Page 1

I & M Mark 25

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Temperature Controllers must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or a

general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a

valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with long, trouble-free service if it is correctly installed and maintained.

Spending a few minutes now reading these instructions

can save hours of trouble and downtime later. When making repairs, use only genuine Jordan Valve parts, available

for immediate shipment from the factory.

Installation & Maintenance Instructions for

Mark 25 TempilotTM Temperature Controller

ing the response time. Turning the screw counterclockwise decreases the sensitivity by increasing the flow and

reducing the response time.

Sensitivity

The sensitivity of the Tempilot controller is adjusted by

turning the restriction screw. (The restriction screw is

factory set for air operation.) For water operation, the restriction screw should be opened a minimum of 1/2 turn

and recalibrated. Restriction screw must NEVER be fully

closed. Make adjustments slowly, allowing about two minutes after each adjustment for the controller to balance.

NOTE: If sensitivity is changed, controller must be recalibrated.

Operation

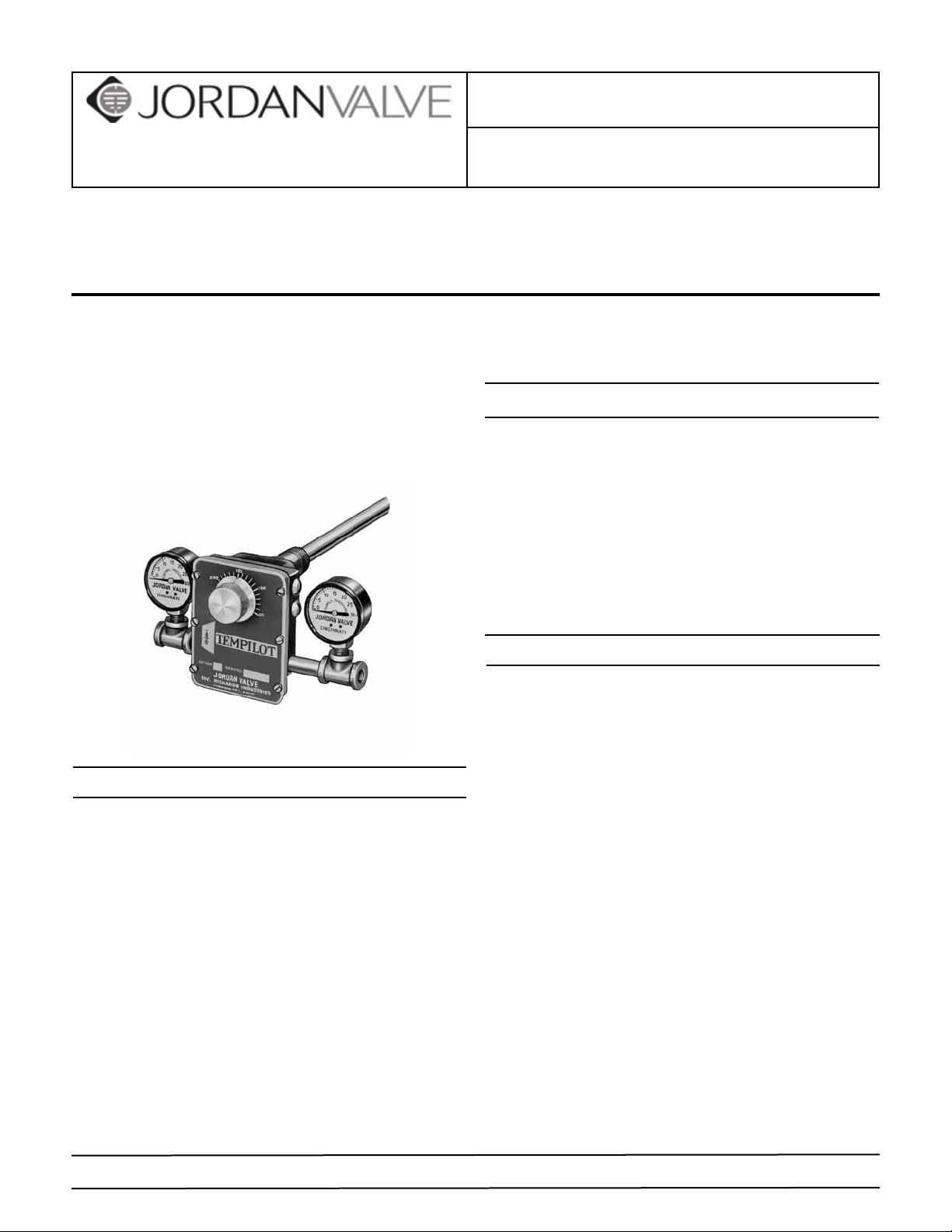

A temperature change in the medium being controlled

creates a change in length of the sensitive tube (1). An

increase in temperature lengthens the sensitive tube (1)

and moves the Invar rod (2) away from the lever (3). The

lever (4), which pivots at Point A, is moved to close the

exhaust valve (4) by spring (5). This permits the supply (air

or water) (S) to increase the pressure in the control line

(R) and close the normally open valve. A decrease in temperature shortens the sensitive tube (1) and moves the

Invar rod against the lever (3). The lever (3) moves against

the pressure spring (5), to open the exhaust valve (4). This

exhausts the pressure in the control line and opens the

valve.

The sensitivity adjustment screw (6) regulates the rate

of flow of the supply air (or water) to the controller to a

change in temperature. Turning the screw clockwise increases the sensitivity by reducing the flow and increas-

Installation

The Jordan Tempilot requires a clean, reliable supply of

compressed air or cold water at 15 - 25 pounds pressure.

Other fluids may be used, such as gas, oil, etc., providing

provision is made for safe disposal.

AIR OPERATION — The Tempilot should normally be installed in the horizontal position; however, other positions

may be used if the supply and control connections are

parallel with the ground and calibration is checked after

installation.

WATER OPERATION — The Tempilot must be installed in

the horizontal position with the drain connection at the

bottom. Drain piping should be 3/8” minimum for positive draining at all times.

1. Select the sensitive element location with care to assure satisfactory results. Bulb must project entirely

into the water or air being controlled.

2. Flush or blow out all lines before making final connections. Put supply pressure through all control

lines and check for leaks.

3. Always locate the Tempilot as close to the control

valve as possible. Piping between the Tempilot and

the control valve should be 1/8” brass pipe or 1/4”

PROTECT VALVES WITH LINE STRAINERS

Page 2

O.D. copper tubing.

4. The difference in height between the Tempilot and

the control valve should be kept to a minimum.

When the regulator is below the control valve, the

elevation cannot exceed 10’ with a 15 psi supply

pressure. If the Tempilot is above the control valve,

adjust springs on the valve to compensate for the

static head pressure.

Positions “B” and “D” (dotted)

show pivot point (B) and spring

location (D) for reverse acting

regulator.

A

B

3

C

D

2

Valve

(Normally

Open)

1

2. Install Lever (6). Tighten the Lever Pivot Screws (21)

as required. The Lever must be in the exact center

of the body and must move freely but without side

play. (For Water only — seal Lever Pivot Screws with

Loctite Grade E.)

3. Install Screws (22).

4. Install parts (8) and (9). (Note relationship for Direct

and Reverse Acting.)

5. Back up Adjustment Screw (5) until Collar (19) touches the Pivots on Lever (6).

6. Install Cover Assembly (2).

7. Install Adjustment Knob (3). The notch on Knob (3)

should be opposite the dial marking corresponding to the room temperature. Tighten the Knob Set

Screw very firmly.

8. Turn the Adjustment Knob to the desired control

temperature for an approximate calibration.

9. Recalibrate as required after the controller is installed

and connected to the supply and control lines.

5

6

R

4

S

Figure 1

Calibration

1. To calibrate the Tempilot, turn the adjusting knob

until a 7-1/2” psi control pressure shows on the

gauge.

2. Read the temperature at the bulb with an accurate

thermometer.

3. Loosen the set screw in the adjusting knob and turn

the adjusting knob to indicate the temperature at

the bulb.

4. Tighten the set screw.

5. Now set the Tempilot for the desired temperature for

your process.

Both Air and Water Controller

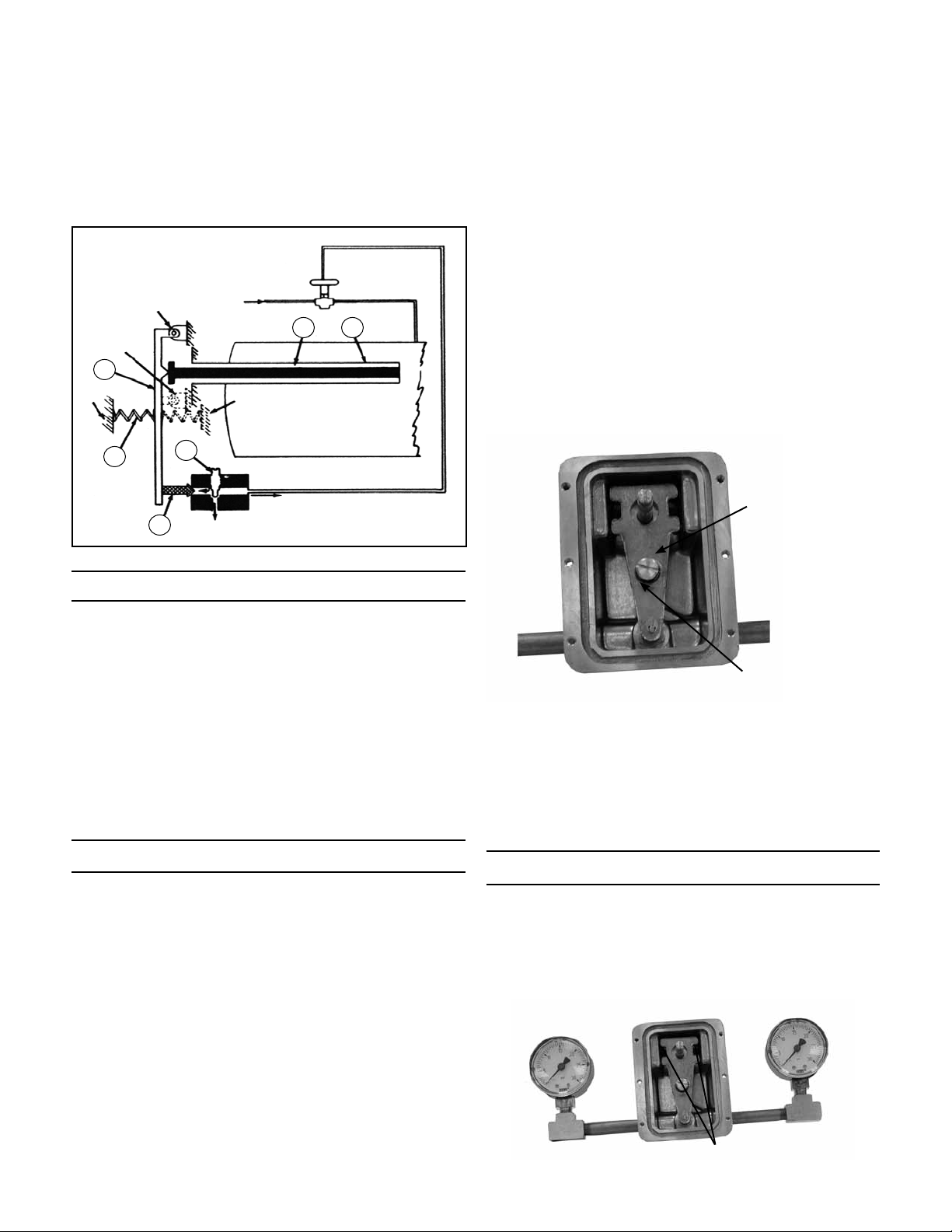

A. Disassembly (Refer to Figure 4 on page 3)

1. Remove Knob (3) after loosening its Set Screw.

2. Remove Cover Assembly (2).

3. Remove Lever Spring Retainer (8) and Lever Spring

(9).

4. Back up one Lever Pivot (21) and remove Lever (6).

5. Unscrew Sensitive Tube Assembly (20) from Body

(1).

Lever Spring

Retainer

Direct Acting spring

in front of lever. For

Figure 2

Reverse Acting, place

spring behind lever.

Please note Figure 2. This figure shows how the lever

spring and the lever spring retainer should be assembled

in front of the lever for direct acting regulators. Also note

that the lever pivots and the lever pivot set screws are assembled in the top two pivots for a direct acting Tempilot

Reversing Tempilot Action

Please note Figure 3. Since this is a reverse acting Tempilot, the lever spring retainer is in front of the lever, and

the lever spring is behind the lever. Also, the lever pivots

and the lever pivot set screws are in the lower two pivot

points.

Figure 3

B. Assembly

1. Install new Sensitive Tube Assembly (20) to body

(1).

Set Screws (Reverse Acting)

-2-

Page 3

Air Service Only:

1. Turn the Adjusting knob clockwise to remove tension.

2. Remove the adjusting knob set screw and remove

the adjusting knob (3).

3. Remove the cover screws (10) and the cover (2).

4. Remove the lever spring retainer (8) and lever spring

(9).

5. Relocate the lever pivot (21) to change the pivot

point.

6. Turn lever pivots in to be snug without binding.

7. Replace the lever spring retainer and lever spring to

obtain the desired action.

8. Replace the cover and the adjusting knob.

9. Recalibrate.

Figure 4

Direct Acting Pivot

AA

22

Reverse

Acting

Pivot

1/8” NPT Return

1/4” NPT Return

Ordering Spare Parts

Use only genuine Jordan Valve parts to keep your valve

in good working order. So we can supply the parts, which

were designed for your valve, we must know exactly which

product you are using. The only guarantee to getting the

correct replacement parts is to provide your Jordan Representative with the valve serial number. This number is

located on the valve identification tag. If the serial number

is not available, the parts needed for your valve might be

determined using the following information: Model number, Valve Body size, Plug Material and Seat Size, Spring

Range or Set Point, Trim Material, Part Name - Number

and Quantity (see parts list chart).

1/8” NPT Return

21

Section “A-A”

Air Operated

Note: Without a valve serial number, any parts ordered

incorrectly are subject to a minimum 25% restock charge

when returned.

-3-

Page 4

Illustration and Parts List

10

1

2

5

7

3

4

6

8

9

11

2-1/4”

13 15 16

12

1-19/32”

19

18

17

20

8

9

Reverse Acting

Spring Location

Water Operated

11-15/16”

30

18

17

Item Description Qty. Item Description Qty.

1 Body 1 13* Valve 1

2 Cover Plate 1 15 Valve Spring 1

3 Adjusting Knob 1 16* Valve Seat 1

4 Quad Ring 1 17 Restriction Screw 1

6 Lever 1 18* O-Ring 1

7 Set Screw 1 19 Thrust Collar 1

8 Spring Retainer Screw 1 20 Sensitive Tube Assembly 1

9 Lever Spring 1 21 Lever Pivot 2

10 Cover Screw 6 30* Insert 1

11 O-Ring 1 31 Sealing Screw 4

12* Retaining Ring 1 32* Gasket 4

* Recommended Spare Parts

Note: Accessory parts included with controller:

Pipe Nipple, QTY 2

1/8” Brass Tee, QTY 2

0-30 psi Gauge, QTY 2

Optional thermowell available is SST or Copper

Bulletin IM-MK25-1111

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...