Jokab Safety RT9 Catalog Page

www.jokabsafety.com

6:14

www.jokabsafety.com

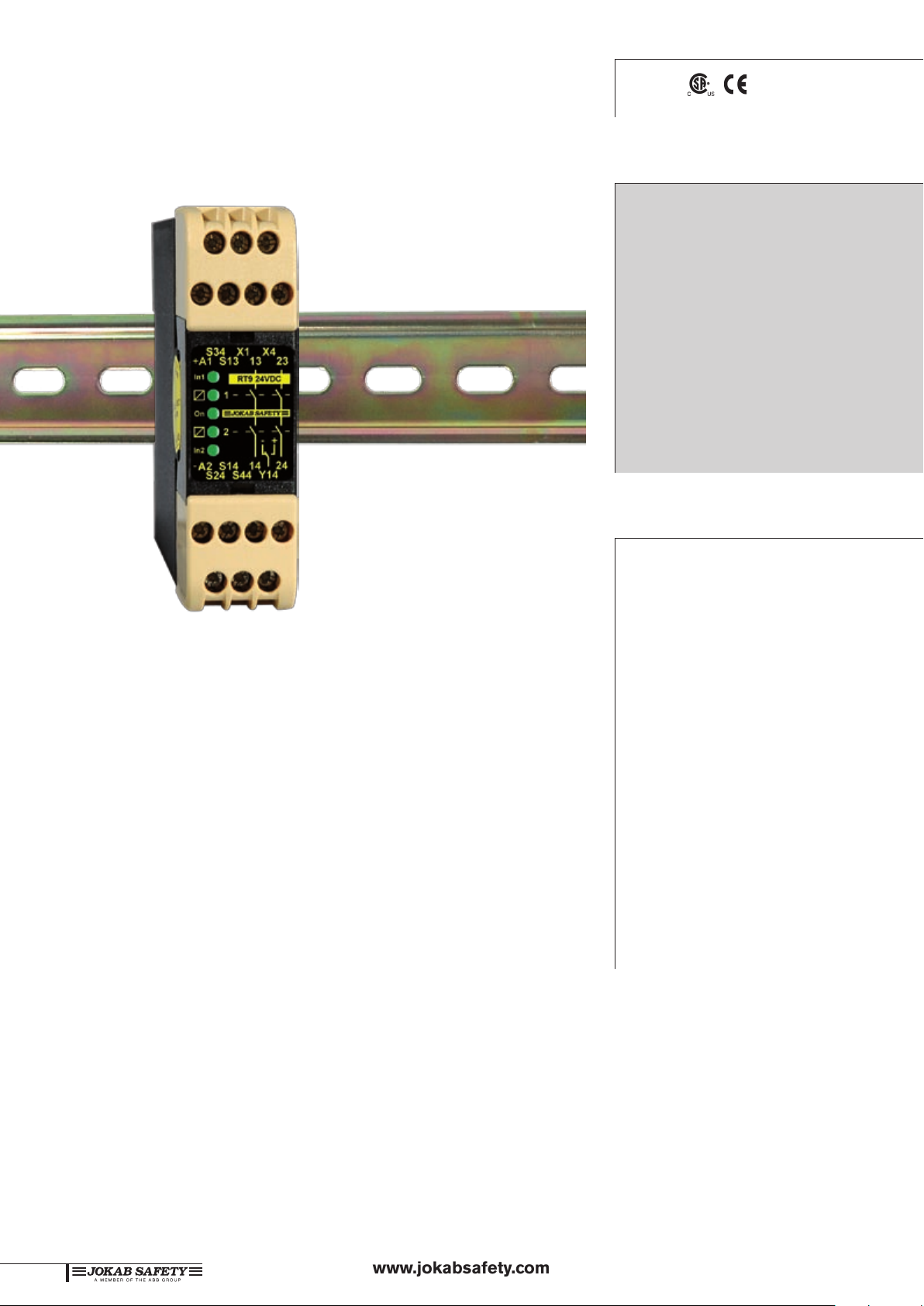

Safety relay

RT9

Approvals:

TÜV Nord

Safety relay for:

Emergency stops

Light curtains

Three position devices

Interlocked gates/hatches

Magnetic switches

Light beams

Safety mats

Contact strips

Foot operated switches

Would you like a small safety relay for all your safety

applications?

Then choose the compact RT9 universal relay to supervise both

your safety devices and the internal safety of your machinery. In

addition, you can select the safety level that is required for each

installation. All this is possible due to the RT9 offering the most

versatile input option arrangement available on the market. The

RT9 can therefore replace many other relays.

Other RT9 options include selection of either manual supervised

or automatic resetting. The manual supervised reset can be used

for gates and other safety devices that can be bypassed. Automatic

reset can be used for small safety hatches, if deemed acceptable

from risk assessment.

In addition, the RT9 has a double information output that will

indicate e.g if a gate is open or if the relay needs resetting.

The RT9 uses the latest component technology and modern assembly techniques to ensure a highly cost effective solution.

Choose the RT9 to simplify your safety circuits and reduce your

costs.

Features:

Five input options

Single or dual channel input

Manual supervised or automatic reset

Test input for supervision of

external contactors

Width 22.5 mm

LED indication of supply,

inputs and outputs, shortcircuit and low voltage level

2 NO relay outputs

One changeover relay with

a double information output

Supply 24 VDC

Quick release connector

blocks

www.jokabsafety.com

6:15

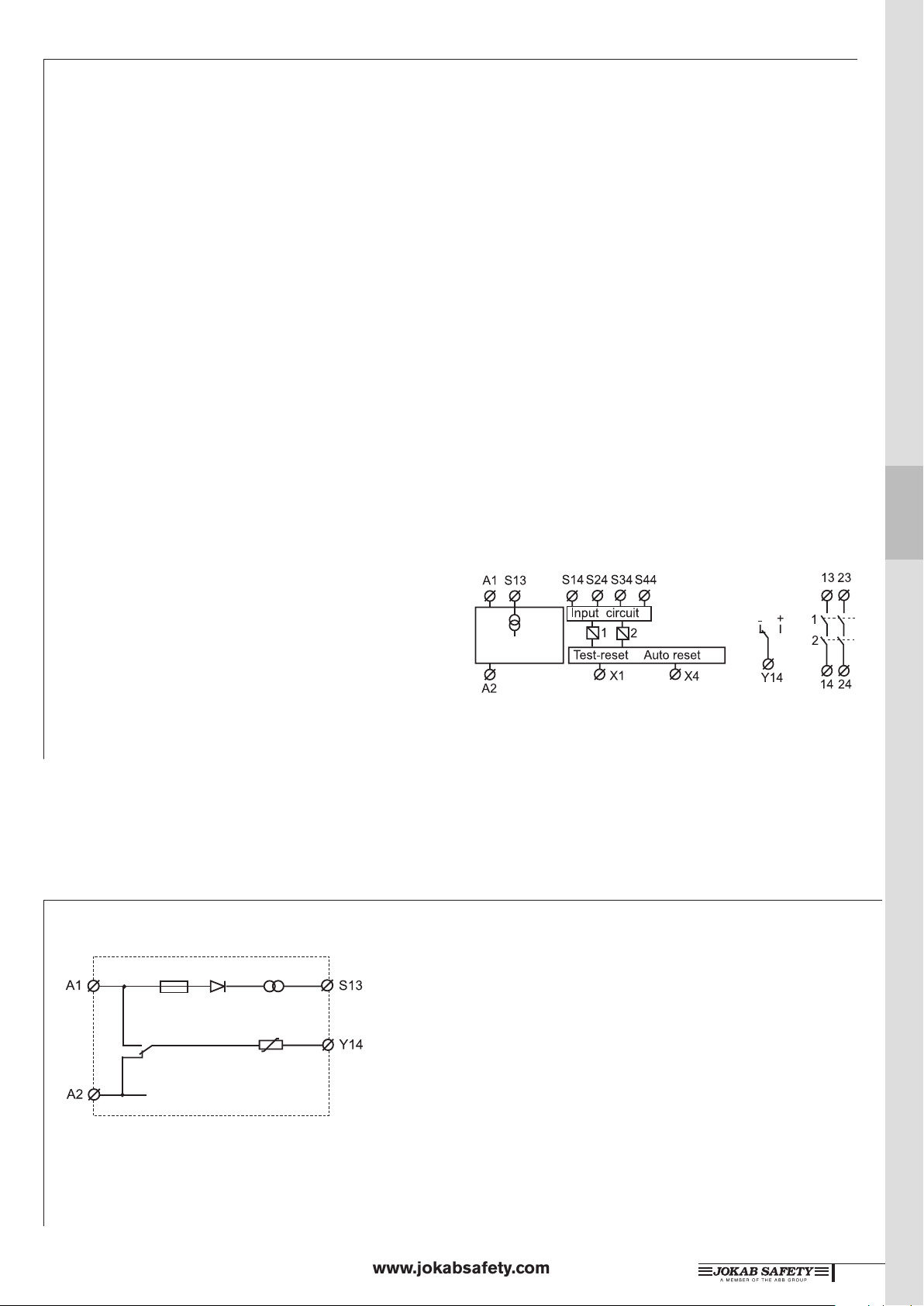

Technical information – RT9

Short circuit

protection

Automatic

fuse

Inputs

The RT9 can be configured to operate in either of the following

input options:

Single channel, 1 NO contact from +24VDC, 1. category 1,

up to PL c

Dual channel, 2 NO contacts from +24VDC, 2. category 3,

up to PL d

Dual channel, 1 NO, 1 NC contact from +24VDC, 3. category

4, up to PL e

Dual channel, 1 NO contact from 0V and 1 NO contact 4.

from +24VDC, category 4, up to PL e

Safety mat/contact strips, 1 ‘contact’ from 0V and 1 5.

‘contact’ +24VDC, category 3, up to PL d

When the input/inputs are activated and the test/supervised reset

is complete, relays 1 and 2 are energised. These are de-energised

when the input/inputs are de-activated in accordance with the

input option chosen or in case of a power failure.

Relays 1 and 2 must both be de-energized before the RT9 can

be reset.

Relay output status information

The RT9 has a changeover contact relay output that can be connected to a PLC, control lamp, computer or similar. The output

gives information about the status of the relay.

Indication of low voltage

The ‘On’ LED will flash if the relay supply voltage falls below an

acceptable level. This indication will also be given if a monitored

safety mat/contact strip is actuated. Please see Connection option 5.

Safety level

The RT9 has internal dual and supervised safety functions. Power

failure, an internal faulty component or external interference will

not present a risk to options with the highest safety level. A manual

reset requires that the reset input is closed and opened before

the safety relay outputs are activated. A short-circuit or a faulty

reset button is consequently supervised.

When the RT9 is configured for dual channel input, both the

inputs are supervised for correct operation before the unit can

be reset.

The input options 3 and 4 have the highest safety levels as all

short-circuits and power failures are supervised. This in combination with an internal current limitation makes the relay ideal for

supervision of safety mats and contact strips.

Regulations and standards

The RT9 is designed and approved in accordance with appropriate directives and standards. See technical data.

1

2

3

4

5

Reset and testing

The RT9 has two reset options; manual and automatic. The manual

supervised reset can be used when the RT9 is monitoring safety

devices that can be bypassed, i.e. to ensure that the outputs of

the safety relay do not close just because a gate is closed. The

automatic reset option should only be used if appropriate from a

risk point of view.

Due to special internal circuits the RT9 can be automatically

reset regardless of the operational voltage rise time, this being

an important factor when large loads are started up on the same

power supplies at the same time.

In addition, the RT9 can also test (supervise), if for example,

contactors and valves etc are de-energised/de-activated before

a restart is made.

Connection of supply - RT9

DC supply

Connection examples

For examples of how our safety relays can solve various safety

problems, please see the section “Connection examples”.

6

7

8

9

10

The RT9 should be supplied with +24 V on A1

and 0 V on A2.

NOTE

If cable shielding is used this must be connected

to an earth rail or an equivalent earth point.

11

12

13

14

Loading...

Loading...