Page 1

I & M Mark 128PQC Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

InstallatIon

Warning:

Service conditions must not exceed the limits shown

on the valve nameplate, or those outlined in this

manual. Consequences could include bursting of

pressure-retaining parts and uncontrolled process

fluid, resulting in personal injury or property damage.

Control valves should also be protected from external

damages.

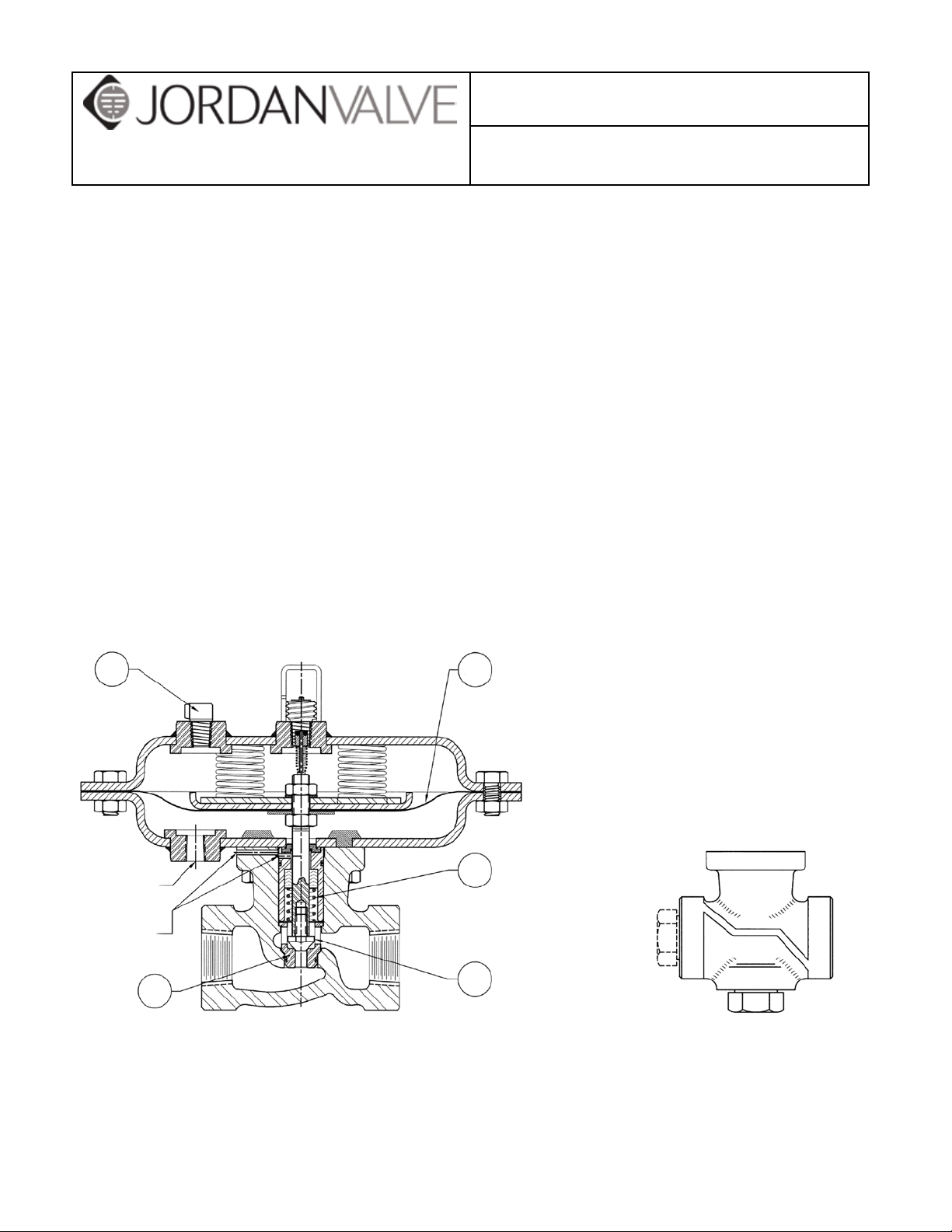

Prior to installing the Mark 128PQC Series Control

Valve, perform a complete inspection for damage,

and remove any foreign debris. Position the valve for

desired flow direction. If angle flow is required, switch

the pipe plug to left-hand connection. (Figure 2)

Installation & Maintenance Instructions for the

Mark128PQC Series Control Valves

The versatility of this valve allows for installation in any

orientation, with the standard method being with the

actuator above the body. Standard orientation is best

when an angle body or angle configuration has been

specified.

When installing the valve into the line, accepted piping

practices must be used. A three-valve bypass should

be used if continuous operation is required during

inspection or maintenance.

For a fail-close control valve, connect the input signal

line into the 1/4-inch NPT actuator connection (Figure

1) in the lower diaphragm case assembly. The input

signal pressure line should be installed in the upper

diaphragm case assembly of a fail-open control valve.

3

1/4 INCH NPT

PRESSURE

CONNECTION

LEAKOFF

VENTS

23

Mark 128PQC Control Valve with Fail-Close Action

Figure 1: Mark 128PQC Control Valve Typical Constructions

35

21

28

Detail of Mark 128PQC

Exterior

Page 2

Mark 128PQC SerieS Control ValVe

MaIntenance

Warning:

Prior to performing any maintenance, isolate the valve from

the process pressure. Vent control input signal pressure.

Relieve the process pressure and drain process media from

both sides of valve (Figure 5, Key 27). A sudden release

of pressure or fluid can cause personal injury or property

damage.

Scheduled inspections and maintenance are vital to continued operation of all pressure control valves and systems.

Parts are subject to wear and tear, and must be replaced

as necessary, depending on the intensity of service conditions. Unless the valve body requires maintenance or

replacement, it may remain in the pressure system or on the

vessel.

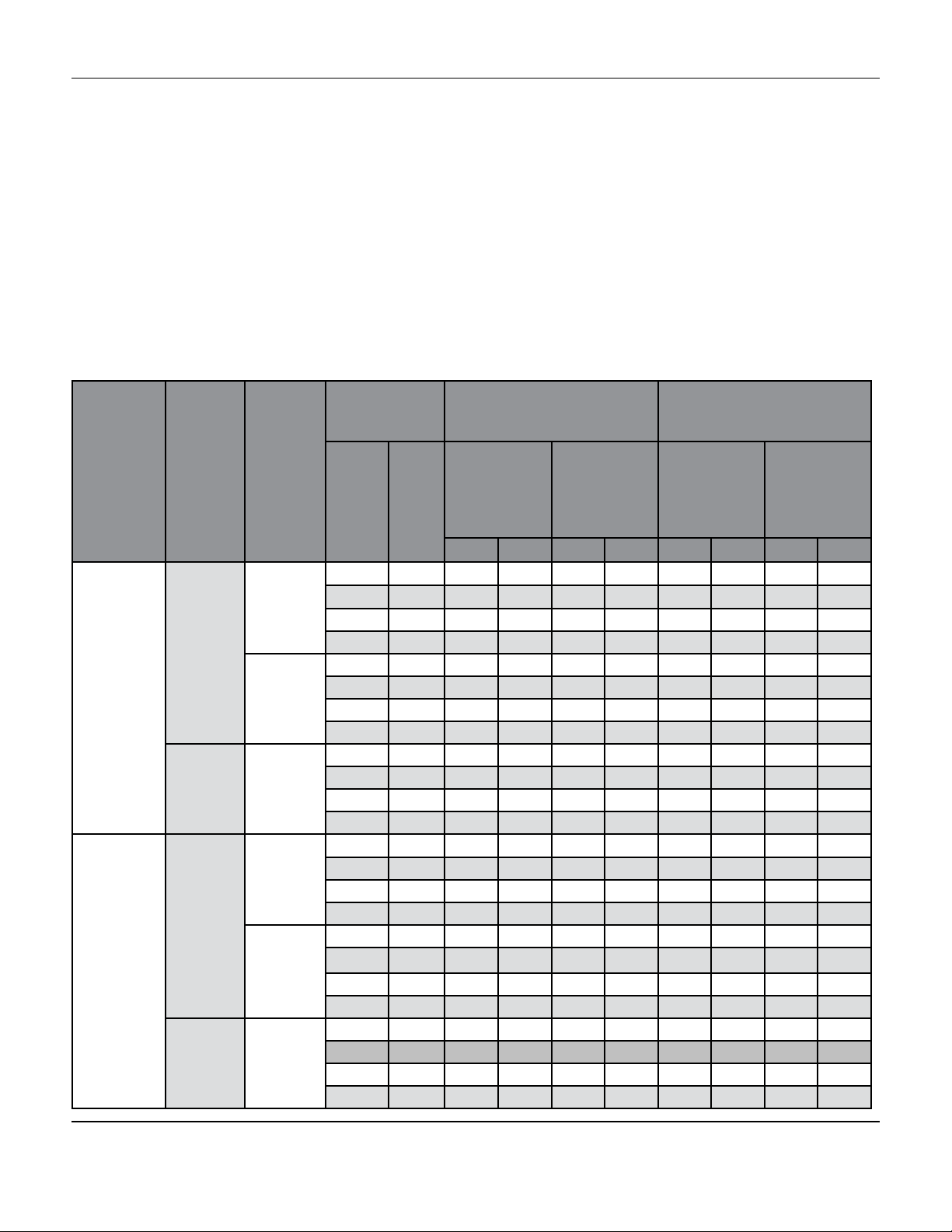

Table 1: Maximum Allowable Shutoff Pressure Drops

Cadmium Coloured Main Spring

At 20 Psig (1.4

bar) Operating

Seating

Metal

(All Types)

Soft

Actuator

Action

Fail Close

Fail

Open

Fail Close

Fail

Open

Flowing

Pressure

Drop

Tends

To:

Open

Valve

Close

Valve

Close

Valve

Open

Valve

Close

Valve

Close

valve

Port Diameter

ln mm

1/4 6.4 1510 104 3370 232 3880 233 3600 248

3/8 9.5 520 36 1340 92 1340 92 3120 215

1/2 12.7 220 15 690 47 700 48 1720 118

3/4 19.1 30 2.1 240 16 240 16 710 49

1/4 6.4 940 65 1860 128 1370 94 2920 201

3/8 9.5 1130 78 2450 169 1540 106 3300 227

1/2 12.7 1330 92 2920 201 1710 118 3600 248

3/4 19.1 2030 140 3600 248 2320 160 3600 248

1/4 6.4 170 12 350 24 --- --- --- ---

3/8 9.5 530 36 610 42 --- --- --- ---

1/2 12.7 540 37 1150 79 --- --- --- ---

3/4 19.1 1400 96 2910 200 --- --- --- ---

1/4 6.4 1000 69 1000 69 1000 69 1000 69

3/8 9.5 710 49 1000 69 1000 69 1000 69

1/2 12.7 400 28 830 57 830 57 1000 69

3/4** 19.1** 160 11 350 24 360 25 790 54

1/4 6.4 940 65 1000 69 1000 69 1000 69

3/8 9.5 1000 69 1000 69 1000 69 1000 69

1/2 12.7 1000 69 1000 69 1000 69 1000 69

3/4** 19.1** 1000 69 1000 69 1000 69 1000 69

1/4 6.4 560 39 660 45 --- --- --- ---

3/8 9.5 480 33 960 66 --- --- --- ---

1/2 12.7 540 37 1000 69 --- --- --- ---

3/4*** 19.1** 1000 69 1000 69 --- --- --- ---

Replacing Packing and Trim

Follow these procedures when replacing the entire packing and trim assembly or individually replacing packing

and trim parts. Unless otherwise indicated, key numbers in this section reference Table 2 for parts listings

for replacement packing and trim assembly, Figure 2 for

packing and trim assembly key numbers and Figure 4

control valve assembly key numbers.

1. Detach the control valve from all pressure, and

release pressure from valve body and actuator.

Ensure the valve is completely closed.

2. Remove the four nuts (Key 32) from the screws

of the lower diaphragm casing. After discon necting the input signal tubing, remove

the actuator from the valve body, along with at tached trim parts.

14A8831X012 Red Main Spring 14A9077X012

At 35 Psig (2.4

Signal

Pressure

(2 Springs

Req’d)

Psi Bar Psi Bar Psi Bar Psi Bar

bar) Operating

Signal

Pressure

(4 Springs

Req’d)

At 20 Psig (1.4

bar) Operating

Signal

Pressure

(2 Springs

Req’d)

At 35 Psig (2.4

bar) Operating

Signal

Pressure

(4 Springs

Req’d)

-2-

Page 3

Mark 128PQC SerieS Control ValVe

Replacing Packing and Trim continued,

3. Accessible areas should be cleaned at this

stage, and all necessary maintenance perf ormed. The actuator and attached trim parts

can be turned over and held by the valve body.

4. To separate trim and access packing parts or

seal O-rings, first loosen and remove the valve

plug (Key 25) and remove the packing box

washer (Key 27).

5. Remove the packing box (Key 28), O-ring

retainer (Key 18), stem O-ring (Key 19) and

diaphragm casing O-ring (Key 31) off the stem.

6. Install replacement parts as necessary.

6.1. If a complete packing and trim assem bly is being installed, remove the as sembly from the tube (Key 37), keepi ng the web sleeve (Key 39) on the

assembly so the parts remain in place.

Roll the sleeve back as necessary dur ing installation.

6.2. Continue pushing the assembly onto

the stem until the valve plug and cage

are pushed away from the packing box

washer or wiper ring. Roll the web

sleeve back into place just past the

packing box.

6.3. If installing nitrile/cotton packing, the

packing rings may be lubricated with

silicon based product.

7. Slide the packing box onto the stem until the

packing box, the O-ring (Key 19) and the O ring retainer (Key 18) and the diaphragm casi ng O-ring (Key 31) are sealed against the dia phragm casing.

7.1. Ensuring proper positioning of the O rings will prevent them from being cut

when other parts are compressed

against them.

7.2. Advance the packing spring washer

(Key 29) , packing spring (Key 21),

second packing spring washer, wiper

ring and packing box washer

(Key 27, if included in the assembly)

down onto the stem.

8. For installation of the packing and trim as

sembly, it is necessary to remove the sleeve,

cage puller (Key 40) and cage (Key 23) from

the valve plug depending on individual valve

configuration.

9. Fix the valve plug onto the stem, rotating the

plug until the shoulder makes snug contact

with the stem. No further tightening is neces sary.

10. To replace the cage or access the cage O-ring

(Key 22), remove the cage from the body (Key

26) using the cage puller or a wire hook. Re placement parts can be installed as necessary.

11. Attach the actuator and trim to the valve body

(Key 26), paying special attention to the cage

O-ring to prevent damage. Thread the four

nuts (Key 32) to the lower diaphragm casing

assembly screws. Nuts must be tightened to

15-foot-pounds (20N•m).

12. Reconnect the input signal tubing to the actua tor connection of the appropriate diaphragm

casing.

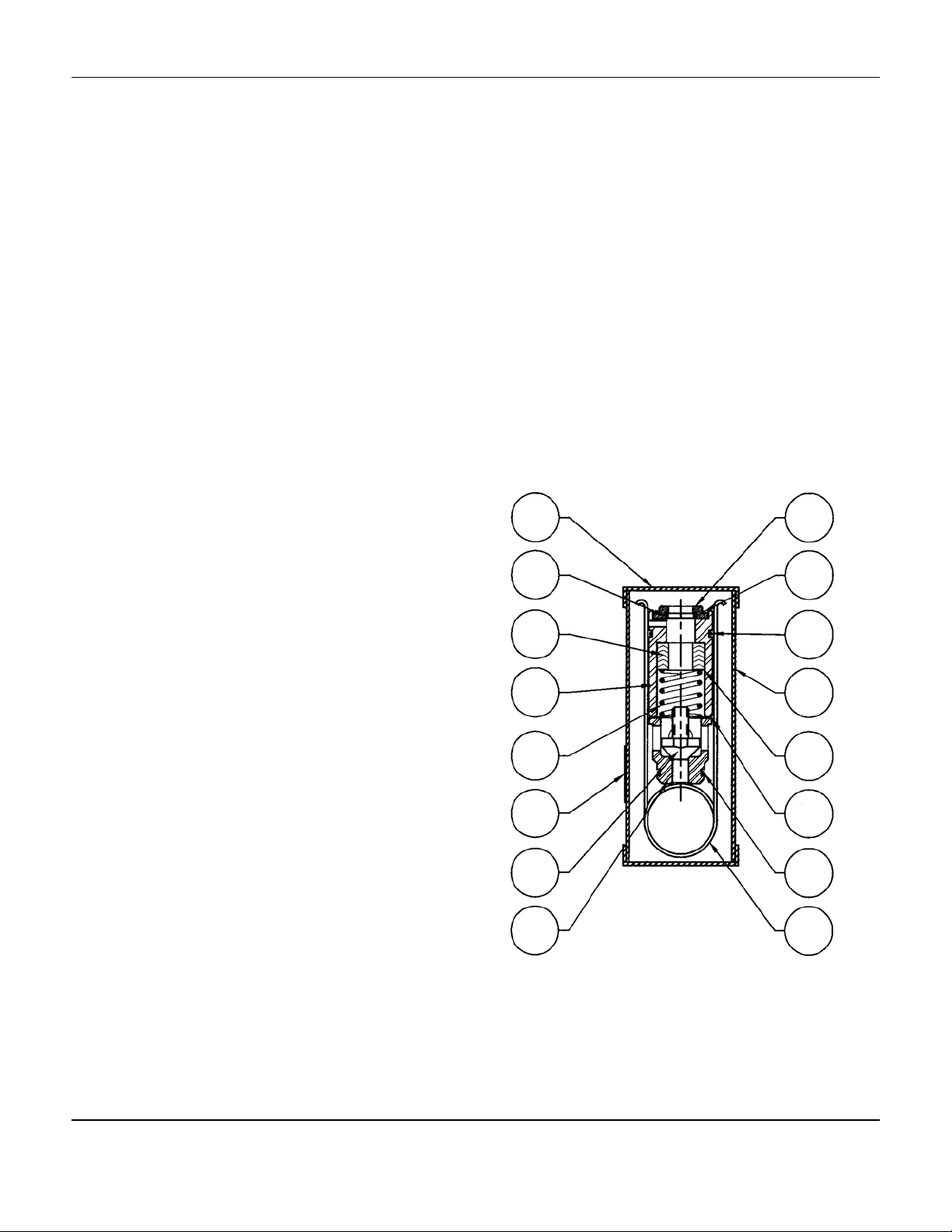

37

19

30

28

21

38

25

23

Figure 2: Replacement Packing and Trim

Assemblies for Metal Seated Constructions

18

31

20

39

29

27

22

40

-3-

Page 4

Mark 128PQC SerieS Control ValVe

Changing Main Spring Range

Unless otherwise indicated, refer to Table 2 for parts

listings for replacement packing and trim assembly,

Figure 2 for packing and trim assembly key numbers

and Figure 4 for control valve assembly key numbers.

1. Isolate off the control valve from all pressure,

and release pressure from valve body and

actuator.

2. Release pressure and drain the process

media from both sides of the valve body. En sure the valve is completely closed.

3. If necessary, disconnect the input signal tub ing; remove the diaphragm casing nuts (Key

15), cap screws (Key 14) and upper dia phragm casing (Key 1).

4. For fail-close action applications, install main

springs (Key 12), using quantities and de scriptions as outlined in Table 2.

Note: It is important to avoid loosening the

stem-nut (Key 15), as this may prevent the

valve from shutting off or from fully opening at

full pressure, and resulting in the need for

complete disassembly of the control valve to

properly install the stem and diaphragm.

5. For fail-open applications, unfasten the lock

nut (Key 16), remove the flat washer (Key

33), diaphragm (Key 35), diaphragm plate

(Key 34), spring plate (Key 2), and main

springs (Key 12).

6. Refer to Table 1 and install main springs as

indicated.

7. Reassemble the removed parts (Keys 2, 34,

35, 33, and 16). The locknut (Key 16) must

be tightened to 12 foot-pounds (16 N•m).

8. Attach the upper diaphragm casing using the

cap screws, and casing nuts, tightening in an

even crisscross pattern to avoid crushing the

diaphragm. Tighten to 15 foot-pounds

(20 N•m).

9. Reconnect the input signal tubing to the

actuator connection of the appropriate dia phragm casing.

Reversing Action or Replacing Actuator Parts

Unless otherwise indicated, refer to Table 2 for parts

listings for replacement packing and trim assembly,

Figure 2 for packing and trim assembly key numbers

and Figure 4 for control valve assembly key numbers.

1. Isolate the control valve from all pressure,

and release pressure from valve body and

actuator and ensure the valve is completely

closed.

2. Remove the input signal tubing, diaphragm

casing nuts (Key 15), cap screws (Key 14)

and upper diaphragm casing (Key 1).

3. Remove the following:

3.1. Main springs (Key 12)

3.2. Stem nut (Key 15)

3.3. Locknut (Key 16) and lock washer

(Key 4)

3.4. Spring plate (Key 2)

3.5. Diaphragm plate (Key 34) and

diaphragm (Key 35)

3.6. Flat washer (Key 33)

4. Unscrew the four nuts (Key 32) from the

screws of the lower diaphragm casing. After

disconnecting the input signal tubing,

remove the actuator from the valve body

along with attached trim parts.

5. Remove the following:

5.1. Valve plug (Key 25)

5.2. Packing box washer (Key 27)

5.3. Slide the packing box (Key 28), O ring retainer (Key 18), stem O-ring

(Key 19) and the diaphragm casing

O-ring (Key 31) off the stem.

6. Replace the valve stem, bottom stem nut or

lock nut (Key 15 or 16) as required.

7. Refer to Figure 3 and ensure that the lower

shoulder of the bottom stem nut (Key 15) (for

fail-open assembly) or locknut (Key 16) (for

fail-close assembly) is the proper distance

from the plug end of the stem.

-4-

Page 5

Mark 128PQC SerieS Control ValVe

Reversing Action or Replacing Actuator Parts

cont’d

8. Perform the following assembly sequenc es as necessary to achieve the required

control valve action:

8.1. Fail–close action: install the follow

ing parts: flat washer (Key 33),

diaphragm (Key 35), diaphragm

plate (Key 34), spring plate (Key

2), lock washer (Key 4) and stem

nut (Key 15). Tighten stem nut

to 12 foot-pounds (16 N•m).

8.2. Fail-open action, install the follow ing parts: lock washer (Key 4),

spring plate, diaphragm

plate, diaphragm, flat washer (Key

33) and locknut (Key 16). Tighten

the lock nut to 12-foot-pounds (16

N•m).

9. With fail-open application, place the main

springs (Key 12) into the lower diaphragm

casing, ensuring that the lower ends of the

springs rest over the weld stud heads of

the lower diaphragm casing.

10. Following steps 6 through 10 of the “Re-

placing Packing and Trim” section, install

packing and trim parts to secure the stem.

11. When reversing action from previous direc tion, move the vent (Key 3) to the 1/4-inch

NPT actuator connection of the lower

diaphragm casing (for fail-open action) or

upper diaphragm casing (for fail-close ac tion).

12. For fail-close application, place the main

springs so that they rest in the spring plate

holes and will not touch the upper dia-

phragm casing vent boss.

13. Mount the upper diaphragm casing, cap-

screws, and casing nuts, tightening in an

even crisscross pattern to avoid crush

ing the diaphragm. Tighten to 15

foot-pounds (20 N•m).

14. Replace the actuator and attached trim

parts into the valve body (Key 26) with nuts

(Key 15) to the lower diaphragm casing

integral assembly screws. Tighten nuts to

15 foot-pounds (20 N•m).

15. Reconnect the input signal tubing to the

actuator connection of the appropriate

diaphragm casing.

Parts orderIng

Mark 128-PQC valves have individual serial numbers,

found on the valve nameplate. Please refer to that

number when ordering parts or contacting your Jordan

Valve Sales Representative. Individual parts numbers

are listed as follows. Please include these numbers

when ordering replacement parts.

-5-

Page 6

Mark 128PQC SerieS Control ValVe

Table 2: Replacement Packing and Trim Assembly Part Numbers

TFE V-Ring Packing, Nitronic 50 SST

Valve Plug and Cage, and Inconel

X750 Packing Spring

Mark 128 PQC

Port Diameter

ln mm

TFE Ring Packing and Heat-Treated

44OC SST Valve Plug and Cage

Mark 128PQC 17-7PH SST

Packing Spring

1/4 6.5 15A2611X012 15A2611X042

3/8 9.5 15A2611X022 15A2611X052

1/2 12.7 15A2611X032 15A2611X062

2

34

4

15

Fail Close Assembly

35

A

Dimension

33

16

33

35

16

A

Dimension

34

2

4

15

Figure 3: Stem and Diaphragm Assembly Dimensions

Fail Open Assembly

Valve

Design

Mark

128PQC

Dimension A

Fail-Open Fail-Close

ln. mm ln. mm

2.72 69.1 2.46 62.5

-6-

Page 7

Mark 128PQC SerieS Control ValVe

7 8

6

5

4

3

2

1

9

10

11

12

14

35

34

33

31

30

29

28

27

26

25

Mark 128PQC Control Valve: Fail-Closed with Cage-Style Metal Seat

and Single TFE-V-Ring Packing

7 8

5

16

33

34

35

1

9

10

11

12

24

23

14

15

16

17

18

19

20

21

22

27

15

2

4

3

Fail-Open Actuator Detail

Figure 4: Typical Mark 128PQC Series Control Valve Assembly

-7-

25

Mark 128PQC Cageless

Soft-Seat Detail

Page 8

Mark 128PQC SerieS Control ValVe

Parts lIst

Key Description Part Number

1 Upper Diaphragm Casing, Steel 24A8816X012

2 Spring Plate, Zinc Plated Steel 14A8819X012

3 Vent Assembly 1C8937000A2

4 Washer, Steel 1A742328992

5 Indicator Bushing, 316 SST 13A2323X012

6 Indicator Cover, Plastic 15A1580X012

7 Travel Indicator Disc Nut, Plastic 1F730506992

8 Machine Screw, SST 14A8818X012

9 Indicator Fitting SST 15A0726X012

10 O-Ring, Nitrile 1H292606992

11 Spring, 302 SST 16A0431X012

12 Main Spring, Cadmium Plated Steel See Table 2

13 Nameplate, Aluminum 24A7156X012

14 Cap Screw, Plated Steel (2 req’d) 1E760324052

15 Hex Nut, Cadmium Plated Steel (17 req’d) 1A346524122

16 Locknut, Plated Steel 15A7591X012

17 Lower Diaphragm Casing, Steel 24A8810X012

18 O-Ring Retainer, Polyethylene Mark 128PQC 14A9053X012

19 O-Ring, Nitrile Mark 128PQC 1P420706992

20 O-Ring, Viton Mark 128PQC 1U841806382

21 Spring Mark 128PQC Inconel X750 15A1809X012

22 O-Ring, Nitrile Mark 128PQC 11A8741X012

316 SST Mark 128PQC

23 Cage

Austenitic SST w/

Tungsten Carbide

Seating Surface

24 Pipe Plug, Steel 1A794728992

Metal Seat

25 Valve Plug

Composition

Seat, Austenitic

SST/polyethylene

Mark 128PQC

Mark 128 PQC

1” Body

Mark 128 PQC

1” Body

1/4” (6.4 mm) 14A8823X022

3/8” (9.5 mm) 14A8805X022

1/2” (12.7 mm) 14A7157X022

1/4” (6.4 mm) 15A6800X012

3/8” (9.5 mm) 15A6801X012

1/4” (6.4 mm)

and 3/8” (9.5

mm) port

1/2” (12.7 mm)

port

1/4” (6.4 mm) through 1/2” (12.7 mm) port 15A3199X012

3/4” port 15A3197X012

316 SST 16A2087X012

Austenitic SST w/

Tungsten Carbide

Seating Surface

316 SST 14A6618X012

15A6804X012

Valve Plug Stem, 316 SST 1” Body, Mark 128PQC 14A8806X012

26 Valve Body, WCB Steel 1” NPT, Mark 128PQC 24A8802X012

27 Packing Box Washer, SST 1/2” (12.7 mm) or smaller port 14A6617X012

3/4” (19.1 mm) port 14A8807X012

28 Packing Box, SST Mark 128PQC 14A8809X012

29 Washer, SST (2 req’d) Mark 128PQC 14A8808X012

-8-

Page 9

MK128PQCIM/0314/2K

Mark 128PQC SerieS Control ValVe

Parts lIst cont.

Key Description Part Number

Complete Set 14A8812X012

30 Packing Set, TFE Mark

128PQC

31 O-Ring, Nitrile 13A1584X012

33 Washer, Cadmium Plated Steel 14A9770X012

34 Diaphragm Plate, Zinc Plated Steel 14A8814X012

35 Diaphragm, Neoprene w/nitrile insert 14A8813X012

37 Paper Tube ---

38 Paper Label ---

39 Protective Sleeve-Web ---

40 Cage Puller 15A2525X012

Keys 5, 7, 8, 9, 10, 11

Complete Assembly 35A1588X0A2

Individual

Parts

Male Adaptor 1J227206242

V-Ring (4 req’d) 1J255206992

Female Adaptor 1J233201012

Wiper Ring 1R2516X0012

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...