Page 1

I & M Mark 2000

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve products must only be used, installed and repaired in accordance with these Installation &

Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event of leakage or other malfunction, call a qualied service person; continued operation may cause system failure or a general

hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disassembling a valve,

be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan Valve product will provide you with long,

trouble-free service if it is correctly installed and maintained. Spending a few minutes now reading these instructions can save hours of trouble and downtime later.

When making repairs, use only genuine Jordan Valve

parts, available for immediate shipment from the factory.

To Disassemble Actuator

Remove position indicator (24) from actuator.1.

Insert actuator removal tool or other suitable device 2.

and thread into actuator where position indicator

pin was located.

Thread tool completely into actuator. Next, 3.

compress the springs in the actuator by tightening

the wing-nut of the tool onto the actuator. NOTE: if

you do not have the actuator tool mentioned above,

a long screw with a bolt can be used to compress

the spring.

Once the springs are compressed, there will be a 4.

space between the ange (9) and the clip ring (20).

Use snap ring pliers or spanner wrench to remove 5.

the clip ring (20) from the bonnet (2).

Remove the bonnet from the actuator by slowly 6.

loosening the wing nut. BE SURE ACTUATOR

TOOL DOES NOT LOOSEN - TOOL COULD

BE FORCEFULLY EJECTED FROM ACTUATOR,

CAUSING INJURY TO PERSON OR PROPERTY.

Pay attention that the actuator tool doesn’t loosen 7.

when the wing-nut of tool is being loosened.

Once sufciently loosened and springs are relaxed, 8.

remove actuator tool from actuator.

At this time, the inside of the actuator will be 9.

exposed and seals can be exchanged.

To Access Seating Seal

To access the seating seal (7), simply loosen the 1.

bonnet section (2) from the ange (9). This can be

done after carrying out the previous steps from

actuator disassembly. If done before actuator is

disassembled, it is recommended to supply air to

the actuator to lift the seat from the valve body to

Installation & Maintenance Instructions for

Mark 2000 Angle Bodied Disc Valves - Air to Open

prevent damage to the seating seal (7).

Once the head section is loosened, remove 2.

actuator and piston rod from valve body.

Loosen seat retaining bolt (16) from valve disc (5) 3.

and remove seating seal (7).

Replace sealing for head section (22) if damaged. 4.

Use snap ring pliers or spanner wrench to remove 5.

the clip ring (20) from the bonnet (2).

To Access Packing Chamber

Note: Previous steps must be carried out beforehand.

Remove the piston (4) from the stem (3) by 1.

removing stem nut (21).

Pull the piston rod out of the bonnet (2) from 2.

below.

The ange (9) should then be removed from the 3.

bonnet (2).

The ange is assembled with an anti-loosening 4.

liquid to prevent it from becoming inadvertently

loosened. Use caution not to damage the

ange, especially at the sealing areas, when

disassembling.

Once the previous steps are completed, the 5.

packing chamber is now accessible.

Ordering Spare Parts

Use only genuine Jordan Valve parts to keep your valve

in good working order. So that we can supply the parts,

which were designed for your valve, we must know

exactly which product you are using. The only guarantee

to getting the correct replacement parts is to provide

your Jordan Representative with the valve serial number.

This number is located on the valve identication tag.

If the serial number is not available, the parts needed

for your valve might be determined using the following

information: Model Number, Valve Body Size, Seat

Material and Cv Rating, Spring Range and Set Point, Trim

Material, Part Name - Number and Quantity.

NOTE: Any parts ordered without a valve serial number

that are found to be incorrect are subject to up to a

minimum 25% restock charge when returned.

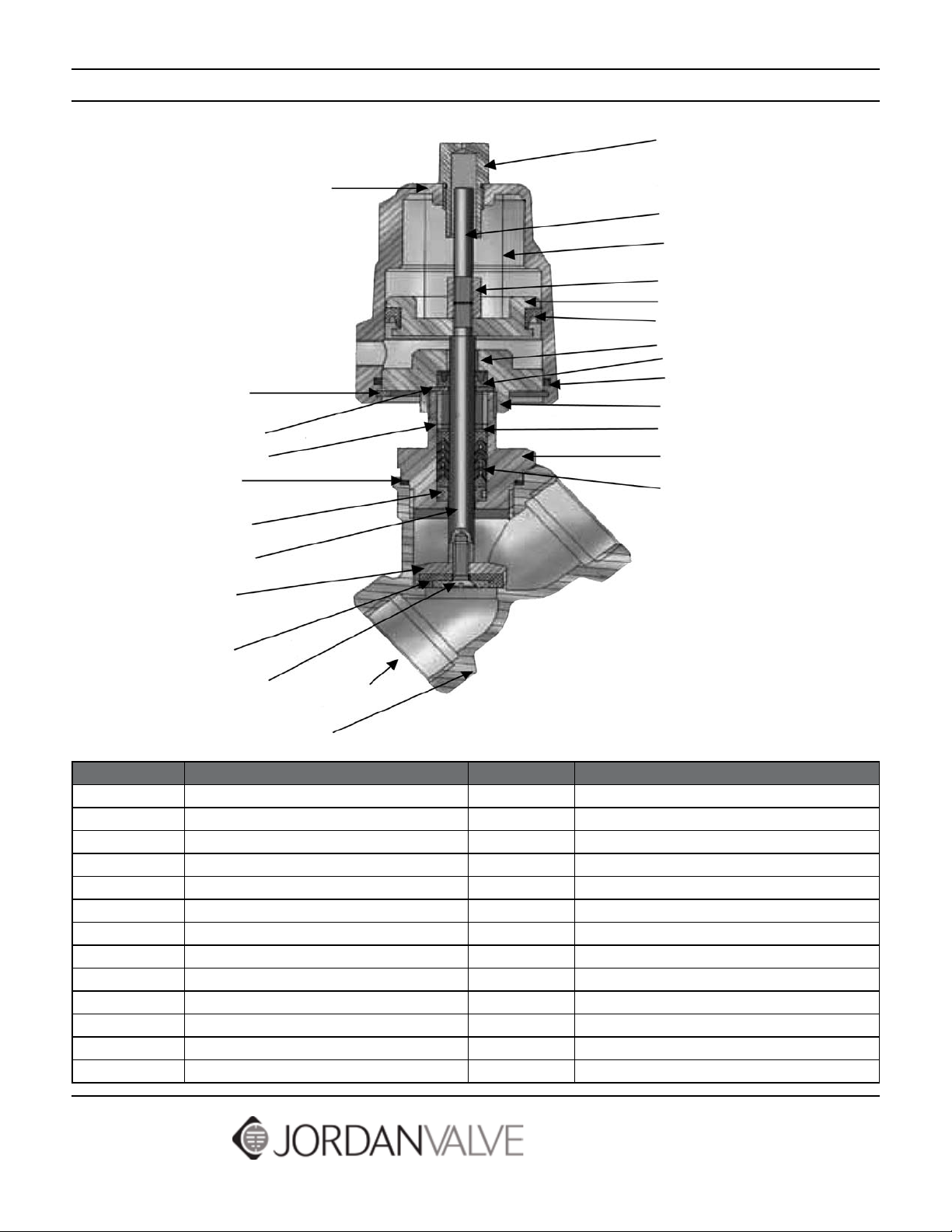

Page 2

22

20

14

10

12

Illustration and Parts List

25

8

24

23

21

4

18

11

17

19

9

13

2

15

3

5

7

16

1

Item Description Item Description

1 Body *14 Packing Wiper

2 Bonnet *15 V-Ring Packing

*3 Stem 16 Seat Retaining Bolt

4 Piston *17 Actuator Stem Seal

*5 Valve Disc 18 Actuator Piston Seal

7 Seat *19 O-Ring

8 Actuator Housing 20 Clip Ring

9 Flange 21 Stem Nut

10 Disc 22 Body Bonnet Gasket

11 Bushing 23 Spring

*12 Packing Spring 24 Position Indicator

*13 Packing Ring 25 Indicator Cover

* Recommended Spare Parts

Bulletin IM-MK2000-1009

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...