Jokab Safety Safe-T-Step Catalog Page

Safe-T-Step Guard Mats

Heavy Duty, Impact

Resistant Safeguarding

For nearly two decades Jokab Safety has set the industry standards

for quality and performance of industrial automation and machine

safeguarding. We are proud to announce the latest addition to our

product line — the Safe-T-Step impact-resistant, heavy-duty mat.

Alumaglas®contact elements blanket the entire surface virtually

eliminating any dead zones in the active surface. Our contact

element will not rust or dent — and it is completely flexible,

enabling it to withstand impacts that could damage other rigid

contact elements. Every Safe-T-Step mat is available with a retainer

trim kit made of extruded aluminum, which is recommended to

surround the mat and secure it in place. The trim kits are available

in straight or miter cut.

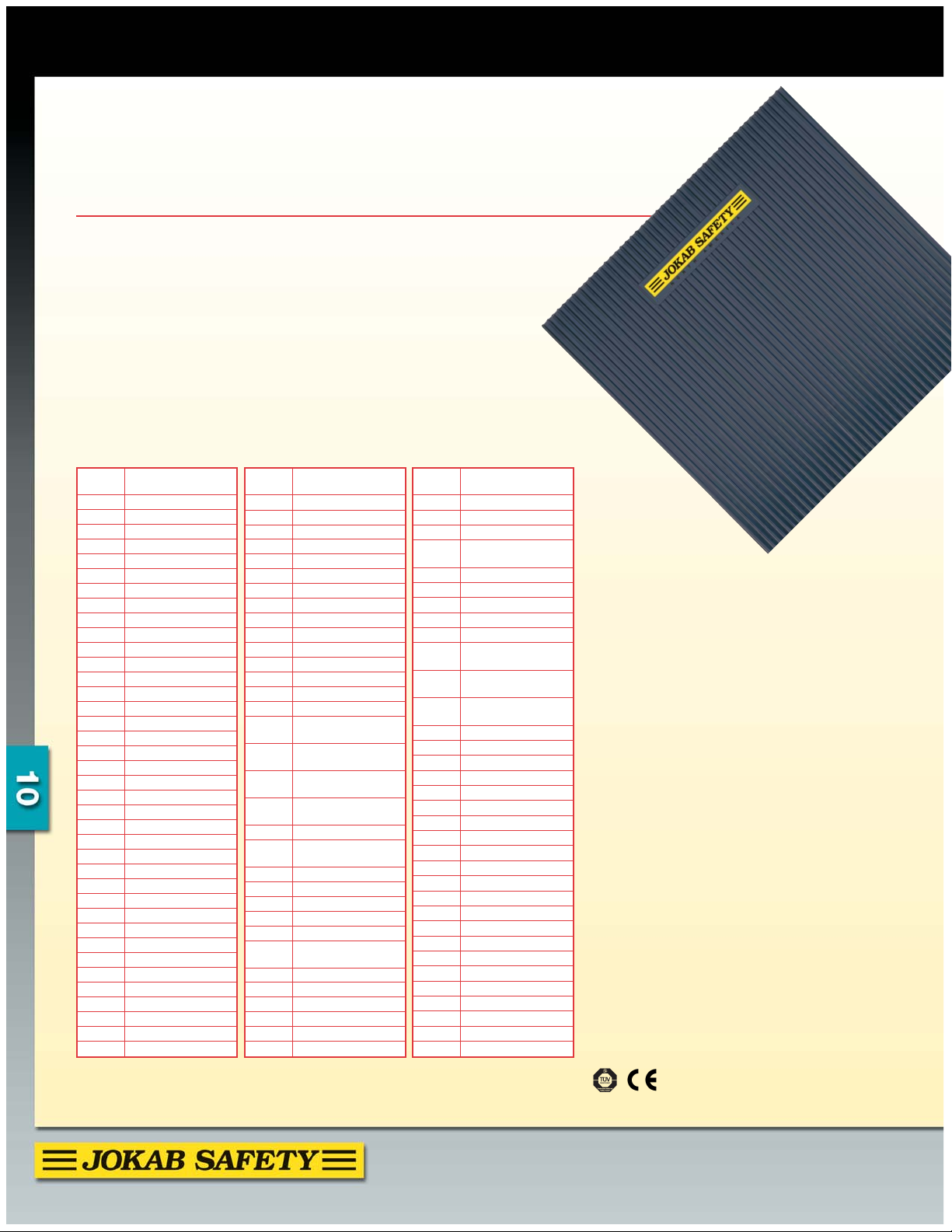

Chemical Resistance

RESIST.

A

*

CHEMICAL

LEVEL

C Acetic Acid, Glacial

B Acetic Acid, 30%

C Acetic Anhydride

U Acetone

A Ammonia Gas (Cold)

A Ammonium Carbonate

A Ammonium Chloride

A Ammonium Hydroxide

A Ammonium Nitrate

A Ammonium Sulfate

U Aniline

A Aqua Regia

C Benzoic Acid

A Boric Acid

U Bromine-Anhydrous

U Bromine Water

U Bromobenzene

B Butter

B Butyl Alcohol

U Butyl Stearate

A Calcium Chloride

A Calcium Hydroxide

B Calcium Hyprochlorite

C Carbolic Acid

U Carbon Bisulfide

B Carbon Tetrachloride

U Cellosolve

B Chloride (Dry)

C Chlorine (Wet)

A Chloroacetic Acid

U Chlorobenzene

U Chloroform

U Chromic Acid

A Cobalt Chloride

A Copper Chloride

A Copper Sulfate

B Cottonseed Oil

B Cyclohexane

=

Little or No Effect

See page 6 - Safe-T-Edge Strips Technical Data

=

B

RESIST.

Minor to Moderate Effect

CHEMICAL

LEVEL

U Diethyl Ether

U Dioxane

U Ethyl Acetate

B Ethyl Alcohol

A Ethyl Chloride

U Ethylene Chloride

A Ethylene Glycol

U Ethylene Oxide

A Ferric Chloride

Formic Acid

B

C Furfural

A Gasoline

A Glycerin

B Hexyl Alcohol

A Hydrobromic Acid

B* Hydrochloric Acid

(Hot) 37%

B Hydrochloric Acid

(Cold) 37%

B* Hydrofluoric Acid

(Conc.) Hot

B Hydrofluoric Acid

(Conc.) Cold

A Hydrofluosilicic Acid

A Hydrogen Peroxide

(90%)

B Hydroquinone

U Isophorone

A Isopropyl Alcohol

A Lead Acetate

B Linseed Oil

A Lubricating Oils

(Petroleum)

A Magnesium Sulfate

B Methyl Alcohol

U Methyl Bromide

A Methyl Cellosolve

U Methyl Ethyl Ketone

U

Methyl Isobutyl Ketone

RESIST.

=

C

Moderate to Severe Effect

CHEMICAL

LEVEL

B Naphthalene

U Nitric Acid (Conc.)

A Nitric Acid (Dilute)

U Nitric Acid

(Red Fuming)

U Nitrobenzene

B Octyl Alcohol

B Oleic Acid

A Oxalic Acid

C Phenol Hydrazine

A Phosphoric Acid

(20%)

A Phosphoric Acid

(45%)

U Phosphorous

Trichloride

B Picric Acid

Potassium Dichromate

A

C Potassium Hydroxide

U Propylene Oxide

U Pyridine

A Silver Nitrate

A Sodium Borate

A Sodium Cyanide

B Sodium Hydroxide

A Sodium Hypochlorite

A Sodium Nitrate

C Stearic Acid

B Sulfur Dioxide

A Sulfuric Acid (Dilute)

U Sulfuric Acid (Conc.)

B Sulfurous Acid

A Tannic Acid

B Tetrachloroethylene

U Tetrahydrofuran

B Toluene

U Trichloroacetic Acid

A Water

=

U

Not Recommended

Applications

■

Area Guarding

■

Machine Guarding

■

Perimeter Guarding

Features

■ Non-skid surface available

in black ribbed top or yellow

diamond top

■ Resistant to common oils

and chemicals

■ No joining strips required

■ 4 pole quick disconnect

■ Electrical requirements:

24 volt, 1/2 amp AC or DC

■ Flame and water resistant

■ Hermetically sealed

■ Sensitive edges

■ No silicone

Warranty

Jokab Safety will replace, within 1 year

of shipment date, any Safe-T-Step mat

that has been subject to normal use

and is found to have defective materials

or workmanship, as determined solely

by our authorized factory representative. Replacements will be shipped to

customer freight collect. This warranty

is void where evidence of misuse or

abuse is present.

Approvals

10:2

www.jokabsafetyna.com 1-888-282-2123

www.jokabsafetyna.com 1-888-282-2123

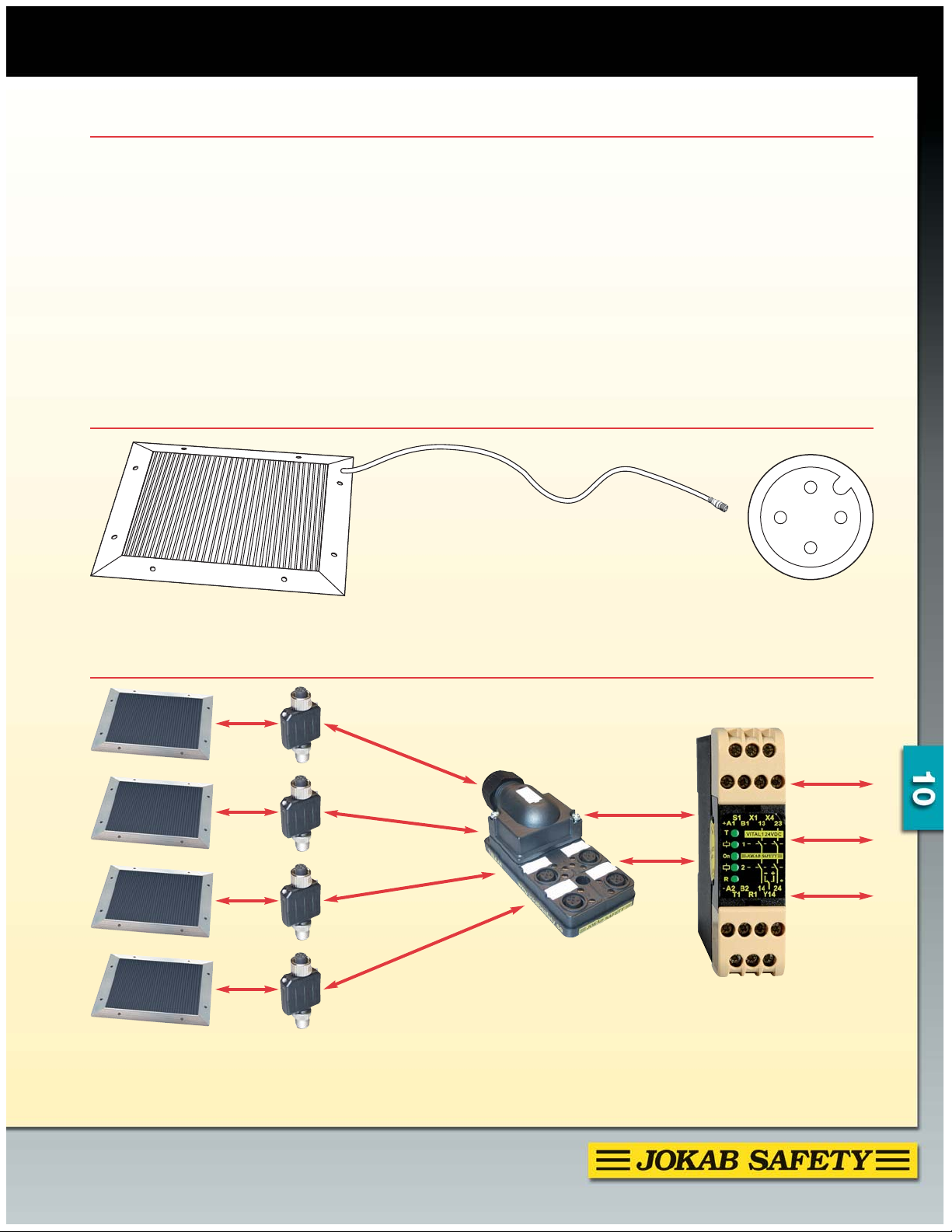

Safe-T-Step Technical Data

Manufacturer.............................................. JOKAB SAFETY

Ordering Data/Article Numbers....................see page 10:4

Outer Material................................................................PVC

Assembled Mat Thickness............................................ 5/8”

Color...............................................................................black

Lead Wire...............10 m, 4 pin yellow micro DC disconnect

Minimum Sensitivity....... 66 lbs. (30 kg) per 3-1/8” (80 mm)

Cycle Test..........................................................1 million plus

Maximum Width..................................36” and 48” standard

Temperature Range

Per EN1760...................................................... -5ºC to +40ºC

Actual..............................................................-29ºC to +71ºC

(diameter per EN1760)

(up to 56” optional)

Safe-T-Step Connecting Cable

Fire Resistance .........................................self-extinguishing

Weathering................................meets or exceeds minimum

requirements per IEC 68-2-3, IEC 68-2-14

Cracking.................................none @ 1/4” mandrel at -40ºF

Hardness...........................................93 +/- 5 ASTM-D-2240

Note: JSNA Safe-T-Step guard mats and trim kits can be

ordered in custom sizes. Trim kits are available in all standard

sizes and include all mounting hardware and pre-drilled

counter sunk holes. For Ordering Data see page 4.

10 meter Cable

4 Pole Micro DC

(M12) Standard

Pin Out

1 - 2 Top

3 - 4 Bottom

Safe-T-Step Application for 4 Mats using Vital Solution

(Q-D)

(Q-D)

(Q-D)

4 Wires

4 Info

2

31

4

Power

Outputs

Status

(Q-D)

Safety Mats with

Quick-Disconnects

(Q-D)

1-888-282-2123 www.jokabsafetyna.com

1-888-282-2123 www.jokabsafetyna.com

Tina 6A (Adapter)

LED Indication and

Diagnostics for

each mat

Tina 4A

(Connection Block)

Field

Vital 1 (Controller)

Panel

10:3

Loading...

Loading...