Page 1

I & M Mark 4150 and 4160 Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

The Mark 4150 and 4160 Series pressure controllers

are designed to provide years of reliable and accurate

service.

These instructions cover maintenance, adjustment,

and changes in mode of control.

Installation & Maintenance Instructions for the

Mark 4150 and 4160 Series Pressure Controllers

If the body is flanged, the bolts should be tightened up

evenly to reduce risk of damage to the valve body and

the flange.

A good quality thread lubricating compound should be

used on all male connections if the body has screwed

connections.

Control Line Connectors

These instructions are intended for the controllers

in general. Any instructions that apply to specific

controllers will be indicated by model number in the

instruction.

Model numbers are stamped on the nameplate located inside the cover of the controller (Key 29, Figure 4).

The connections should be made in an area of the

pipeline that is free of bends and elbows. Piping

connections should be made with 1/4” or 3/8” pipe or

tubing.

Tap the pipeline as close to the valve body as possible

allowing for these limiting factors.

Controllers

Inspect the controllers for shipping damage and foreign debris when uncrating.

Valve

Ensure the pipeline is free of welding slag, chips and

other debris by blowing out the line prior to installation.

It is recommended that a strainer be installed up

stream of the valve to protect the valve from foreign

debris in the line. Jordan Valve recommends a standard three-valve maintenance bypass be installed.

This allows isolation of the control valve without shutting down the pipeline system.

The valve should be positioned on the line so the flow

direction indicator corresponds to the direction of the

flow of the pipeline.

1. The tap area should be an area that is free

from abnormal velocities.

2. The ideal distance away from the body should

be 10 x the pipeline diameter.

The control pressure line is run from the tapped hole in

the side or the back of the case to the main pipeline.

Install a lock shield needle valve in the control line to

slow down the controlled pressure or to dampen out

any pulsations. While the control valve is operational,

the needle valve must never be entirely closed.

An air vent is provided on all controllers and works well

when air is used as the operating medium. When gas

is used the vent can be removed, this allows for an additional 1/4” NPT connection for gas to be piped away.

Page 2

Mark 4150 and 4160 SerieS PreSSure ControllerS

Operation

Although the output for these controllers are set prior

to shipping, upon arrival the following items should be

checked.

Bellofram Mark 50 Filter Regulator

Bellofram Mark 50 Filter Regulator is a self-contained

filter regulator designed to deliver air or gas to the

pilot at a constant pressure. The Bellofram Mark 50 is

designed to handle inlet pressures up to 250 psi. The

Series 4150/4160 delivers an outlet pressure of 3 - 15

psi when the regulator is set to 20 and it will deliver 6-30

psi output when the regulator is set to 35 psi.

The filter component ensures that operation is clean and

dry.

The relief valve is geared to open when the pressure is

reduced to 1 psi above the regulator set point.

Releasing the lock nut and adjusting the adjusting screw

located on the top of the regulator can reduce pressure

setting for the regulator.

Proportional Controllers

Most of the proportional controls will be used in applications that require a band set to approximately 15%. The

following steps are used to test this setting.

1. The air supply should be connected to Bello-

fram Mark 50 filter regulator.

2. Zero the pressure setting dial.

3. Set the proportional band adjustment to 15%

4. There should be no pressure sent to the mea

suring element.

5. For direct or reverse acting controllers the

range and output should be set as follows.

Range Output

3-15 psi 8-10 psi

6-30 psi 16-20 psi

Proportional-Reset Controllers

1. The reset dial should be set to maximum.

2. The air supply should be connected to Bello-

fram Mark 50 filter regulator.

3. Zero the pressure setting dial and proportioned

setting dial.

4. There should be no pressure sent to the mea-

suring element.

5. For direct or reverse acting controllers the

range and output should be as follows.

Range Output

3-15 psi 8-10 psi

6-30 psi 16-20 psi

Start Up

Proportional Controllers

1. The air supply should be connected to Bellofram

Mark 50 filter regulator.

2. Connect the control pressure line and open the

lock shield needle valve.

3. Ensure all piping and connections are free from

leaks.

4. Set the pressure to the desired control point.

5. Proportional band should be set at 15% of the

bandwidth.

6. Open the manual control valves that are up

stream and downstream, at the same time close

the by-pass valves.

7. Set the controller near the desired control point.

When it reaches that point, begin to broaden the

proportional band. Broaden the band as little

as possible. The narrowest band that

will not result in cycling provides

the best control. This band adjustment

will affect the zero. Re-zero the unit.

8. Test the bandwidth by changing the pressure

setting adjustment for a moment. If this

causes cycling, then broaden the proportional

band and test again. This procedure is

to be repeated until stability is reached.

-2-

Page 3

Mark 4150 and 4160 SerieS PreSSure ControllerS

Proportional-Reset Controllers

1. The air supply should be connected to Bellofram

Mark 50 filter regulator.

2. Connect the control pressure line and open the

lock shield needle valve.

3. Ensure all piping and connections are free from

leaks.

4. Set pressure to the desired control point.

5. Proportional band should be set at 100% of

bandwidth.

6. Maximize the setting on the reset dial.

7. Open the manual control valves that are up

stream and downstream, at the same time close

by-pass valves.

8. Set the controller near the desired control point.

When it reaches that point, begin to narrow

the proportional band until a cycling condition

exists. Broaden the band slightly until a stable

condition is reached. There is no need

to reset the zero in controllers that have reset.

9. Try to obtain the fastest reset time without intro

ducing cycling control carefully by adjusting the

reset rate.

10. Test the bandwidth and the reset rate by chang-

ing the pressure setting adjustment for

a moment. If this causes cycling, then broaden

the proportional band and test again. This

procedure is to be repeated until stability is

reached.

Example: with the proportional band set @ 1 (10%),

using a Bourdon tube of 0-1000 psi that is set @ 500 psi

on the pressure dial. The full travel of the valve would

occur between 450 psi (3 psi output) and 550 psi (15 psi

output) to try to maintain the set point.

Using this theory, an input pressure of 500 would give

you an output pressure of 9 psi. The greater the proportional band setting is the slower the reaction.

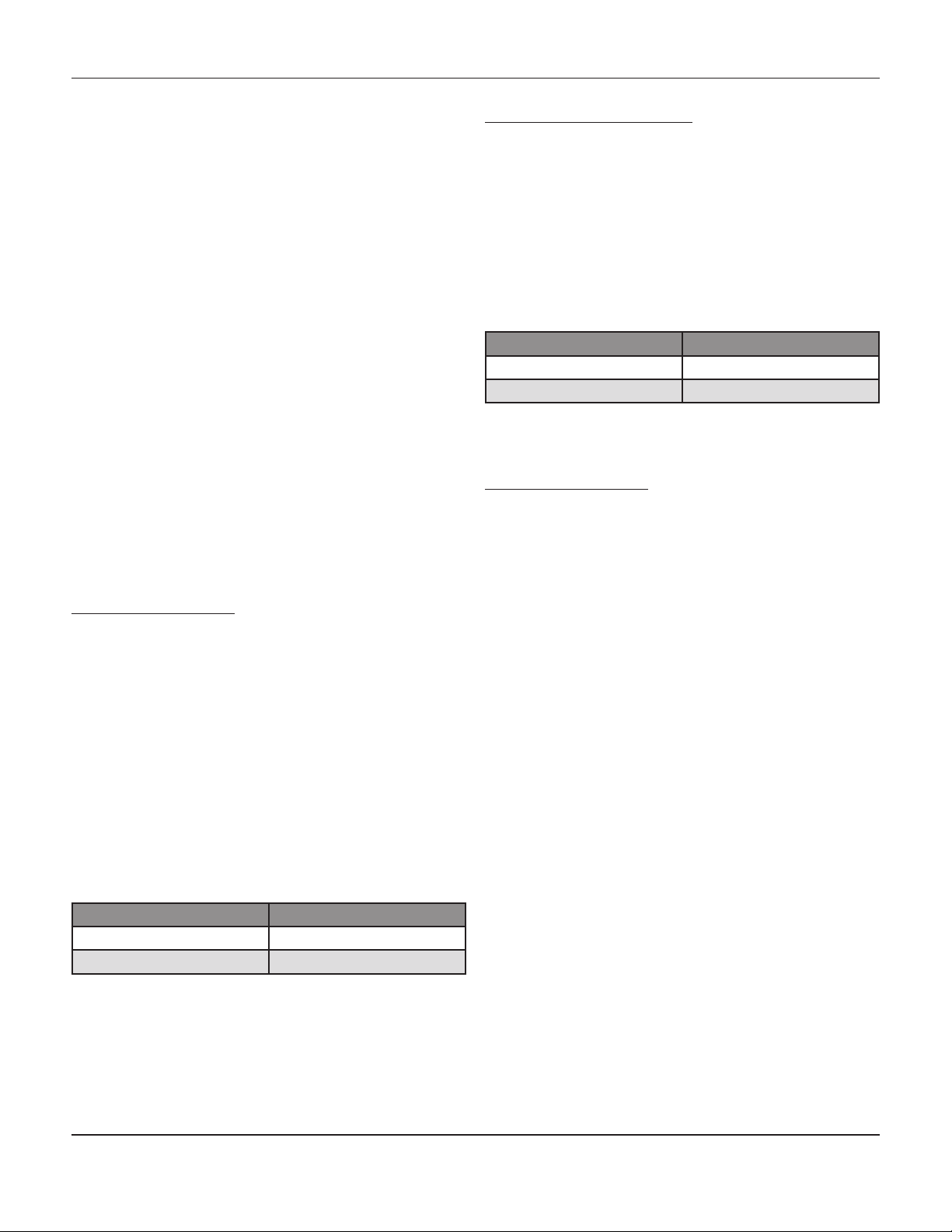

Figure 1: Pressure Connections for

Proportional Controller

The goal for the controller setting is to have the narrowest proportional band and the fastest reset rate that will

not cause cycling.

Changing Controller Action

One advantage of the Mark 4150/4160 is the ease at

which you can change from one mode of control to another. There is a connection for both direct and reverse

action in all modes of control. There is also a screw (key

5, figure 6) provided to plug the hole opposite of the

nozzle. It will be necessary to follow INITIAL SETTINGS

after any change in mode of control.

Adjustments

Proportional Band Width Adjustments

The proportional band width adjustment determines the

change in control pressure required to cause the control

valve to travel full open or full closed.

Figure 2: Pressure Connections for

Proportional-Reset Controller

Reset Rate Adjustment

By definition the reset rate is the number of minutes that

it takes to adjust the controller to adjust the output pressure up or down by the same amount of proportional

change output caused by the process change.

The reset rate is calibrated in minute per repeat.

-3-

Page 4

Mark 4150 and 4160 SerieS PreSSure ControllerS

Pressure Setting Adjustment

The Mark 4150 and 4160 come with calibrated set point

adjustment. The dial is calibrated for pressure ratings

of the measurement element. If start up instructions are

followed, the pressure setting dial is correct for any settings on proportional-reset controllers.

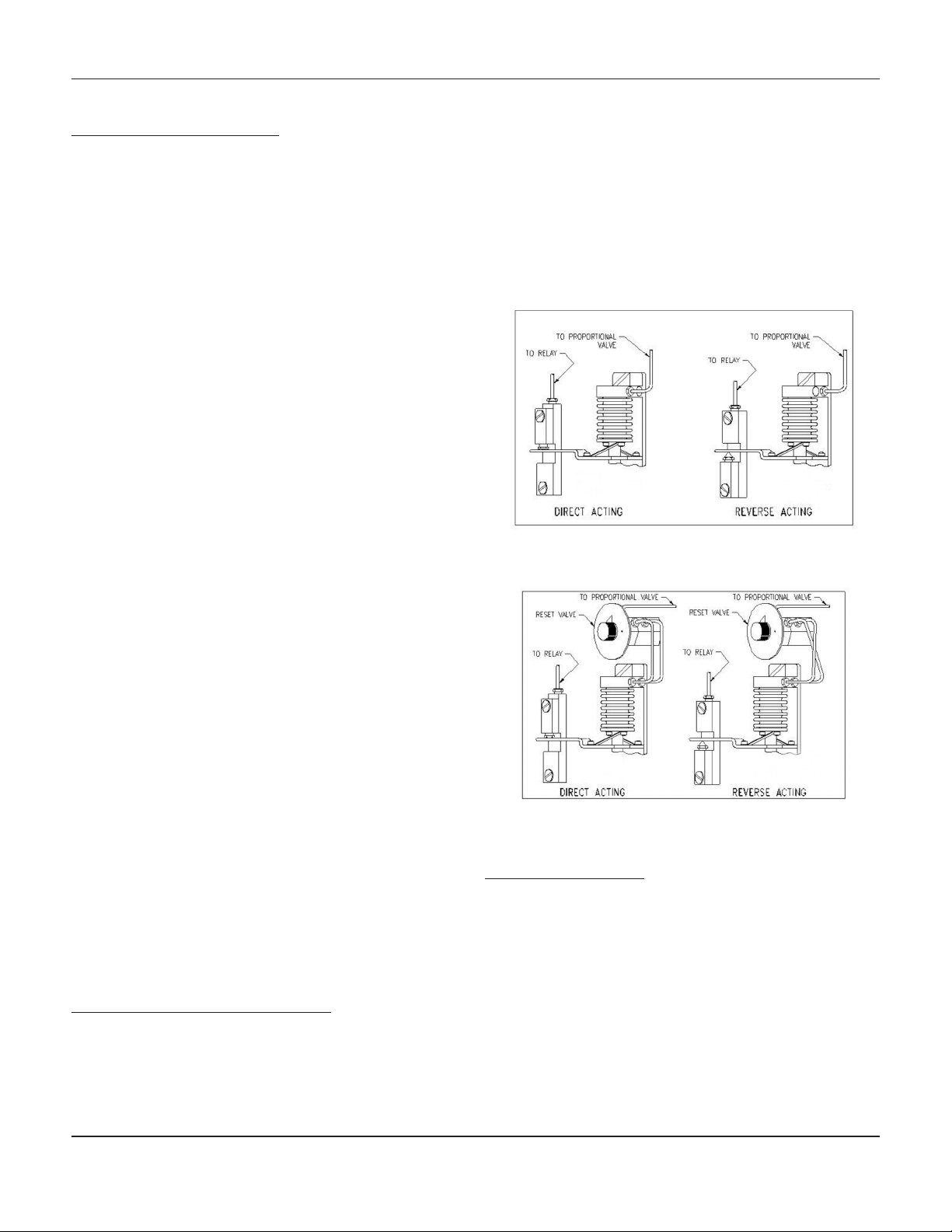

Mark 4150 Pressure Controller

The theory of operation can be broken down into steps.

Refer to the schematic diagram figure 3.

I. The pressure first enters the Bourdon tube. As

the pressure increases the Bourdon tube

straightens causing the beam (B) attached to

the end of the Bourdon tube to move closer to

nozzle (C).

2. Closing the nozzle (C) will cause a build up of

pressure in chamber (D) from the constant air or

gas supply through the orifice (E).

3. The resulting pressure built up in chamber (D)

cause the diaphragm (F) to push up and

open valve (G).

4. An open Valve (G) will cause the constant air or

gas supply to flow into chamber (H).

5. The build up of pressure in chamber (H) causes

diaphragm (F) to be pushed back to its original

position and therefore closes valve (G).

6. The increase in pressure in chamber (H) sends

the supply pressure to flow to the diaphragm

of the control valve causing the control valve to

start to close.

7. At the same time, the pressure flows through the

three-way valve (K) causing an increase in pres

sure in bellows (I).

8. The increase in the pressure bellows (I) cause

the beam (B) to move away from nozzle (C). As

a result there will no longer be a build up of

pressure in (D). The control valve is now at the

desired pressure setting.

If there is a decrease in control pressure the above mentioned steps will proceed in reverse. The control pressure will bleed out through the exhaust vent (J).

Please note that the changes in pressure are continuous

in nature. The process has been explained in steps for

ease of explanation.

As seen in the figure 3, schematic illustration of Mark

4150, the output pressure from relay chamber (H) goes

to both the proportional band adjustment relay three-way

valve (K) and the control valve diaphragm. The amount

of feedback to the proportional bellows (I) can be adjusted by adjusting the orifice. If valve (K) is fully open,

then the total of the diaphragm pressure is sent to the

bellows chamber (I).

This causes the beam (B) to move away from nozzle (C)

allowing the pressure to be released from chamber (D).

The result of this is 100% proportional band based on

the rating of the Bourdon tube. Closing the three-way

valve (K) will result in a lowering of proportional band response. The proportional band would be approximately

3% when fully closed.

Figure 3: Schematic Illustration of

Mark 4150 Proportional Controller

-4-

Schematic Illustration of Mark 4150

Proportional-Reset Controller

Page 5

Mark 4150 and 4160 SerieS PreSSure ControllerS

Mark 4160 Pressure Controller

The operation of Mark 4160 - proportional-reset controller, is the same as the Mark 4150 with the addition of a

reset rate adjustment (L). Follow steps 1-6 from operation of the 4150 then proceed with the following:

1. In step No. 7, for the Mark 4160 the pressure will

flow through the three-way valve (K), to reset

valve (M) where a portion of pressure

will be diverted to the bellows (O).

2. The pressure will be built up in bellows (O)

pushing beam (B) to nozzle (C) and therefore

increased pressure to valve and to bellows (I).

This process will continue until control pressure

is equal to the set point.

3. The proportional bandwidth determines how

much the pressure will deviate from the

set point. The reset determines the amount of

time the deviation is away from the set point.

MaIntenance

The Mark 4150/4160 Series Bourdon Tubes can be

replaced. They may be replaced due to changes in

pressure regulations or for maintenance.

Replacing Bourdon Tube

(Refer to Figure 6)

1. Detach the connecting link and bearing (Key 37)

from the beam.

2. Unscrew the two fixing screws (Key 8) holding

the tube. Detach tube from the sub-assembly.

3. Replace the Bourdon tube by removing the con-

necting link and bearing from the exist

ing tube. Attach the connecting link and

bearing on the new Bourdon tube.

4. Zero the pressure dial.

5. Install the Bourdon tube in the sub-assembly.

Reconnect the connecting link and bearing to

the beam.

6. Ensure that the tube is in a horizontal position

and that there is tension in the connect

ing link. The tension can be adjusted by bend-

ing the cross springs (Key 28).

7. Adjust and calibrate for start-up.

Two steps should be carried out in regular scheduled

maintenance. A cleaner button allows you to clean the

passages in the relay orifice. This button should be

pushed regularly. The second step is using the drain

cock that is located on the underside of the drip well in

the Mark 50 filter. This drip well, should be allowed to

bleed off to atmosphere to prevent moisture from contaminating the controller.

trouble ShootIng

1. The control valve continually cycling or hunting.

1.1. The constant cycling of a controller can

occur if the reset rate is set too

fast or the band setting is set too narrow.

1.2. Ensure that the controller valve plug is

not sticking.

1.3. A control valve always operating near its

seat will indicate an oversized control

valve.

2. Incomplete Pressure Change on the Diaphragm.

2.1. Ensure an accurate reading is being

displayed from the diaphragm pressure

gauge.

2.2. Verify that lines and connections are free

from leaks.

Replacing Bellows

(Refer to Figure 6)

1. Detach sub-assembly from controller.

2. Remove the connecting link and bearing (Key

37) from the beam.

3. Remove the bellows unit from the frame (Key 16)

4. Install the bellows in the control assembly. Begin

by ensuring that the beam is horizontal and with

the pressure setting dial at zero.

Then attach the connecting link and the bearing

link to bellows and beam. Ensure that there is

tension on the connecting link. Tension

can be added by bending the cross springs

(Key 28).

5. Adjust and calibrate for start up.

Calibration of Controllers

1. Move the calibration adjuster (Key 30, Figure 6)

to the right or the left.

2. Repeat the nozzle adjustment and step 5 for

proportional controller or step 6 for proportional-

reset controller.

3. To release the calibration adjuster, loosen the

two screws, above and below the beam,

to the left of the nozzle.

-5-

Page 6

Mark 4150 and 4160 SerieS PreSSure ControllerS

Calibrate Zero on Proportional Controllers

1. Depending on the controller type the supply

pressure will be 20 or 35 psi. Attach a suitable

pressure gauge to the output pressure.

2. Connect the pressure source to the pressure

block and set the proportional bandwidth to 15%

(1.5).

3. Zero the pressure setting dial.

4. Raise or lower the nozzle (Key 34, Figure 6)

to get the desired setting of zero as per chart

below. Nylon insert will hold the nozzle in place.

5. Allow maximum pressure to the measuring ele-

ment. Set the pressure dial to maximum. Output

pressure should comply with the zero setting

column in the following table, if not go to

Note 1.

Control

Action

Direct 3-15 psi 20 psi 8-10 psi

Direct 6-30 psi 35 psi 16-20 psi

Reverse 15-3 psi 20 psi 8-10 psi

Reverse 30-6 psi 35 psi 16-20 psi

Output

Range

Supply

Pressure

Zero

Setting

Note 1 - These steps are to be used if the zero setting

pressure or output range is not obtained when maximum

pressure is applied to the measuring element.

1. Move the calibration adjuster (Key 30, Figure 6)

to the right or the left.

2. Repeat the nozzle adjustment and Step 5 for

proportional controller, or Step 6 for proportional reset controller.

3. To release the calibration adjuster, loosen two

screws, above and below the beam, to the left of

the nozzle.

Control

Action

Direct 3-15 psi 20 psi 8-10 psi

Direct 6-30 psi 35 psi 16-20 psi

Reverse 15-3 psi 20 psi 8-10 psi

Reverse 30-6 psi 35 psi 16-20 psi

Output

Range

Supply

Pressure

Zero

Setting

Calibrate Zero on Proportional- Reset

Controllers

1. Depending on the controller type the supply

pressure will be 20 or 35 psi. Attach a suitable

pressure gauge to the output pressure.

2. Connect the pressure source to pressure block

and set the proportional bandwidth to zero.

3. Set the reset dial to .005 minutes per repeat.

4. Zero the pressure setting dial.

5. Raise or lower the nozzle (Key 34, Figure 6) to

get the desired setting of zero as per

chart below. Nylon insert will hold the nozzle in

place.

6. Allowing maximum pressure to the measuring

element. Set the pressure dial to maximum. Out-

put pressure should comply with the zero setting

column in the following table, if not go to Note 1.

Changing of Controller Output

Controllers having an output range of 3-15 psi, can be

converted to having an output range of 6-30 psi. This

can be done by changing the two color coded control

bellows. The green bellows is for 3-15 range, and yellow

bellows for 6-30 psi range.

When the pressure range is changed, it is necessary to

change the pressure gauges. This can be completed

by unscrewing the old pressure gauges from their boss

and screwing in the new gauges.

-6-

Page 7

aSSeMbly

Mark 4150 and 4160 SerieS PreSSure ControllerS

Figure 4: Mark 4150 Proportional Pressure Controller with

Bourdon Tube Measuring Element

PartS reference

Figure 5: Partial view of Mark 4160

Pressure Controller Showing the Reset

Valve and the Arrangement of Tubing

-7-

Page 8

Mark 4150 and 4160 SerieS PreSSure ControllerS

Controller Main Assembly (Refer to Figures 4 and 5)

Key

No.

1 1H2889 Spring Washer Steel Cd. Pl

2 1H2891 Groove Pin Aluminum

3 1H2886 Cover Latch Steel Cd. Pl

4

5*

6 367X3 Proportional Band Adj.

7 1H2890 Groove Pin Aluminum

8 1C8937 Screen and Elbow Assy Sub-Assy

9* 1C3286 Cont. Pres. Block

10*

11* 0T0191 Glass Gasket, 2 Req’d Neoprene

12 1A4658 Retaining Ring, 2 Req’d Galv, Steel

13 1A5120 Screw, 8 Req’d Steel Cd. Pl

14* 0T0192 Gauge Glass, 2 Req’d Acrylic

15* 1C3762 O-Ring Buna-N

16 1C2256 Lockwasher, 4 Req’d Steel Cd. Pl

17 1C3333 Screw, 4 Req’d Steel Cd. Pl

18 1H2698 Cont. Pres. Block Steel

19 1H3435 Supply Pres. Gauge

20 1H2759 Relay Tubing Assy Copper

21 536X47 Pilot Relay

Part

No.

1H2712 Output Pres. Gauge 30

psi.

1H3048 Output Pres. Gauge

60 psi

1H2753 Compensator Tubing

Assy

1H6864 Compensator Tubing

Assy

1H2966 Reset Tubing Assy Copper

1H6866 Reset Tubing Assy 304 SST

Assy

Gasket

1H2887 Relay Base Gasket Neoprene

1N8737 Relay Base Gasket Hi-

Temp

1H2895 Cont Pres. Block 316 SST

0-30 psi

1H3436 Supply Pres. Gauge

0-60 psi

1H6861 Relay Tubing Assy 304 SST

536X84 Pilot Relay Hi-Temp

Part

Description

Material

Sub-Assy

Sub-Assy

Copper

304 SST

Sub-Assy

Neoprene

Si Rubber

Cd. Pl.

Sub-Assy

Sub-Assy

Key

No.

22 3H2885 Relay Base Zinc

23 1H5269 Screw, 17 Req’d Steel Cd. Pl

24 4H2684 Cover Aluminum

25* 1J24075 Cover Gasket Sponge

26 4H2699 Case Aluminum

27*

28 1C9419 Screw, 2 Req’d Steel Cd. Pl

29 1H2702 Instruction Plate Aluminum/

30 1H2888 Roll Pin, 2 Req’d Steel Cd. Pl

31*

32

33 1A3321 Screw, 6 Req’d Steel Cd Pl

34 536X61 Reset Valve

35*

36*

37 1H5271 Screw, 2 Req’d Steel Cd. Pl

38 1H5270 Screw, 4160 Steel Cd. Pl

39

* Recommended Spare Parts

Part

No.

1C8974 Relay Gasket Neoprene

1N8738 Relay Gasket, Hi-Temp Silicone

1H3013 Cont. Tubing Assy,

4150, 4160

1H4528 Cont. Tubing Assy. Copper

1H3011 Cont. Tubing Assy,

4150, 4160

1H4526 Cont. Tubing Assy. 304 SST

ML536X Cont. Sub-Assy. 4150,

4160

ML536XH Cont. Sub-Assy.

Hi-Temp, 4150, 4160

536X15 Reset Valve, Hi-Temp

1H2755 Compensator Tubing

Assy.

1H6870 Compensator Tubing

Assy.

1H2757 Conpensator Tubing

Assy.

1H6870 Conpensator Tubing

Assy.

1A7675 Pipe Plug Steel

1A7675 Pipe Plug 316 SST

Part

Description

Material

Rubber

Rubber

SST

Copper

304 SST

Sub-Assy.

Sub-Assy.

Copper

304 SST

Copper

304 SST

-8-

Page 9

Mark 4150 and 4160 SerieS PreSSure ControllerS

PartS reference

Figure 6: Controller Sub-Assembly for Bourdon

Tube Controllers Mark 4150 and 4160

Controller Sub Assembly (Refer to Figure 6)

Key

No.

1 1C8969 Screw, 4 Req’d Steel Cd. Pl

2 1B2751 Screw Steel Cd. Pl

3 1C8990 Screw, 4 Req’d Steel Cd. Pl

4 1A5733 Screw, 8 Req’d Steel Cd. Pl

5* 1H2674 Screw Steel Cd. Pl

6* 1H2673 Screw Steel Cd. Pl

7 1H2676 Screw, 2 Req’d Steel Cd. Pl

8 1H2677 Screw, 2 Req’d Steel Cd. Pl

9* 1H2678 Screw, 2 Req’d Steel Cd. Pl

10* 1B2776 Screw, 2 Req’d Steel Cd. Pl

11* 1A3319 Screw, 2 Req’d Steel Cd. Pl

12 1E8730 Washer, 2 Req’d Steel Cd. Pl

13 1H2671 Washer, 2 Req’d Steel Cd. Pl

14* 1H2672 Washer, 2 Req’d Acrylic

15*

16 1H2653 Bellows Frame Aluminum

17

Part

No.

1H2655 Bellows Assy. 3-15 psi,

2 Req’d

1H2680 Bellows Assy. 6-30 psi,

2 Req’d

1H2654 Bellows Frame Gasket Neoprene

1N8735 Bellows Frame Gasket,

Hi-Temp

Part

Description

Material

Si Rubber

Key

No.

18 1D3976 Bellows Screw, 2 Req’d 18-8 SST

19*

20 1H2658 Bellows Stud 18-8 SST

21* 1E2226 O-Ring Buna-N

22 1H2650 Bourdon Tube Mounting

23 2H2651 Mounting Plate Steel

24 536X4 Pressure Adj. Assy.

25 1H2652 Adj. Spacer 2 Req’d Steel

26 1J4234 Rotary Shaft Spring 302 SS

27 1H2659 Spacer Zinc

28 1H2660 Cross Spring, 2 Req’d 304 SS

29 1H2661 Pressure Set Arm Steel

30 2H2662 Calibration Adj. Zinc

31 1U6392 Reversing Block Assy.

32* 1H2664 O-Ring, 3 Req’d Viton

33 16A0976 Nylon Insert Nylon

* Recommended Spare Part

Part

No.

1D3970 Bellows Gasket, 2 Req’d Neoprene

1N8736 Bellows Frame Gasket,

2 Req’d

1N8387 O-Ring, Hi Temp Viton

Bracket

536X8 Zero Adj. Assy.

Part

Description

Material

Si Rubber

Aluminum

-9-

Page 10

Mark 4150 and 4160 SerieS PreSSure ControllerS

Controller Sub Assembly Continued,

Key

No.

34* 1U6391 Nozzle 316 SS

35 1H2668 Beam Steel

36* 1H2669 Flapper Spring Steel

37 1L3796 Connecting Link 316 SS

38 1C8977 Flexure Strip Base Steel, Cd Pl

39 1C8978 Flexure Base Spring Steel

40 1C8975 Flexure Strip Nut, 2 Req’d Steel, Cd Pl

41*

Part

No.

1R8729 Bourdon Tube, 0-30 psi

1R8730 Bourdon Tube, 0-60 psi

1R8731 Bourdon Tube, 0-100 psi

1R8732 Bourdon Tube, 0-200 psi

1R8733 Bourdon Tube, 0-300 psi

1R8734 Bourdon Tube, 0-600 psi

1R8735 Bourdon Tube, 0-1000 psi

1R8736 Bourdon Tube, 0-1500 psi

1R8737 Bourdon Tube, 0-3000 psi

Part

Description

Material

316 SS

42

1R8738 Bourdon Tube, 0-5000 psi

2H2883 Bourdon Tube, 0-8000 psi

2H2884 Bourdon Tube, 0-10000 psi

2H6785 Bourdon Tube, 0-15000 psi

1H3044 Press. Adj. Dial, 0-30 psi

1H3034 Press. Adj. Dial, 0-60 psi

1H3035 Press. Adj. Dial, 0-100 psi

1J5237 Press. Adj. Dial, 0-200 psi

1H3036 Press. Adj. Dial, 0-300 psi

1H3037 Press. Adj. Dial, 0-600 psi

1H3038 Press. Adj. Dial, 0-1000 psi

1H3039 Press. Adj. Dial, 0-1500 psi

1H3040 Press. Adj. Dial, 0-3000 psi

1H3041 Press. Adj. Dial. 0-5000 psi

1H3042 Press. Adj. Dial. 0-8000 psi

1H3043 Press. Adj. Dial. 0-10000 psi

Aluminum

1H3043 Press. Adj. Dial. 0-15000 psi

* Recommended Spare Part

-10-

Page 11

Mark 4150 and 4160 SerieS PreSSure ControllerS

Pilot Relay Assembly

Key

No.

1 1A3319 Screw, 4 Req’d Steel

2 1H2697 Spring Plate Steel

3*

4 0X0836 Valve Plug Spring Inconel

5* 1C8961 Relay Spring Inconel

6* 0Y0617 Valve Plug 316 SS

7 1C9370 Dia. Assy. Temp To 150°F Sub Assy.

8 1L5556 Top Dia., Temp 150°F Buna-N

9* 1C8969 Screw Temp to 150°F 6 Req’d Steel

10* 1D6875 O-Ring Syn. Rubber

11* 1H8266 Restriction Plug Orifice Assy. Sub Assy.

12 1E2303 Core & Wire Assy. Sub Assy.

13 2H2693 Relay Body Zinc

Part

No.

1H2696 Spring Plate Gasket,

Part

Description

Material

Neoprene

Temp. To 150°F

1K7000 Spring Plate Gasket,

Sil. Rubber

Temp. To 150°F-250°F

0Y0617B Brass

1K6996 Dia. Assy. Temp 150°-250°F

1A3294 Screw 150°F-250°F 6 Req’d

MK4150and4160IM/0214/2K

14* 2K4404 Spacer Ring Zinc

15* 1C9369 Diaphragm Case Assy Sub Assy.

1K7001 Bottom Gasket (Not Shown)

16

Temp. 150°F-250°F Sil. Rubber

Figure 7: Exploded View of Pilot Relay

used in Mark 4150 and

4160 Controllers

1K7002 Top Gasket, Temp 150°-250°F

17 1P8261 Washer, 6 Req’d (Not Shown) Steel

* Recommended Spare Part

Supply Pressure Data

Normal Operating

Output Signal Range

Supply

Pressure (*)

Psig Bar Psig Bar Psig Bar Min

3 to 15 or

0 & 20 (on-off)

6 to 30 or

0 & 30 (on-off)

0.2 to 1.0 or

0 & 20 (on-off)

0.4 to 2.0 or

0 & 2.4 (on-off)

20 1.4 50 3.4 4.2 (0.12) 27 (0.76)

35 2.4 50 3.4 7 (0.20) 42 (1.2)

* Stability and control may be compromised if pressure is exceeded.

A Proportional Band setting of 0-10

B Proportional Band setting of 5

Maximum Allowable

Supply Pressure to

Prevent Internal

Damage

Steady State Air Consumption

SCFH of Air at 60°F and 14.7PSIA

(Normal M3/Hr of Air at 0°C and

1.01325 Bar)

A

Max

B

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...