Jokab Safety Safety contact mats Catalog

ABB JOKAB SAFETY Products

Safety contact mats

Disclaimer: This document and any attachments may include suggested specifications, drawings, schematics and similar materials from ABB Inc. Use of such information and/or documentation by the recipient

is subject to and conditioned upon your acceptance of the terms of the General Document Disclaimer which can be found at www.jokabsafetyna.com. Your acceptance of the terms of such General Document

Disclaimer is conclusively presumed unless you notify ABB in writing of your disagreement with the terms of such Disclaimer immediately upon receipt of this document and you return to ABB all specifications,

drawings, schematics and similar materials provided to you by ABB in this document.

2 | ABB JOKAB SAFETY - Safety mats

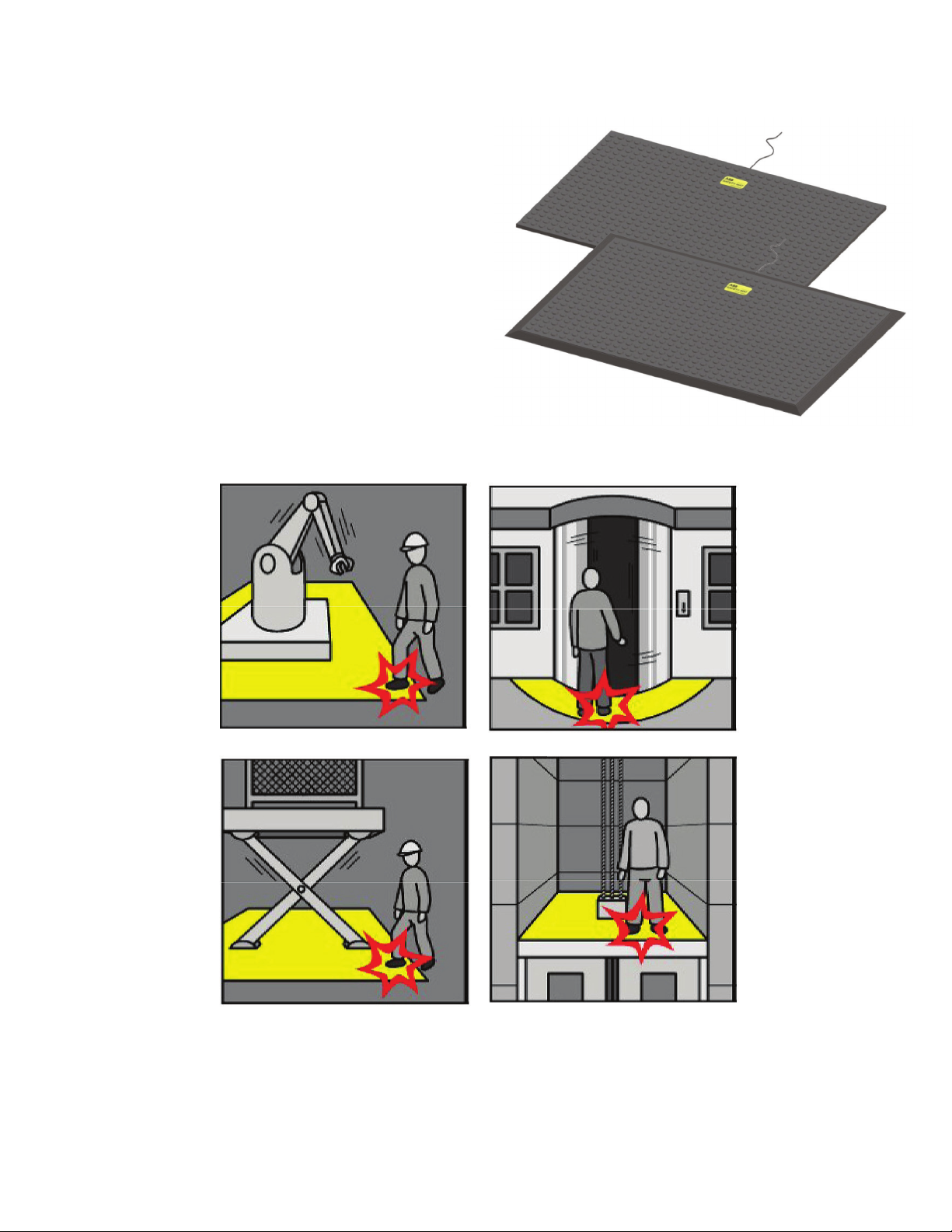

When should I use safety mats?

A safety mat is used as personal

protection within dangerous areas.

The ABB JOKAB SAFETY contact mat is used for safeguarding

sections in hazardous areas around machines, presses, robots

and other types of active equipment. When connected to a

suitable monitoring system, stepping on the mat surface triggers

a control signal to the stop circuit of the potentially hazardous

motion. This fast contact occurs due to the area switch design

on the inside of the mat.

An anti-slip surface is also implemented into the design. The

safety mat and its connection cabling can be supervised by a

suitable ABB JOKAB SAFETY safety relay, Vital Controller or

Pluto Safety PLC which provides PL d.

ABB JOKAB SAFETY - Safety mats | 3

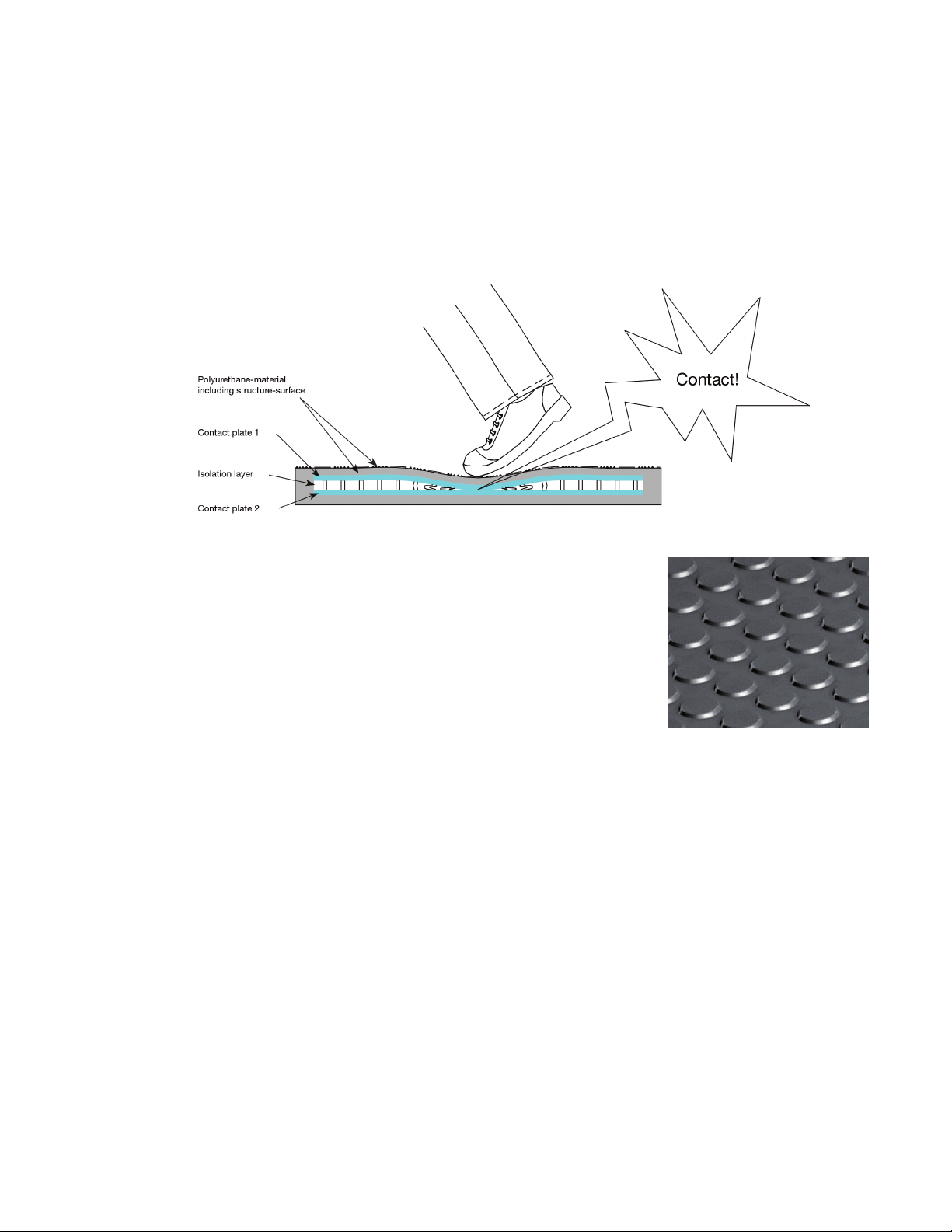

Safety mat construction

The basic construction of the ABB JOKAB SAFETY mat consists of two conductive plates which are separated by a proprietary

isolating layer. These plates are completely potted in a polyurethane material so that they are impervious to oil, water and dirt. The

top consists of a slip resistant dotted pattern. This surface provides excellent resistance against oil and grease. Mounting to the

floor can be realized with either aluminum ramp rails or integrated rubber ramp trim.

Safety mat surface layer

Safety mats are normally supplied with a dotted polyurethane non-slip surface layer that

withstands tough conditions very well (oil, acid or caustic substances) and has anti-slip

properties. If required, other patterns can be supplied, or for special requirements, even other

materials. Please contact us for more information about these alternatives.

Safety mat electrical connection

Safety mats must be connected to a suitable monitoring unit (e.g. ABB JOKAB SAFETY safety relays RT6, RT7A/B, RT9, Vital

with Tina 6A or Pluto Safety PLC). The monitoring unit monitors the functionality of the contact protection and detects any

breaks or short-circuits in the lines. Several safety mats can be connected in series while still retaining the same level of safety.

When pressure is applied, the active surface of the contact area in the contact protection is closed and the safety output on the

monitoring unit trips. A stop signal will be sent to the machine’s safety circuits preventing any dangerous movements. Safety

mats are supplied with a 4 conductor 10m cable exiting out the middle of the long side. Conductors 1 and 3 are connected to

the top plate (Safety channel 1) and conductors 2 and 4 are connected to the bottom plate (Safety channel 2).

Note: If alternative units are used rather than the recommended ABB JOKAB SAFET Y relays, it is essential that the

user checks their suitability with ABB JOKAB SAFET Y before use. Failure to do so may result in incorrect operation

and/or damage to the safety mat and invalidate warranty.

4 | ABB JOKAB SAFETY - Safety mats

Loading...

Loading...