Page 1

I & M 657M Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

All Jordan Valve equipment, including actuators, are

to be installed and maintained in accordance with

instructions supplied by Jordan Valve. Only qualified

personnel may install and service the actuator, and, if

necessary, contact a gas service person.

InstallatIon

The 657M Diaphragm Actuator is usually delivered

furnished mounted on a Jordan valve body. When

installing the valve body into the pipeline, consult the

instructions for that particular valve body. Should you

have any questions during the installation procedure,

consult your Jordan Valve representative.

The loading pressure is connected to the NPT connection in the top of the diaphragm case (1/4” for sizes 30

through 60, 1/2” size 70). With larger sizes, it may be

beneficial to reduce the connection down to 1/4”. Pipe

or tubing may be used, and should be run to the output pressure connection on the automatic controller.

Avoid transmission lag in the control signal by keeping

the length of pipe or tubing as short as possible. When

long distances are involved, install a valve positioner

on the actuator. If the valve positioner is provided as

part of the original equipment, the loading pressure

connection will be made at the Jordan Valve manufacturing facility.

If the 657M Diaphragm Actuator is shipped alone for

field mounting, it should be mounted onto the valve

body and secured in place with the yoke locknut.

Clamp the actuator stem and valve plug stem together

using the stem connector to provide the proper valve

travel. Refer to the “Assembly Instructions” section of

this manual for complete instructions.

Installation & Maintenance Instructions for the

657M Series Diaphragm Actuator

above for accessibility. Ensure that sufficient room is

provided below should removal of the actuator and

valve plug be necessary.

operatIon and adjustment

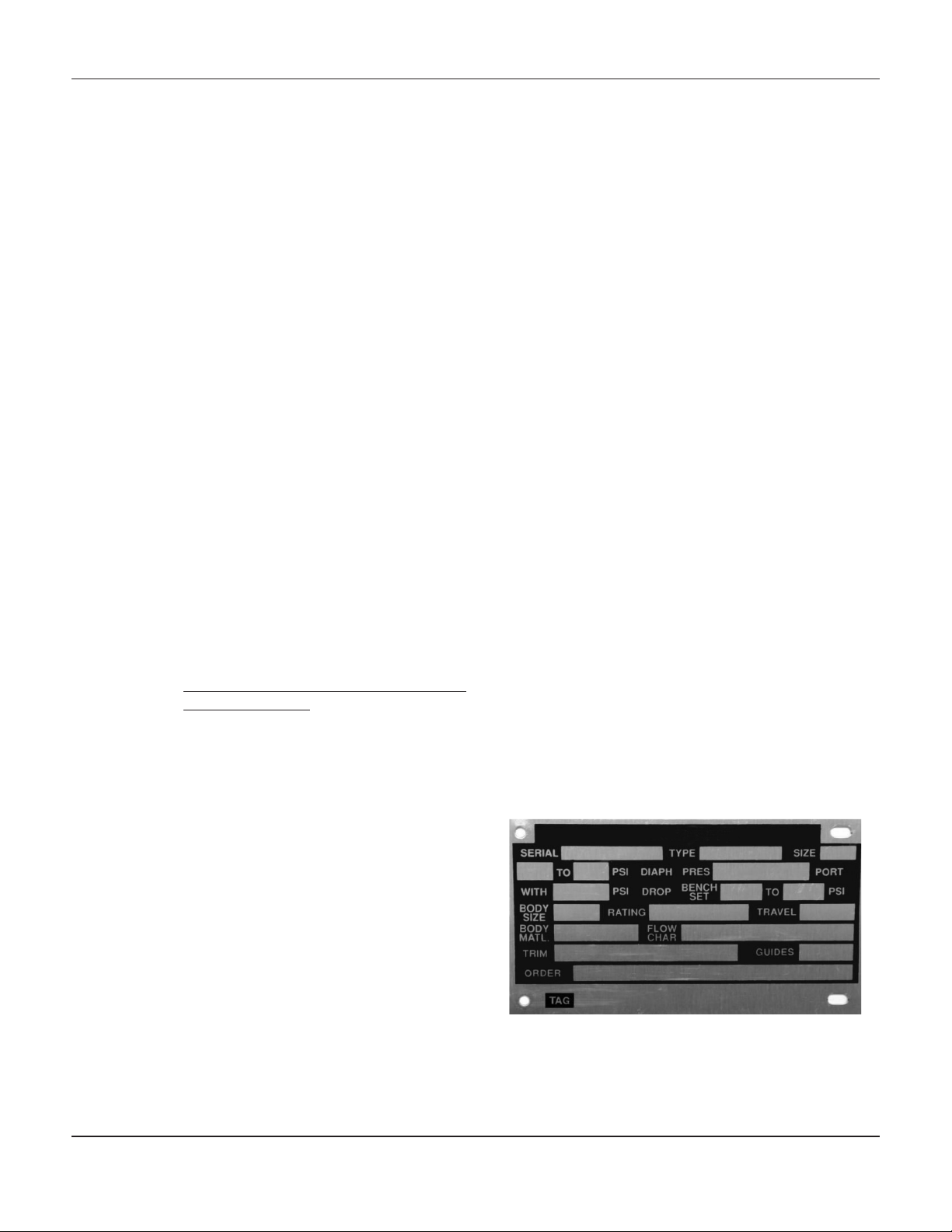

Refer to the nameplate on the yoke of the actuator

for details on the specific construction and operating

range. The requirements of your specific application

will dictate the spring and diaphragm used in your

657M Actuator. When in service, the actuator will create

full travel of the valve plug when diaphragm pressure is

applied according to the range indicated on the name

plate. Generally, the diaphragm pressure range is 3 to

15 PSI or 6 to 30 PSI, but other ranges may be used.

Pressure within the valve body creates forces on the

valve plug which directly affect the actual operating

diaphragm pressure range. When pressure conditions

in the valve body are different from those indicated in

the factory settings, the valve may not stroke completely

over the indicated range. To achieve correct travel for

the diaphragm pressure range utilized, a simple spring

adjustment is necessary. Note, however, that the actuator spring has a fixed pressure span and that adjustment of the spring compression simply shifts this span

up or down to make the travel of the valve correspond

with the diaphragm pressure range.

657M Direct Acting Diaphragm Actuator

Air Pushes Down

Spring Lifts

For ease of service, ensure that the control valve is

located for easy access and serviceability with room

Stem moves upward with loss of

operating medium

Figure 1: Schematic of 657M Actuator

Page 2

657M SerieS DiaphragM actuator

Operation and Adjustment Continued,

The Jordan Valve nameplate indicates a “bench set”

pressure range in addition to a standard diaphragm

pressure range. The “bench set” pressure range indicates the range required to completely stroke the valve

with out any pressure in the valve body, for example

as if the valve were being tested on the work bench.

While In service, however, with the specified pressure

drop applied across the valve, it should stroke over the

standard diaphragm pressure range as indicated on the

nameplate.

Once the control valve has been installed and connected to the controller, it should be tested for correct travel,

lack of friction and correct action (air-to-open or air-toclose) to match the controlling instrument. To ensure the

most effective operation, the actuator stem and the valve

plug stem must move freely when responding to the

loading pressure change on the diaphragm.

Disassembly Instructions

Although the following instructions describe how the

657M Diaphragm Actuator can be completely disassembled, when inspection or repairs are required, only

disassemble those parts required to accomplish the job.

Consult Figure 3, and proceed as follows for

disassembly:

1. Bypass the control valve and exhaust any actua tor loading pressure to atmospheric. Discon-

nect the actuator supply line and any

leakoff piping.

2. Relieve all pressure from the spring by threading

the spring adjuster (key 2) out of the yoke.

3. To remove the valve body from the actuator,

separate the stem connector (key 21)

and remove the yoke locknut.

4. Loosen the stem locknuts (keys 13 and 14),

remove the two cap screws and separate the

stem connector.

5. Loosen the diaphragm case cap screws and

nuts (keys 19 and 20) and remove the

upper diaphragm case.

6. Remove the molded diaphragm (key 6).

7. Extract the diaphragm plate and actuator stem

(keys 5 and 3) as an assembly. These parts can

be further separated if required.

8. Remove the actuator spring (key 1) and spring

seat (key 4).

9. If necessary, remove the lower half of the dia-

phragm case (key 8) by loosening the

cap screws.

10. Removing the spring adjuster will complete the

disassembly.

Assembly Instructions

1. The 657M Actuator can be assembled

in the reverse order of the disassembly

instructions. These additional steps below will

assist with proper assembly and continued

operation.

2. Apply lubricant to the threads and spring seat

bearing surface of the spring adjuster (See loca tion marked “LP” on Figure 3).

3. Ensure that the spring seats and the lower seat

align properly and rest against the diaphragm

plate.

4. Use a criss-cross pattern to evenly tighten the

nuts on the casing bolts.

5. If the stem locknuts were removed during disas-

sembly, install them onto the valve plug stem

and place the travel indicator (key 12) with the

cupped side downward.

6. Secure the actuator onto the valve body using

the yoke locknut.

7. Assemble the stem connection as follows

according to the required action:

a. Mounted on Body with “Push Down to

Close” Valve Plug

i. When the body is assembled

and the actuator is mounted,

ensure the valve plug is in the

closed position.

ii. Once the locknuts are secured

onto the stem, set the travel

indicator disc onto the locknuts

with the cupped portion

facing downward.

iii. Raise the valve plug off of the

seat, with the travel specified on

the nameplate, or, pressure the

actuator until the stem

moves down the specified valve

travel.

iv. Install the stem connector by

clamping the actuator

stem to the valve stem.

v. Raise the indicator disc to the

stem connector, using

the locknuts to tighten in

position.

-2-

Page 3

657M SerieS DiaphragM actuator

vi. Ensure that the desired total

travel is available by cycling the

actuator. This will also

demonstrate that the valve

plug seats properly. If

necessary, minor travel

adjustments can be made

by slightly loosening the stem

connecter, tightening the

locknuts and screwing the

stem either into or out of the

stem connecter using a wrench

on the locknuts.

vii. Once the valve travel has been

accomplished, secure

the stem connector, lock

the travel indicator disc

against the connector

using the locknuts, and

adjust the travel indicator scale

(key 16) to show

valve plug position.

viii. Using a gauge, measure the

pressure delivered to

the actuator. Make any

adjustments on the actuator, or

the positioner,

to set the starting point of

valve travel and ensure

full range of travel as desired.

vi. Apply loading pressure to the

diaphragm case and move the

valve plug down off of its seat.

vii. Rotate the valve plug stem into

the stem connector

approximately 1/8”. Slightly

tighten the stem lock

nuts to move the travel indicator

to the proper position.

viii. Check the availability of desired

travel by fully cycling the actua-

tor. The valve plug should seat

before the upper travel stop. If

required, minor adjustments to

total travel can be made

by slightly loosening the

stem connector, tightening the

locknuts and screwing the stem

either into or out

of the stem connector

using a wrench on the locknuts.

Note: When making adjustments to the valve stem,

do not rotate the valve stem more than the 1/8” that it

was screwed into the actuator stem in step “vii”. Over

rotating the valve stem will prevent the valve from

shutting off.

ix. Proceed with steps “vii” and

“viii” as in section “A” above.

b. Mounted on Body with “Push Down to

Open” Valve Plug

i. Attach the locknuts to the stem

and set the travel indicator disc

into position.

ii. Raise the valve plug to the

closed position. On larger body

sizes, a pry bar may be inserted

through the body line flange

opening. If the valve is located

in a pipeline application,

you may remove

the bottom flange and raise the

valve plug from below.

iii. Install the stem connector and

ensure that the actuator

stem threads are fully engaged.

iv. Install the two cap screws in the

stem connector to clamp the

actuator stem to the valve stem.

v. If a pry bar has been used,

remove it now. If the

bottom flange has been

removed, replace it now.

Serial Number

Each 657M Actuator has a serial number, stamped on

the nameplate. When corresponding with your Jordan

Valve representative, always refer to that serial number

when requiring replacement parts or technical information.

Figure 2: Nameplate on 657M Actuator

-3-

Page 4

657M SerieS DiaphragM actuator

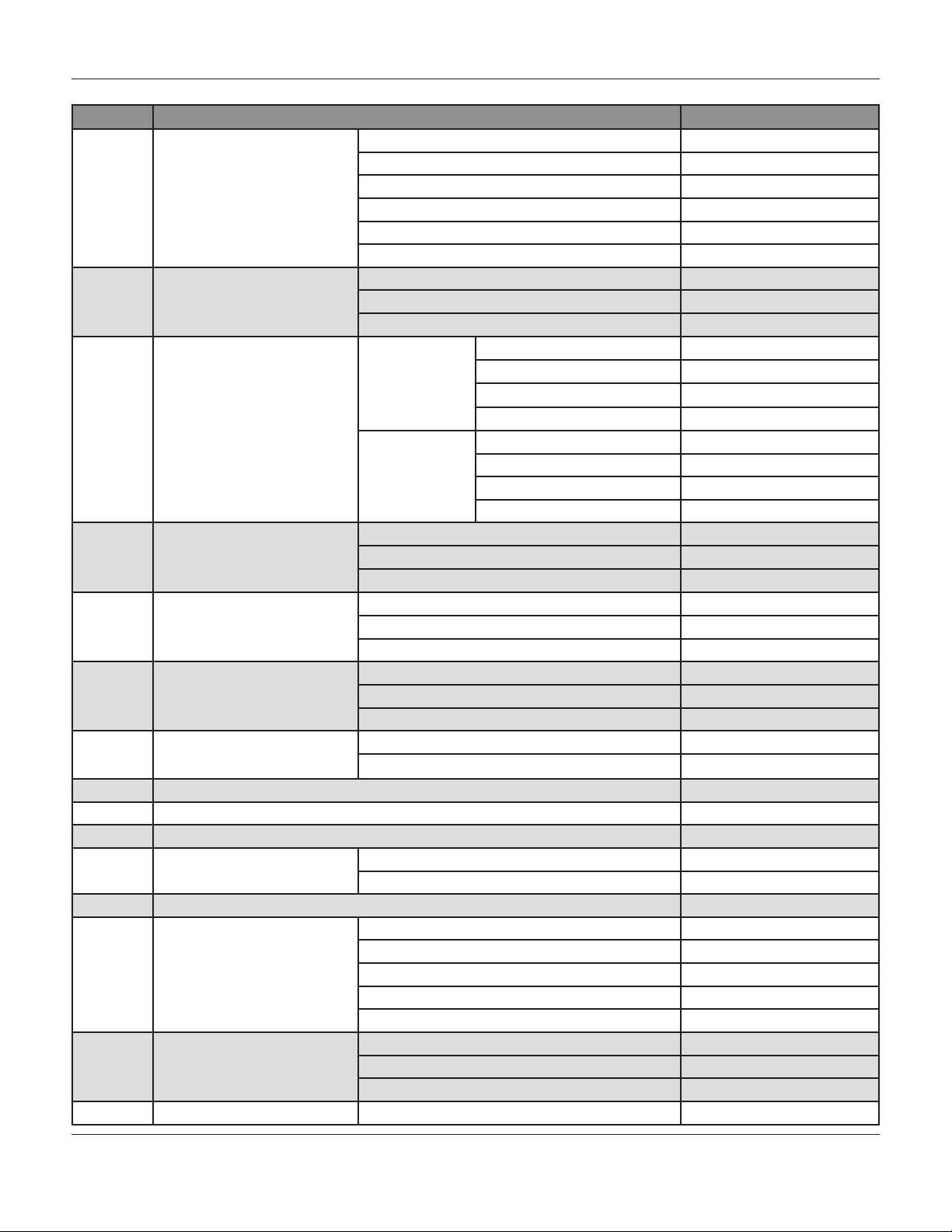

657m actuator parts lIst

The following parts list includes complete part numbers

for components of the 657M Actuator that are generally replaceable in the field, and are most commonly

used. Key numbers correspond to those in Figure 3. If

materials and parts are required, but are not outlined in

this literature, consult your Jordan Valve representative.

Include the serial number of your actuator in all correspondence regarding replacement parts.

657m actuator

Figure 3: 657M Actuator Assembly Drawing

Table 1: Parts Reference

Key Part Name

1 Actuator Spring

2 Spring Adjuster

3 Actuator Stem

4 Spring Seat

5 Diaphragm Plate

6* Diaphragm

7 Upper Diaphragm Case

8 Lower Diaphragm Case

9 Yoke

10 Cap Screw

11 Cap Screw

12 Travel indicator

13 Hex Nut

14 Hex Jam Nut

15 Self-Tapping Screw

16 Travel Indicator Scale

17 Nameplate

18 Drive Screw

19 Cap Screw

20 Hex Nut

21 Stem Connector

22 Twin Speed Nut (not shown)

23 Pipe Bushing (Size 70 only)

(Not shown)

*Recommended Spare Part

-4-

Page 5

657M SerieS DiaphragM actuator

Table 2: Parts List

Key Description Part Number

1 Actuator Spring Consult Jordan Valve

Size 30 1E792924102

2 Spring Adjustor

3 Actuator Stem

Steel, CD PL

4 Lower Spring Seat

5 Diaphragm Plate

Cast Iron

6 Diaphragm Nitrile

7 Upper Diaphragm

Casing Steel

8 Lower Diaphragm

Casing Steel

Sizes 34, 40 1E807324102

Sizes 45, 46, 50, 60 1E832624102

Size 70 1N129724102

Size 30 1E792824102

Size 34 1E872924102

Size 40 1E807124102

Sizes 45, 46 1J332924102

Sizes 50, 60 1E832424102

Size 70 Up to 2” Travel 1N129424102

Over 2” Travel 1N132524102

Size 30, Steel 1U425623122

Sizes 34,40, Steel 1R179923122

Sizes 45, 46, 50, 60, Steel 1R180023122

Size 70, Cast Iron 1N129619052

Size 30 2E880419042

Sizes 34,40 3E880519042

Sizes 45, 50 2E831519042

Sizes 46, 60 2E847519042

Size 70 2N127019042

Size 30 2E791902202

Sizes 34, 40 2E670002202

Sizes 45, 50 2E859502202

Sizes 46, 50 2E859702202

Size 70 2N126902202

Size 30 2E791528992

Sizes 34, 40 2E806028992

Sizes 45, 50 3E830928992

Sizes 46, 50 2E847228992

Size 70 2N126628992

Size 30 2E792225062

Sizes 34, 40 2E806325062

Sizes 45, 50 3E831625062

Sizes 46, 50 2E847425062

Size 70 2N127125062

-5-

Page 6

657M SerieS DiaphragM actuator

Table 2: Parts List, continued

Key Description Part Number

Size 30 3E792619042

Size 34 2E869619042

9 Yoke

Cast Iron

Cap Screw

10

11 Cap Screw

12 Travel Indicator, SST

13 Hex Nut, SST

14 Hex Jam Nut, SST

15 Self-tapping Screw, SST Sizes 30, 34, 45, 46 (2 req’d) 11793238992

16 Travel Indicator Scale, SST See following Table 4

17 Nameplate, SST 12B6508X0A2

18 Drive Screw, SST (4 req’d) 1A368228982

19 Cap Screw,

20 Hex Nut, Standard 3/8” Nut 1” Nut

21 Stem Connector, STL

22 Twin Speed Nut, SST

23 Pipe Bushing, Steel, PL Size 70 1C379026232

Steel, CD PL

Standard 3/8” Bolt

Size 40 3E807019042

Sizes 45, 46 2E903719042

Sizes 50, 60 3E832319042

Size 70 3N127319042

Size 30 1E798032982

Sizes 34, 40 1E760432992

Sizes 45, 46, 50, 60, 70 1E775432982

Size 30 (6 req’d) 1D529824052

Push Down to

Close Valve

Push Down to

Open Valve

Sizes 30, 34 1E793138992

Sizes 40, 45, 46 1E807238992

Sizes 50, 60, 70 1B832838992

Sizes 30, 34 (2 req’d) 1P131224142

Sizes 45, 46 (2 req’d) 1A413224122

Sizes 50, 60, 70 1A375424122

Size 40 1A353724122

Sizes 45, 46 (2 req’d) 1A353724122

Sizes 50, 60, 70 1A351124122

Sizes 50, 60, 70 (2 req’d) 1E831338992

Size 30, 34, 40, 45, 50, 60 1” bolt

Size 70 1-1/4” bolt

Sizes 30, 34 1E7977000A2

Size 40 1F659225142

Sizes 45, 46 1J3330000A2

Sizes 50, 60 1E8337000A2

Size 70 1H8655000A2

Sizes 30, 34 1E793938992

Sizes 40, 45, 46 1E808438992

Sizes 50, 60, 70 1E833538992

Sizes 34, 40 (6 req’d) 1A368424052

Sizes 45, 46, 50, 60 (8 req’d) 1A368424052

Size 70 1N129328992

Size 30 (3 req’d) 1D368424052

Sizes 34, 40 (3 req’d) 1A368424052

Sizes 45, 46, 50, 70 (4 req’d) 1A368424052

Size 70 (9 req’d) 1N129328992

-6-

Page 7

657M SerieS DiaphragM actuator

Table 3: Travel Indicator Scale

Actuator

Size

30, 34 1E793638992

40, 45, 46 1E808138992

50, 60 1E833138992

70 1E833138992

Table 4: Thrust Capabilities by Input Signal Range

Travel

mm Bar N

19

29

38

51 70 0.2-1 7930

Inch Psig Lb

3/4

1-1/8

1-1/2

2 70 3-15 1760

3/4" Travel 1-1/8" Travel 1-1/2" Travel 2" Travel 3" Travel

1E808228992 1E808338992 1R444538982

1E833128992 1E833338992 1E833428992

1E833238992 1E833338992 1E833438992 1N129838992

Pressure Range to

Actuator Size

30 0.2-1 2250

34 0.2-1 3380

40 0.2-1 3380

45 0.2-1 4670

46 0.2-1 6940

50 0.2-1 5140

60 0.2-1 6940

30 3-15 506

34 3-15 759

40 3-15 759

45 3-15 1050

46 3-15 1560

50 3-15 1155

60 3-15 1560

Actuator

Diaphragm

0.4-2 3890

0.4-2 5830

0.4-2 5530

0.4-2 8410

0.4-2 13,190

0.4-2 8410

0.4-2 13,190

0.4-2 18,590

6-30 874

6-30 1311

6-30 1242

6-30 1890

6-30 2964

6-30 1890

6-30 2964

6-30 4180

Thrust Capabilities

657MIM/0214/2K

Part Numbers

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...