Jokab Safety Optical safety devices Catalog

OPTICAL SAFETY DEVICES

—

Optical safety devices

3– 1

3– 2 Introduction and overview

3– 8 Safety light curtain - Orion1 Base

3– 16 Safety light curtain - Orion1 Extended

3– 24 Safety light grid - Orion2 Base

3– 32 Safety light grid - Orion2 Extended

3– 40 Safety light grid - Orion3 Base

3– 48 Safety light grid - Orion3 Extended

3

3– 2 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Introduction and overview

Selection guide

Light curtains and light grids that cover most types of applications.

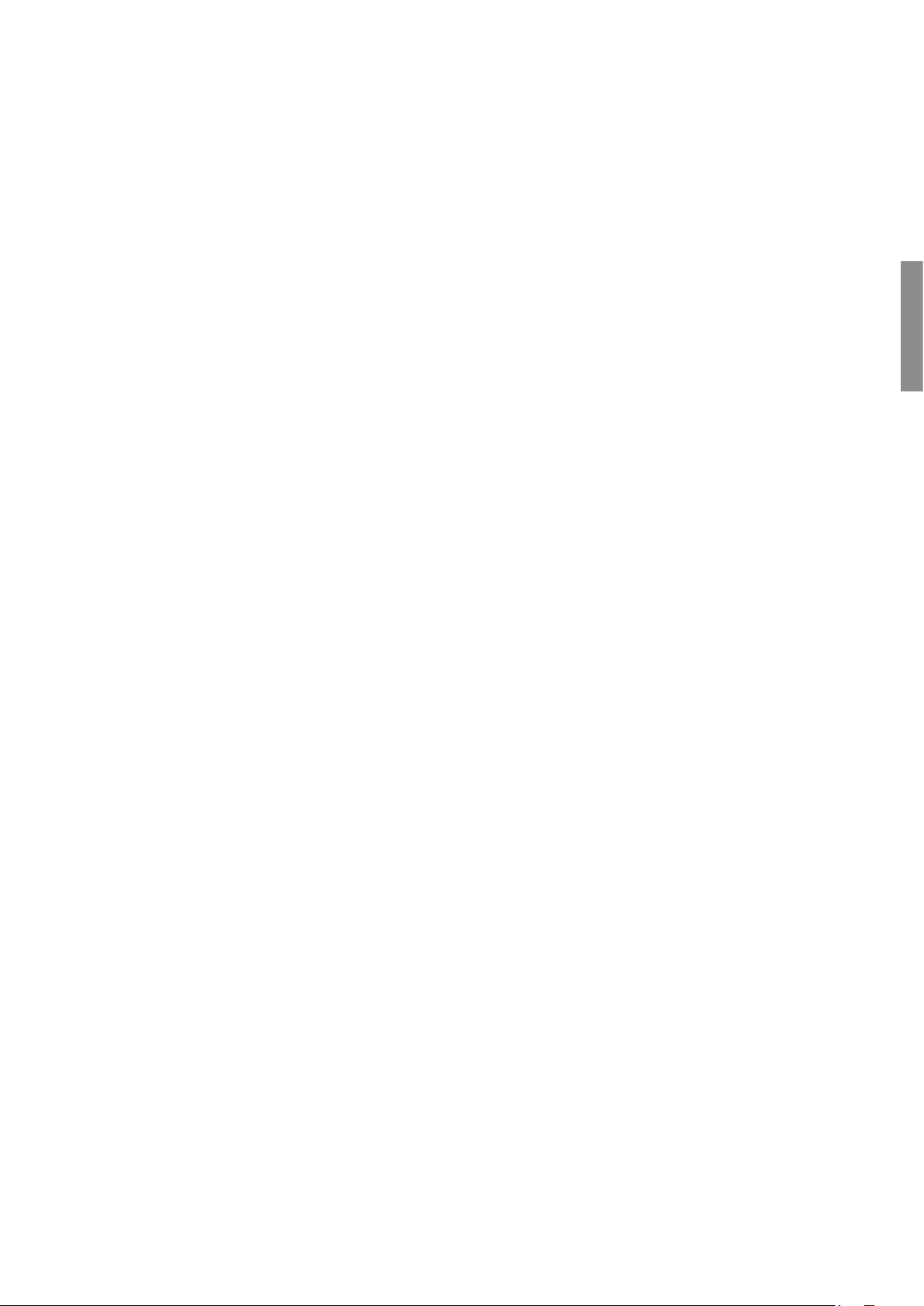

Orion1

Function Light curtain, Transmitter + Receiver, Slim profile Function Light grid, Transmitter + Receiver,

3

Image

Type Orion1 Base Orion1 Extended Type Orion2 Base Orion2

Type of detection

Finger

Resolution 14 mm 30 mm 14 mm 30 mm Resolution

Protected height 15-180 cm 15-180 cm 30-180 cm 30-180 cm Protected height 50-120 cm

Applications Manually serviced machines with short safety

distances.

Functions Functions

Range 6 m 19 m 7 m 20 m Range 50 m 50 m Up to 8 m Up to 8 m

Auto/Manual reset Auto/Manual reset

EDM EDM

Muting Muting

Override Override

Integrated muting

lamp

Blanking Blanking

No dead zone No dead zone

Coding Coding

Hand

Manually serviced machines with short safety

distances. With advanced features like muting,

blanking and cascading.

Finger

Hand

Cascading Cascading

OPTICAL SAFETY DEVICES 3– 3

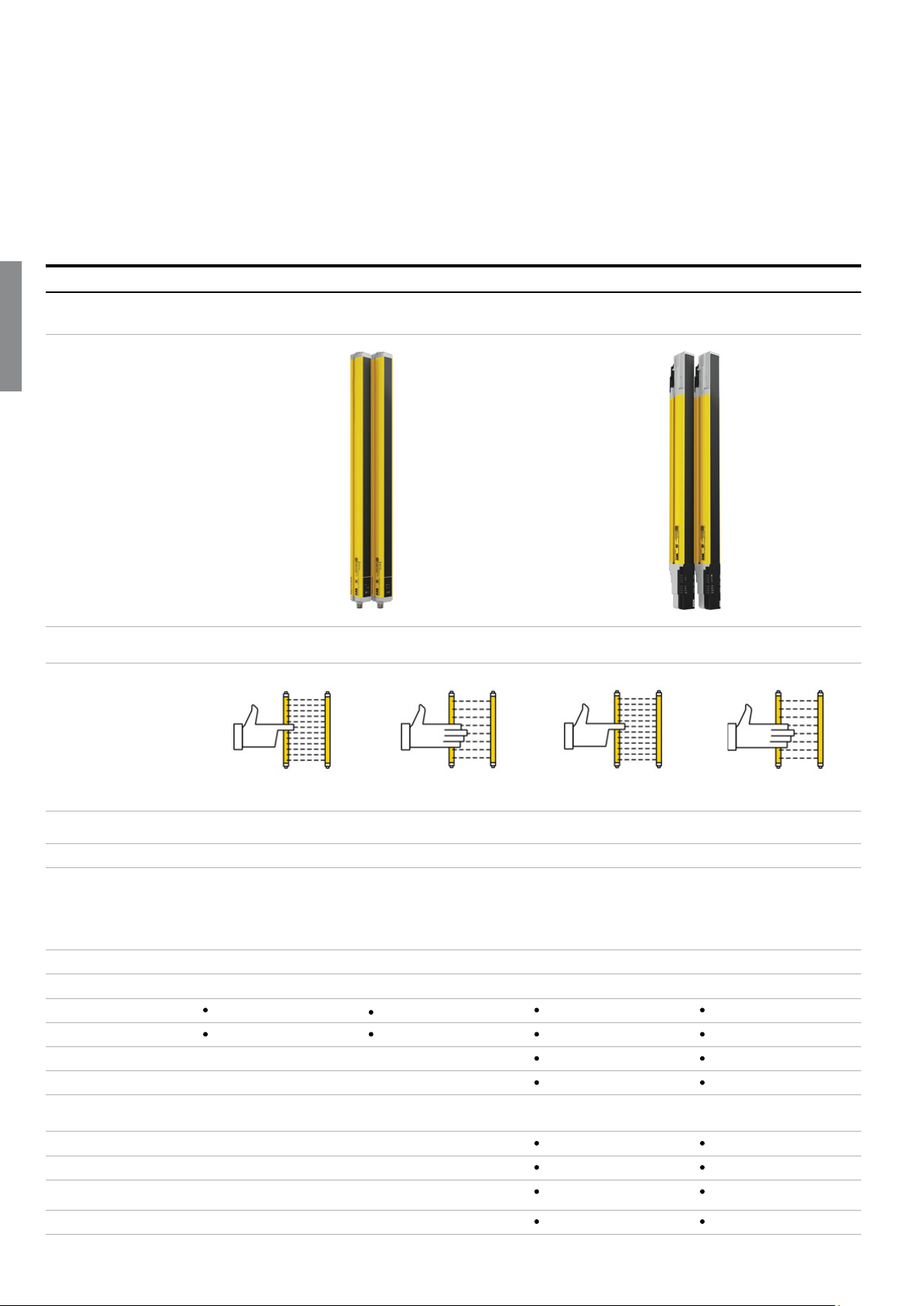

Orion2 Orion3

Light grid, Active + Passive units, Sturdy profile

Slim profile

Image

3

Type of detection

Applications

2, 3 or 4 beams

Perimeter guarding

over long distances

Extended

Body

Perimeter guarding

over long distances

with muting

Orion3 Base Orion3

Extended

Perimeter guarding

with one-sided con-

Perimeter guarding with one-sided

connection and muting

nection

Body

Integrated muting

lamp

3– 4 SA FETY PRODUCTS C ATALOG ABB JOKAB SAFETY

—

Introduction and overview

Selection orientation

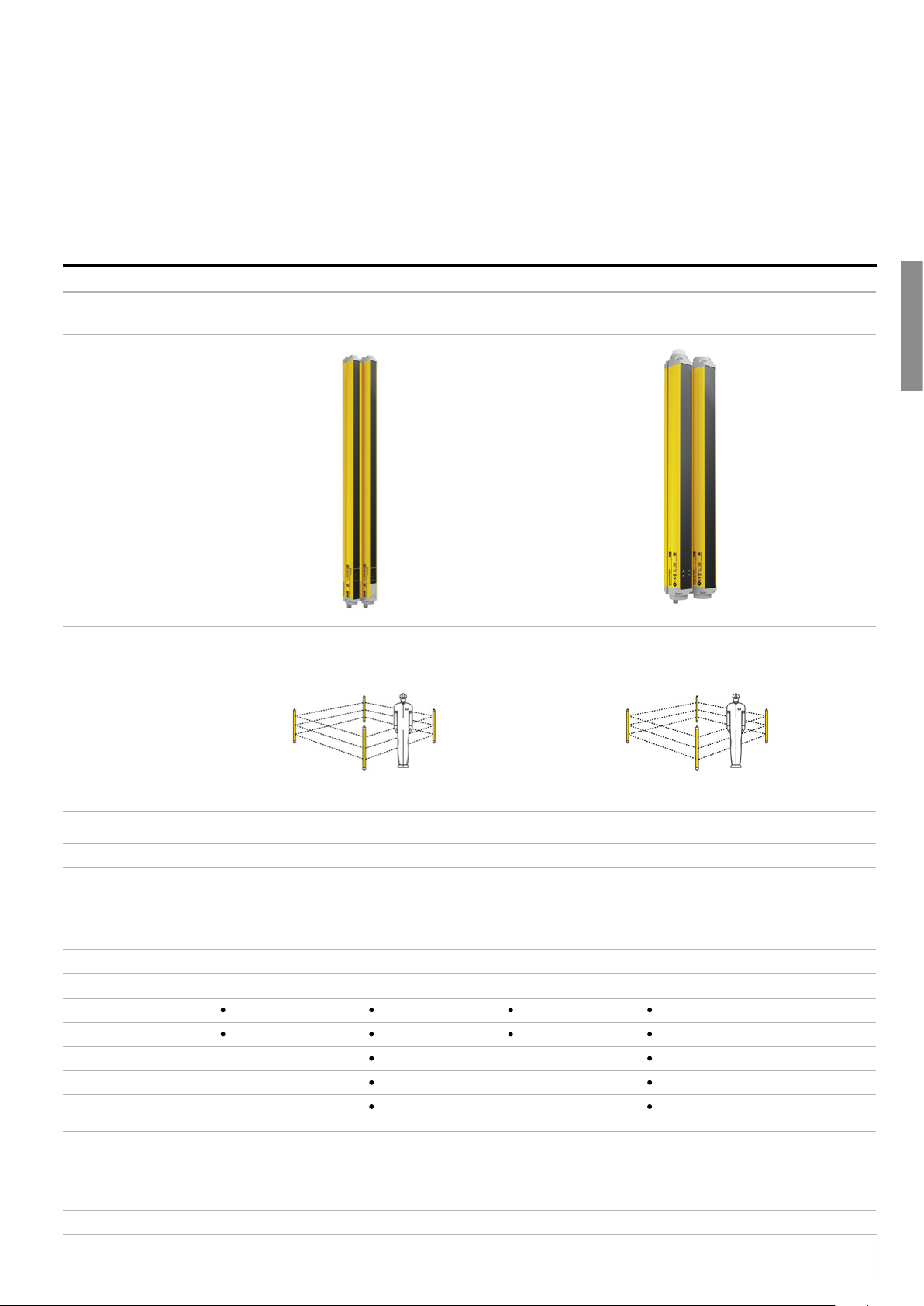

Choose the right resolution for your application

Finger detection

Light curtains with 14 mm resolution are intended for finger

detection when the light guard needs to be very close to the

machine in order to give the operator a good view and easy

3

accessibility to the machine.

Body detection

Light grids have a resolution adapted for detection of the

whole body and are intended for perimeter guarding where

there is a requirement for high accessibility. They offer a

very good sensing range, but require a much greater safety

distance than light guards for finger and hand detection.

Hand detection

Light curtains with 30 mm resolution are intended for hand

detection and area protection and is often a good compromise between cost and accessibility to the machine. They

offer a better sensing range than finger detection light

curtains, but require a slightly greater safety distance.

OPTICAL SAFETY DEVICES 3– 5

—

Introduction and overview

Standards

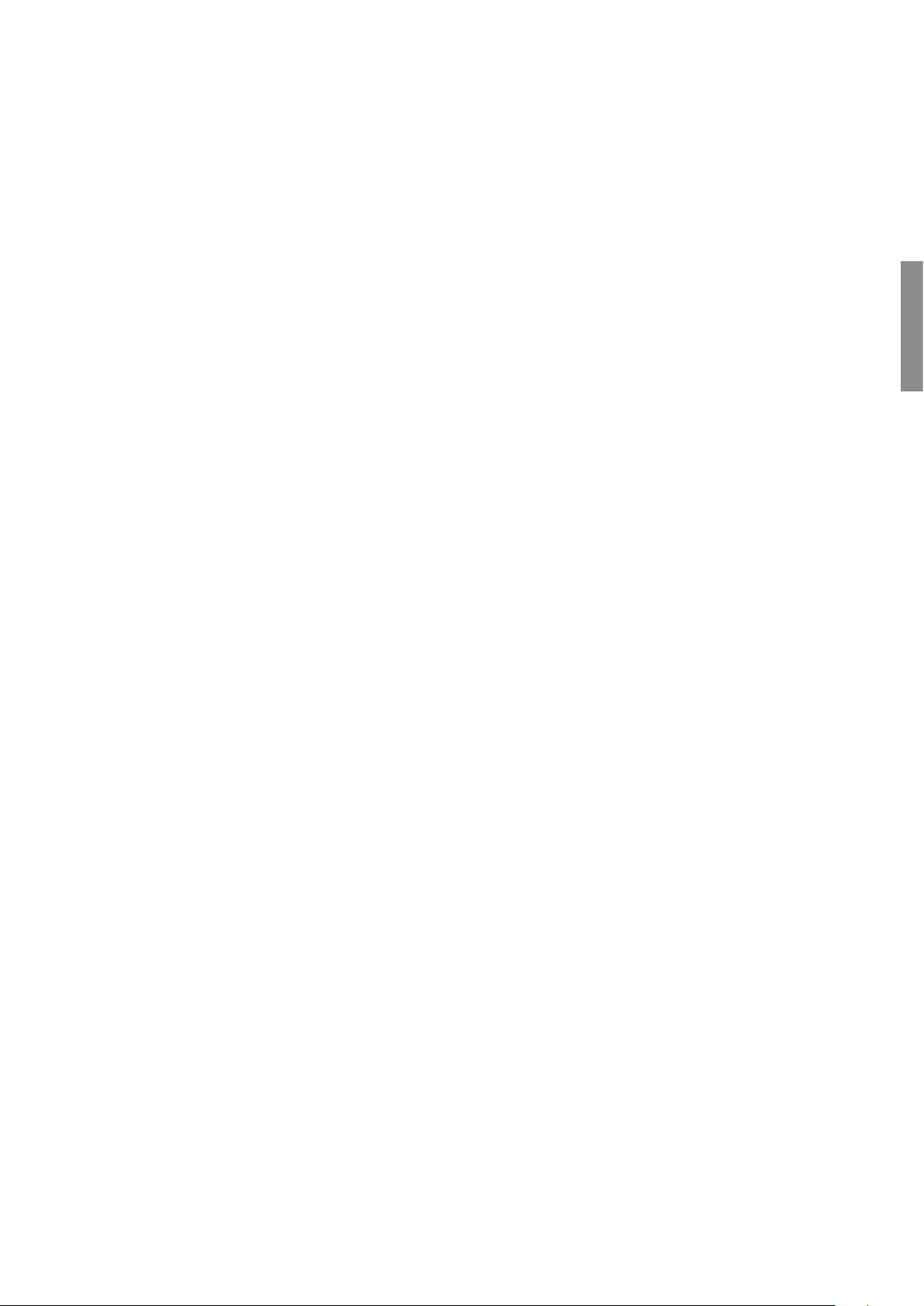

Resolution and safety distance

The optical safety device must be installed so that no-one can reach the hazardous area

without first passing through the detection zone of the light guard. The distance from the

hazardous area to the detection zone of the optical safety device must be large enough in

order for the machine to have time to stop before someone can reach the hazardous area.

This distance is called the safety distance, and it shall be calculated using the formula from

EN ISO 13855.

The safety distance is influenced by the distance between each beam in the light guard. The

closer the beams are together, the smaller the safety distance can be, which is why light curtains for finger detection can be placed much closer to the hazardous area than light grids

for body detection.

3

3– 6 SAFET Y PRODUCTS C ATALOG ABB JOKAB SAFETY

—

Safety distance according to EN ISO 13855

The distance ’S’ is the minimum distance between a light curtain and a hazardous

area. This is calculated with the formula from EN ISO 13855 - Safety of machinery

- Positioning of safeguards with respect to the approach speeds of parts of the

human body.

S = (K x T) + C

3

S = minimum distance in mm

K = approach speed (of hand or body) in mm/s

T = stopping time of the machine (including reaction time of

safety devices) in seconds

C = additional distance in mm based upon the body´s

intrusion towards the hazardous area before the safety

device has been actuated.

NB If it is possible to reach the hazard zone by reaching over

the light beam, an adjustment is made to the formula. In

table 1 in EN ISO 13855 an alternative safety distance addition (C

value out of C and C

hazard zone by reaching over the light curtain/grid.

) is given to the formula S = (K x T) + C. The greatest

ro

Resolution for finger (≤14 mm) gives C = 0

is to be used to prevent reaching the

ro

Minimum distances for light curtains installed vertically and horizontally

according to EN ISO 13855

S = minimum distance in mm

H1 = the lower beam may not

be situated higher than 300

mm above the ground

H2 = the upper beam may

not be situated lower than

900 mm above the ground

For S ≤ 500 mm the minimum distance for vertical

installation is calculated with the following formula:

S = minimum distance in mm

H = the light curtain detection zone must be positioned between 0 and 1000

mm above the floor

The minimum distance for horizontal installation is

calculated with the following formula:

S = (2000 x T) + 8 x (d-14)

where d is the light curtain´s resolution in mm.

K = 2000 mm/s is used to represent the speed of the hand.

The expression (8 x (d-14)) may never be less than 0. Minimum distance S may never be less than 100 mm.

If the minimum distance according to the formula above

gets larger than 500 mm one can instead use:

S = (1600 x T) + 8 x (d-14)

K = 1600 mm/s is used to represent the speed of the body.

Minimum distance according to this formula is 500 mm.

S = (1600 x T) + (1200 - 0.4 x H)

where H is the height of the detection zone above the reference plane, e.g. the ground

(1200 – 0,4 x H) may not be less than 850 mm. Depending on

the resolution, d, that the light curtain has, there is a minimum height where the detection zone may be placed. This is

calculated with:

H = 15 x (d – 50).

H cannot be less than 0. With a resolution d =14 or 30 mm

one can therefore install the light curtain from H = 0 and up.

The higher it is situated, the shorter the minimum distance

gets. The highest permissible height H of the detection zone

is 1000 mm.

When you use a horizontal light curtain as perimeter protection, the depth of the light curtain shall be at least 750 mm

to prevent people from inadvertently stepping over it. The

estimated minimum distance is measured from the machine’s hazardous section to the outermost beam of the

horizontal light curtain (seen from the machine).

OPTICAL SAFETY DEVICES 3 – 7

Minimum distance for light beams according to EN ISO

13855

For light beams the minimum distance is calculated from

the following:

S = (1600 x T) + 850 mm

NOTE! The additional distance will in most cases be more

than 850 mm due to the possibility to reach over a light

beam. (C

The formula applies to light guards with 2, 3 or 4 beams. It

is the risk assessment that decides the number of beams

that are to be chosen. The following possibilities must be

considered.

– to crawl under the lowest beam;

– to reach over the top beam;

– to reach in between two beams;

– that the body passes in between two beams.

To fulfill the requirements the beams shall be installed at the

following heights:

)

ro

Minimum distance for single beams according to EN ISO

13855

A single beam as only protection is normally not suitable to

prevent whole body access. Single beams are mostly used in

combination with other safety devices or fixed guards.

3

The risk assessment should determine if a single beam is a

suitable protection for the hazard in question.

The safety distance is calculated using:

S = (1600 x T) + 1200 mm

A height of 750 mm from the reference plane has been found

suitable to prevent inadvertent access to the danger zone.

Number of beams Height over the reference plane,

4 300, 600, 900, 1200

3 300, 700, 1100

2 400, 900

e.g. ground

3– 8 SA FETY PRODUCTS C ATALOG ABB JOKAB SAFETY

—

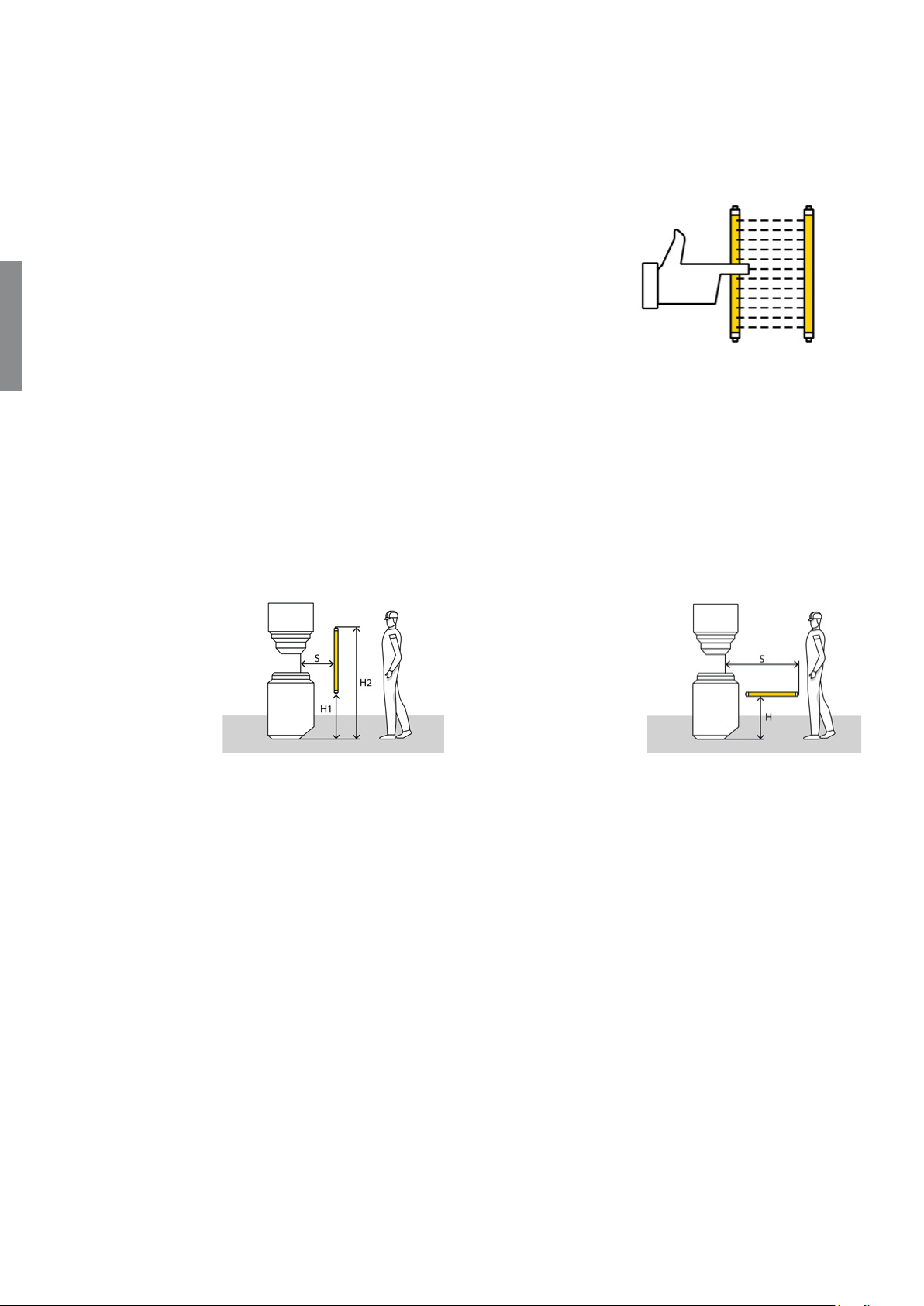

Safety light curtain

Orion1 Base

Orion1 Base is an easy to use light

curtain with compact dimensions

3

and two resolutions for detection of

fingers and hands.

Light curtains are usually used closed

to the hazardous zone when repeated

access to the machine is necessary,

for example manually serviced

machines.

Light curtains can also be used to

limit work zones inside the hazardous

area and be mounted horizontally for

area protection.

Cost effective solution

No more functions than neccessary

Orion1 Base comes with a minimum of

advanced functionalities to save cost.

Minimized cabling

A local reset button can be connected

directly to the light curtain. In this way

there is no need for a cable between

the reset button and the electrical

cabinet or for an extra control module.

External device monitoring

Each light curtain can monitor the

actuators without any extra control

module (EDM function).

Continuous

operation

Visible alignment level

Since the alignment level is displayed,

the alignment can be improved before

the occurrence of an unwanted stop.

Extensive error indication

Extensive error indication reduces

troubleshooting time.

Protection against harsh environment

Protective tubes and lens shields

protect the devices in harsh environments.

Easy to install

Easy to align

Alignment help and a wide angle within

the limits of a Type 4 device facilitate

alignment. Rotation brackets also simplify alignment.

Easy to connect

M12 connectors speed up cabling.

OPTICAL SAFETY DEVICES 3– 9

—

Applications and features

Orion1 Base

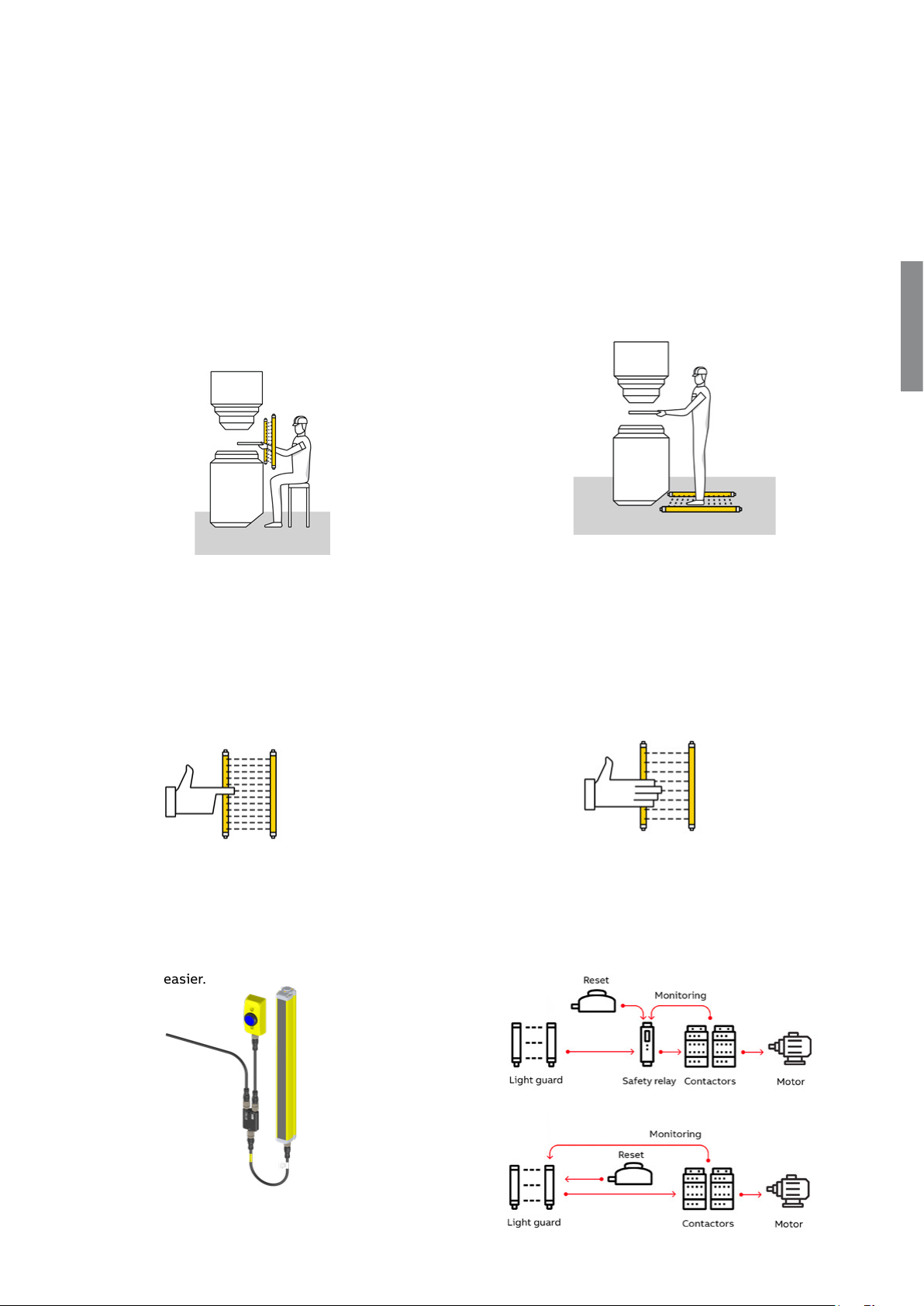

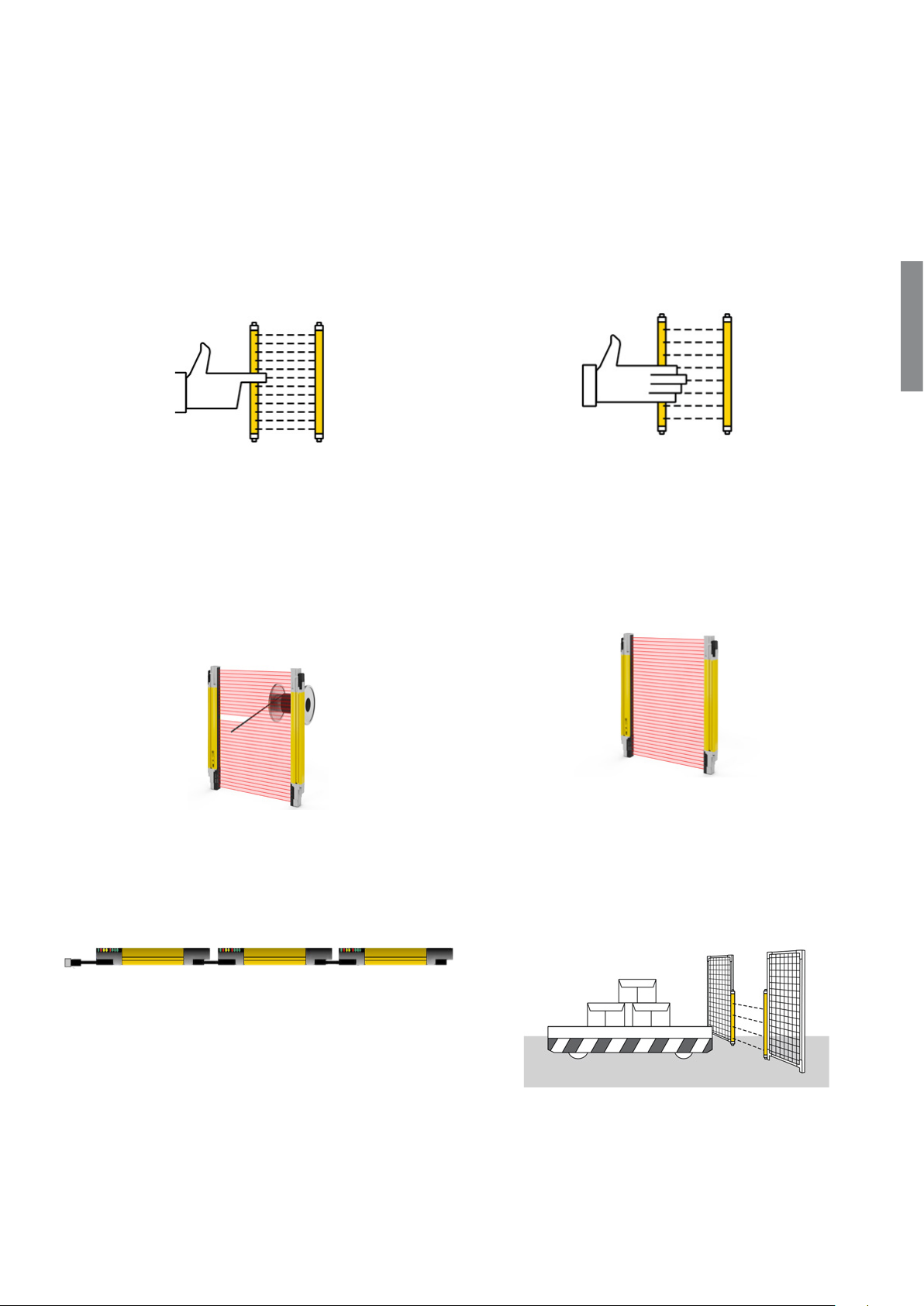

Applications

Vertical mounting

When using standard vertical mounting the light guard can

be placed close to the hazard zone. This is suitable for applications where repeated access to the machine is necessary,

e.g. manually serviced machines.

Features

Finger detection

A 14 mm resolution is intended for finger detection when

the light guard needs to be very close to the machine in

order to give the operator a good view and easy accessibility

to the machine. A 14 mm resolution enables a sensing range

of 6 m.

Horizontal mounting

Horizontal mounting is mainly used for area protection and

limitation of work zones.

3

Hand detection

A 30 mm resolution is intended for hand detection and area

protection and is a good compromise between cost and

accessibility to the machine. A 30 mm resolution enables a

sensing range of 19 m.

Local reset

A local reset button is connected directly to the light guard

instead of to the safety control module in the electrical

cabinet. This saves safety relays/PLC inputs and minimizes

cabling to the electrical cabinet. Clever accessories makes

the connection easier.

EDM

External Device Monitoring is a feature allowing the light

guard to supervise the actuators in simpler applications,

eliminating the need for a safety relay or programmable

safety controller.

3– 10

—

Safety light curtain

Orion1 Base

3

2TLC172787F0201

Orion1 Base

SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Ordering Details

Detection

(Resolution mm)

Finger

(14)

Hand

(30)

Protected height

mm

150 Orion1-4-14-015-B 2TLA022300R0000

300 Orion1-4-14-030-B 2TLA022300R0100

450 Orion1-4-14-045-B 2TLA022300R0200

600 Orion1-4-14-060-B 2TLA022300R0300

750 Orion1-4-14-075-B 2TLA022300R0400

900 Orion1-4-14-090-B 2TLA022300R0500

1050 Orion1-4-14-105-B 2TLA022300R0600

1200 Orion1-4-14-120-B 2TLA022300R0700

1350 Orion1-4-14-135-B 2TLA022300R0800

1500 Orion1-4-14-150-B 2TLA022300R0900

1650 Orion1-4-14-165-B 2TLA022300R1000

1800 Orion1-4-14-180-B 2TLA022300R1100

150 Orion1-4-30-015-B 2TLA022302R0000

300 Orion1-4-30-030-B 2TLA022302R0100

450 Orion1-4-30-045-B 2TLA022302R0200

600 Orion1-4-30-060-B 2TLA022302R0300

750 Orion1-4-30-075-B 2TLA022302R0400

900 Orion1-4-30-090-B 2TLA022302R0500

1050 Orion1-4-30-105-B 2TLA022302R0600

1200 Orion1-4-30-120-B 2TLA022302R0700

1350 Orion1-4-30-135-B 2TLA022302R0800

1500 Orion1-4-30-150-B 2TLA022302R0900

1650 Orion1-4-30-165-B 2TLA022302R1000

1800 Orion1-4-30-180-B 2TLA022302R1100

Typ e

(Transmitter + receiver)

Order code

JSM Orion01

—

Spare parts (included when ordering Orion)

Description Typ e Order code

4 standard brackets for Orion1 & Orion2 JSM Orion01 2TLA022310R0000

2TLC172781F0201

—

Accessories

Orion1 Base

Orion Laser pointer

2TLC172783F0201

JSM Orion03

Smile 11 RB

M12-3R

Tina 10C

OPTICAL SAFETY DEVICES 3– 1 1

—

Accessories

Mounting accessories

Typ e Order code

2TLC172816F0201

Description

Orion Test Piece 14 mm Orion TP-14 2TLA022310R5200

Orion Test Piece 30 mm Orion TP-30 2TLA022310R5300

Orion Laser pointer Orion Laser 2TLA022310R5000

JSM M5B special T-nut M5 to be used with M5x12 screw for mounting Orion on Quick-Guard T-nut JSM M5B 2TLA040035R0400

4 rotation brackets for Orion1 Base JSM Orion03 2TLA022310R0100

Kit for mounting of Orion1 & Orion2 in Stand (4 pieces for lengths shorter than 1200 mm) JSM Orion06 2TLA022310R0400

Kit for mounting of Orion1 & Orion2 in Stand (6 pieces for lengths of 1200 mm or more) JSM Orion07 2TLA022310R0500

Kit for mounting of Orion1 Mirror in Stand JSM Orion11 2TLA022310R0900

Orion Plate kit for adjustment of protective stand Orion Stand Plate 2TLA022312R5000

Deviating mirror to be mounted in Orion Stand with one kit JSM Orion11 Orion1 Mirror*

Protective stand Orion Stand*

Protective tube Orion WET*

Lens shield Orion Shield*

2TLC172367F0201

Connection accessories

Smile reset button with NO contact Smile 11 RA 2TLA030053R0000

Smile reset button with NO contact for Pluto Smile 11 RB 2TLA030053R0100

Smile reset button with NO contact for Orion1 Base Smile 11RO1 2TLA022316R3000

Y-connector for series connection of DYNlink devices with M12-5 connectors, e.g. Eden M12-3A 2TLA020055R0000

2TLC172012V0201

Y-connector for connection of a Smile reset button to Orion M12-3R 2TLA022316R0000

Y-connector for easy connection of a transmitter M12-3D 2TLA020055R0300

Adaptation of OSSD to DYNlink. Two M12-5 connectors. Tina 10A v2 2TLA020054R1210

Adaptation of OSSD to DYNlink with possibility to connect a local reset button. Three M12-5

Tina 10B v2 2TLA020054R1310

connectors.

Adaptation of OSSD to DYNlink with possibility to power the transmitter. Three M12-5 connectors.

*These accessories are available in different sizes.

2TLC172477F0201

For more information see:

Orion1 Mirror 2TLC172058L0201, Orion Stand 2TLC172059L0201, Orion WET 2TLC172061L0201, Orion Shield 2TLC172071L0201

Tina 10C v2 2TLA020054R1610

For more information about the connection accessories, please see:

Orion connection accessories 2TLC172101L0201

3

—

How to choose correct reset button

Local or global reset Adaption to DYNlink* Safety controle module Typ e Useful connection accessories

Local

reset button con-

nected to the light guard

(Orion in manual reset

mode)

Global reset button

connected to the control

module

(Orion in automatic reset

mode)

* The ABB Jokab Safety DYNlink solution offers the following advantages:

- Serial connection of safety devices while maintaining PLe/cat. 4, up to 25 Tina 10 per Vital and up to 5 Tina 10 per

Pluto input.

- Only one safety input of the Pluto instead of two with the standard OSSD outputs.

** Smile 11 RA has one NO contact, which is the most common for reset buttons. Please check what is requested for the chosen

safety control module.

Yes Vital or Pluto Smile 11RO1

Tina 10B: OSSD to DYNlink + local

reset button

M12-3A: Serial connection of DYNlink

No Any safety control module

compatible with light guard

Smile 11RO1 M12-3R: Easy connection of a local

reset button

Yes Vital Smile 11 RA Tina 10A: OSSD to DYNlink

Tina 10C: OSSD to DYNlink + supply

to transmitter

Pluto Smile 11 RB Tina 10A: OSSD to DYNlink

Tina 10C: OSSD to DYNlink + supply

to transmitter

No Any safety control module

compatible with light guard

Smile 11 RA**

-

3– 1 2

SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Cables and connectors

Orion1 Base

M12-C61

3

M12-C61HE

M12-C334

M12-C01

C5 cable

2TLC172657F0201

2TLC010003F0201

—

Cable with connectors

Connector Female/male Length Special feature Typ e Order code

M12-5 Female 3 m M12-C31 2TLA020056R0500

(b) 6 m M12-C61 2TLA020056R0000

2TLC172951F0201

10 m M12-C101 2TLA020056R1000

Harsh environment, halogen free

20 m M12-C201 2TLA020056R1400

Female + male 0.3 m M12-C0312 2TLA020056R5800

(a) 0.06 m M12-C00612 2TLA020056R6300

1 m M12-C112 2TLA020056R2000

3 m M12-C312 2TLA020056R2100

6 m M12-C612 2TLA020056R2200

10 m M12-C1012 2TLA020056R2300

16 m M12-C1612 2TLA020056R5400

20 m M12-C2012 2TLA020056R2400

Male 6 m M12-C62 2TLA020056R0200

(c) 10 m M12-C102 2TLA020056R1200

M12-8 Female 6 m M12-C63 2TLA020056R3000

(d) 10 m M12-C103 2TLA020056R4000

Harsh environment, halogen free

2TLC172931F0201

Female + male 0.06 m M12-C00634 2TLA020056R6400

20 m M12-C203 2TLA020056R4100

(e) 1 m M12-C134 2TLA020056R5000

3 m M12-C334 2TLA020056R5100

M12-8 male + female Female + male 0.2 M12-CTO1BA

M12-8 male + female Female + male 0.2 M12-CTO1BM

M12-8 female - M12-5 male Female + male 1 M12-CTURAX-O1B

Letters (a, b, c, d, e, t1, t2, t3) refer to cables in connection examples, e.g:

2TLC010002T0001 Connection diagram Orion_cables_Tina10_M12-3A_M12-3D

2TLC010003T0001 Connection diagram Orion_cables_Smile11R_Urax_M12-3R

1)

M12-CTO1BA (t1) can be used for: - connection of Orion1 Base to Tina 10A/C

2) M12-CTO1BM (t

3)

M12-CTURAX-01B (t3) is used for: - the connection of Orion1 Base to URAX-D1R.

—

Separate cables and connectors

) can be used for: - connection of Orion1 Base to Tina 10B or M12-3R for use of a local reset button,

2

- replacement of Focus II in automatic reset with Orion in automatic reset.

The EDM function should be deactivated in all cases.

for example Smile 11ROx

- replacement of Focus II in manual reset with Orion in manual reset.

The EDM function should be deactivated in all cases.

The light guard is automatically configured in automatic reset and the EDM

function should be deactivated.

Description Typ e Order code

Connectors

M12-5 pole female, straight M12-C01 2TLA020055R1000

M12-5 pole male, straight M12-C02 2TLA020055R1100

M12-8 pole female, straight M12-C03 2TLA020055R1600

M12-8 pole male, straight M12-C04 2TLA020055R1700

Cable with 5 conductors

10 m cable with 5 x 0.34 shielded conductors C5 cable 10 m 2TLA020057R0001

50 m cable with 5 x 0.34 shielded conductors C5 cable 50 m 2TLA020057R0005

100 m cable with 5 x 0.34 shielded conductors C5 cable 100 m 2TLA020057R0010

200 m cable with 5 x 0.34 shielded conductors C5 cable 200 m 2TLA020057R0020

500 m cable with 5 x 0.34 shielded conductors C5 cable 500 m 2TLA020057R0050

2TLC010038F0201

Cable with 8 conductors

50 m cable with 8 x 0.34 shielded conductors C8 cable 50 m 2TLA020057R1005

100 m cable with 8 x 0.34 shielded conductors C8 cable 100 m 2TLA020057R1010

200 m cable with 8 x 0.34 shielded conductors C8 cable 200 m 2TLA020057R1020

500 m cable with 8 x 0.34 shielded conductors C8 cable 500 m 2TLA020057R1050

M12-C61HE 2TLA020056R8000

M12-C101HE 2TLA020056R8100

1

2TLA022315R3000

2

2TLA022315R3100

3

2TLA022315R3300

(a)

Orion receiver or active part

Tina 10B

Smile reset

1. + 24 VDC

2.

In

3.

0 V

4.

Out

5. Info

M12 5-pole male

5. Info

OPTICAL SAFETY DEVICES 3– 1 3

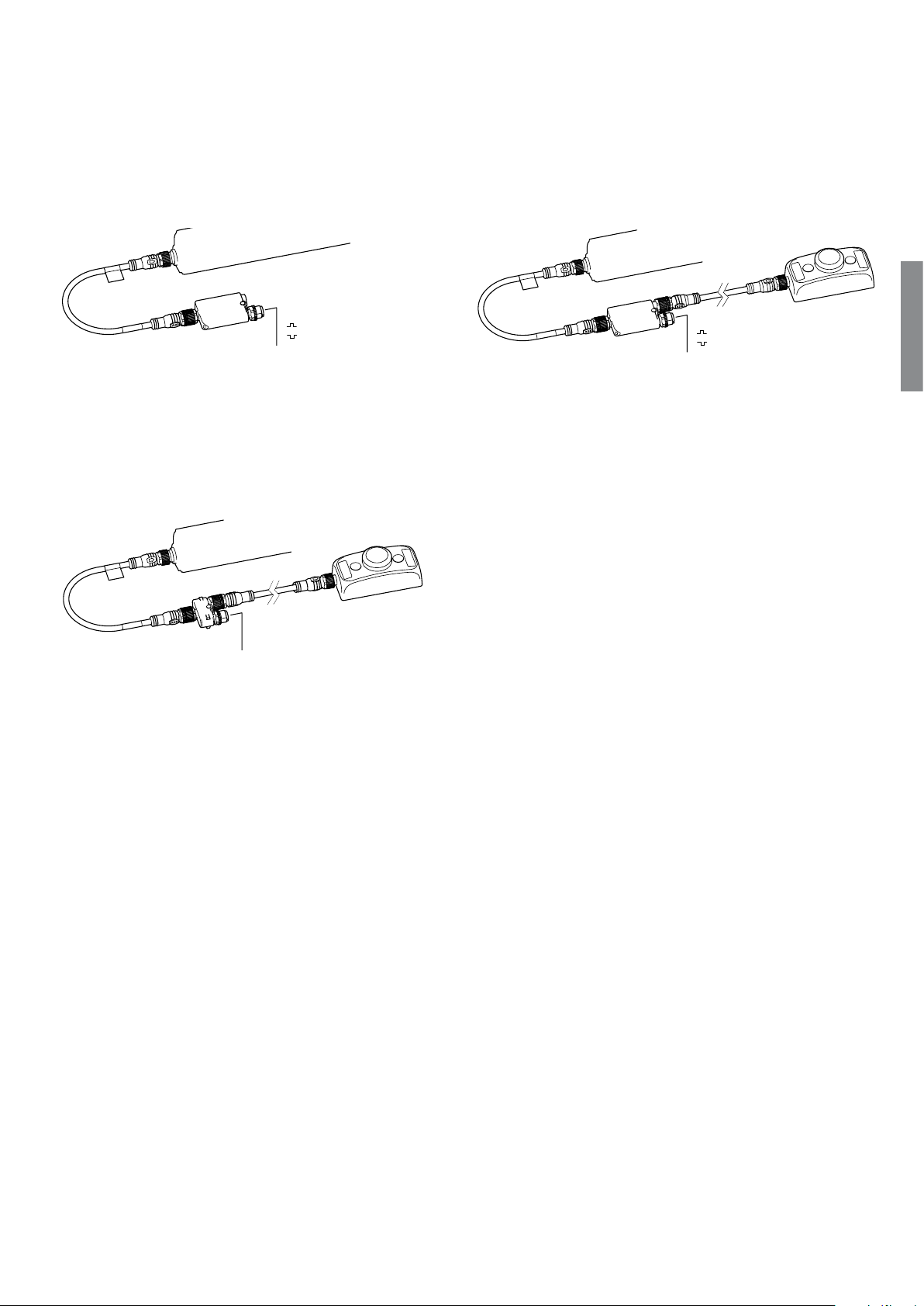

—

Connection examples

Orion1 Base

Orion receiver or active part

Reset to Orion with Tina 10BOrion with Tina 10A/C

(t1)

Cable

Tina 10A/C

M12 5-pole male

1. + 24 VDC

In

2.

0 V

3.

Out

4.

Without local reset button

Connection to the ABB Jokab Safety DYNlink signal via

Tina 10 A/C. To be used with Vital safety control module

or Pluto programmable safety controller.

Reset to Orion with M12-3R

Orion receiver or active part

M12-3R

)

(t

2

(a)

M12 5-pole male

1. + 24 VDC

2. OSSD1

3.

0 V

4. OSSD2

5. -

Smile reset

Connection of a local reset button via M12-3R.

(t

)

2

With local reset button

Connection to the ABB Jokab Safety DYNlink signal via

Tina 10B. To be used with Vital safety control module or

Pluto programmable safety controller.

3

3– 14 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Technical data

Orion1 Base

Technical data

Approvals

Conformity

2006/42/EC - Machinery

2004/108/EC - EMC

3

Functional safety data

EN 61508:2010 SIL3, PFH

EN 62061:2005+A1:2013 SILCL3, PFHD = 2.64 x 10

EN ISO 13849-1:2008 PL e, Cat. 4, PFHD = 2.64 x 10

Electrical data

Power supply +24 VDC ± 20%

Power consumtion, transmitter 1.5 W max

Power consumption, receiver 4 W max (without load)

Outputs 2 PNP

Short-circuit protection 1.4 A max

Output current 0.5 A max / output

Output voltage – ON Vdd -1 V min

Output voltage – OFF 0.2 V max

Capacitive load 2.2 μF at +24 VDC max

Cable length (for power supply) 50 m max

Connectors M12-4 pole male on transmitter (compatible with M12-5 pole female)

Optical data

Light emission (λ) Infrared, LED (950 nm)

Resolution 14 or 30 mm

Operating distance 0.2…19 m for 30 mm

Ambient light rejection According to IEC-61496-2:2013

Mechanical data

Operating temperature 0…+ 55 °C

Storage temperature - 25…+ 70 °C

Humidity range 15…95% (no condensation)

Protection class IP65 (EN 60529:2000)

Weight 1.3 kg / meter for each single unit

Housing material Painted aluminium (yellow RAL 1003)

Front glass material PMMA

Cap material PC MAKROLON

EN ISO 13849-1:2008, EN 62061:2005/A1:2013, EN 61496-1:2013, EN 61496-2, EN 61508-1:2010, EN 61508-2:2010, EN 61508-3:2010, EN

61508-4:2010

= 2.64 x 10

D

M12-8 pole male on receiver

0.2…6 m for 14 mm

-9

-9

-9

More information

For more information, e.g. the complete technical information, please see product manual for:

Orion1 Base 2TLC172287M0201

OPTICAL SAFETY DEVICES 3– 1 5

—

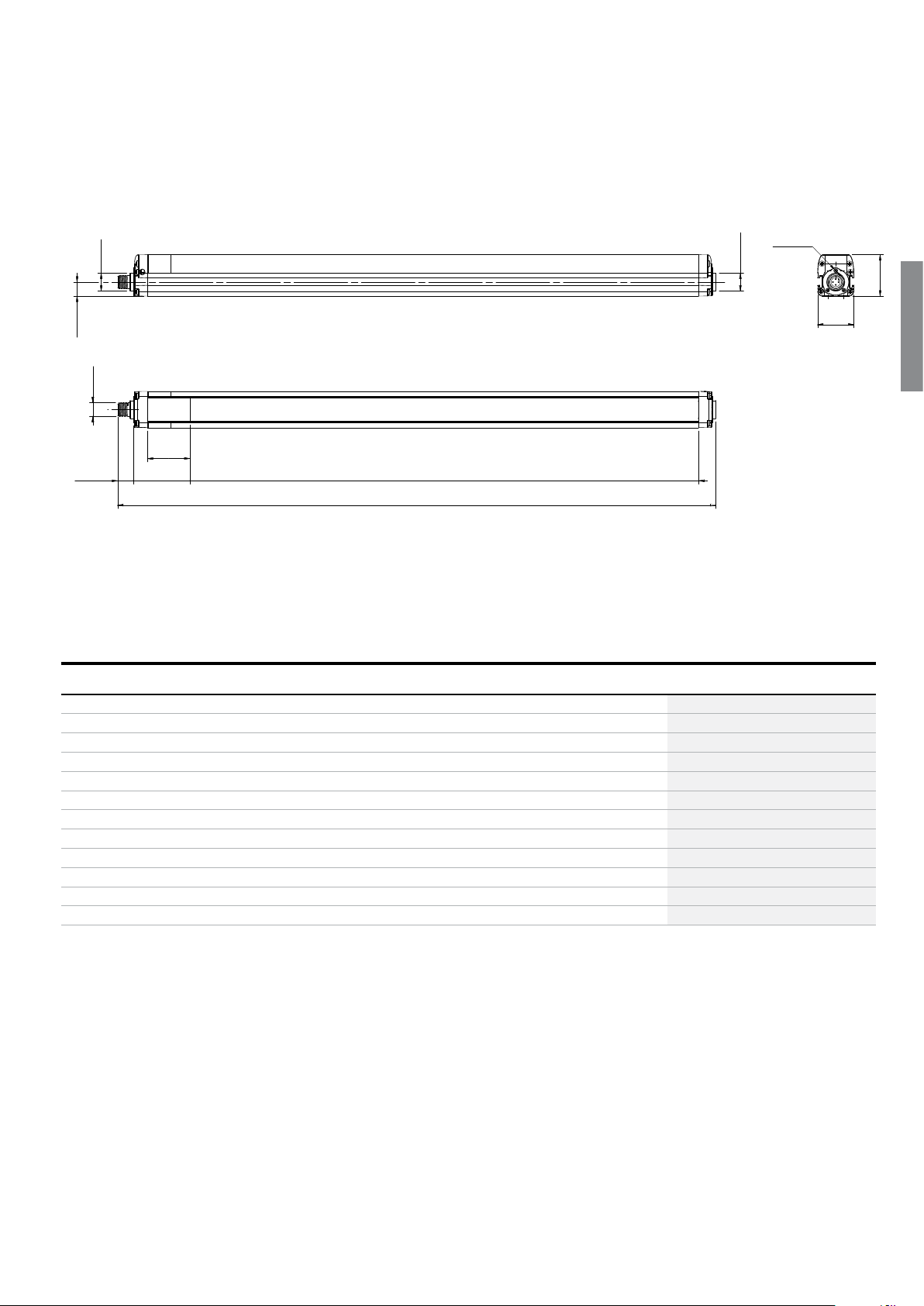

Dimension drawings

Orion1 Base

Orion1 Base

Ø16

Ø16

M2 n°3

x2

36,9

12,5

M12

38

50,514

All dimensions in mm

—

Dimension

L2

L1

Protected height

mm

150 233.3 153.3

300 383.2 303.2

450 533.2 453.3

600 683.3 603.2

750 833.2 753.3

900 983.2 903.2

1050 1133.2 1053.2

1200 1283.2 1203.3

1350 1433.2 1353.2

1500 1583.3 1503.3

1650 1733. 3 1653.3

1800 1883.3 1803.3

xx = Resolution

L1

mm

L2

mm

Typ e

Orion1-4-xx-015-B

Orion1-4-xx-045-B

Orion1-4-xx-045-B

Orion1-4-xx-060-B

Orion1-4-xx-075-B

Orion1-4-xx-090-B

Orion1-4-xx-105-B

Orion1-4-xx-120-B

Orion1-4-xx-135-B

Orion1-4-xx-150-B

Orion1-4-xx-165-B

Orion1-4-xx-180-B

32,3

3

3– 16 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Safety light curtain

Orion1 Extended

Orion1 Extended is an easy to

use light curtain with compact

3

dimensions. It has two resolutions for

detection of fingers and hands, and

comes with advanced features like

cascading, muting and blanking.

Light curtains are usually placed

closed to the hazardous zone when

repeated access to the machine is

necessary, for example manually

serviced machines.

Cost effective solution

Integrated muting function

Muting sensors are connected directly

to the light grid, with no need for a

remote muting module.

No dead zones

The light beams cover all of the profile

length, without the usual dead zones

at the ends requiring extra mechanical

guards.

Easy serial connection

Cascading with the standard units:

no separate slave or master units.

Easy to install

Easy to align

Alignment help and a wide angle within

the limits of a Type 4 device facilitate

installation.

Easy to connect

Cables with M12 connectors speeds up

connection.

Continuous

operation

Reduced downtime

Extensive error indication reduces

troubleshooting time.

Interference protection

Protection against mutual interference with coding.

OPTICAL SAFETY DEVICES 3 – 17

—

Features

Orion1 Extended

Finger detection

A 14 mm resolution is intended for finger detection when

the light guard needs to be very close to the machine in

order to give the operator a good view and easy accessibility

to the machine. A 14 mm resolution enables a sensing range

of 7 m.

Blanking

The blanking function allows to define a number of beams

that can be constantly interrupted without stopping the

machine. In this way a fixed material or a cable is allowed in

the protected field, but a hand interrupting an extra beam

would stop the machine. With floating blanking, the object,

for ex. the cable, can move within the protected field.

Hand detection

A 30 mm resolution is intended for hand detection and area

protection and is a good compromise between cost and

accessibility to the machine. A 30 mm resolution enables a

sensing range of 20 m.

3

No dead zones

A special feature of Orion1 Extended is that the light beams

cover all of the profile length, without any dead zones. This

enables to place it inside openings, instead of having a larger light guard in front of an opening.

Cascading

All Orion1 Extended units can be connected in series (cascaded) to easily create a suitable light curtain setup with no

special units needed.

Local reset

A local reset button is connected directly to the light guard

instead of to the safety control module in the electrical

cabinet. This saves safety relays/programmable inputs and

minimizes cabling to the electrical cabinet.

Muting

By connecting muting sensors to the light guard, it can

distinguish material from persons and allow the material to

pass through an opening but not persons.

EDM

External Device Monitoring is a feature allowing the light

guard to supervise the actuators in simpler applications,

eliminating the need for a safety relay or programmable

safety controller.

Loading...

Loading...