Page 1

I & M Mark 33 Series

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve electric motor control valves must only be used, installed and repaired in accordance with

these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In

the event of leakage or other malfunction, call a qualied service person; continued operation may cause system

failure or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before

disassembling a valve, be sure to release all spring tension.

Installation & Maintenance Instructions for

Mark 33 Electric Motor Control Valves

Please read these instructions carefully!

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

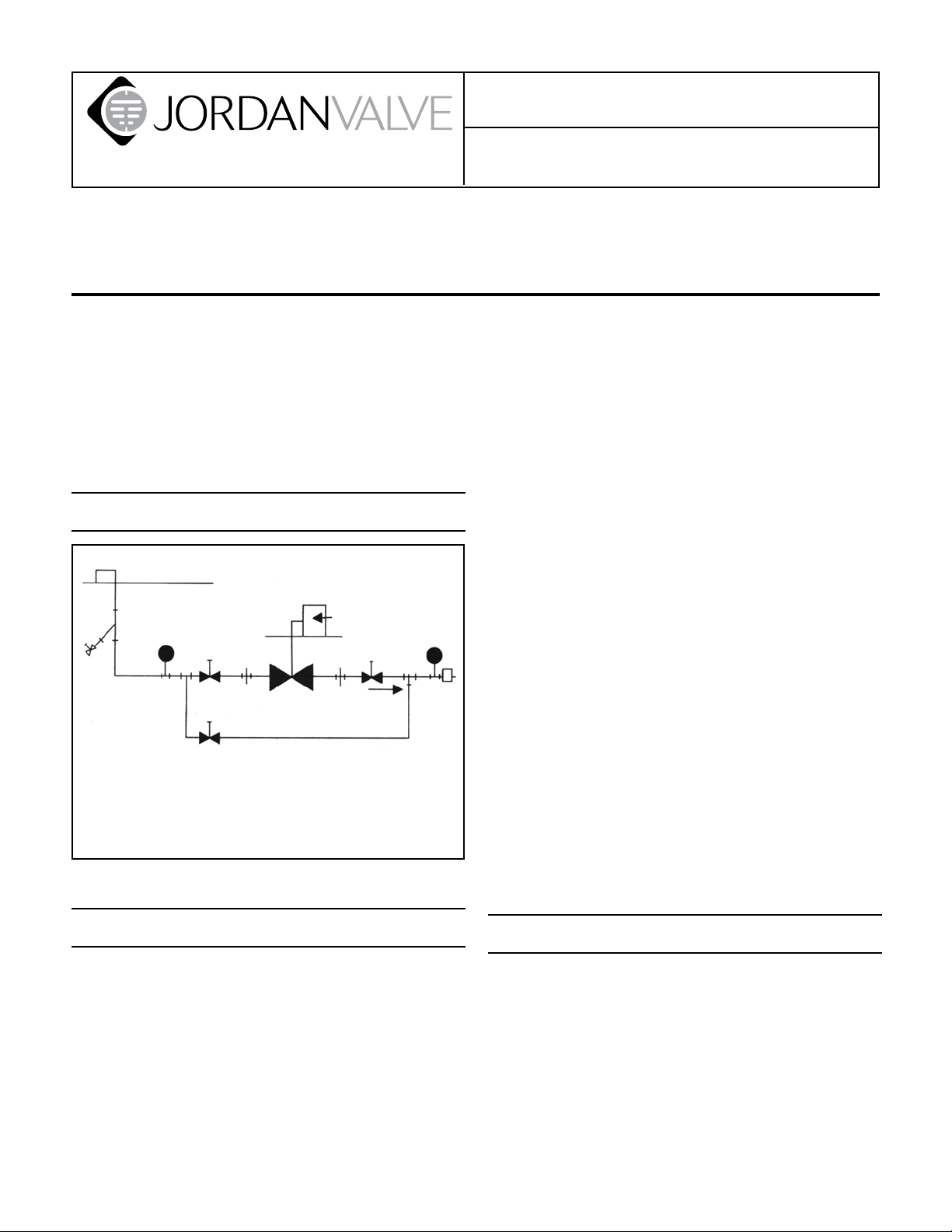

Ideal Installation

Main Line

Electric

3

4

5

2

1

Bypass Line

1 Shut-off Valve

2 Pipe Union

3 Strainer & Drain Valve

4 Pressure Gauge

5 Motor Valve

6 Relief Valve

Connection

1

2

4

R

6

should be used sparingly, leaving the two lead threads

clean.

A line strainer should be installed on the inlet side of 4.

the regulator to protect it from grit, scale and other

foreign matter. A 0.033 perforated screen is usually

suitable. Line strainers are available for immediate

shipment from Jordan Valve.

Install the valve in the highest horizontal line of pip-5.

ing to provide drainage for inlet and outlet piping, to

prevent water hammer and to obtain faster response.

The ow arrow on the regulator body must be 6.

pointed in the direction of ow. The valve may be

installed in any direction, but damage to the seating

surfaces may occur if installed in a vertical line with

the ow upwards.

To minimize condensation in hot vapor lines and to 7.

protect the motor from excessive heat, piping near

the valve should be insulated.

If possible, install a relief valve downstream from the 8.

regulator. Set at 15 psi above the control point of the

valve.

Expand the outlet piping at least one pipe size if the 9.

downstream pressure is 25% of the inlet pressure or

less. A standard tapered expander connected to the

outlet of the valve is recommended.

Where surges are severe, a piping accumulator is 10.

recommended.

For best control, 3’ straight sections of pipe should 11.

be installed on either side of the valve.

Installation

To protect the valve from grit, scale, thread chips, 1.

and other foreign matter, all pipe lines and piping

components should be blown out and thoroughly

cleaned before the valve is installed.

Shutoff valves, pressure gauges, and bypass piping 2.

should be installed as indicated in the diagram to

provide easier adjustment, operation, and testing.

In preparing threaded pipe connections, care should 3.

be exercised to prevent pipe sealing compound from

getting into the pipe lines. Pipe sealing compound

Wiring

Caution: Disconnect electrical power supply before

wiring motor into circuit to avoid electrical show or

possible damage to equipment. Always disconnect

power supply before attempting any wiring changes.

See the Motor Manufacturer’s literature, supplied with

the valve, for wiring connections and instructions.

Page 2

Start-Up

Be sure that the action of the control valve and of 1.

the controller are such as to give the desired results.

With the inlet, outlet and bypass shutoff valves 2.

closed, and no pressure in the downstream line, fully

open the outlet shutoff valve. Slowly open the inlet

valve just enough to start ow through the control

valve. Increase ow gradually by slowly opening the

inlet shutoff valve. Do not fully open the inlet valve

until you are sure that the controller and control

valve have control of the system. Usually the handwheel on the inlet valve will turn freely when this

point is reached.

To shutoff the line uid, close the inlet shutoff valve 3.

rst, then the outlet shutoff valve.

Close the shutoff valve on each side of the control 1.

valve, and remove the valve from line.

Note scribed “<” on the side of the valve body and 2.

cap. Secure the body outlet ats in a vise. Remove

the cap bolts and two nuts, and lift the cap straight

up.

Before removing, check the valve disc for a stamped 3.

arrow. This arrow points to the “<” on the body.

Remove the disc guide and the valve disc. Place the

valve disc on the bench with lapped surface facing

up. Protect the lapped surfaces on both sides of the

disc guide.

It is imperative that the disc pin is not rotated

when disassembling, cleaning or reassembling, since this affects the stroke adjustment

of the valve.

Maintenance

Caution: Make certain that there is no pressure in the

valve before loosening any ttings or joints. The following steps are recommended:

Close inlet shutoff valve.1.

Allow pressure to bleed off through downstream 2.

piping. Do not attempt to reverse the ow through

the valve by bleeding pressure from the upstream

side of the valve.

When the pressure gauges indicate that all pressure 3.

has been removed from the system, close the outlet

shutoff valve and the valve may be serviced.

Note: refer to the drawing at the end of this document for description and proper orientation of parts.

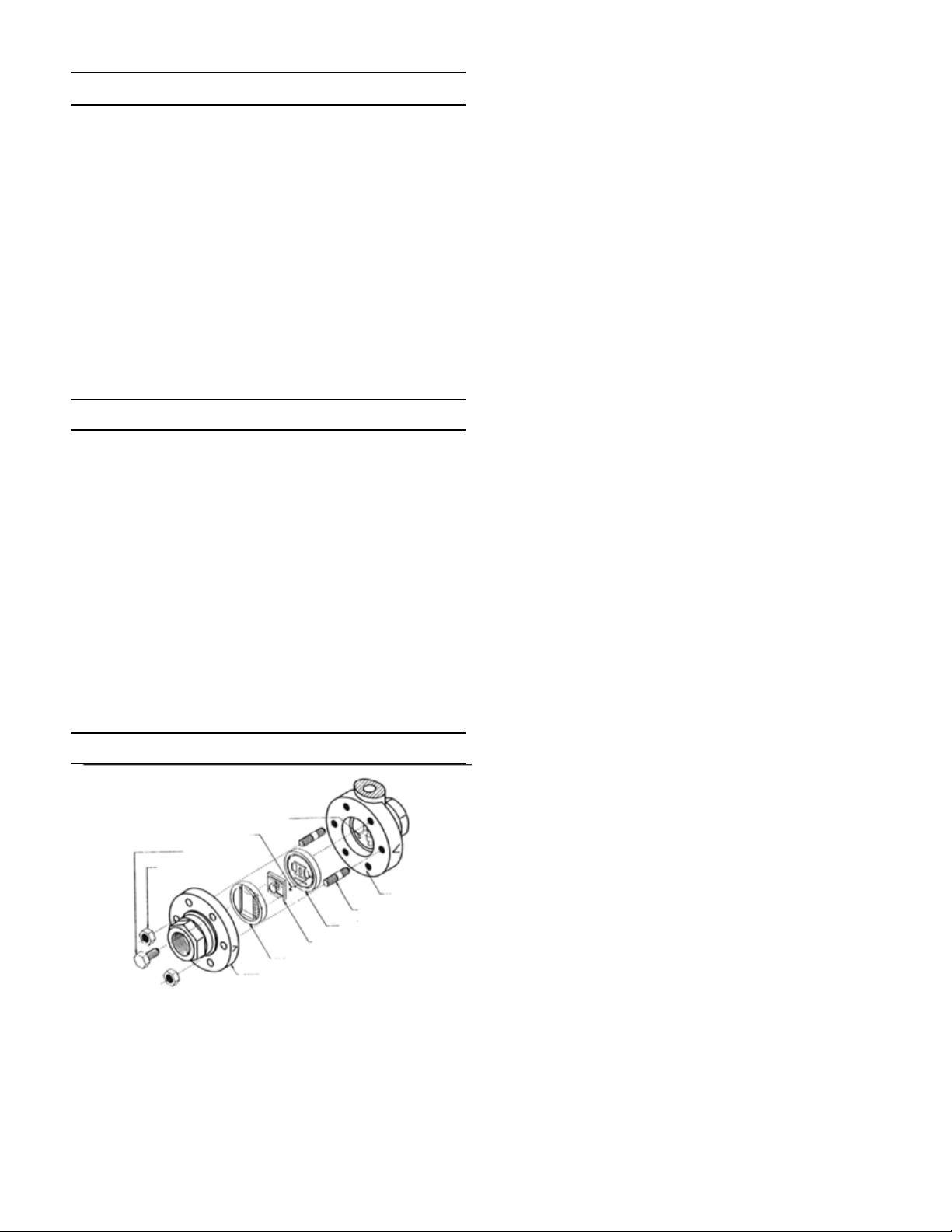

Valve Seats

Disc Pin

Index Pin

Cap Screws

Hex Nuts

Body

Studs

Valve Plate

Valve Disc

Disc Guide

Cap

A. Disassembly

The seats of Jordan valves are precision-lapped. Maintaining such tolerances is of paramount importance for

your assurance of excellent control and tight shutoff. Do

not use metallic objects in removing the seats. Care in

handling is imperative.

Lightly tap on the body to remove the valve plate. 4.

Invert the body, let valve plate drop out into your

hand, and place it on the bench with lapped surface

facing up.

Clean all the parts, body and cap with solvent. Place 5.

a piece of 4/0 polishing cloth or jewelers cloth on

a smooth, at surface such as surface plate, and

polish the lapped seating surfaces of the disc, plate

and disc guide using a “gure 8” motion. If the parts

are scarred, do not attempt to relap them, but return

them to the factory for repair or replacement. If the

seats are not scarred deeply, they can be repaired at

a nominal cost.

The vertical sections of the disc guide serve as 6.

guides for the valve disc while stroking. A 0.005

feeler gauge should be used to check for clearance

between this surface and the side of the valve disc. If

the clearance is less, clean the guide surfaces in the

disc guide with a ne le.

B. Reassembly

Place the valve plate in the body, lapped surface 1.

facing the cap. The index pin hole should be on the

same side as the “<” on the body. Align the disc pin

so that it is centered in the body bore and protrudes

through the center slot in the valve plate.

Place the valve disc on the valve plate, engaging the 2.

disc pin. The arrow on the disc should point to the

“<” on the body.

Place the disc guide onto the valve plate, engaging 3.

the index pin. Rotate the assembly slightly until the

slot openings in the valve disc are parallel to the

openings in the valve plate, and perpendicular to the

valve stem. Stroking the valve will aide in this alignment.

Align the “>” on the cap with the “<” on the body, 4.

and place the cap over the two studs in the body.

Install the nuts and cap bolts. Tighten uniformly. See 5.

torque requirements and tightening procedures.

Page 3

Stem & Disc Pin Replacement

Remove the valve disc and the valve place, following 1.

the procedure outlined under VALVE SEATS.

Loosen the stem connector nut and bolt and remove 2.

connector assembly.

Back out the four allen head screws which will allow 3.

the valve body to be separated from the valve yoke.

Loosen the stem locknut and rotate the disc pin 4.

counter-clockwise, pulling the valve stem upward

while doing so. Do not remove the valve stem completely, but raise it sufciently so that the disc pin

may be removed by pulling up and out.

Replace the disc pin and reassemble in reverse 5.

order following the procedure outlined under VALVE

SEATS and STROKE ADJUSTMENT.

Packing

Remove connector assembly.1.

Remove both packing ange nuts.2.

Remove packing ange and packing follower.3.

Remove packing retainer and the packing spring.4.

Clean the packing bore with solvent and blow out 5.

thoroughly.

Assemble in reverse order and tighten the packing 6.

nut so that the packing follower bottoms out on top

of the valve body.

Engage the valve stem and actuator stem with con-7.

nector. Tighten connector nut and bolt. No stroke

adjustment is required.

Valve Stroke Adjustment

The valve stroke is set at the factory and no eld adjustments are necessary. The position of the seats can be

adjusted by starting from the normally open position

(when the orice in the plate and in the disc are perfectly aligned). For direct acting service, adjust the motor

rotation to the full CCW position (as viewed from the

power end). For reverse acting service, adjust the motor

rotation to the CW position. If the seats are not properly

full open, loosen the nut that locks the actuator stem to

the rod end bearing and loosen the stem connector assembly just enough to rotate the actuator stem. Carefully

thread the actuator stem in or out of the rod end bearing

until the seats are full open. If further adjustments are

necessary, consult factory.

Motor Replacement

If it becomes necessary to change motors, the following

procedure should be followed:

Remove the valve from the line.1.

Remove socket head crew and lockwasher.2.

Important: Note position of lobe of the cam on the

motor shaft. Do not attempt to remove the socket set

screws.

Remove the four motor mounting bolts, lockwashers, 3.

and nuts.

Slide motor back off of mounting plate.4.

Install new motor on mounting plate. 5. Important -

make sure cam is in the same lobe position as

described in step 2.

Replace and tighten mounting bolts, lockwashers, 6.

and nuts.

Replace and tighten socket head screw and lock-7.

washer on motor shaft.

Check valve stroke as described in STROKE ADJUSTMENT.8.

Motor Maintenance

The drive motor and gear train are immersed in oil and

sealed in a die cast enclosure, and thus periodic maintenance is not required. Field repairs must not be made.

Replacement actuators may be obtained through the

nearest Jordan Valve representative. When ordering a replacement actuator, specify product model number and

serial number as shown on the valve name plate.

Troubleshooting

If you experience erratic control:

Oversizing causes cycling and hunting, and reduces •

the rangeability of the valve. Make certain that your

sizing is correct.

Steam traps downstream may require maintenance.•

Safety valve may be defective and need repair.•

There may be excessive foreign matter on the seats, •

and seats should be removed and cleaned. Valve

stroke may been readjustment.

Valve disc may not be moving freely. Check disc •

guide clearance and correct if needed.

If valve will not operate:

Electric power may be off or there may be a loose •

connection.

There could be a defective control device.•

The motor actuator may be defective and require •

replacement.

Ordering Spare Parts

Use only genuine Jordan Valve parts to keep your valve

in good working order. So we can supply the parts which

were designed for your valve, we must know exactly

which product you are using. By furnishing the following

information with your order, you will prevent delays and

errors: Serial number of your existing valve; Model number; Body size; Body material; End connections (ange

rating if applicable; Part name and quantity (see chart on

back page).

Page 4

Torque Requirements

5

3

2

1

4

6

3

7

5

2

1

6

8

4

6 bolts (or multiples) 8 bolts (or multiples)

Valve Size CI or BRZ DI, CS, SS

1/4” & 3/8” 70 in-lbs 150 in-lbs

1/2” – 2” 140 in-lbs 200 in-lbs

Page 5

Illustration & Part List

40

39

41

35

36

38

37

34

33

28

29

27

26

11

12

13

20

*

21

*

16

23

44

43

6

5

14

22

15

17

18

19

10

31

32

9

8

30

42

4

2

3

1

Item Description Qty Item Description Qty Item Description Qty

1 Body 1 16 Packing Follower 1 31 Nut 4

2 Cap 1 17 Packing 1 32 Lockwasher 4

3 Cap Screw 4-6 18 Packing Retainer 1 33 Jam Nut 1

4 Disc 1 19 Packing Spring 1 34 Adapter 1

5 Plate 1 20 Packing Stud 2 35 Rod End Bearing 1

6 Disc Guide 1 21 Packing Nut 2 36 Cam 1

7 Index Pin not shown) 1 22 Yoke 1 37 Bushing 1

8 Disc Pin 1 23 Socket Head Set Screw 4 38 Socket Head Set Screw 4

9 Locknut 1 24 Nameplate (now shown) 1 39 Socket Head Cap Screw 1

10 Stem 1 25 Drive Screw (not shown) 2 40 Lockwasher 1

11 Stem Connector 2 26 Actuator Stem 1 41 Retaining Ring 1

12 Lockwasher 1 27 Mounting Plate 1 42 Motor 1

13 Nut 1 28 Cap Screw 4 43 Stud 2

14 Bolt 1 29 Lockwasher 4 44 Nut 2

15 Packing Flange 1 30 Cap Screw 4

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

Bulletin IM-MK33-1208

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...