Jokab Safety JSBT5 Catalog Page

www.jokabsafety.com

6:28

www.jokabsafety.com

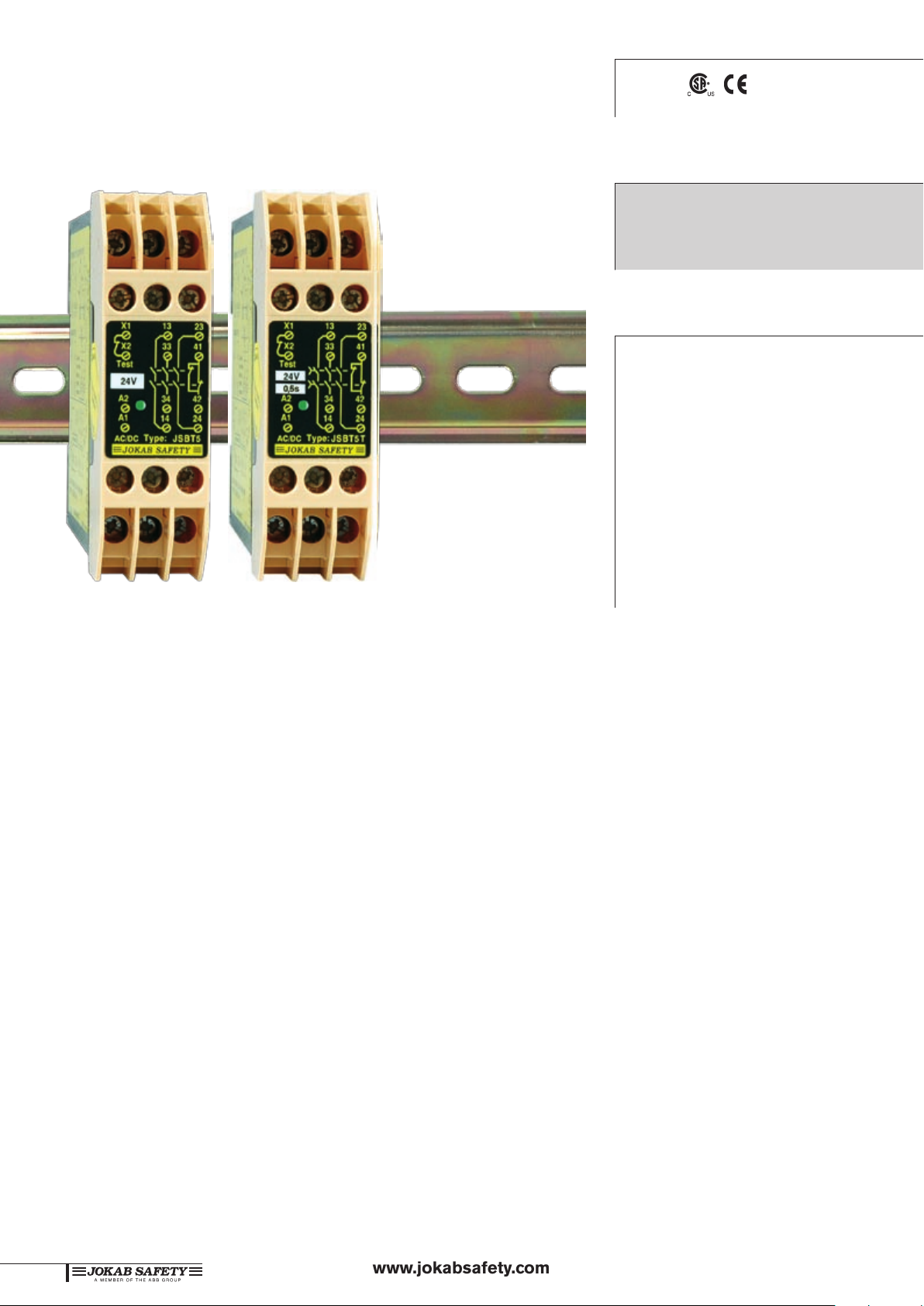

Safety relay

JSBT5(T)

Approvals:

TÜV Nord

Safety relay for:

Emergency stop

Interlocked hatch

Features:

Single and “dual” channel

Test/start input

Width 22.5 mm

LED indication

3 NO/1NC relay outputs

Single channel safety relay

The JSBT5 is designed to connect safety devices, such as

emergency stops, directly in the voltage supply circuit to

the relay. Despite a maximum built-in width of 22.5 mm the

relay is very powerful.

With 3 NO safety outputs, 1 NC, test input and complete

internal supervising, the JSBT5 is quite unique. In addition

you can order delayed outputs (JSBT5T).

In order for the safety outputs to close, the supply voltage, e.g. by means of an emergency stop button, must be

connected to A1 and A2 and the test input closed. After

actuation of the relay the test input can be opened again.

The test input is intended to supervise that contactors

or valves have dropped/returned before a new start can

be permitted.The test input can also be used for starting

and the start button can be supervised (see connection

example on next page).

(T) = delayed outputs

0.5 sec.

Supply 12 VDC, 24 VDC/

AC

Safety level

The JSBT5 has a twin and supervised internal safety function. Power failure, internal component faults or external

interference cannot result in dangerous functions.

Input via A1 only is not protected from short circuiting,

and therefore installation is critical for the safety level to be

achieved. To achieve a higher safety level a screened cable can be used and/or connection made to both A1 and

A2 (see example overleaf).

Regulations and standards

The JSBT5 is designed and approved in accordance with

appropriate directives and standards. See technical data.

Connection examples

For examples of how our safety relays can solve various safety

problems, please see the section “Connection examples”.

www.jokabsafety.com

6:29

Technical data – JSBT5(T)

mm

99

8 2

2 2 , 5

Manufacturer ABB AB/Jokab Safety, Sweden

Article number/Ordering data

JSBT5 24 AC/DC 2TLJ010005R0100

JSBT5 12 VDC 2TLJ010005R0700

JSBT5T 24 AC/DC 2TLJ010005R1100

Colour Black and beige

Operational voltage

JSBT5: 24 VDC/AC + 15%–25%, 50–60 Hz

JSBT5 T: 12 VDC, 24 VDC/AC + 15% –

25%, 50 - 60 Hz

Power consumption 1 W/1,9 VA

Relay Outputs 3 NO + 1 NC

Max. switching capacity

Resistive load AC 6A/250 VAC/1500 VA

Inductive load AC AC15 240VAC 2A

Resistive load DC 6A/24 VDC/15 0 W

Inductive load DC DC13 24VDC 1A

Max. res. load total switching

capacity: 9A distributed on all contacts

Min. load 10mA /10 V (if load on contact has

not exceeded 100 mA)

Contact material AgCuNi

Fuses Output (External) 5A gL/gG

Conditional short-circuit current

(1 kA) 6A gG

Max Input Wire res. at nom.

voltage 200 Ohm

Response time at deactivation <60 ms or delayed max 500 ms

(JSBT5T)

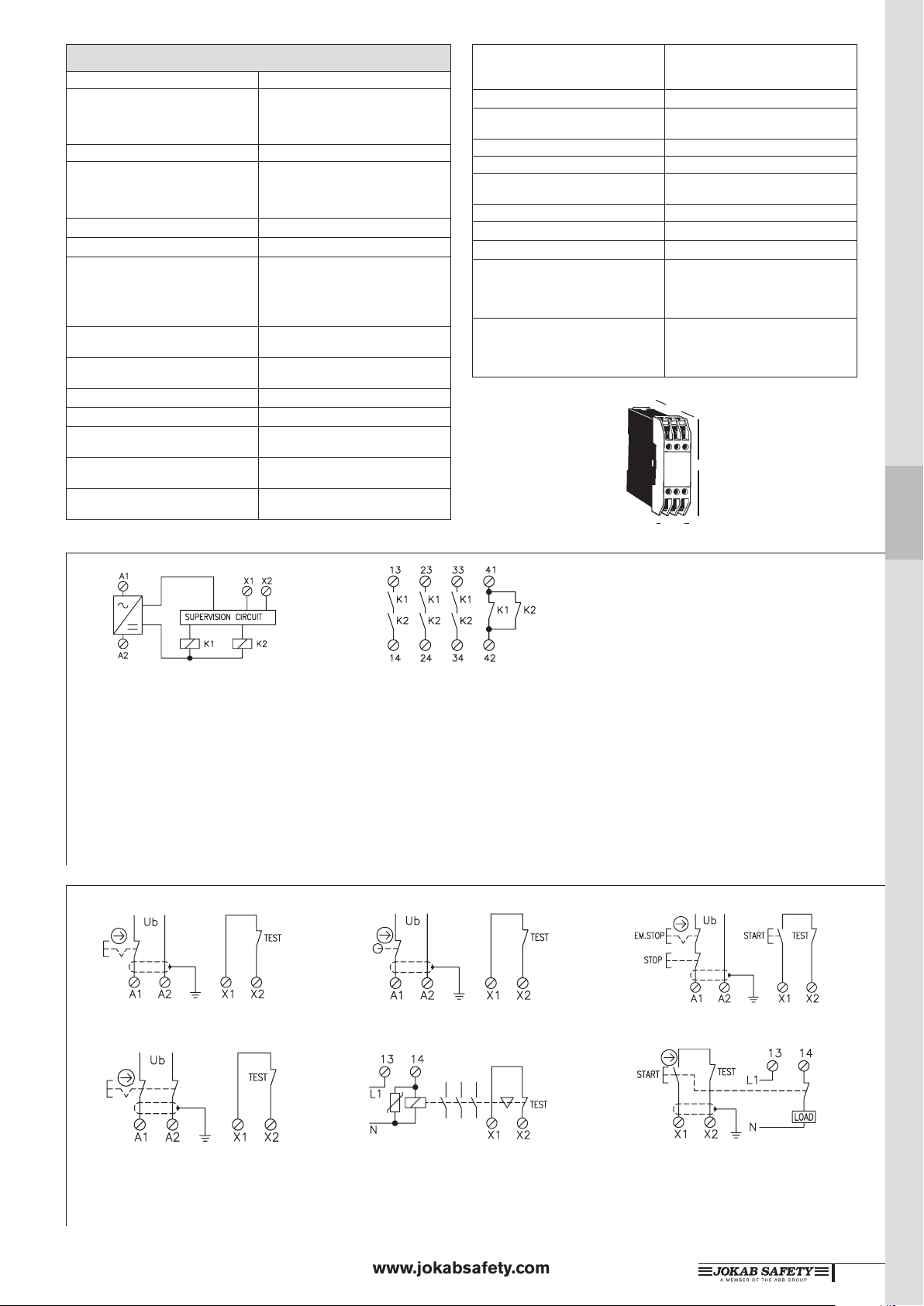

Technical description – JSBT5(T)

Terminals (Max. screw torque 1 Nm)

Single strand: 2x1.5 mm

Conductor with socket contact: 2x1mm

Mounting 35 mm DIN-rail

Protection class enclosure/

terminals IP 40/20 IEC 60529

Impulse Withstand Voltage 2.5kV

Pollution Degree 2

Operating temperature range -10°C to +55°C (with no icing or

Operating humidity range 35% to 85%

Function indication Electrical Supply

Weight 200 g

Performance (max.)

Functional test: The relays must be

cycled at least once a year.

Conformity 2006/42/EC, 2006/95/EC,

condensation)

Category 4/PL e

(EN ISO 13849-1:2008)

SIL 3 (EN 62061:2005)

PFHd 1.22E-08

2004 /108/ EC

EN 954-1:1996, EN 62061:2005

EN ISO 13849-1:2008

2

2

1

2

3

4

5

6

When supply voltage is connected to A1

and A2, relays K1 and K2 are activated.

K1 and K2 drop if the supply voltage is

disconnected. Both relays K1 and K2 must

drop for them to be activated again. Another

requirement is that the test circuit, X1 - X2,

must be closed for the outputs to be activated. Thereafter X1 - X2 can either be open

or constantly closed.

The supervising circuit ensures that both

Electrical connection – JSBT5(T)

Emergency stop with automatic reset when

emergency button returns.

K1 and K2 have dropped before they can

be reactivated. The stop function complies

with the requirement that a component fault

or external interference cannot lead to a

dangerous function.

The safety outputs consist of contacts

from K1 and K2 connected internally in

series across terminals 13 - 14, 23 - 24,

and 33 - 34. These contacts are used to

cut the power to components which stop

Hatch with automatic reset. JSBT5 as emergency stop and control

or prevent hazardous movements/functions.

It is recommended that all switched loads

are adequately suppressed and/or fused in

order to provide additional protection for the

safety contacts.

The NC output 41 - 42 should only be

used for monitoring purposes e.g. indication

lamp for emergency stop pressed.

relay with Start and Stop function.

7

8

9

10

11

Emergency stop with dual connection direct

to the supply voltage.

Controlled monitoring of external contactor,

relay, valve or ABB Jokab Safety’s expansion relays.

Monitoring to ensure that the On button is not stuck in pressed position. A

short circuit over the closing contact is

not monitored. The JSBR4 has built in

short circuit monitored re setting.

12

13

14

Loading...

Loading...