Page 1

I & M 667M Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

All Jordan Valve actuators are to be installed and

maintained in accordance with instructions supplied

by Jordan Valve.

This manual includes information on installing, maintaining and adjusting the 667M Actuator, sizes 30 to

70. Part numbers for the entire assembly is also included. For information on other equipment used with

these actuators, consult the appropriate manuals.

InstallatIon

Installation & Maintenance Instructions for the

667M Series Diaphragm Actuator

6. Align the indicator disc with the travel side on

the actuator by adjusting the locknuts.

7. Raise the valve plug until the travel disc aligns

with the top of the scale (full travel).

8. Clamp the actuator and valve body stems

between the two stem connector halves. Insert

and tighten both stem connector cap screws.

Note: Avoid clamping the tip of either the valve stem

or the actuator stem in the stem connector. Failure

to completely clamp the stems may strip the threads

and affect proper operation. The length of each stem

clamped in the stem connector should be equal to or

greater than the diameter of that stem.

The 667M Diaphragm Actuator is usually delivered

mounted on a Jordan Valve valve body. When installing the valve body into the pipeline, consult the

instructions for that particular valve body.

Should you have any questions during the installation

procedure, consult your Jordan Valve Representative.

Actuator Mounting

1. Install the stem locknuts onto the valve stem

and place the travel indicator disc onto the

locknuts.

2. If the valve is direct-acting, push the valve

stem down to close the valve. If the valve is

reverse-acting, push the valve stem down to

open the valve.

3. Place the actuator onto the valve bonnet. If

necessary, use a hoist or lift the actuator in

order to slip the yoke locknut over the valve

stem.

4. Screw the yoke locknut onto the bonnet secur ing the actuator to the bonnet.

5. Apply required supply pressure to actuator. If

using a 6-30 signal, apply 35 psi. If using a

3-15 signal, apply 20 psi to move the actuator

stem to the top of the travel.

9. Lift the travel indicator disc to the stem

connector and thread the stem locknuts against

the stem connector.

10. Realign the travel indicator scale to show the

valve position.

Loading Connection

1. The loading pressure is connected to the 1/4 inch NPT connection in the side of the yoke.

2. For the 667M Series Actuator Size 70, re move the 1/4-inch bushing in the 1/2-inch NPT

female connection to increase the connection

size if desired. Piping or tubing can be used,

but should be kept as short as possible to

avoid transmission lag in the control signal. If

an accessory is attached to the actuator ensure

that it has been properly secured.

3. If the valve positioner is provided as part of the

original equipment, the loading pressure con nection will be made at the Jordan Valve manu facturing facility.

4. Check the valve stem travel by cycling the

actuator several times. Ensure that the proper

travel occurs when the correct pressure range

is applied to the diaphragm.

Page 2

667M SerieS DiaphragM actuator

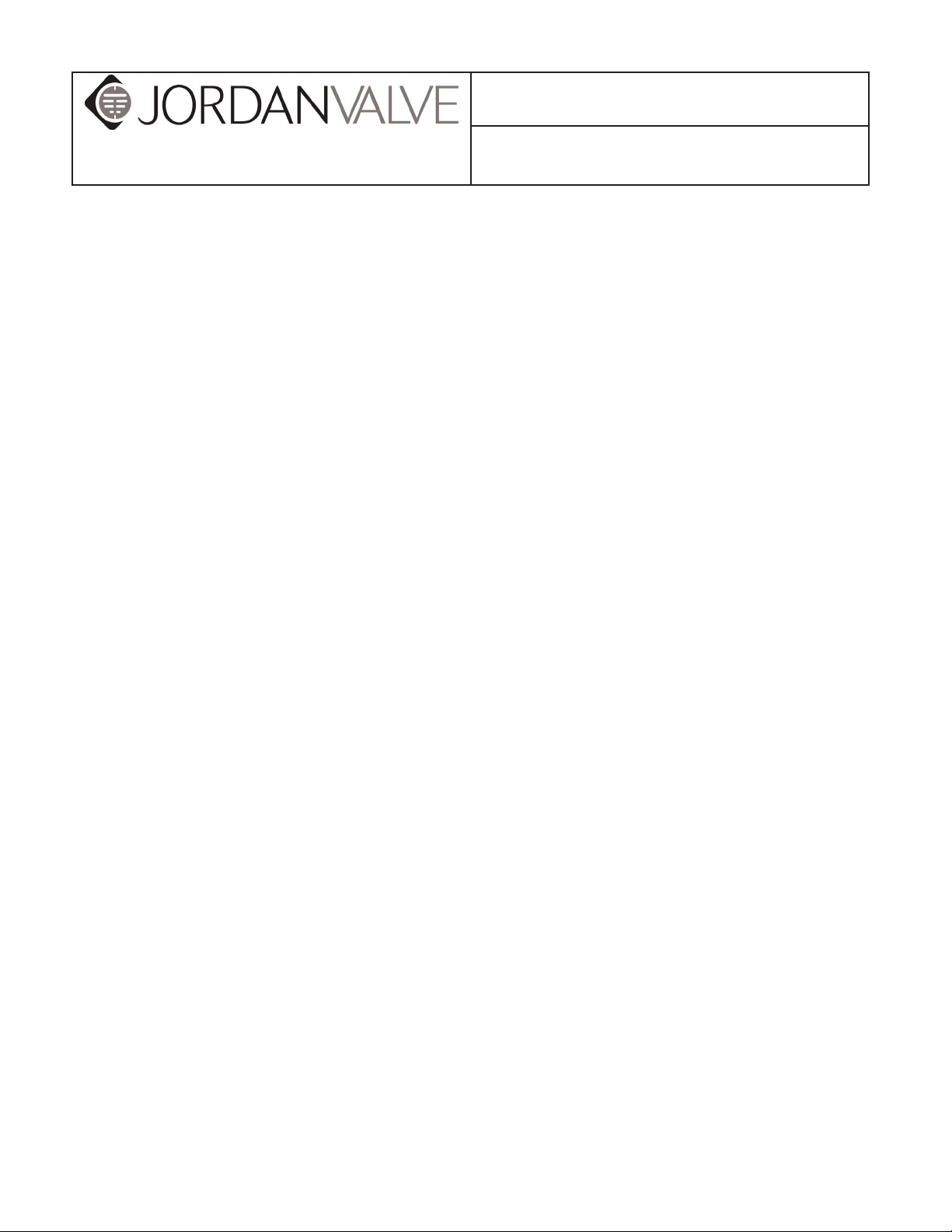

Figure 1: Schematic of 667M Actuator

Loading Connection cont’d

5. If the valve stem travel or pressure range is in

correct, refer to the “Adjustments” section of this

manual.

Do not place the valve in service if it is not responding

properly to diaphragm loading pressure changes.

1. Loosen and back off the stem locknuts and

indicator disc from the stem connector.

2. Loosen the stem connector cap screws.

Note: Do not use wrenches or other tools directly on

the valve stem as this could cause damage to the

stem surface and valve packing.

3. Tighten the locknuts (Keys 14 and 20) and

complete the adjustment by either screwing the

valve stem into the stem connector to lengthen

travel or out of the stem

connector to shorten travel.

4. Cycle the actuator to ensure that the correct

travel has been achieved and repeat the

adjustment if necessary.

5. When the correct travel has been reached

tighten the stem connector cap screws.

6. Raise the travel indicator disc by threading the

stem locknuts against the stem connector.

7. Adjust the travel scale to match the disc.

Spring

For ease of service, ensure that the control valve is located for easy access and serviceability with room above

for accessibility. Ensure that sufficient room is provided

below should removal of the actuator and valve plug be

necessary.

adjustments

Travel

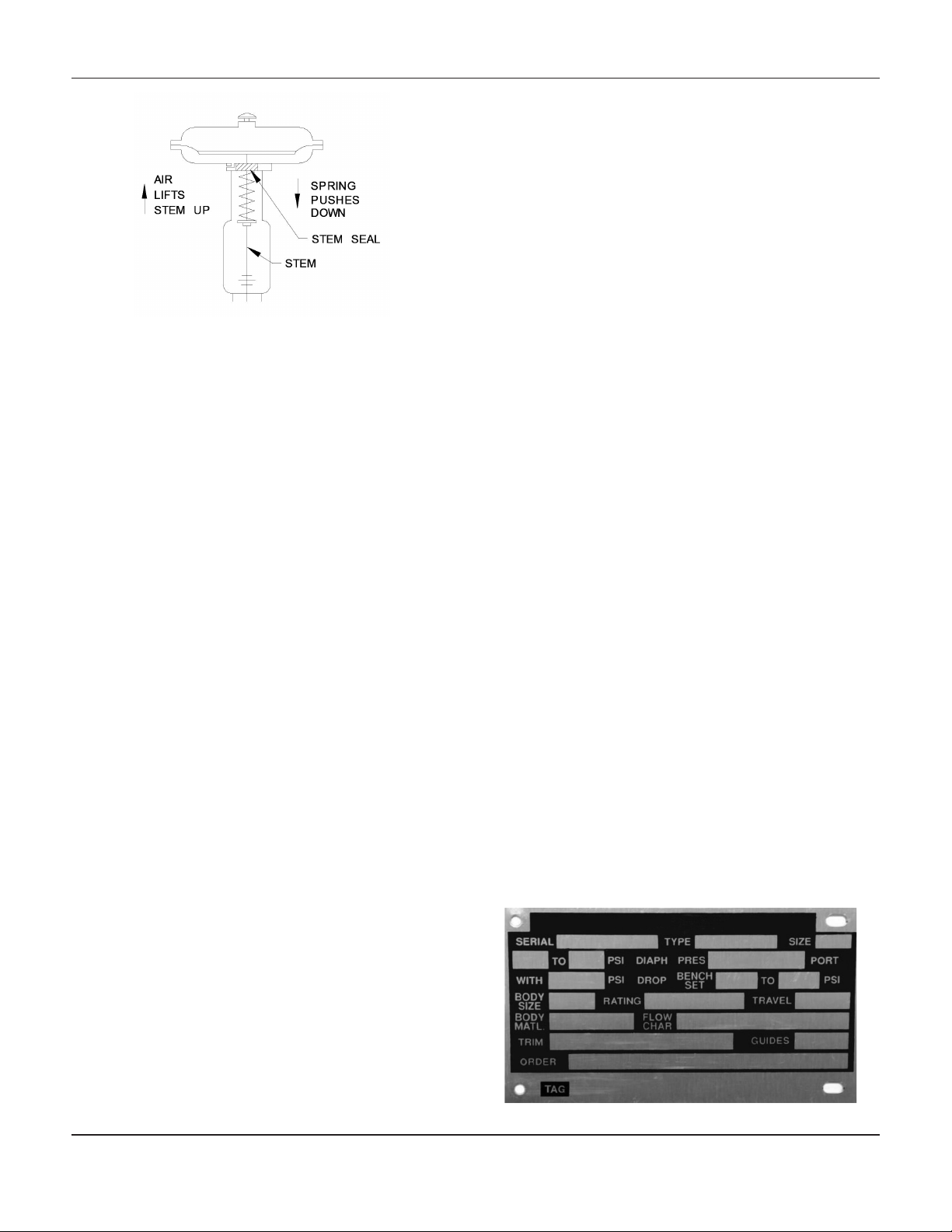

Refer to the nameplate on the yoke of the actuator for

details on the specific construction and operating range

of the control valve assembly.

The requirements of your specific application will dictate

the spring and diaphragm used in your 667M Actuator, and when in service, the actuator should create full

travel of the valve plug when diaphragm pressure is

applied according to the range indicated on the name

plate. Generally, the diaphragm pressure range is 3 to

15 PSI or 6 to 30 PSI, but other ranges may be used.

If the motion during the actuator travel differs from the

travel stamped on the actuator nameplate, adjust according to the following directions. In order to adjust

the travel of a direct-acting valve, slightly pressure the

actuator to move the valve plug off of the seat. This

reduces the chance of damaging the valve plug or seat

during adjustments.

If the loading pressure range applied to reach the desired travel differs from that specified on the nameplate,

a spring adjustment is required.

Check the “Bench Set” pressure range on the nameplate

when the valve contains no pressure and the packing is

loosely inserted in the bonnet. Refer to the “Diaphragm

Pressure” range on the nameplate when the valve is

controlling the specified pressure drop and the packing

is tightened to stop leaks around the stem.

1. Monitor the loading pressure while making

adjustments. Be sure not to exceed the

pressure specifications of either

the loading regulator or the actuator casings.

2. Each actuator spring has a fixed pressure span.

Changing the spring compression shifts the

span up or down to make the valve

travel coincide with the loading pressure range.

-2-

Figure 2: Nameplate on the 667M Actuator

Page 3

667M SerieS DiaphragM actuator

Spring Adjustments cont’d

3. To shift the span up, turn the spring adjustor

(Key 11) into the yoke. To shift the span

down, turn the spring adjustor out of the yoke.

For operation of the 667M Diaphragm Actuator the

actuator stem and valve plug stem must move freely in

response to the loading pressure change on the diaphragm.

maIntenance

Actuator parts are subject to normal wear and tear and

should be inspected regularly. The frequency of inspection and replacement of parts is dependent on the

severity of operating conditions.

WARNING:

A sudden release of pressure or any uncontrolled

process uid can cause personal injury or damage to

property. Prior to any disassembly, be sure to:

• Isolate the valve from the process,

• Release all process pressure

• Vent the actuator loading pressure, and

• Relieve all spring compression.

Disassembly

Although the following instructions describe how the

667M Diaphragm Actuator can be completely disassembled, when inspection or repairs are required, only

disassemble those parts required to accomplish the job.

Key numbers refer to Figures 3 and 4.

1. Bypass the control valve and reduce the loading

pressure to atmospheric.

2. Remove the tubing or piping from the con-

nection in the top of the yoke (Key 9). For top-

loaded construction also remove the piping or

tubing from the connection in the upper

diaphragm casing (Key 7).

3. Thread the spring adjustor (Key 2) off the stem

(Key 3) to remove all spring compression.

4. If necessary remove the actuator from the valve

body by separating the stem connector (Key 21)

and removing the yoke locknut.

5. Remove the spring adjustor (Key 2) from the

actuator stem (Key 3) and lift the spring

seat and spring (Keys 4 and 1) out of the yoke.

6. Remove the diaphragm casing cap screws and

nuts (Keys 10 and 14) and lift off the upper

diaphragm casing (Key 7).

7. Remove the following parts: diaphragm (Key 6),

diaphragm plate (Key 5), spacer (Key 32),

cap screw (Key 11) and actuator stem (Key 3).

Be careful not to damage the O-rings (Key 25)

when pulling the threads of the actuator

stem through the seal bushing (Key 24).

Remove the stem through the housing

of the yoke so as not to pull the threads through

the seal bushing.

8. Separate the parts of this assembly by removing

the cap screw (Key 11).

9. To remove the seal bushing, remove the snap-

ring (Key 30) and lift out the bushing.

10. Remove the cap screws (Key 19), the lower dia-

phragm casing (Key 8) and the gasket (sizes 30

through 60) or O-ring (size 70) (Key 28).

11. If necessary, the down travel stops can be re-

moved (Key 33).

Assembly

1. Place a new gasket or O-ring (Key 28) on the

yoke (Key 9) and apply lubricant to the O-ring.

2. Position the lower diaphragm casing (Key 8) on

the yoke, align the holes and insert and

tighten the cap screws (Key 19).

3. If the down travel stops (Key 33) were removed,

insert and tighten them.

4. Coat the O-rings (Keys 28 and 29) with lubricant

and place them in the seal bushing (24).

5. Fill the seal bushing with lubricant, slide the

bushing into the yoke (Key 9) and install

the snap ring (Key 30).

6. Insert the actuator stem (Key 3) through the

spring housing of the yoke, then add

the lower diaphragm plate (Key 29), diaphragm

(Key 6), diaphragm plate (Key 5), and the travel

stop cap screw and spacer (Keys 11 and 32).

7. Place this assembly in the actuator, being care

ful when pushing the actuator stem through the

seal bushing that the threads do not damage the

O-rings.

Note: Over tightening the diaphragm cap screws and

nuts can damage the diaphragm. Do not exceed 20

foot-pounds (27 Newton meters) torque.

8. Install the upper diaphragm casing (Key 7) and

secure with cap screws and nuts (Keys 10 and

14). Tighten evenly using a crisscross pattern to

ensure a proper seal.

9. Install the actuator spring (Key 1) and spring

seat (Key 4). Apply lubricant to the threads of

the actuator stem and to the surface of

the spring adjustor (Key 2) that contacts the

spring seat. Thread the spring adjustor onto the

actuator stem.

10. Mount the actuator onto the valve, following

procedures in the “Installation” section

of this manual.

-3-

Page 4

667M SerieS DiaphragM actuator

667m actuator Parts lIst

The following parts list includes complete part numbers for components of the 667M Actuator that are generally

replaceable in the field, and are most commonly used. Key numbers correspond to those in Figures 3 and 4.

Include the serial number of your actuator in all correspondence regarding replacement parts.

Table 1: Parts Reference

Key Part Name

1 Actuator Spring

2 Spring Adjuster

3 Actuator Stem

4 Spring Seat

5 Diaphragm Plate

6* Diaphragm

7 Upper Diaphragm Case

8 Lower Diaphragm Case

9 Yoke

10 Bolt

11 Cap Screw

Figure 3: 667M Actuator, Sizes 30 through 60

Key Part Name

12 Travel Indicator

13 Hex Nut

14 Hex Jam Nut

15 Self-Tapping Screw

16 Travel Indicator Scale

17 Nameplate

18 Drive Screw

19 Bolt

20 Hex Nut

21 Stem Connector

22 Twin Speed Nut (not shown)

-4-

Key Part Name

23 Pipe Bushing (Size 70 only)

24 Seal Bushing

25 O-Ring

26 O-Ring

27 Vent assembly

28 Gasket/ O-Ring

29 Lower Diaphragm Plate

30 Snap Ring

31 Washer

32 Spacer

33 Down Stop

* Recommended spare part

(not shown)

Page 5

667M SerieS DiaphragM actuator

Figure 4: 667M Actuator, Size 70

Table 2: Parts List

Key Description Part Number

1 Actuator Spring Consult Jordan Valve

Size 30 1E801724102

2 Spring Adjustor

3 Actuator Stem

Steel, CD PL

4 Spring Seat

5 Diaphragm Plate

6 Diaphragm Nitrile

Sizes 34, 40 1E821024102

Sizes 45, 46, 50, 60 1E846224102

Size 70 1N131824102

Size 30 1E801624222

Size 34 1E884724222

Size 40 1E820924222

Sizes 45, 46 1J332824222

Sizes 50, 60 1E846124222

Size 70 2N131724222

Size 30, Steel 1U425623122

Sizes 34,40, Steel 1R179923122

Sizes 45, 46, 50, 60, Steel 1R180023122

Size 70 Cast Iron 1N129619052

Steel 1N757722012

Size 30, Aluminum 30A2880X012

Sizes 34,40, Cast Iron 3E880519042

Sizes 45, 50, Aluminum 30A2882X012

Sizes 46, 60, Cast Iron 2E847519042

Size 70, Cast Iron 2N127019042

Size 30 2E800002202

Sizes 34, 40 2E669902202

Sizes 45, 50 2E859602202

Sizes 46, 60 2E859802202

Size 70 2N130902202

-5-

Page 6

667M SerieS DiaphragM actuator

Table 2: Parts List, continued

Key Description Part Number

Size 30 2E800728992

7 Upper Diaphragm

Casing Steel

8 Lower Diaphragm

Casing Steel

9 Yoke Cast Iron

10 Cap Screw

Steel, CD PL

11 Cap Screw See Following Table

12 Travel Indicator, SST

13 Hex Nut, SST (Refer to Key 10 for quantities)

14 Hex Jam Nut, CD PL

15 Self-tapping Screw, SST Sizes 30, 34, 40, 45, 46 (2 req’d)

16 Travel Indicator Scale, SST

17 Nameplate, SST

18 Drive Screw, SST (4 req’d)

19 Cap Screw CD PL

Sizes 34, 30 2E681428992

Sizes 45, 50 3E844628992

Sizes 46, 60 3E846728992

Size 70 2N127828992

Size 30 2E801125062

Sizes 34, 40 2E682625062

Sizes 45, 50 3E845325062

Sizes 46, 60 3E847725062

Size 70 2N131025062

Size 30

Size 34

Size 40

Sizes 45, 46

Sizes 50, 60

Size 70

3E801419042

2E884619042

3E820819042

3E900819042

3E845919042

3N130319042

Size 30 (12 req’d) 1E760324052

Sizes 34, 40 (16 req’d) 1E760324052

Sizes 45, 50 (20 req’d) 1A675124052

Size 46, 60 (24 req’d) 1A675124052

Size 70 (28 req’d) 1A582824052

Sizes 30, 34 1E793138992

Sizes 40, 45, 46 1E807538992

Sizes 50, 60

1E832838992

Size 70 1B971838992

1A346524122

Sizes 30, 34 (2 req’d)

1P131224142

Size 40 (1 req’d) 1A413224122

Size 45 (None req’d) ---

Size 46 (1 req’d) 1A413224122

Sizes 50, 60, 70 (1 req’d) 1A375424122

1E793238992

Sizes 50, 60, 70 (2 req’d)

1E831338992

See Following Table

1K325738992

1A368228982

Size 30 (6 req’d)

1D529824052

Sizes 34, 40 (6 req’d) 1A368424052

Sizes 45, 46, 50, 60 (8 req’d) 1A368424052

Size 70 (12 req’d) 1N129328992

-6-

Page 7

667M SerieS DiaphragM actuator

Table 2: Parts List, continued

Key Description Part Number

Sizes 30, 34 (None req’d) ---

20

21 Stem Connector, STL

22 Twin Speed Nut, SST

23 Pipe Bushing, CD PL Size 70

24

25

26

27

28

Hex Nut CD PL

Seal Bushing, Brass

O-Ring, Nitrile (2 req’d)

O-Ring, Nitrile Sizes 30, 34, 40 1C415706992

Vent Assembly Y602X1A11

Gasket, Garlock

O-Ring, Nitrile Size 70 1D269106992

29

Lower Diaphragm Plate

30

31

32

33

Snap Ring, SST Sizes 30, 34, 40 1E801337022

Washer (2 req’d) Size 70, Steel 1E873028992

Spacer, Steel See Following Table

Down Stop, Steel Sizes 30 to 40 1H493524092

Size 40 (1 req’d) 1A353724122

Size 45 (2 req’d) 1A353724122

Size 46 (1 req’d) 1A353724122

Sizes 50, 60, 70 (1 req’d) 1A351124122

Sizes 30, 34 1E7977000A2

Size 40 1E8033000A2

Sizes 45, 46

Sizes 50, 60

Size 70

Sizes 30, 34

Sizes 40, 45, 46

Sizes 50, 60, 70

1J3330000A2

1E8337000A2

1N1319000A2

1E793938992

1E808438992

1E833538992

1C379026232

Size 30 1E791214012

Sizes 34, 40 1E682814012

Sizes 45 to 60 1E845714012

Size 70 1N131614012

Size 30 1E591406992

Sizes 34, 40 1D237506992

Sizes 45 to 60 1C562206992

Size 70 1E736906992

Sizes 45, 46, 50, 60, 70 1E845806992

Sizes 30, 34, 40 1E801204022

Sizes 45, 46, 50, 60 1E845404022

Size 30, Aluminum 1E791344022

Sizes 34, 40, Aluminum 1E682744022

Sizes 45, 46, 50, 60, Aluminum 1E845544022

Size 70, Steel 1N131524092

Sizes 45 to 70 1E845638992

Sizes 45 to 60 1H494324092

-7-

Page 8

667M SerieS DiaphragM actuator

Key 11 Cap Screw

Key 32 Spacer, Steel

Actuator Size Key Travel In (mm)

7/16 (11) 5/8 (16) 3/4 (19) 1-1/8 (29)

30 11

32

34 11

32

40 11

32

45, 46, 50, 60 11

32

70 11

32

Actuator Size Key Travel In (mm)

30 11

32

34 11

32

40 11

32

45, 46, 50, 60 11

32

70 11

32

1A685724052 1A685724052 1B227524052 ---

1R408724092 1R408624092 1R408524092 ---

1R408828992 1R408928992 1R408928992 ---

1R409324092 1R409424092 1R409524092 ---

1R408828992 1R408828992 1R408928992 1R409128992

1R409324092 1R409424092 1R409524092 1R409624092

1R409824052 1R409824052 1R409824052 1R409924052

1R410324092 1R410424092 1R410524092 1R410824092

--- --- 1R411024052 1R411524092

--- --- 1R411624092 1R411124052

1-1/2 (38) 2 (51) 3 (76)

--- --- ---

--- --- ---

--- --- ---

--- --- ---

1R409228992 --- ---

1R409724092 --- ---

1R410124052 1R410224052 ---

1R410624092 1R410724092 ---

1R409824052 1R409924092 1R410224052

1R411424092 1R411324052 1R410724092

667MIM/0214/2K

Key 16 Travel Indicator Scale

Actuator Size Travel In (mm)

7/16 (11) 5/8 (16) 3/4 (19) 1-1/8 (29)

30

34

40, 45, 46

50

60

70

Actuator Size Travel In (mm)

30

34

40, 45, 46

50

60

70

1E793438992 1E793538992 1E793638992 ---

1E793438992 1E793538992 1E793638992 ---

1E807638992 1E807738992 1E808138992 1E808238992

1E833038982 1E833038992 1E833138992 1E833238992

1F535238982 1E833038992 1E833138992 1E833238992

--- --- 1H745738992 1H745838992

1-1/2 (38) 2 (51) 3 (76)

--- --- ---

--- --- ---

1E803838992 1R444538982 ---

1E833338992 1E833438992 ---

1E833338992 1E833438992 ---

1H745938992 1H746038992 1H746138992

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...