Page 1

I & M Mark 44

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Regulators and Control Valves must only be used, installed and repaired in accordance with

these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the

event of leakage or other malfunction, call a qualied service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disassembling

a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with long, trouble-free service if it is correctly installed and maintained.

Spending a few minutes now reading these instructions

can save hours of trouble and downtime later. When making repairs, use only genuine Jordan Valve parts, available

for immediate shipment from the factory.

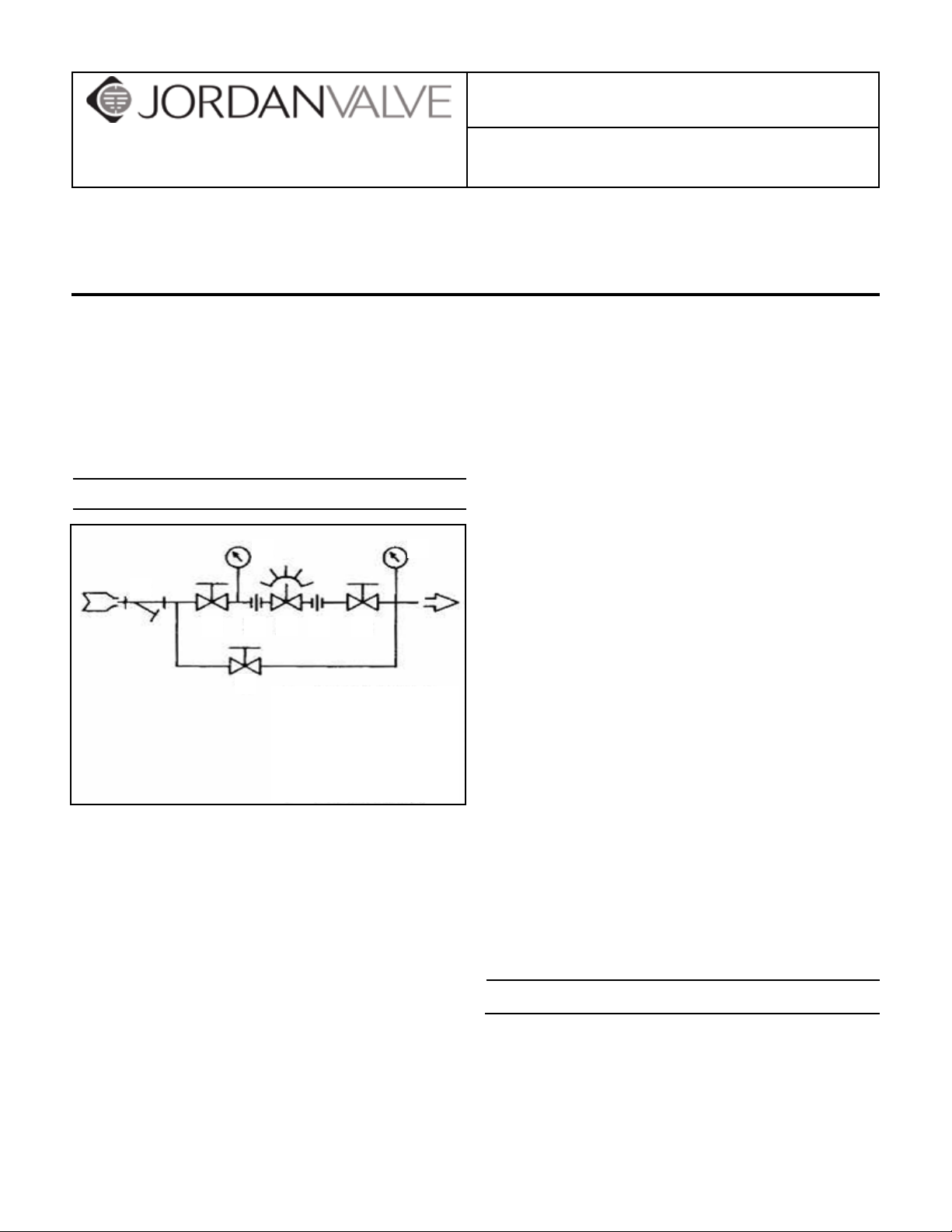

Installation

4

3

5

21

1

1. Shut-Off Valve

2. Pipe Union

3. Strainer

4. Pressure Gauge

5. Jordan MK44

To protect the valve from grit, scale, thread chips 1.

and other foreign matter, all pipe lines and piping

should be blown out and thoroughly cleaned before

the valve is installed.

Shut-off valves, pressure gauges and bypass piping 2.

should be installed as indicated in the diagram to

provide easier adjustment, operation, and testing.

In preparing threaded pipe connections, care 3.

should be exercised to prevent pipe sealing compound from getting into the pipe lines. Pipe sealing

compound should be used sparingly leaving the two

end threads clean. Jordan uses, and recommends,

Teon tape.

A line strainer should be installed on the inlet side of 4.

the regulator to protect it from grit, scale and other

foreign matter. A 0.033 perforated screen is usually

suitable. Line strainers are available for immediate

shipment from Jordan Valve.

12

4

Installation & Maintenance Instructions for

Mark 44 Adjustable Cam Valve

The ow arrow on the valve body must be pointed in 5.

the direction of the ow. The valve may be installed

in any position. The motor arm may be located on

either side of the body. Refer to the “Maintenance”

portion for correct bolt torques.

The motor arm position may be adjusted in 30° in-6.

crements relative to the rocker. Adjust to suit by removing the slotted nut (30) and washer (25). Then

separate the motor arm from the pins in the rocker

(23) and reposition it on the pins to suit. Replace the

parts in reverse order and tighten the nut as tight as

possible, without binding it to the shaft.

Operate the valve within its rated pressure and tem-7.

perature limits, which are on the valve nameplate,

along with materials of construction.

The rotation of the valve may be clockwise or coun-8.

terclockwise to open. This is controlled by the adjustment of the nineteen (19) set screws (24) on the

top of the rocker. The screws must be adjusted in

progressive steps to cause the rotation of the rocker

to stroke the valve. If too large a difference in adjustment between successive screws is attempted

the valve may be difcult or impossible to stroke. It

is not necessary to utilize the full valve stroke. The

adjustability feature allows customizing of the valve

operating characteristic to suit your needs.

The motor arm must be connected to the mecha-9.

nism that will drive the valve. The motor arm travel is

limited to 72° by two set screws (32) threaded into

the angle bracket (7). Be sure that your mechanism

is adjusted so that it does not try to drive the valve

past the stops and cause damage.

The Jordan MK44 valve is not a tight shut-off device. 10.

Other valve means must be provided to insure ow

shutoff.

Trouble Shooting

If the operate lever is difcult to operate:

Slotted nut (30) adjusted too tight. Readjust.

Set screws (24) are improperly adjusted. Adjust for

smooth operation. Do not attempt to make large

changes between adjacent screws.

Defective bearing (13). Replace.

Stem (4) binding in bonnet or seat. Inspect, repair,

Page 2

or replace.

Stem O-Ring Replacement

If there is external leakage:

Stem or bonnet o-ring (9) or (5) defective. Replace.

Maintenance

Routine maintenance should be expected due to normal wear and tear, damage from external sources or debris. The regulator components, especially the moving

and sealing parts, should be inspected periodically and

replaced as necessary. Frequency of inspection/replacement depends upon severity of conditions, but may also

be required by local/state/federal law or industry standards.

Warning: Be sure that there is no pressure in the

valve before loosening any ttings or joints. The

following steps are recommended.

Close inlet shut-off valve and by-pass valve.1.

Allow pressure to bleed off through the downstream 2.

piping.

When pressure gauge indicates that there is no pres-3.

sure in the valve, it may be serviced or removed.

Refer to the drawing for proper orientation of parts and

nomenclature.

Body/Bonnet O-Ring

Remove all pressure from the line as outlined in 1.

“Warning” above.

Remove the low ow end stop set screw (32) and 2.

rotate the rocker (23) to disengage the stroke stop

bearing (13).

Remove the four (4) cap screws (8) and lift the bon-3.

net (6) off of the body (1).

Remove the o-ring and clean the mating surfaces on 4.

the body and bonnet. Inspect these surfaces for any

scratches or defects that could cause seal leakage.

Lubricate the new o-ring with DOW CORNING #4 or 5.

any other lubricant that is suitable for use with the

o-ring material and your product at your operating

temperature.

It is strongly recommended that the stem o-ring (9) 6.

also be replaced if the valve has been disassembled.

If you are going to replace it, proceed to section B,

step 4, otherwise go on to step 7 below.

Remove the seat from the body and place it over the 7.

end of the stem. Hold the bonnet upright and take

the body and place it over the bonnet and install the

bonnet into the body. Continue the reassembly of

the valve in the reverse order that you disassembled

it and then torque the cap screws according to the

“Torque Procedure” at the end of this manual.

Remove all pressure from the line as outlined in 1.

“Warning” under the Maintenance Section.

Remove the low ow end stop set screw (32) and 2.

rotate the rocker (23) to disengage the stroke stop

bearing (13).

Remove the four (4) cap screws (8) and lift the bon-3.

net (6) off of the body (1).

Using a blunt pin punch, drive out the roll pin (15) 4.

and thread the stroke stop (12) off of the stem (4).

Push the threaded end of the stem into the bonnet 5.

and remove the stem from the cage end of the bonnet. (The cage end is the portion of the bonnet that

is normally in the body).

Remove the o-ring, and clean the stem and the bore 6.

in the bonnet where the o-ring operates. Inspect

the bore for any scratches that might damage the

o-ring.

Lubricate the new o-ring with DOW CORNING #4 or 7.

any other lubricant that is suitable for use with the

o-ring material and your product at your operating

temperature.

Install the o-ring onto the stem from the threaded 8.

end so that the stem ow prole does not cut the

o-ring.

Carefully reinstall the stem back into the bonnet 9.

from the cage end.

Remove the seat from the body and place it over the 10.

end of the stem. Hold the bonnet upright and take

the body and place it over the bonnet and install the

bonnet into the body. Continue the reassembly of

the valve in the reverse order that you disassembled

it and then torque the cap screws according to the

Torque Procedure Section.

Seat or Seal Replacement

If the seat or stem is to be replaced it is strongly rec-1.

ommended that the body/bonnet o-ring and stem

o-ring be replaced also. Therefore follow step A to

replace both o-rings.

While the stem is out of the bonnet, remove the re-2.

taining ring and install it onto the new stem. Otherwise follow the steps in A.

Bearing (Stroke Stop) Replacement

Remove all pressure from the line as outlined in 1.

“Warning” under the Maintenance Section.

Remove the low ow end stop set screw (32) and 2.

rotate the rocker (23) to disengage the stroke stop

bearing (13).

Using a blunt pin punch, drive the roll pin (15) out of 3.

the bearing (13).

Replace the bearing and reassemble in reverse or-4.

der.

-2-

Page 3

Rocker Plates, Etc.

Ordering Spare Parts

Remove all pressure from the line as outlined in 1.

“Warning” under the Maintenance Section.

Remove the low ow end stop set screw (32) and 2.

rotate the rocker (23) to disengage the stroke stop

bearing (13).

Remove the cotter pin (31), slotted nut (30), and 3.

washer (25). Remove the rocker from the support

stud (26).

The sub-assembly containing the rocker plates, and 4.

support straps (16) & (20) can now be removed from

the rocker and the necessary parts replaced.

Reassemble in reverse order.5.

Bearing (Rocker) Replacement

Remove all pressure from the line as outlined in 1.

“Warning” under the Maintenance Section.

Remove the low ow end stop set screw (32) and 2.

rotate the rocker (23) to disengage the stroke stop

bearing (13).

Remove the cotter pin (31), slotted nut (30), and 3.

washer (25) and remove the rocker from the support stud (26).

Press the bearing out of the rocker. A .75” diameter 4.

shaft will be helpful.

Press the new bearing into the rocker and then reas-5.

semble in reverse order.

Use only genuine Jordan Valve parts to keep your valve

in good working order. So we can supply the parts, which

were designed for your valve, we must know exactly which

product you are using. The only guarantee to getting the

correct replacement parts is to provide your Jordan Representative with the valve serial number. This number is

located on the valve identication tag. If the serial number

is not available, the parts needed for your valve might be

determined using the following information: Model number, Valve Body size, Plug Material and Seat Size, Spring

Range or Set Point, Trim Material, Part Name - Number

and Quantity (see parts list chart).

Note: Without a valve serial number, any parts ordered

incorrectly are subject to a minimum 25% restock charge

when returned.

Torque Procedure

Caution: Do not over-tighten cap screws.

Install all cap screws hand tight.1.

Tighten in the order of the pattern shown below to 2.

75-100 in/lbs., (6-8 ft./lbs.) then repeat to 140 in/

lbs. (12 ft/lbs.).

-3-

Page 4

Illustration and Parts List

24

13

23

12

10

30

7

4

3

2

28

11

14

Item Description Qty. Material

1 Body 1 Bronze

15

2 Seat 1 Brass

3 Retaining Ring 1 Stainless Steel

9

4 Stem / Plug 1 Stainless Steel

5 O-Ring 1 Viton

5

6 Bonnet 1 Brass

7 Angle 1 Steel

8

31

8 Cap Screws 4 Alloy Steel

9 O-Ring (Stem) 1 Viton

6

26

10 Spring 1 Steel

11 Guide Pin 1 Steel

27

25

29

12 Stroke Stop 1 Steel (KI Plated)

13 Ball Bearing 1 Steel

14 Roll Pin (Bearing) 1 410 SST

15 Roll Pin (Stem) 1 410 SST

1

16 Lower Support Strap 1 Steel

17 Rocker Plates 20 Steel

18 End Plates 2 Steel

19 Wire 8” Music Wire

22

20

18

19

17

20 Upper Support Strap 1 Steel

21 Drive Screws 8 Aluminum

22 Guide Rods 2 Steel

23 Rocker 1 Cast Iron

24 Set Screws 19 Alloy Steel

21

16

25 Washer 2 Steel

26 Support Stud 1 Steel

27 Flanged Bearing 1 Oilite Bronze

28 Motor Arm 1 Steel

29 Dowell Pins 2 Steel

30 Slotted Nut 1 Steel

32

31 Cotter Pin 1 Steel

32 Stop Screws 2 Alloy Steel

Bulletin IM-MK44-0410

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...