Jordan Valve Mark 508 User Manual

I & M Mark 508 (1½” & 2”)

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Pressure Regulators must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or a

general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling

a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with longterm, trouble-free service if it is correctly installed.

Spending a few minutes of your time reading these instructions now may save hours of trouble and downtime

later.

Installation & Maintenance Instructions for

Mark 508 Back Pressure Regulators

piping to provide drainage for inlet and outlet piping, and to obtain faster regulation.

6. The flow arrow on the regulator body must be

pointed in the direction of flow. The regulator may

be installed vertically or horizontally without affecting its operation.

7. For best control, 3’ 0” straight sections of pipe

should be installed on either side of the regulator.

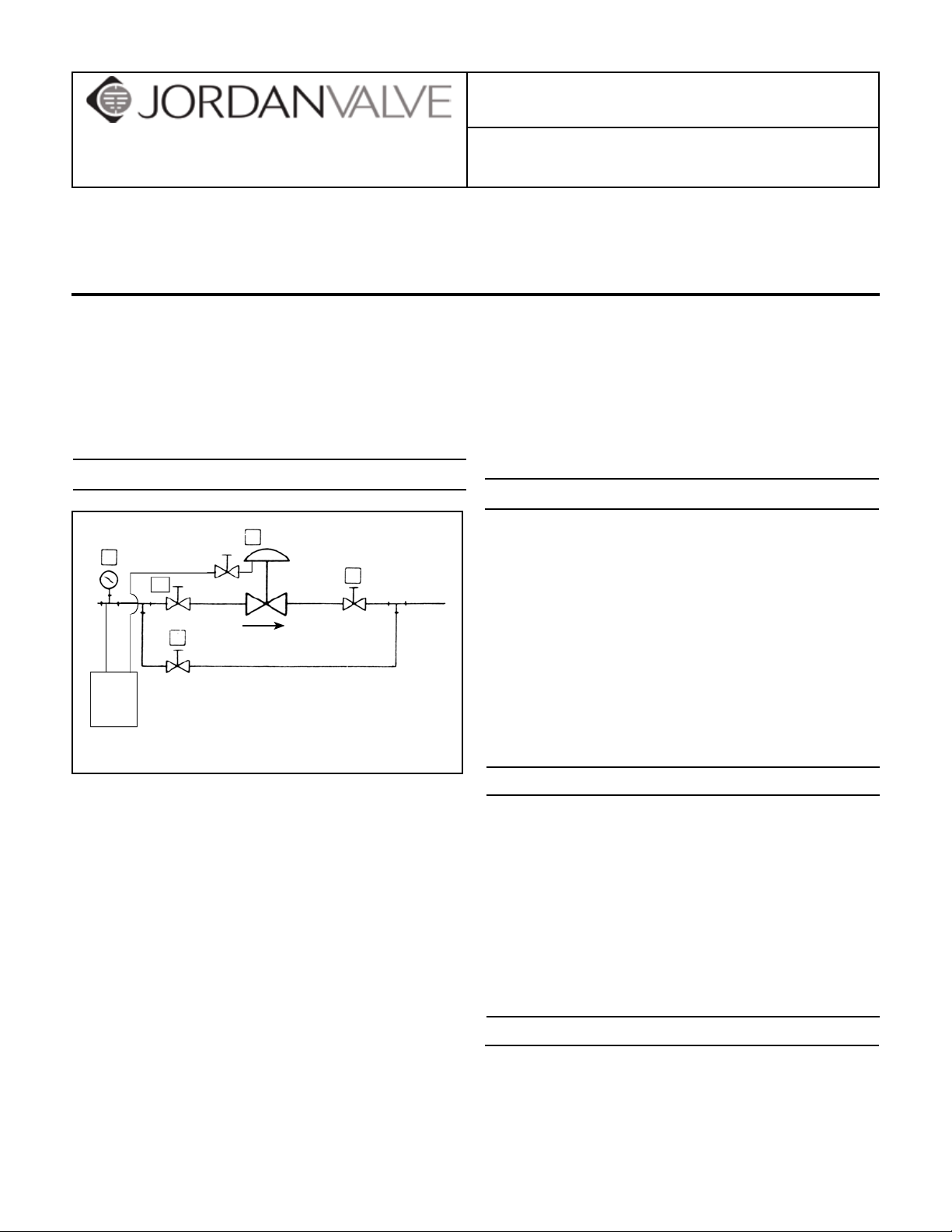

Installation

Start-Up Procedure

With the inlet and outlet shutoff valves closed:

1. Throttle the bypass valve so that the pressure to be

controlled is maintained near the seat point.

2. Slowly open the inlet shutoff valve.

3. Open the outlet shutoff valve.

4. Slowly close the bypass valve, but do not close it

fully until you are certain that the regulator has control of the system.

5. To change the controlled pressure, turn the adjusting screw clockwise to increase pressure, counterclockwise to decrease pressure.

4

Tank

or Gas

Source

5

2

1

1

By-pass

1. Shut-off valve - full port

2. Control line (when used)

4. Pressure gauge

5. MK508 back pressure regulator

1

1. To protect the regulator from grit, scale, thread

chips, and other foreign matter, all pipe lines and

piping components should be blown out and thoroughly cleaned before the regulator is installed.

2. Shut-off valves, pressure gauges, and by-pass

piping should be installed as indicated in the

diagram to provide easier adjustment, operation,

and testing.

3. In preparing threaded pipe connections, care

should be exercised to prevent pipe sealing compound from getting into the pipe lines. Pipe sealing

compound should be used sparingly, leaving the

two lead threads clean. Jordan uses, and recommends, thread sealer Teflon ribbon.

4. A 3/4” control line should be connected to this

actuator lower case if used for vapor recovery. Otherwise, leave plug in place.

5. Install the regulators in the highest horizontal line of

Maintenance

Caution: Make certain that there is no pressure in the

valve before loosening any fittings or joints. The following steps are recommended:

1. Close inlet shutoff valve.

2. Allow pressure to bleed of through downstream

piping. Do not cause a reverse flow through valve

by bleeding pressure from upstream side of valve.

3. When downstream pressure gauge indicates no

pressure in the line, close the outlet shutoff valve.

Replacing the Main Diaphragm

1. Remove the closing cap (1).

2. Thread the adjusting screw (2) out of the spring

tube.

3. If the set range is in psi, remove the spring guide.

4. Remove range spring (3).

5. Remove the actuator flange bolts (8) and nuts (9).

6. Remove the upper case (5).

7. Lift the diaphragm assembly as far up as possible

and place a wrench on the valve stem (23).

8. Remove the spring guide (4), diaphragm plate (6),

main diaphragm (7). Discard the main diaphragm.

9. Using new replacement parts, reverse the above

procedure to reassemble. Lubricate o-rings prior

to installation with a suitable lubricant such as Dow

Corning #4 grease.

Plug and Seat Replacement

1. Perform all steps in the section on replacing main

diaphragm.

2. Remove the seat washer (30) and the thread seal

washer (31).

3. Remove the ring nut (11), the lower case (10), and

the bonnet seal o-ring (12) and the stem bushing

(13). It is recommended that the stem bushing and

bonnet seal o-ring be replaced when performing

this maintenance.

4. Remove the bolts (26) and lockwashers (27) that

secure the bonnet (14) to the body (16).

5. Remove the bonnet (14), and the body/bonnet oring (24). It is recommended that the body/bonnet

seal o-ring be replaced when performing this maintenance.

6. Grasp the valve stem (23) and remove the stem/

plug assembly.

7. Use seat removal tool (Jordan Part Number 15533-

110) to remove the seat (22).

8. Remove the seat o-ring (21). Jordan recommends

that this o-ring be discarded and replaced with a

new one when this maintenance is performed.

9. Lubricate the new seat o-ring (21) prior to installation with a suitable lubricant such as Dow Corning

#4 grease. Install the o-ring (21) over the threads

and on the seat (22).

10. Carefully thread it into the body (16).

11. Use the seat removal tool to tighten the seat. Do

not over tighten! Compressing the seat o-ring into

the body bore is all that is required to produce a

seal.

12. Place the new stem/plug assembly into the seat

(22).

13. Lubricate the new body/bonnet o-ring (24) and

place it into the body (16).

14. Place the bonnet (14) over the stem and onto the

body (16). Bolt the bonnet in place using the four

cap screws (26) and lockwashers (27).

15. Install the new stem bushing (13). Lubricate and

install the bonnet seal o-ring (12) into the bonnet

(14).

16. Place the lower case (10) over the bonnet (14).

Install ring nut (11) on bonnet threads and tighten

securely.

17. Place the seal washer (30) and the thread seal

washer (31) on top of the valve stem (23).

18. Proceed to step 9 in the section on replacing main

diaphragm.

Troubleshooting

If you experience erratic control:

Oversizing causes cycling and hunting, and reduc-

es the rangeability of the valve. Make certain that

your sizing is correct.

Excessive foreign matter may be on seats; clean

seats.

Valve stem may not be moving freely; inspect and

clean.

Moving parts may be binding; inspect and realign

or replace if necessary.

If valve will not operate:

Diaphragm may be ruptured and require replace-

ment.

Adjusting spring may be broken and require re-

placement.

Spring may be set improperly and require resetting.

Ordering Spare Parts

Jordan Valves are ruggedly built, carefully assembled to

accurate dimensions, and individually tested for performance. A complete stock of finished parts is maintained

for immediate delivery. In order to supply you with the

precise parts designed for your specific valve, please

supply the following: valve serial number (found on

nameplate), body material, valve model number, end

connections (if flanged, supply flange rating), body size,

spring range or set point.

-2-

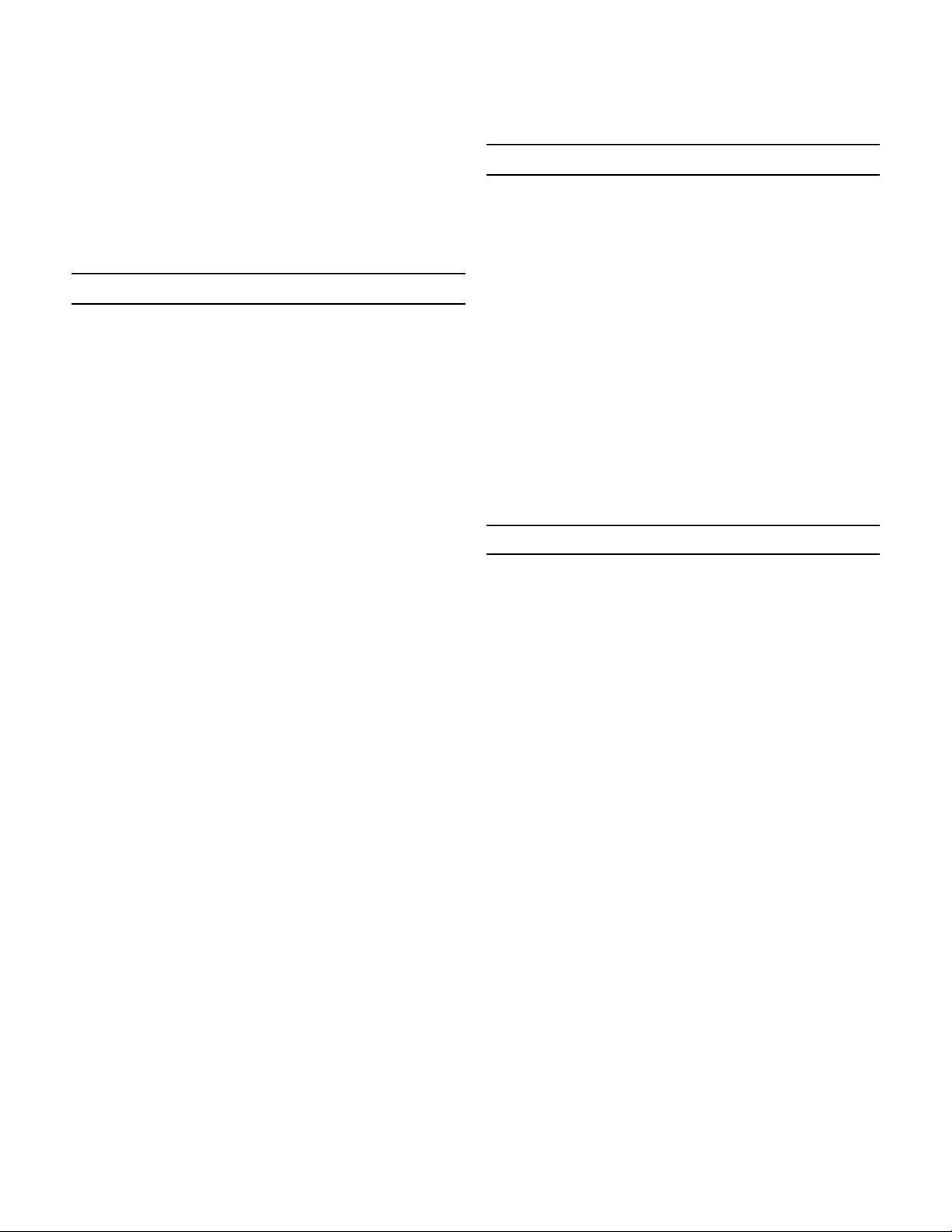

Illustration and Parts List

1

32

17

29

27 26

23

24

22

21

19

20

2

3

4

5

3130

12

11

13

14

18

31

17

6

7

16

8

9

10

Item Description Qty. Item Description Qty.

1 Closing Cap 1 16 Body 1

2 Adjusting Screw 1 17 HHCS 2

3 Range Spring 1 †18 Seat Plate 1

4 Spring Guide 1 † 19 Soft Seat 1

5 Actuator Case (Upper) 1 †20 Plug Face 1

6 Main Diaphragm Plate 1 *21 O-Ring 1

7 Main Diaphragm 1 *22 Seat 1

8 Hex Bolt 22 †23 Stem 1

9 Hex Nut 22 *24 Bonnet Plate O-Ring 1

10 Actuator Case (Lower) 1 26 HHCS 4

11 Ring Nut 1 27 Lockwasher (not shown) 3

*12 O-Ring 1 30 Seal Washer, Large 1

*13 Stem Bushing 1 31 Seal Washer (not shown) 3

14 Bonnet 1 32 Adjusting Bolt 1

* Recommended Spare Parts † Furnished as an assembly in Repair Kits

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

Bulletin IM-MK508lg-0115

info@richardsind.com • www.jordanvalve.com

API -2000

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

The tank blanketing valve is not a substitute for the

vacuum relief device.

API Standard 2000 states, “The design of a gas

repressuring system to eliminate the requirement for

vacuum relief valves is beyond the scope of this standard and should be considered only when the induction

of air represents a hazard equal to or greater than failure

of the tank”.

The tank blanketing valve failure must be

taken into account when considering possible

causes of overpressure in a tank.

CAPACITY REQUIREMENTS

The capacity requirement of the tank blanketing valve

is composed of two components. The first being inbreathing due to liquid or product movement out of the tank, and

the second being inbreathing due to contraction of the

vapors/product because of weather changes.

Standard Information

Tank Blanketing Regulator Selection

API Standard 2000 states, “When the possible

causes of overpressure or vacuum in a tank are being

determined, other circumstances resulting from equipment failures and operating errors must be considered

and evaluated by the designer.” Failure of the tank blanketing valve can result in unrestricted gas flow into the

tank, reduced gas flow or complete loss of the gas flow.

Tank blanketing valve set point denition is

determined by manufacturers. Jordan Valve defines

set point as the point where the tank blanketing valve is

just beginning to open, and the valve requires a pressure above the set point in order to close completely.

Others define set point somewhere in between opening

and closing but still the pressure must go above the

defined set point in order to close completely.

The second component, inbreathing due to

weather changes, is selected from Table 1 (Table 2

for metric). The tank capacity is found in column 1

and the corresponding inbreathing requirement is

selected from column 2.

Inbreathing due to maximum liquid or product

movement out of the tank equals 8.0 SCFH of air for each

US gallon per minute of maximum emptying rate or 0.94

Nm3/h of air for each m3/h of maximum emptying rate.

Q displacement (SCFH)=Max. Pumpout Rate (gpm)x8.0

or

Q displacement (Nm3/h)=Max. Pumpout Rate (m3/h)x.94

The two components are added together to

give the total inbreathing requirement and the capacity requirement of the tank blanketing valve.

Q total = Q displacement = Q thermal

VALVE SELECTION

If the tank blanketing supply pressure varies, use the minimum supply pressure in selecting the tank blanketing

valve and the maximum supply pressure to determine blanketing valve failure capacity. Using the minimum supply

pressure, consult the flow chart to determine if the valve will meet the Total Inbreathing Requirement (Q total). Next

determine if a specific range selection can be used to make the capacity of the tank blanketing valve more closely

match the inbreathing requirement. This will also reduce the fail open flow of the blanketing valve.

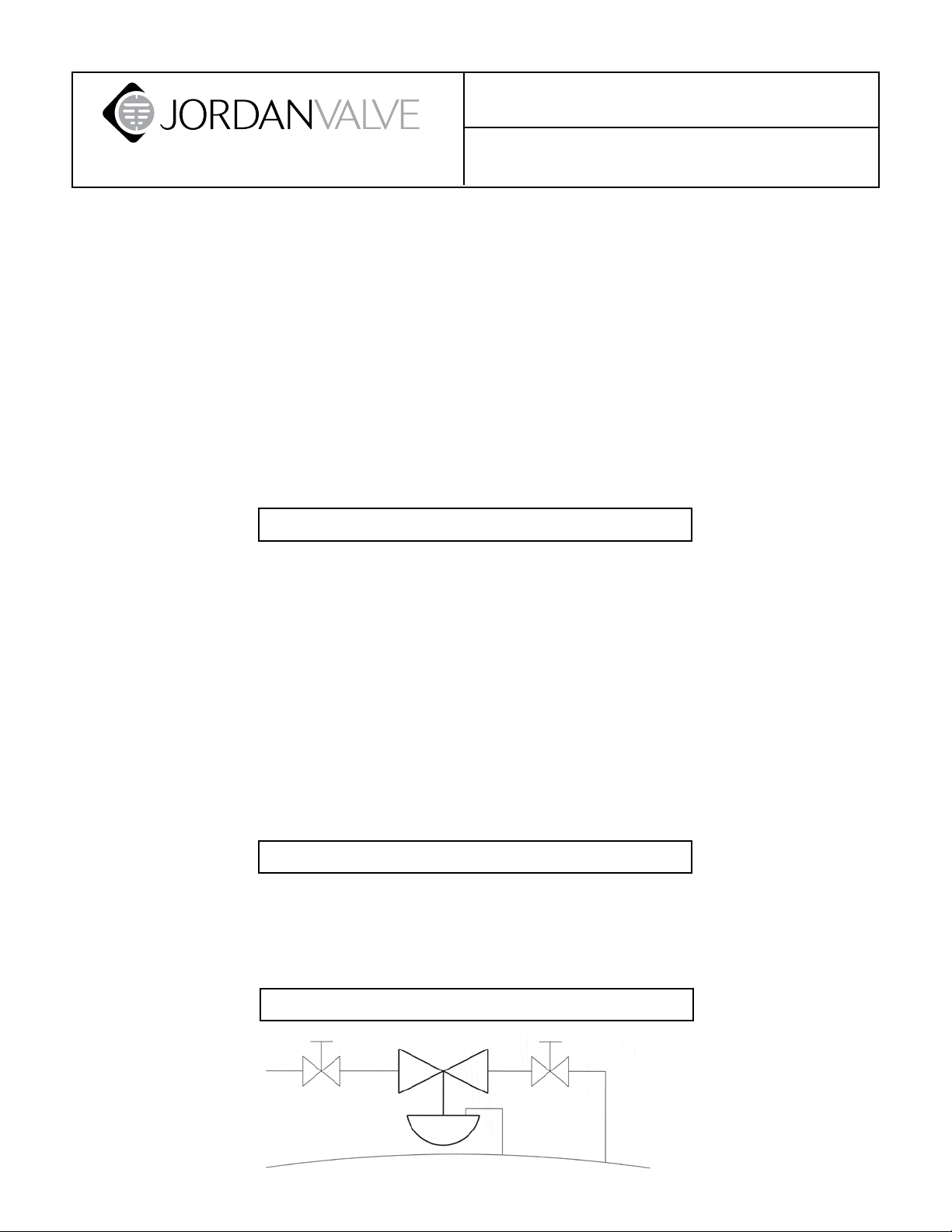

NORMAL INSTALLATION

Tank Blanketing Valve

Supply Gas

Isolation Valve

(Full Bore)

Top of Tank

Tank Isolation Valve

(Full Bore)

Sensing Line

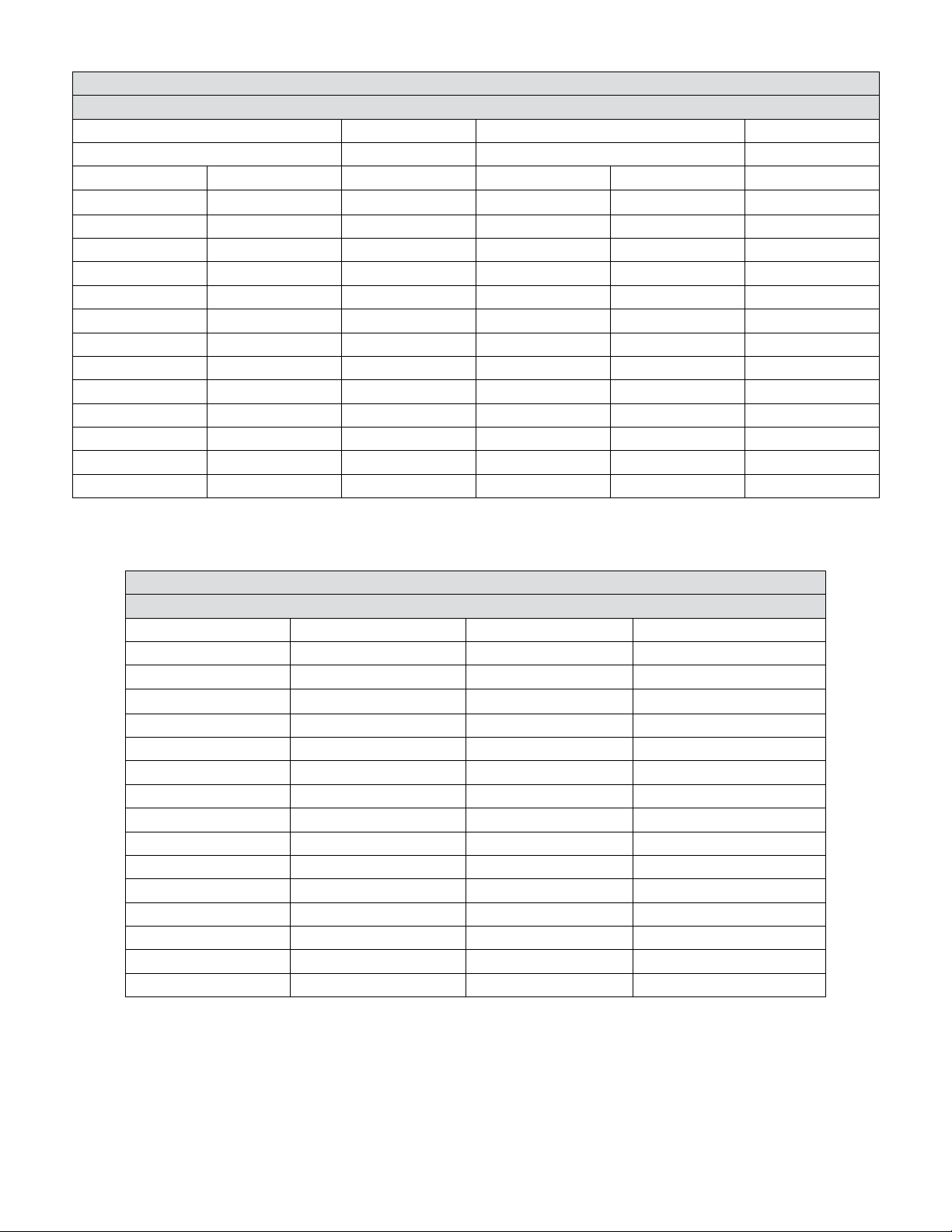

TABLE 1

REQUIREMENTS FOR THERMAL INBREATHING - ENGLISH UNITS (AIR)

(Column 1) (Column 2) (Column 1) (Column 2)

TANK CAPACITY INBREATHING TANK CAPACITY INBREATHING

Barrels Gallons SCFH Barrels Gallons SCFH

60 2,500 60 35,000 1,470,000 31,000

100 4,200 100 40,000 1,680,000 34,000

500 21,000 500 45,000 1,890,000 37,000

1000 42,000 1000 50,000 2,100,000 40,000

2,000 84,000 2,000 60,000 2,520,000 44,000

3,000 126,000 3,000 70,000 2,940,000 48,000

4,000 168,000 4,000 80,000 3,360,000 52,000

5,000 210,000 5,000 90,000 3,780,000 56,000

10,000 420,000 10,000 100,000 4,200,000 60,000

15,000 630,000 15,000 120,000 5,040,000 68,000

20,000 840,000 20,000 140,000 5,880,000 75,000

25,000 1,050,000 24,000 160,000 6,720,000 82,000

30,000 1,260,000 28,000 180,000 7,560,000 90,000

NOTE: Table and sizing from API 2000 fifth edition, April 1998

TABLE 2

REQUIREMENTS FOR THERMAL INBREATHING - METRIC UNITS (AIR)

(Column 1) (Column 2) (Column 1) (Column 2)

TANK CAPACITY INBREATHING TANK CAPACITY INBREATHING

CUBIC METERS Nm3/H CUBIC METERS Mn3/H

10 1.69 5000 787

20 3.37 6000 896

100 16.9 7000 1003

200 33.7 8000 1077

300 50.6 9000 1136

500 84.3 10000 1210

700 118 12000 1345

1000 169 14000 1480

1500 253 16000 1615

2000 337 18000 1745

3000 506 20000 1877

3180 536 25000 2179

4000 647 30000 2495

NOTE: Table and sizing from API 2000 fifth edition, April 1998

-2-

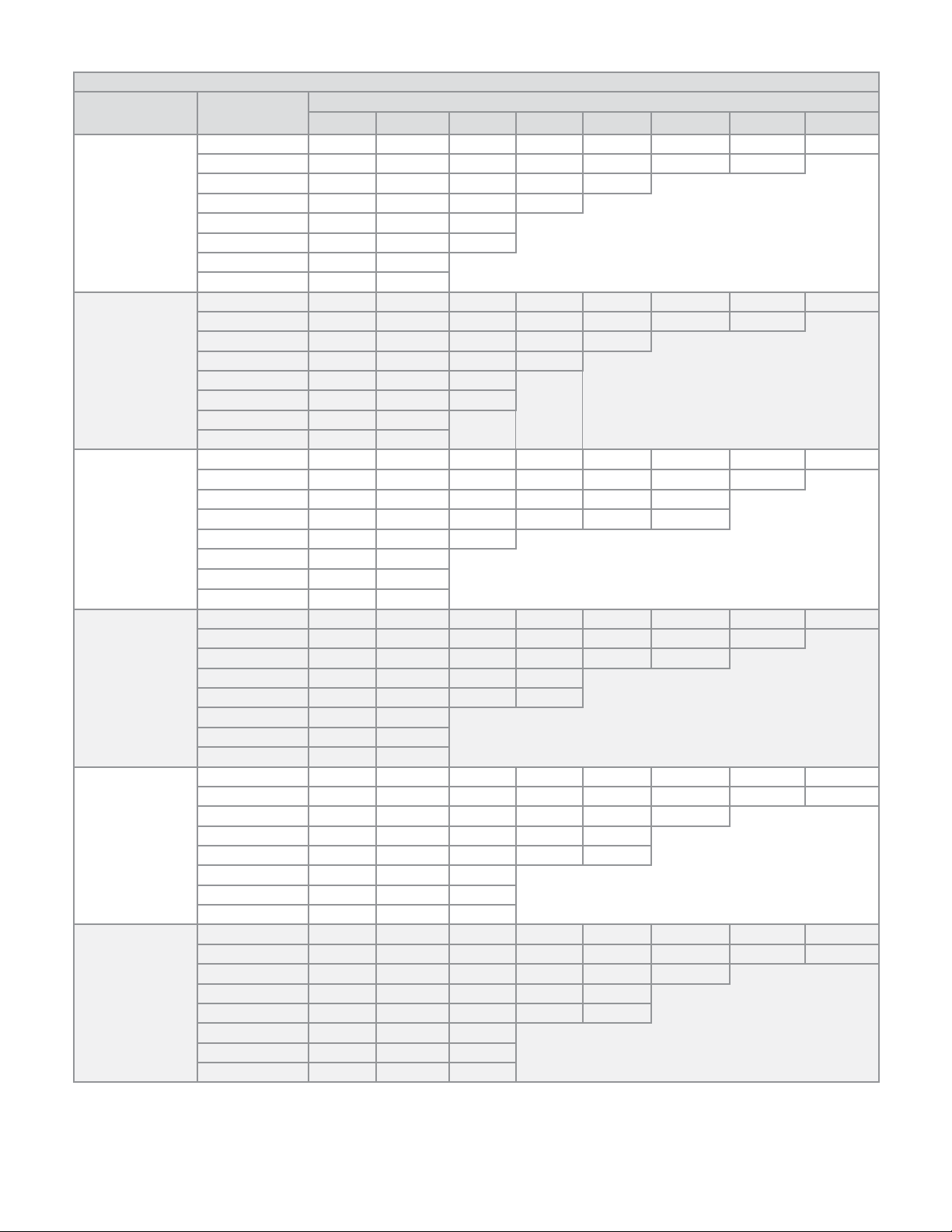

TABLE 6 TANK BLANKETING VALVE CAPACITIES 3/4” MARK 608IS

Set Pressure Inlet (psi)

5 201 374 430 261 477 888 1043 1169

10 213 402 456 580 506 784 943

2" H20

(1-2.5" H20)

1" H20 Droop

2" H20 Boost

20 222 392 475 619 361

40 299 465 639 764

60 665 897 1161

80 816 873 1139

100 598 640

150 770 825

5 239 373 503 560 613 886 1163 1195

10 231 402 566 580 591 783 977

3" H20

(2-5" H20)

1" H20 Droop

2" H20 Boost

20 211 392 570 619 295

40 277 465 649 764

60 597 897 1194

80 753 873 976

100 675 776

150 880 825

5 220 295 372 409 441 619 799 661

10 277 427 578 527 476 732 982

7" H20

(4-10" H20)

1" H20 Droop

2" H20 Boost

20 258 462 661 893 1118 1154

35 276 592 897 967 1035 1294

75 525 980 1426

90 727 1364

100 813 1503

150 1040 1926

5 302 454 604 722 839 941 1040 1074

10 337 533 723 981 1239 1378 1514

28" H20

(5-30" H20)

5-1/2" H20

Droop

30 283 816 1335 1666 1982 2154

45 617 1373 2058 2487

60 817 1866 2906 2899

75 820 1812

100 840 1867

150 1089 2421

5 180 272 439 395 526 465 658 921

10 235 333 522 535 783 665 913 848

1.25 psi

(0.5 - 1.75 psi)

0.2 psi Droop

30 279 469 824 785 1014 1141

45 354 561 886 856 1033

60 418 669 1003 937 1087

75 427 762 1152

100 543 949 1402

150 715 1266 1816

5 145 217 289 315 338 371 402 675

10 209 312 418 502 592 625 661 731

3 psi

(1 - 3.5 psi)

0.3 psi Droop

30 226 468 701 783 859 1136

45 354 561 812 856 856

60 415 669 922 937 945

75 427 762 1059

100 503 949 1408

150 660 1266 1816

Orice Size

1/8" 3/16" 1/4" 5/16" 3/8" 7/16" 1/2" 9/16"

-3-

Loading...

Loading...