Page 1

I & M Mark 5108 Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

The Mark 5108 may be generically described as

a back pressure control valve, i.e., it controls the

pressure at its inlet. With this type of control, the

Mark 5108 may be employed in two different ways:

1. As a Pressure Relief Valve. Here the 5108

is installed on a bypass from a main line. It

opens to relieve any pressure above its set

point.

2. As a Pressure Sustaining Valve. Here the

Mark 5108 is installed in the main line itself. It

functions to control the incoming pressure at

the set point, or more commonly, to prevent

the pressure from falling below a

predetermined minimum. For example, it may

be installed on the discharge of a pump to

ensure that the pump remains "on its curve."

Installation & Maintenance Instructions for the

Mark 5108 Back Pressure Regulating Valve

4. Flow Control Valve, a needle-type valve

which provides adjustable, restricted flow in

one direction, and free flow in the opposite

direction. On the Mark 5108, the flow control

valve is connected as a closing speed

control.

5. The Y-Strainer (standard on water

service valves) or Mark 5123 Inline Strainer

(standard on fuel service valves). The strainer

protects the pilot system from solid

contami nants in the line fluid.

6. Two Ball Valves (standard on water service

valves, optional on fuel service valves), useful

for isolating the pilot system for maintenance

or trouble shooting.

At user option, the 5108 may also be equipped with

the following:

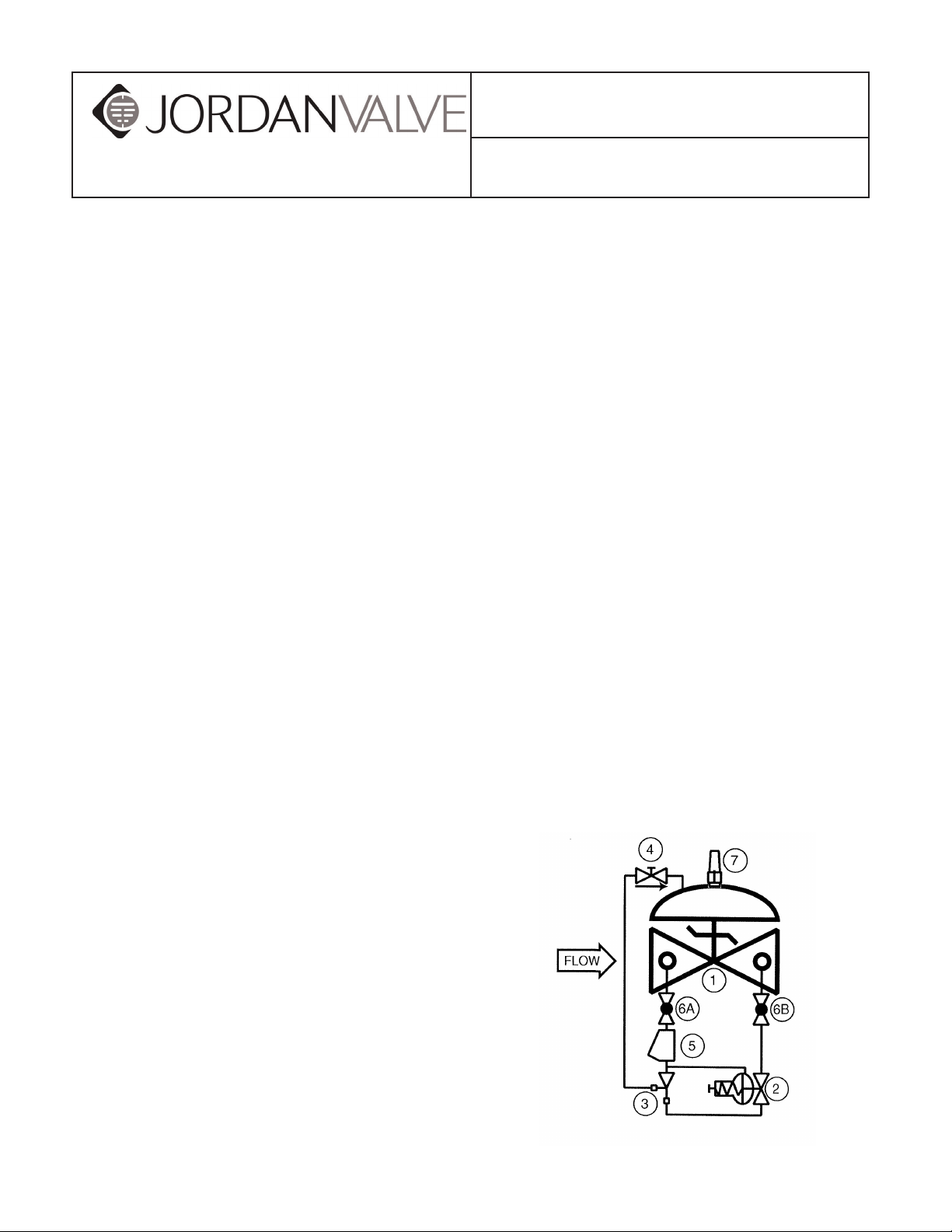

The Mark 5108 consists of the following components,

arranged as shown on the schematic diagram:

1. Basic Control Valve, a hydraulically

operated, diaphragm-actuated, globe or

angle valve which closes with an elastomer-on-

metal seal.

2. Pressure Relief Pilot, a two-way, normally

closed pilot valve which senses up-stream

presure under its diaphragm and balances it

against an adjustable spring load. An increase

in upstream pressure tends to make the pilot

open.

3. Ejector, a simple "tee" fitting with a fixed orifice

in its inlet port. It provides the proper pressure to

the diaphragm chamber of the main valve

depending on the position of the pressure relief

pilot.

1. Visual Indicator.

2. Limit Switch Assembly (includes visual

indicator).

3. Opening Speed Control.

Page 2

Mark 5108 SerieS Back PreSSure regulating ValVe

theory of operatIon

To understand how the Mark 5108 operates, it is best

to start with the Ejector (3). Due to the orifice in its

upstream port, the ejector creates a pressure drop

proportional to the flow through it. The flow through the

ejector is in turn controlled by the degree of opening of

the Pressure Relief Pilot (2). The wider the pilot opens,

the greater the flow through the ejector and the lower the

pressure downstream of the orifice. Conversely, the more

the pilot closes, the lower the flow through the ejector

and the greater the pressure downstream of the orifice.

Now note that the diaphragm chamber of the Main Valve

(1) is connected to the branch port of the ejector and is

thus downstream of the orifice. Therefore, the pressure in

the diaphragm chamber of the main valve is effectively

controlled by the pressure relief pilot in the manner

described above. As the pilot opens, the diaphragm

pressure decreases and the main valve opens; as the

pilot closes, the diaphragm pressure increases and the

main valve closes.

If the Mark 5108 is installed as a pressure relief valve,

the pressure upstream of the main valve is normally

below the set point of the relief pilot. Therefore, the pilot

is fully closed, and so is the main valve. However, if, for

any reason, the pressure rises above the set point, the

pilot will open, and the main valve will follow in turn. The

net effect is that the main valve will open and control

the pressure at the set point, not allowing it to rise any

further. Once pressure returns to normal, the pilot and

main valve will return to the closed position.

If the Mark 5108 is installed as a pressure sustaining

valve, the pressure upstream of the main valve is

normally above the set point of the relief pilot. Therefore,

the pilot is wide open as is the main valve. However, if

system demand increases to the point that the upstream

pressure tries to fall below the set point, the pilot will

start to close and the main valve will follow, throttling as

required to keep the pressure from falling any further.

InstallatIon

Figure 1 shows a typical installation of an angle pattern

Mark 5108 in pressure service. Here it will relieve the

startup surges of the centrifugal pump, but this time in

pressure sustaining service. Here it will keep a

minimum back pressure on the pump to keep it from

running off the right of its curve in periods of high system

demand. These illustrations are intended only as rough

guides for valve installation, as indeed there are many

other places in a system where the Mark 5108 can be

effectively employed. However, note the use of isolation

valves. While these do not affect the operation of the

5108, they can be extremely useful if the valve needs to

be isolated from the line for maintenance or repair.

For full installation details, the user is referred to the Main

Valve section of this manual.

start- up and adjustments

The following procedures should be followed in the order

presented in order to affect an initial startup of the Mark

5108. Note that the procedure differs somewhat between

a pressure relief valve and a pressure sustaining valve.

Procedure A. Pressure Relief Valve

1. Install a pressure gauge of the proper range

upstream of the Mark 5108. The unused inlet

side port in the main valve body may be

used for this purpose if there is no

convenient location in the upstream piping.

2. Remove the plastic cap from the pressure relief

pilot (2) and loosen the adjusting screw jam nut.

Turn the adjusting screw clockwise to a full stop.

3. Loosen the adjusting screw jam nut on the flow

control valve (4) (closing speed control). Turn

the adjusting screw clockwise to a full stop, then

counterclockwise three full turns.

4. Make sure both pilot system isolation ball valves

(6A and 6B) are open.

5. Start the pump or otherwise start the system

flowing. The main valve at this time should

be fully closed.

6. Carefully loosen a pipe plug in the main valve

bonnet until fluid begins to discharge around

the threads. When only clear fluid (no air)

is discharging, retighten the plug.

-2-

Page 3

Mark 5108 SerieS Back PreSSure regulating ValVe

7. While observing the inlet pressure gauge ,retard

flow in the system by closing valves or otherwise

reducing demand until the pressure increases to

approximately 5 psi above the desired set point.

8. Slowly turn the adjusting screw of the pressure

relief pilot (2) counterclockwise until the valve

opens and the pressure falls to the set

point. Tighten the adjusting screw jam nut and

replace the plastic cap.

9. Increase flow in the system or otherwise in-

crease demand until pressure returns to normal.

Observe the closing speed of the valve. Ideally,

the valve should close just slow enough

to avoid inducing any secondary surges

in the system. Turn the adjusting screw of the

flow control valve (4) clockwise to

decrease closing speed; counterclockwise to

increase closing speed. CAUTION: Do

NOT adjust the/low control valve fully closed. To

do so can keep the valve from closing at all.

10. Shut down the pump.

Procedure B. Pressure Sustaining Valve

1. Install a pressure gauge of the proper range

upstream of the Mark 5108. The unused inlet

side port in the main valve body may be used

for this purpose if there is no convenient location

in the upstream piping.

2. Remove the plastic cap from the pressure relief

pilot (2) and loosen the adjusting screw jam nut.

Turn the adjusting screw clockwise to a full stop.

3. Loosen the adjusting screw jam nut on the flow

control valve (4) (closing speed control). Turn

the adjusting screw clockwise to a full stop, then

counterclockwise three full turns.

4. Make sure both pilot system isolation ball valves

(6A and 6B) are open.

5. Start the pump or otherwise start the system

flowing. The main valve at this time should be

fully closed.

6. Carefully loosen a pipe plug in the main valve

bonnet until fluid begins to discharge around the

threads. When only clear fluid (no air) is

discharging, retighten the plug.

7. Turn the adjusting screw of the pressure relief

pilot (2) counterclockwise until it is loose enough

to be turned with the fingers. The main

valve should open fully.

8. Observing the inlet pressure gauge, open valves

or otherwise increase flow until the pressure falls

to a point approximately 5 psi below the desired

set point.

9. Slowly turn the adjusting screw of the pressure

relief pilot (2) clockwise until the pressure rises

to the set point. Tighten the adjusting screw jam

nut and replace the plastic cap.

10. Shut down the pump.

maIntenance

Because of the simplicity of design of the Mark 5108,

required maintenance is minimal. However, the following

checks, periodically performed, can do much to keep

the valve operating properly and efficiently.

1. Check for chipped or peeling paint. Touch up as

required.

2. Check for leaks at fittings and around flanges

and connections. Tighten as required.

3. If the valve is equipped with a Y-strainer, check

the screen for buildup of solid material. Clean as

required. This point is most important, as 1

a clogged strainer can keep the valve

from closing. On new installations, it is

recommended that the strainer be checked

every day or two until experience dictates a

greater or lesser interval. Strainer maintenance

is covered in detail on a special page

later in this manual.

troubleshootIng

In the event of malfunction of the Mark 5108, the

following guide should enable the technician to

isolate the specific cause of the problem and take the

appropriate corrective action.

A. Main Valve fails to Open:

1. Valve closed upstream or downstream of the

Mark 5108. Open as required.

2. Downstream pilot system ball valve (6B) closed.

Open as required.

3. Pressure relief pilot (2) adjusted too far clock-

wise. See Adjustment instructions.

4. Diaphragm of pressure relief pilot (2) ruptured.

This will be evidenced by a discharge of

fluid from the vent hole in the pilot bonnet.

Replace diaphragm.

5. Stem of pressure relief pilot (2) binding. Disas-

semble pilot and determine cause.

6. Stem of main valve binding. Disassemble valve

and determine cause.

-3-

Page 4

Mark 5108 SerieS Back PreSSure regulating ValVe

B. Main Valve fails to Close:

1. Upstream pilot system ball valve (A) closed.

Open as required.

2. Strainer (5) clogged. Clean as required.

3. Closing speed control adjusted fully closed.

Open as required. See Adjustment instructions.

4. Pressure relief pilot (2) adjusted too far counter-

clockwise. See Adjustment instructions.

5. Close the downstream pilot system ball valve

(6B).

(a) If valve closes, proceed to Step 6.

(b) If valve remains open, proceed to Step

7.

6. Pressure relief pilot (2) stem binding or seat

badly deteriorated. Disassemble pilot

and determine cause.

7. Close both pilot system ball valves (6A and 6B)

and loosen a pipe plug in the main valve

bonnet. A continuous discharge of fluid

from the loosened plug indicates that the main

valve diaphragm is ruptured. Replace

diaphragm.

NOTE: Certain valves, predominantly those in fuel

service, are assembled "fail closed." In this case, a

ruptured diaphragm would keep the valve from opening,

rather than keep it from closing. To determine which type

you have, examine the "bridgemark" cast into the side

of the main valve body and compare it with the diagram

below.

(a) If the leak stops, the problem is in the

pressure relief pilot (2), likely a

damaged seat. Disassemble

pilot and determine cause.

(b) If the leak continues, the problem is

in the main valve, likely a damaged seat.

Disassemble valve and determine

cause.

8. Main valve stem binding or object caught in

valve. Disassemble valve and determine

cause.

C. Main Valve Opens and Closes, but Leaks

When Closed

1. Pressure relief pilot (2) adjusted slightly too low.

See Adjustment instructions.

2. Close downstream pilot system ball valve (6B).

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...