the bypass valve, but do not close it 4.

fully until you are certain that the regulator has control of the system.

To change the controlled pressure, turn the adjust-5.

ing screw clockwise to increase pressure, counterclockwise to decrease pressure.

Body and cap bolts should be retightened per 6.

torque procedures after valve reaches operating

temperature.

Maintenance

CAUTION: Be sure that there is not pressure in the

valve before loosening any ttings or joints. The following steps are recommended:

Close the inlet shut-off valve. 1.

Release the compression of the adjusting spring by 2.

turning the handwheel counter-clockwise until free.

(This allows the pilot valve to open and release the

pressure on the inlet of the valve.)

Allow pressure to bleed off downstream from the 3.

regulator.

Close the outlet shut-off valve.4.

Valve Seats

The seats of Jordan regulators are lapped to light

band atness. Maintaining such tolerances is of paramount importance for your assurance of excellent

control and dead end shut-off. DO NOT use metallic

objects in removing the seats. Care in handling is

imperative.

A. DISASSEMBLY

Close the shut-off valve on each side of the regula-1.

tor.

Remove the regulator from the line. 2.

Note the scribe marking >< on the side of the 3.

valve body (15) and cap (7). Secure the outlet body

hex in a vise. Remove the cap screws (11) and lift

the cap straight up. Please note that there is an

index pin secured in the cap (7). This index pin is

on the same side as the scribe marking >< on the

valve cap and body and it positions the valve plate

in the body.

Before removing check the valve disc (8) for a 4.

stamped arrow. This arrow points to the scribe

marking >< and the index pin hole in the valve

plate. Since the disc can be rotated 180º in some

sizes without affecting the stroke adjustment, there

may be no arrow on the valve disc. Remove the

valve disc and place on bench with the lapped surface up.

Lightly tapping on the valve body is usually suf-5.

cient to loosen a stuck plate (10) or disc guide

guide (9). Invert the body so that the seat set will

drop into your hand.

IMPROPER HANDLING OF THE SEATS WILL RESULT

IN LEAKAGE OR IMPROPER CONTROL.

Clean out all parts of the body and cap with sol-6.

vent. The valve disc and plate may then be cleaned.

Place a piece of 4/0 polishing paper or jeweler’s

cloth on a smooth, at surface such as a surface

plate and polish the lapped surfaces with a “gure

eight” motion. If parts are scarred, do not attempt

to re-lap them, but return them to the factory for

repair or replacement. If seats are not scarred

deeply they can be renished several times at minimum cost.

The vertical milled portions of the valve cap serve 7.

as a guide for the disc while stroking. A 0.0005

feeler gauge should be used to check the clearance between the valve disc and disc guides. To

do so, place the valve disc in the cap disc guides

with the lapped surface facing upwards and check

this clearance. If the clearance is less than 0.005”,

clean the disc guide with a smooth le.

B. REASSEMBLY

Replace the valve plate. In replacing, make certain 1.

that the index pin hole is on the same side as the

scribe marking >< on the valve body. Align the disc

pin so that it is centered in the body bore and protrudes upward through the slot in the plate.

In replacing the vale disc, the stamped arrow 2.

should be pointing to the scribe line on the valve

body. Place the valve disc on the valve plate, engaging the disc pin.

Turn the adjusting screw (28) counter clockwise to 3.

release spring compression, thus opening the pilot

valve.

To check the stroke adjustment, blow air into the 4.

inlet connection. The main valve will stroke to the

open position, and the orices should be open and

in perfect alignment. If they are not, an adjustment

is required.

To obtain the proper adjustment, remove the valve 5.

plate and disc from the valve body and loosen

the stem locknut (18). Adjustment is obtained by

-2-

Loading...

Loading...