Page 1

I & M Mark 501 / 502

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Installation & Maintenance Instructions for

Mark 501/502 High Flow Back Pressure Regulators

Warning: Jordan Valve Back Pressure Regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualied service person; continued operation may cause system failure or a

general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disassembling a

valve, be sure to release all spring tension.

Please read these instructions carefully!

Valve.

Install the regulator in the highest horizontal line of 5.

Your Jordan Valve product will provide you with long, trouble- free service if it is correctly installed and maintained.

Spending a few minutes now reading these instructions

can save hours of trouble and downtime later. When making repairs, use only genuine Jordan Valve parts, available

for immediate shipment from the factory.

piping to provide drainage for inlet and outlet pip-

ing, to prevent water hammer, and to obtain faster

regulation.

The ow arrow on the regulator body must be point-6.

ed in the direction of ow. The regulator may be in-

stalled vertically or horizontally without affecting its

operation.

Installation

For best control, 3’ 0” straight sections of pipe should 7.

be installed on either side of the regulator.

In hot vapor lines, upstream piping near the regula-8.

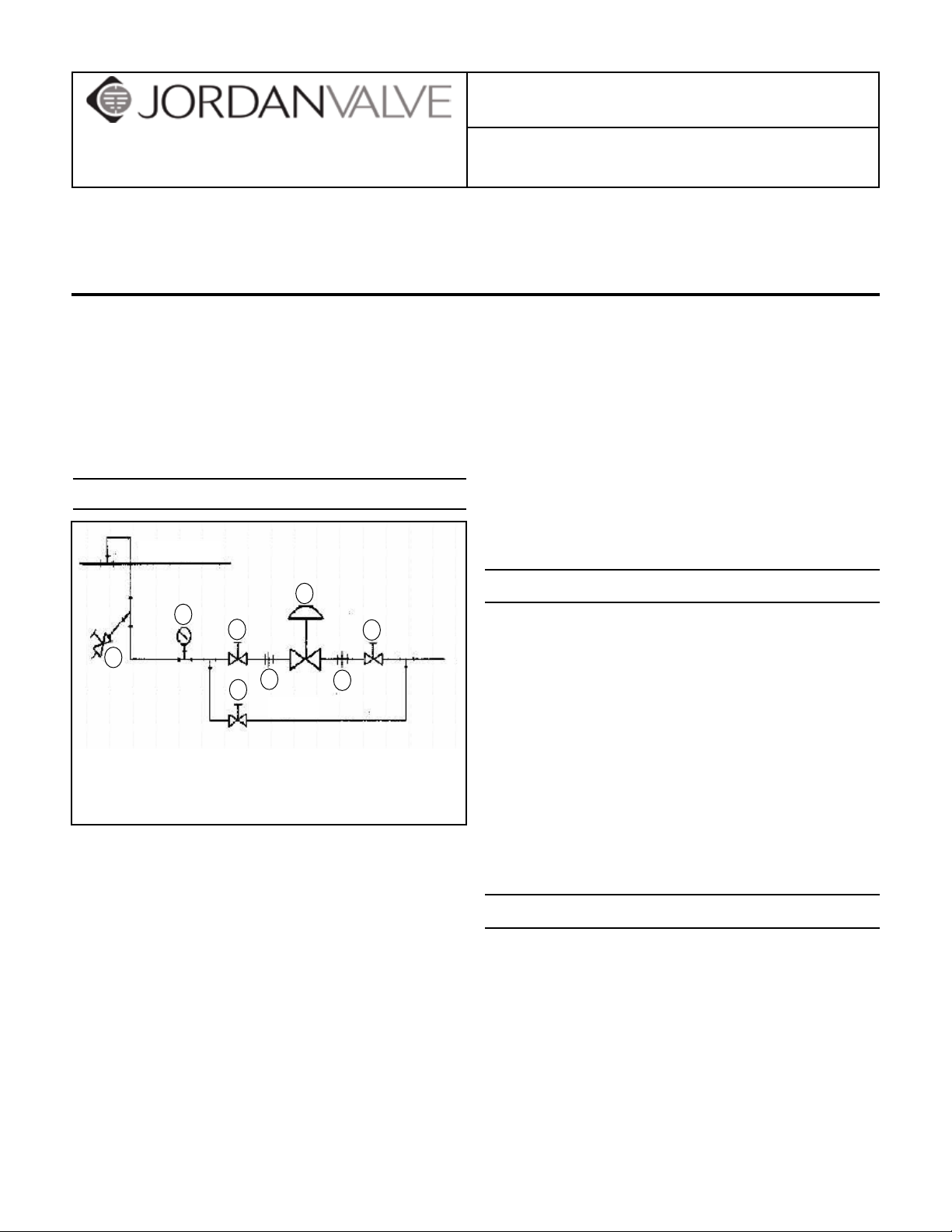

Main Line

4

5

1

1

tor should be insulated to minimize condensation.

Start-Up Procedure

With the inlet and outlet shutoff valves closed:

3

2

1

Bypass

1. Shutoff Valve

2. Pipe Union

3. Strainer & Drain Valve

4. Pressure Gauge

5. Back Pressure Regulator

2

To protect the regulator from grit, scale, thread chips, 1.

and other foreign matter, all pipe lines and piping

components should be blown out and thoroughly

cleaned before the regulator is installed.

Shutoff valves, pressure gauges, and bypass piping 2.

should be installed as indicated in the diagram to

provide easier adjustment, operation, and testing.

In preparing threaded pipe connections, care should 3.

be exercised to prevent pipe sealing compound

from getting into the pipe lines. Pipe sealing compound should be used sparingly, leaving the two

end threads clean. Jordan uses, and recommends,

thread sealer Teon ribbon.

A line strainer should be installed on the inlet side of 4.

the regulator to protect it from grit, scale and other

foreign matter. A 0.033 perforated screen is usually

suitable. Line strainers are available from Jordan

Throttle the bypass valve so that the pressure to be 1.

controlled is maintained near the set point.

Slowly open the inlet shutoff valve.2.

Open the outlet shutoff valve.3.

Slowly close the bypass valve, but do not close it 4.

fully until you are certain that the regulator has con-

trol of the system.

To change the controlled pressure, turn the adjust-5.

ing screw clockwise to increase pressure, counter-

clockwise to decrease pressure.

Body & end cap should be retightened per torque 6.

procedures after valve reaches operating temp.

Maintenance

Caution: Make certain that there is no pressure in the

valve before loosening any ttings or joints. The following steps are recommended:

Close inlet shutoff valve.1.

Allow pressure to bleed off through downstream 2.

piping. Do not cause a reverse ow through valve

by bleeding pressure from upstream side of valve.

When downstream pressure gauge indicates no 3.

pressure in the line, close the outlet shutoff valve.

Page 2

Valve Seats

A. DISASSEMBLY

The seats of Jordan regulators are precisionlapped. Maintaining such tolerances is of paramount importance for your assurance of excellent control and tight shutoff. Do not use metallic

objects in removing the seats. Care in handling

is imperative.

Close shutoff valve on each side of the regulator.1.

Remove the regulator from line.2.

Secure the inlet body hex in the vise. Remove the 3.

cap bolts and lift cap straight up.

Remove the disc and plate assembly by lifting the 4.

assembly straight up from the valve body. Place the

assembly on the bench with the disc up. Remove

the pressure ring.

SPECIAL NOTE: It is imperative that the disc pin

is not rotated in disassembly, cleaning, or reassembly, since this affects the stroke adjustment

of the valve.

Clean the plate seat with ne emery cloth. Clean the 5.

body and cap cores with good quality solvent.

To clean the disc and plate, remove the guide screws. 6.

Place 4/0 polishing cloth or jeweler’s cloth on a

smooth, at surface, and polish the lapped surfaces

of the disc and plate. If these parts are scarred, do

not attempt to re-lap them, but return them to the

factory for repair or replacement. The pressure ring

may be polished in the same manner.

Once the orices in the plate and disc are prop-5.

erly aligned, place a straight edge across the body

bolt holes on the horizontal center line of the valve

(perpendicular to the valve movement.) Gently rotate the disc and plate assembly until the edges of

the orice slots are parallel to the straight edge and

replace the cap, being careful not to rotate the disc

and plate assembly.

Replace the cap and cap bolts, and tighten uniform-6.

ly, being careful not to torque excessively. See back

page for recommended torque values.

Diaphragm Replacement

A. DISASSEMBLY

In removing the diaphragm, you must rst remove 1.

the valve disc and valve plate. This is outlined under

VALVE SEATS.

Remove the compression of the adjusting spring by 2.

rotating the adjusting screw counterclockwise.

Remove the spring housing bolts and spring hous-3.

ing. Remove adjusting spring and spring seat.

Hold the disc pin with an open end wrench and 4.

remove the diaphragm assembly by rotating counterclockwise. The diaphragm assembly consists of

the upper diaphragm plate, diaphragm, and lower

diaphragm plate.

If the diaphragm must be replaced, secure the upper 5.

diaphragm plate in the vise. A face spanner wrench

should be used to remove the lower diaphragm

plate from the assembly. If a face spanner wrench

is not available, use a punch and hammer, but make

certain to remove all burrs prior to reassembling.

B. REASSEMBLY

Place disc on the plate and replace the guide 1.

screws. Tighten the guide screws but do not allow

the screws to bind the disc against the plate.

Replace the pressure ring and the disc/plate assem-2.

bly. Make sure that the disc pin engages the disc

and that the plate seats solidly against the plate seat

in the body.

Check the orice alignment of the disc and plate 3.

by releasing the compression of the range spring

and then stroking the valve fully upwards. (To stroke

valve upwards, pry the disc pin upwards with a

screwdriver through the inlet of the valve -- see gure on next page.) In this position, the orices of

the disc and plate must be fully open and in perfect

alignment. If the orices are not aligned, the disc

pin has probably been rotated. Remove the disc and

plate assembly and rotate the disc pin to raise it or

lower it for proper alignment.

If further adjustment of the disc pin does not pro-4.

vide perfect alignment, proceed to VALVE STROKE

ADJUSTMENT.

B. ASSEMBLY AND STROKE ADJUSTMENT

The valve stroke adjustment is determined by how 1.

far the diaphragm assembly is screwed onto the

stem. Hold the disc pin with an open end wrench

and screw the diaphragm assembly onto the valve

stem all the way, and back off two turns initially.

To check the stroke adjustment, put the pressure 2.

ring, valve disc, and valve plate in position in the

valve body, using the same precautions outlined under VALVE SEATS.

Secure the spring housing to the valve body with 3.

two spring housing bolts and tighten.

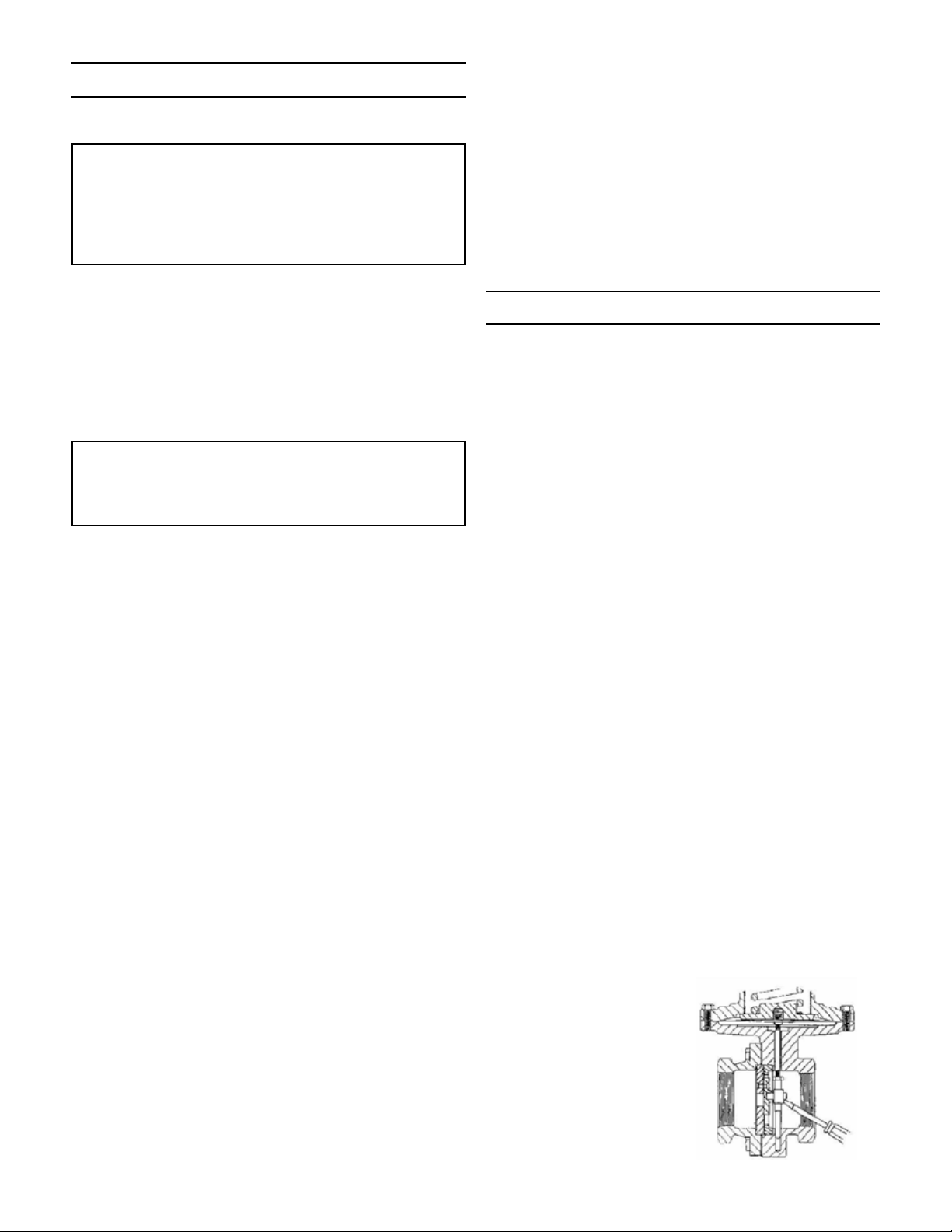

Using a small screw-4.

driver through the

upstream opening of

the valve body, stroke

the valve against the

upper travel stop of

the spring housing.

The orices should

be aligned in the full

open position.

-2-

Page 3

If the orices are not aligned in the open position, 5.

remove the spring housing and rotate the diaphragm

assembly counterclockwise to lower the disc, and

clockwise to raise the disc.

A further check on the stroke adjustment can be 6.

made by checking the orices in the closed position.

This is a “normally closed” valve, and there should

be a 1/32” overlap when the diaphragm assembly is

down against the valve body.

Remove the valve plate and the valve disc to elimi-7.

nate the possibility of damage during the topworks

reassembly.

Reassemble the adjusting spring and spring seat.8.

Before replacing the spring housing, make certain 9.

that the diaphragm is centered in the body recess.

This recess aligns the spring housing and diaphragm.

In replacing the spring housing, make certain that it 10.

seats properly in the valve body recess.

Replace the spring housing bolts and tighten only n-11.

ger tight. Thread the adjusting screw into the spring

housing until the seats are in their fully closed position. Tighten the spring housing bolts to the torque

values shown on the last page of this document.

Replace the pressure ring, disc, plate, and cap. 12.

See last page of this document for recommended

torque.

Disc Pin and Stem

Valve disc may not be moving freely; inspect and

clean.

Moving parts may be binding; inspect and realign or

replace if necessary.

If Valve Will Not Operate:

Diaphragm may be ruptured and require replace-

ment.

Adjusting spring may be broken and require re-

placement.

Spring may be set improperly and require resetting.

Torque Values

Torque for Valve Cap to Valve Body Bolts

Cast Iron or Bronze 140 in/lbs

Ductile Iron, Carbon Steel or

Stainless Steel

Torque for Spring Housing Bolts

170 in/lbs

5

3

2

4

1

6

7

2

6

200 in/lbs

3

5

1

8

4

Remove the valve disc and valve plate as explained 1.

under VALVE SEATS.

Remove the diaphragm and topworks as described 2.

under DIAPHRAGM REPLACEMENT.

Hold the disc pin with an open end wrench and loos-3.

en the locknut. Now the stem may be unscrewed

from the disc pin and removed.

To reassemble, rst insert the disc pin into the valve 4.

body; followed by the stem and locknut. Screw the

stem into the disc pin about 1/4” or midway on the

stem threads and lock the locknut against the disc

pin.

To reassemble the diaphragm and topworks and 5.

valve seats, refer to the reassembly instructions

under VALVE SEATS and DIAPHRAGM REPLACEMENT.

Troubleshooting

If You Experience Erratic Control:

Oversizing causes cycling and hunting, and reduces

the rangeability of the valve. Make certain that your

sizing is correct.

Excessive foreign matter may be on seats; clean

seats.

Valve stroke may be out of adjustment; readjust and

tighten locknuts securely.

6 bolts

(or multiples)

8 bolts

(or multiples)

Ordering Spare Parts

Use only genuine Jordan Valve parts to keep your valve

in good working order. So we can supply the parts, which

were designed for your valve, we must know exactly which

product you are using. The only guarantee to getting the

correct replacement parts is to provide your Jordan Representative with the valve serial number. This number is

located on the valve identication tag. If the serial number

is not available, the parts needed for your valve might be

determined using the following information: Model number, Valve Body size, Plug Material and Seat Size, Spring

Range or Set Point, Trim Material, Part Name - Number

and Quantity (see parts list chart).

Note: Without a valve serial number, any parts ordered

incorrectly are subject to a minimum 25% restock charge

when returned.

-3-

Page 4

Illustration and Parts List

15

11

10

19

20

Item Description Qty.

21

17

1 Body 1

2 Cap 1

3 Cap Bolt 8

4* Disc Pin 1

14

16

5* Stem 1

6* Locknut 1

7* Plate 1

8* Disc 1

1213

9* Pressure Ring 1

10* Guide Screws 2

11 Lower Diaphragm Plate 1

12* Diaphragm 1

13 Upper Diaphragm Plate 1

14 Spring Housing 1

3

5

15 Spring Housing Bolt 12

16 Range Spring A.R.

1

9

17 Spring Seat 1

19 Adjusting Screw 1

20 Jam Nut 1

6

8

4

21 Name Plate 1

* Recommended Spare Parts

7

2

Bulletin IM-MK501/502-0510

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...