Jokab Safety RT7 Catalog Page

www.jokabsafety.com

6:10

www.jokabsafety.com

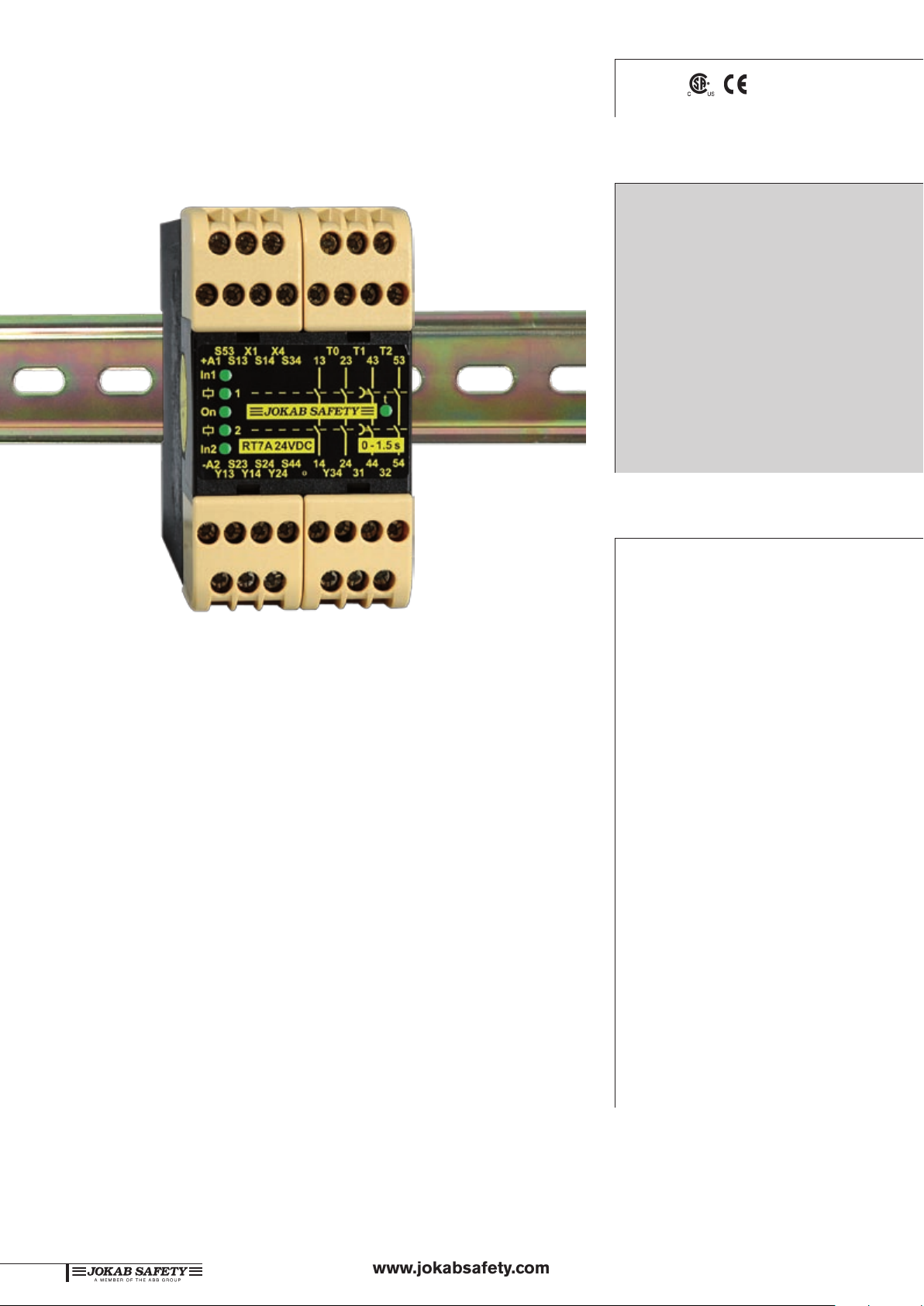

Safety relay

RT7

Approvals:

TÜV Nord

Safety relay for:

Emergency stops

Light curtains

Three position devices

Interlocked gates/hatches

Magnetic switches

Light beams

Safety mats

Contact strips

Foot operated switches

Universal relay with delayed outputs

The RT7 is a universal relay that can be used to supervise both

safety devices and the internal safety of your machinery. In addition, you can select the safety level that is required for each

installation. All this is possible because the RT7 has the most

versatile input options arrangement available on the market. The

RT7 can therefore replace many other relays.

The RT7 has four (4 NO) dual safety outputs of which two may

be delayed for up to three seconds in order to achieve a safe

and ‘soft’ stop. A ‘soft’ stop allows machinery to brake and stop

gently before power is removed. A ‘soft’ stop has many benefits:

the machinery life will be prolonged, processed products will not

be damaged, and restarts from the stopped position are made

possible and easier.

Another option with the RT7 is manual or automatic resetting. A

manual supervised reset is used for gates and other safety devices

that can be bypassed, while an automatic reset is used for small

safety hatches if deemed appropriate from a risk point of view.

In addition, the RT7 has information outputs that follow the

inputs and outputs of the relay. These outputs indicate if for example a gate is opened or closed, if there is a delay or if the relay

needs to be reset.

Choose the RT7 to simplify your safety circuits and reduce

your costs.

Features:

4 NO/1 NC relay outputs, 2

NO outputs can be delayed

for soft stops

Delay times RT7A 0; 0,5;

1,0; 1,5 s RT7B 0; 1,0; 2,0;

3,0 s

Five input options

Single or dual channel input

Manual supervised or automatic reset

Test input for supervision of

external contactors

Width 45 mm

LED indication of supply,

inputs, outputs, short-circuit

and low voltage level

Three voltage free transistor

information outputs

Supply 24 VDC, 24, 48, 115

or 230 VAC

Quick release connector

blocks

www.jokabsafety.com

6:11

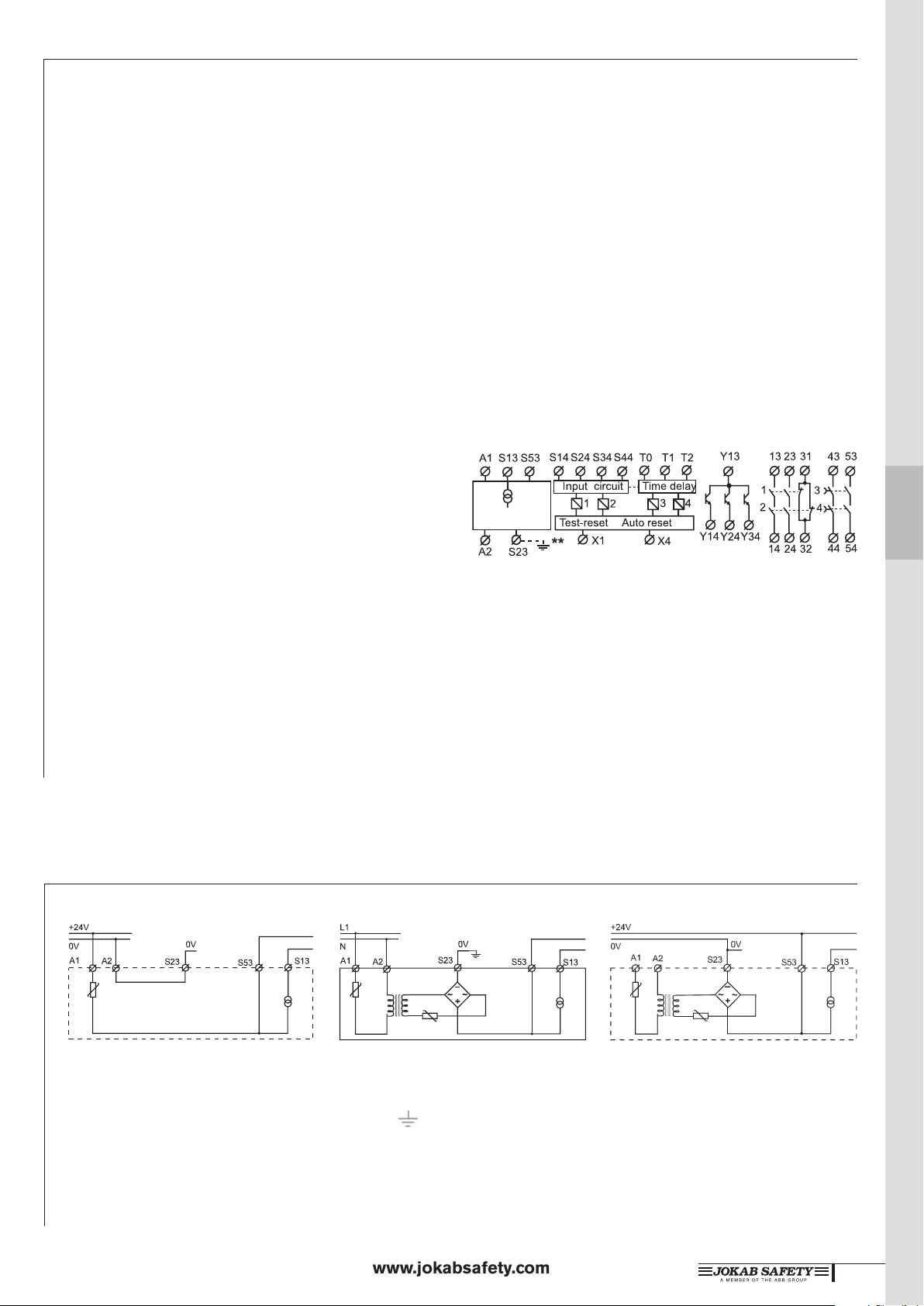

Technical information - RT7 A/B

Inputs

The RT7 can be configured to operate in either of the following

input options:

Single channel, 1 NO contact from +24 VDC, safety 1.

category 1, up to PL c

Dual channel, 2 NO contacts from +24 VDC, 2. category 3,

up to PL d

Dual channel, 1 NO, 1 NC contact from +24 VDC, 3.

category 4, up toPL e

Dual channel, 1 NO contact from 0V and 1 NO contact 4.

from +24 VDC, category 4, up toPL e

Safety mats/contact strips, 1 ‘contact’ from 0V and 1 5.

‘contact’ from +24 VDC, category 3, up toPL d

Safety level

The RT7 has internal dual and supervised safety functions. Power

failure, an internal faulty component or external interference will

not present a risk to options with the highest safety level. A manual

reset requires that the reset input is closed and opened before

the safety relay outputs are activated. A short-circuit or a faulty

reset button is consequently supervised.

When the RT7 is configured for dual channel input, both the

inputs are supervised for correct sequence operation before the

unit can be reset. The input options 3 and 4 have the highest safety

levels as all short-circuits and power failures are supervised. This

in combination with internal current limitation makes the relay ideal

for supervision of safety mats and contact strips.

1

2

3

When the input/inputs are activated and the test/supervised reset is complete, relays 1,2,3 and 4 are activated. Relays 1 and 2

are immediately de-energized when the inputs are deactivated in

accordance with the input option selected. Relays 3 and 4 are

either de-energized immediately or after the selected time delay.

All the relays (1,2,3 and 4) must be de-energized before the RT7

can be reset.

Transistor output status information

The RT7 has three(3) voltage free transistor outputs that can be

connected to a PLC, computer or other monitoring device. These

outputs give the input and output status of the relay.

Reset and testing

The RT7 has two reset options; manual and automatic.

The manual supervised reset is utilised when the RT7 is used

to monitor safety devices that can be bypassed, i.e. to ensure

that the outputs of the safety relay do not close just because the

gate is closed.

The automatic reset should only be used if acceptable from a

risk point of view. The RT7 can also test (super vise), if for example,

contactors and valves etc are de-energized/de-activated before

a restart is allowed.

Indication of low voltage

The ‘On’ LED will flash if the relay voltage falls below an acceptable

level. This indication will also be given if a monitored safety mat/

contact strip is actuated. See connection option 5.

Regulations and standards

The RT7 is designed and approved in accordance with appropriate directives and standards. Se tekniska data.

Connection examples

For examples of how our safety relays can solve various safety

problems, see the section “Connection examples”.

**Only for AC supply

4

5

6

7

8

Connection examples – RT7

DC supply

The RT7 DC option should be supplied

with +24 V on A1 and 0 V on A2.

AC supply

The RT7 AC option should be supplied

with the appropriate supply voltage via

connections A1 and A2.

The S23/ must be connected to protective earth

DC-supply of AC-units

Samtliga AC-moduler kan också matas

med +24 VDC på S53 och 0V på S23.

NOTE

With both DC and AC modules, if cable

shielding is used this must be connected

to an earth rail or an equivalent earth

point.

9

10

11

12

13

14

Loading...

Loading...