Jokab Safety Emergency stops, pilot devices Catalog

EMERGENCY STOPS AND PILOT DE VICES 6– 1

—

Emergency stops

and pilot devices

6– 2 Introduction and overview

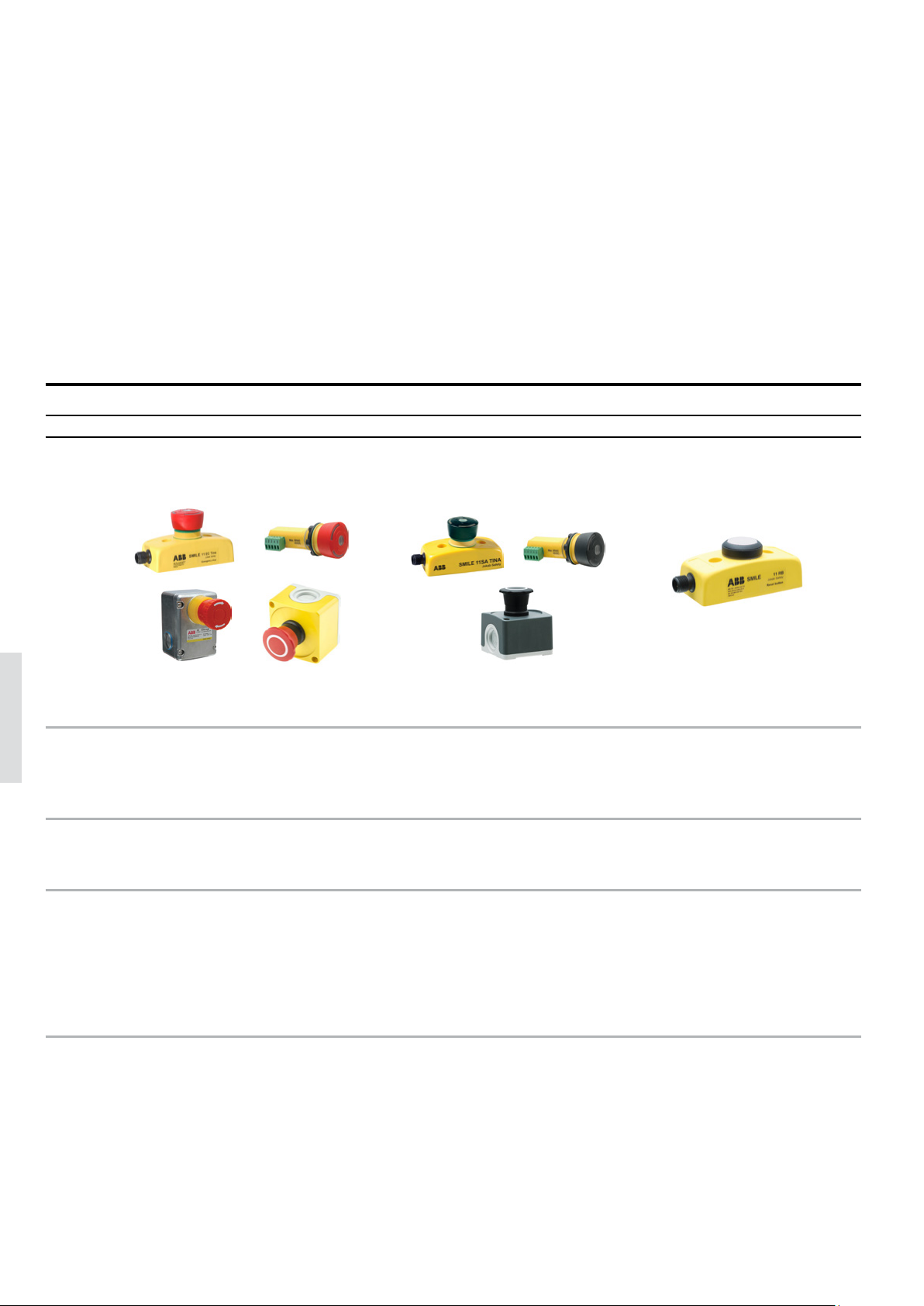

6– 6 Emergency stop buttons

Smile, INCA, EStrong and Compact

6– 16 Safety stop buttons

Smile, INCA, and Compact

6– 24 Pull wire emergency stop switch

LineStrong

6– 34 Push-button box

Smile 41

6– 40 Reset button

Smile

6– 46 Pilot devices

Modular and Compact range

6

6– 2 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Introduction and overview

Selection guide

ABB offers a full range of buttons and pull wires for emergency stop functions,

as well as pilot devices for e.g. reset functions.

Emergency stop buttons Safety stop buttons Reset buttons Pull wire emergency stop switches Push button boxes Pilot devices

Name

Image Image

Smile, Inca, EStrong, Compact Smile, Inca, Compact Smile

6

Description

Applications

Advantages

Emergency stop buttons for external

mounting and panel mounting in

different sizes and material

Safely stop dangerous machine

functions

Models with:

- Compact size

- Robust enclosure for harsh

environments

- Quick installation with M12 connectors

- LED indication

Safety stop buttons for external

mounting and panel mounting

Safely stop a limited part of a

dangerous machine

Models with:

- Compact size

- Robust enclosure for harsh

environments

- Quick installation with M12

connectors

- LED indication

Small and easy to install reset

button

Pushbutton for resetting safety

devices

- Compact size

- Quick installation

- M12 connector

- LED indication

EMERGENCY STOPS AND PILOT DE VICES 6– 3

Name

Description

Applications

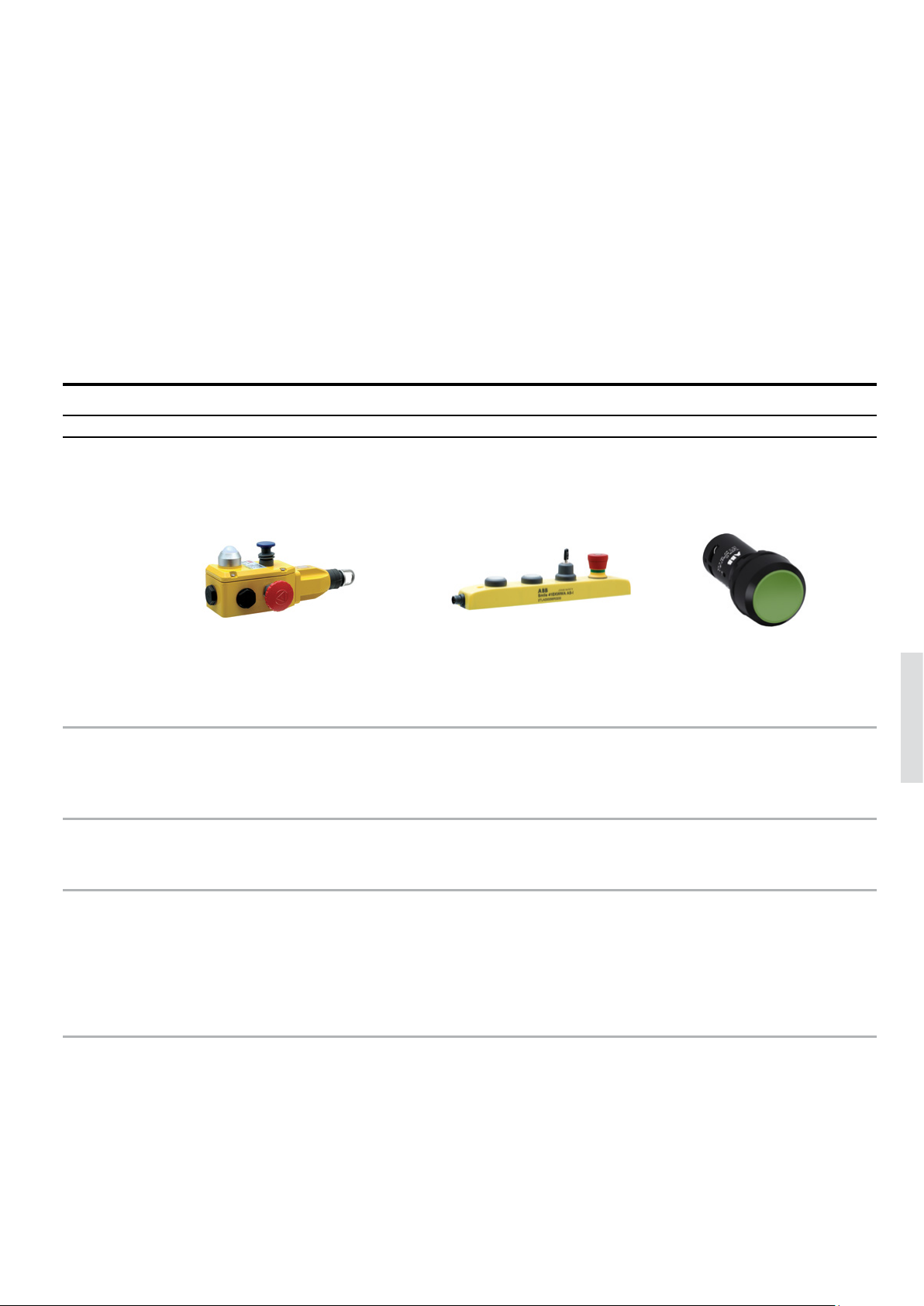

LineStrong Smile 41 Modular range, compact range

Emergency stop switches in robust

enclosures for pull wires of various

lengths.

Gathers up to four push buttons, including emergency stop,

in a single compact device

Push buttons, selector switches, pilot lights, joysticks and

signal towers in a compact and

robust design

Emergency stop line to safely stop

conveyor belts and long transporta-

Emergency stop and pushbuttons

in one device

For control and indication of machines and processes

tion lines.

6

Advantages

- Up to 200 m wire with one switch

- Reliable mechanical connection

- Robust construction

- Compact size

- Quick installation

- M12 connector

- LED indication

- Highly adaptable with several

button colors

- Compact size

- Up to IP69K

- Long life-time thanks to

self-cleaning contacts

- Quick snap-on design for

simple installation without

tools

6– 4 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Introduction and overview

Selection orientation

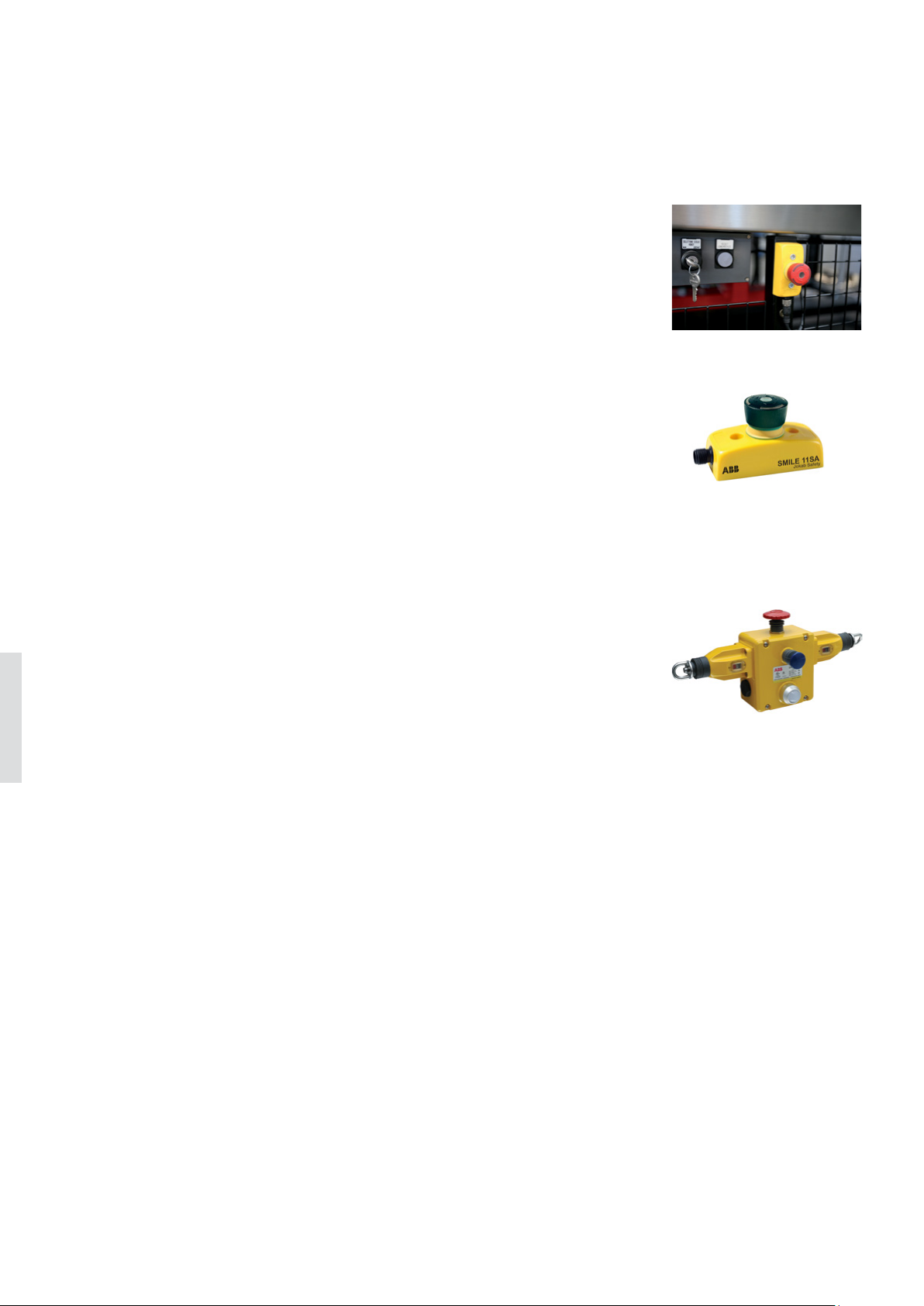

Why an emergency stop is necessary

If a machine breaks down or if someone is in danger, anyone should be able to stop the machine, regardless of their knowledge of the specific application.

When a safety stop could be used

A safety stop (also called machine stop) should be used to safely stop a part of the machine,

e.g. as a stop for an individual hazardous motion. It should not be used as an emergency

stop and stop the complete machine. Likewise, an emergency stop with red push button

must not be used as a safety stop.

In order to separate the safety stop function from the emergency stop function, the safety

stop buttons should be colored black.

When a pull wire emergency stop could be used

A pull wire emergency stop is easier to install than a system of several emergency stop

buttons along a carriage path which makes it ideal for installations over long distances.

LineStrong can handle wires up to 200 m on one single switch and the emergency command

can be initiated from any point along the installed wire length.

6

EMERGENCY STOPS AND PILOT DE VICES 6– 5

—

Introduction and overview

Standards

Important standards to follow when implementing emergency stop functions are e.g. EN ISO 13850 and EN ISO 60204-1.

Stop categories

The following stop categories are defined in the standards:

Stop Category 0 stopping by immediate removal of power to the machine actuators

Stop Category 1

Stop Category 2 a controlled stop with power left available to the actuators

Note that these categories should not be confused with the categories used to describe the architecture when calculating PL

in EN ISO 13849.

to be suitable for emergency stops.

The risk assessment should determine which stop category to use, but stop category 2 is normally considered not

a controlled stop with power available to the machine actuators to achieve the stop and then removal of

power when the stop is achieved

Text and symbols

Neither the emergency stop nor its background should be labelled with text or symbols. It has previously been common with

white arrows indicating the direction of unlatching, but this is not allowed anymore.

Location and signs

The risk assessment should determine the locations of the emergency stop buttons, but they should in general be placed at

operator stations, at locations where man/machine interaction is required and at entry/exit points. Signs to mark the location

of emergency stops are not required, but if used they should be green with white markings.

6

6– 6 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Emergency stop buttons

Smile, INCA, EStrong and Compact

Emergency stop buttons are used to

safely stop dangerous machine functions.

ABB offers a wide range of emergency

stop buttons for external mounting or

panel mounting, with plastic or metal

housing and for different types of

connections.

6

Easy to install

Compact size

Models with a compact and appealing

housing saves space and makes it easy

to place.

Quick installation

Quick and easy installation of models

with features such as centered mounting holes, removable terminal blocks

and M12 connectors.

Optimum interface

Highly adaptable

Several models to choose between

depending on position, installation

and function.

Reliable in extreme conditions

Robust models and models in stainless

steel for use in demanding environments.

Continuous operation

LED diagnostics

Models with integrated LED diagnostics reduce downtime when troubleshooting.

Serial connection

Tina models save cable length and installation time with serial connection.

EMERGENCY STOPS AND PILOT DE VICES 6 – 7

—

Models and application

Emergency stop buttons

Models for external mounting

Smile

Smile is a small and easy to install emergency stop button.

Its size allows mounting in reduced spaces, and its centered mounting holes makes it especially easy to mount on

aluminum extrusions (e.g. Quick-Guard fencing system).

Smile is available with M12 connectors or cable.

Smile has an integrated LED in the button that shows the

status and simplifies error tracking.

The standard models of Smile have 2 contacts and can be

used with safety controllers from all brands. Smile Tina

models belong to the ABB DYNlink solution, with the advantages of serial connection using only one channel and

still reaching Cat. 4/PL e.

Compact

Compact emergency stop buttons offer a robust enclosure

with a high IP rating that fulfill the demands in severe and

humid environments, such as food and beverage industry.

Compact can be fitted with a Tina adapter for use in a DYNlink solution (Tina 2A, Tina 2B or Tina 3A).

Models for panel mounting

INCA

INCA is an emergency stop button for panel mounting,

designed for installation in 22.5 mm holes. Its removable

terminal block facilitates connection and exchange.

INCA has an integrated LED in the button that shows the

status and simplifies error tracking.

The standard model of INCA has 2 contacts and can be used

with safety controllers from all brands. INCA Tina models

belongs to the ABB DYNlink solution, with the advantages of

serial connection using only one channel and still reaching

Cat. 4/PL e.

Smile Reverse

Smile Reverse is identical to the regular Smile emergency

stop button besides from being reversed in order to be

mounted on the back side of a panel. Smile Reverse has an

IP65 housing that makes it suitable in panels where moisture and dust may occur.

Smile Reverse has an integrated LED in the button that

shows the status and simplifies error tracking.

The standard model of Smile Reverse has 2 contacts and can

be used with safety controllers from all brands. The Smile

Reverse Tina model belongs to the ABB DYNlink solution,

with the advantages of serial connection using only one

channel and still reaching Cat. 4/PL e.

6

EStrong

EStrong is an emergency stop button designed to provide

a robust unit in exposed and severe environments. The unit

has a stainless steel enclosure with IP69K rating that withstands high pressure and high temperature wash-down. It is

therefore ideally suited for industries with special demands,

such as food processing or chemical industry.

Application

Emergency stop buttons are used to safely stop a dangerous machine function in order to prevent an accident, or

minimize the consequences of an accident. An emergency

stop should be a complement to other safety devices, and

not a replacement for them.

6– 8 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Features

Emergency stop buttons

Communication features

DYNlink

Emergency stop buttons with Tina in their name belong to

the DYNlink solution, which enables serial connection using

only one channel and still reaching Cat. 4/PL e. DYNlink

devices must be used with Vital safety controller or Pluto

programmable safety controller. Up to 30 DYNlink devices

can be connected in series to Vital and up to 10 can be connected to each input on Pluto.

StatusBus

StatusBus is a simple and cost effective way to collect the

status information of emergency stops and safety sensors. The StatusBus functionality is available with some

DYNlink devices and allows to collect the status of each

individual safety device, even when connected in series. A

Pluto programmable safety controller must be used to read

the StatusBus information, and a single input on Pluto can

collect the status of up to 30 safety devices. The devices are

connected using standard cable and M12-5 connectors. No

specific bus cable or extra communication module is

necessary.

AS-i

Smile is available in a model compatible with the AS-i safety

bus. Smile AS-i can be used with any AS-i monitor. AS-i is a

bus system that offers a very simple connection of up to 31

6

safety devices to one monitor according to PL e and makes

it easy to move, remove and add safety devices. When Smile

AS-i is used with Pluto programmable safety controller, no

other AS-i master or monitor is necessary, and no specific

knowledge of AS-i is required.

EMERGENCY STOPS AND PILOT DE VICES 6– 9

—

Ordering information

Emergency stop buttons

—

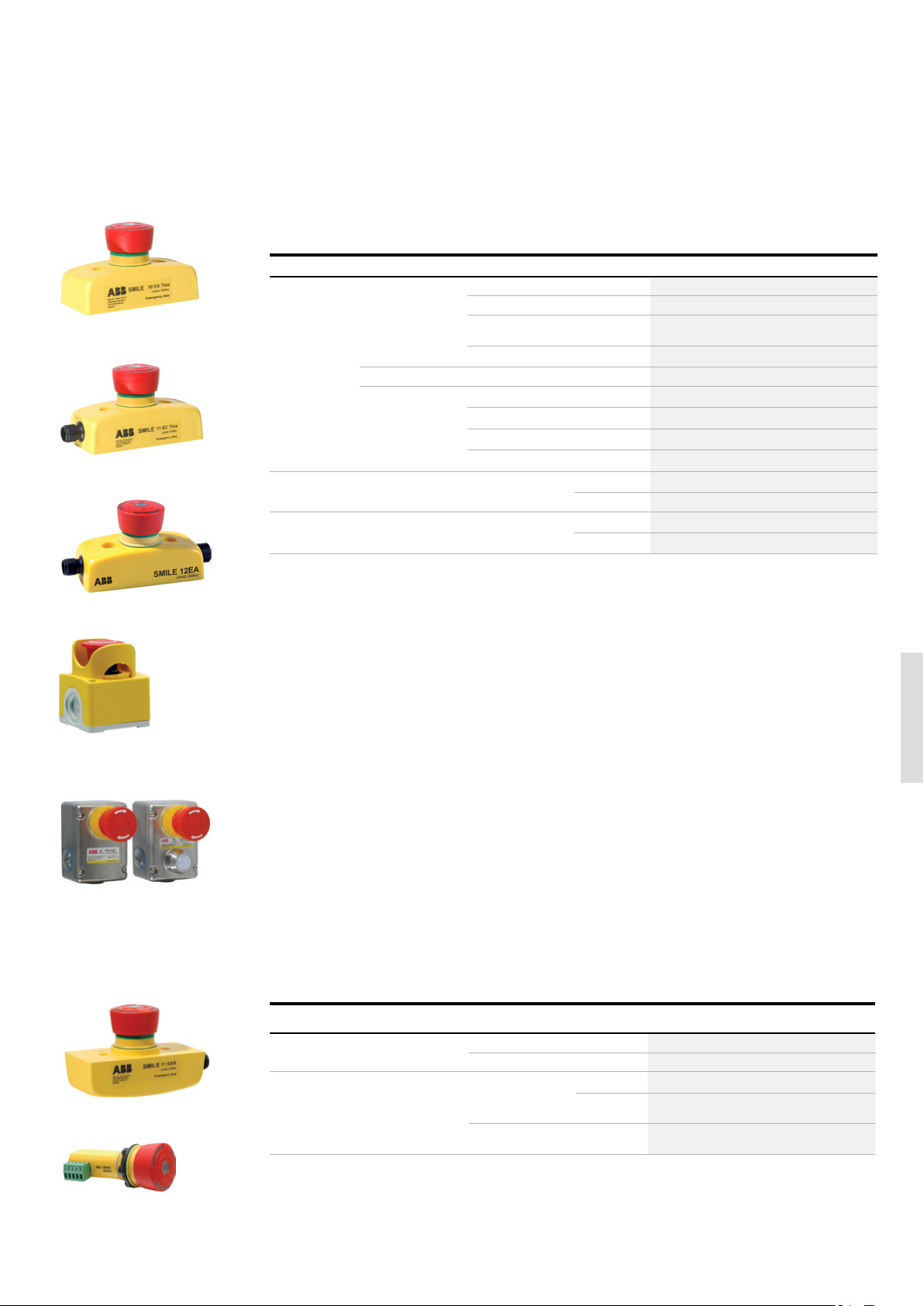

External mounting

Description Type of safety signal Connection type Feature Typ e Order code

Compact size

2TLC172863F0201

Smile 10 EA Tina

2TLC172857F0201

Smile 11 EC Tina

Smile 12 EA

Plastic housing

IP65

Plastic housing

IP66, IP67 and IP69K

Metal housing

IP67 and IP69K

* Can be adapted to DYNlink with Tina

2TLC172187F0201

DYNlink 1 m cable from bottom Status LED Smile 10 EA Tina 2TLA030050R0400

1 x M12-5 male Status LED Smile 11 EA Tina 2TLA030050R0000

1 x M12-5 male Status LED,

Smile 11 EC Tina 2TLA030050R0900

StatusBus

2 x M12-5 male Status LED Smile 12 EA Tina 2TLA030050R0200

AS-i 1 x M12-4 male Status LED Smile 11 EA AS-i 2TLA030052R0000

2 NC 1 m cable from bottom Status LED Smile 10 EA 2TLA030051R0400

1 m leads from bottom - Smile 10 EK 2TLA030051R0600

1 x M12-5 male Status LED Smile 11 EA 2TLA030051R0000

2 x M12-5 male Status LED Smile 12 EA 2TLA030051R0200

2 NC* 2 x M20 conduits - CEPY1-1002 (Compact) 1SFA619821R1002

With shroud CEPY1-2002 (Compact) 1SFA619821R2002

2 NO + 2 NC 3 x M20 conduits Status LED EStrongZ LED 2TLA050220R0222

- EStrongZ 2TLA050220R0020

ABB Compact emergency stop

shroud

EStrongZ and EStrongZ LED

Smile 11 EAR

2TLC172689F0201

—

Panel mounting

IP rating Depth Connection type Type of safety signal Feature Typ e Order code

IP65 26 mm 1 x M12-5 male DYNlink Status LED Smile 11 EAR Tina 2TLA030050R0100

2 NC Status LED Smile 11 EAR 2TLA030051R0100

2TLC172861F0201

Button IP65,

connector IP20

53 mm Removable termi-

nal block

DYNlink Status LED INCA 1 Tina 2TLA030054R0000

Status LED,

INCA 1 EC Tina 2TLA030054R1400

StatusBus

2 NC Status LED INCA 1 2TLA030054R0100

6

INCA 1

2TLC172363F0201

6– 10

SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

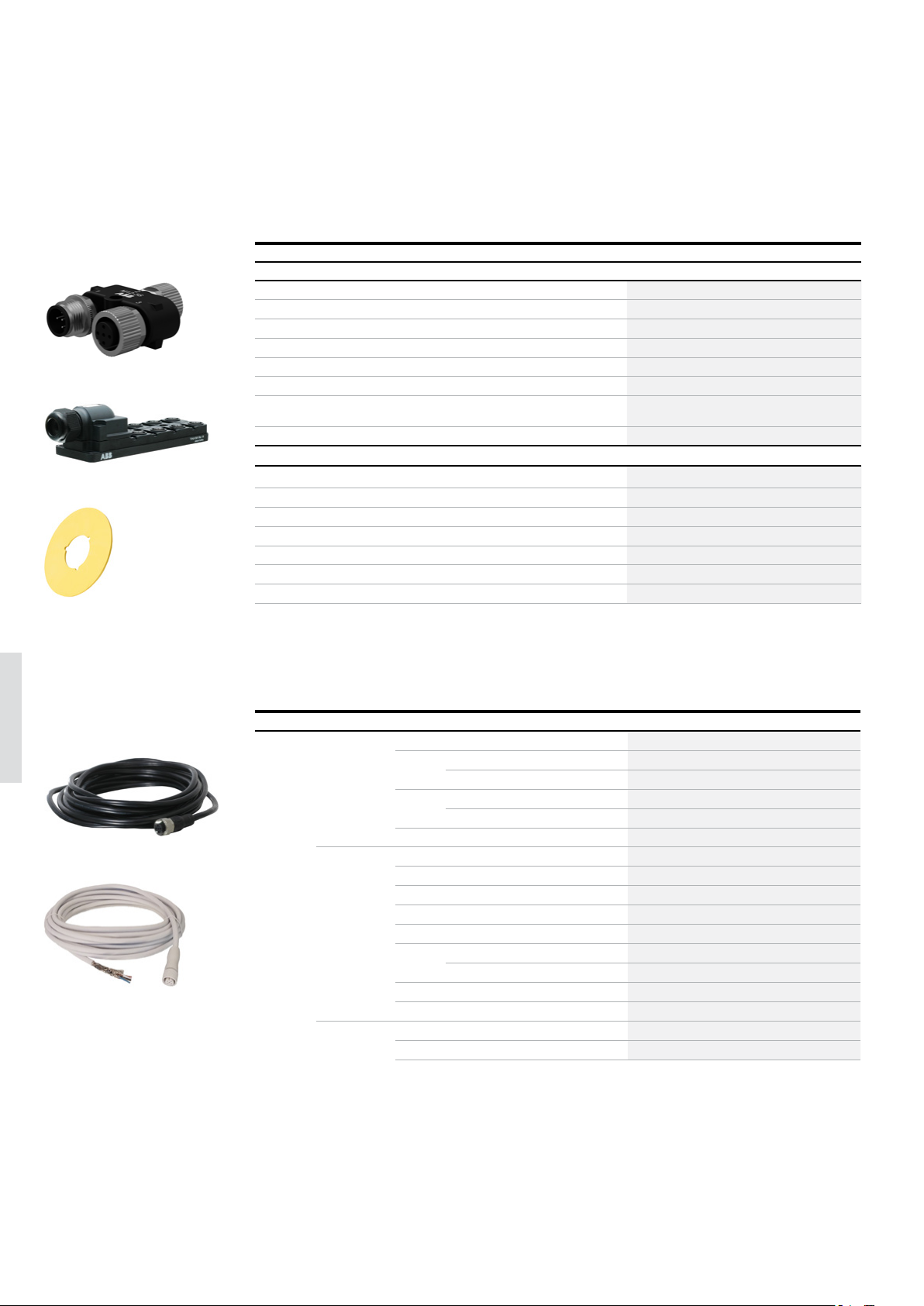

Accessories

Emergency stop buttons

—

Connection accessories

Description Typ e Order code

Connection accessories

M12 Y-connector for serial connection of device with StatusBus functionality. M12-3S 2TLA020055R0600

M12 Y-connector for serial connection of devices without StatusBus functionality. M12-3A 2TLA020055R0000

Connection block for the serial connection of up to 4 DYNlink devices with 12-5 connectors.

2TLC172034V0201

M12-3S

Tina 8A

2TLC172906F0201

E-sign 22.5

Connection block for the serial connection of up to 8 DYNlink devices with 12-5 connectors.

Adaptation unit for DYNlink solution with M20 fitting. For e.g. Compact. Tina 2A* 2TLA020054R0100

Adaptation unit for DYNlink solution, internal assembly. For e.g. Compact. Tina 2B* 2TLA020054R1100

Adaptation unit for DYNlink solution with M20 fitting and M12 connector. For e.g. con-

necting Compact to Pluto/Vital.

Termination for Smile 12 JST2 2TLA030051R1300

Accessories

2TLC172471F0201

Emergency stop sign, yellow, no text, for INCA (22.5mm) E-Sign 22.5 2TLA030054R0900

Emergency stop sign, yellow, no text, for Smile (32.5mm) E-Sign 32.5 2TLA030054R1000

Yellow surround for Inca Surround for Inca 2TLA030054R0400

Yellow shroud for Compact CA1-8053 1SFA619920R8053

Stainless steel cable gland, for EStrong Gland M20x1.5 2TLA050040R0002

Stainless steel conduit plug, for EStrong Conduit Plug M20x1.5 2TLA050040R0004

LED Green/Red 230 VAC, for EStrong LED 230 2TLA050211R0003

* For more information about Tina adapter units, please see Pluto and Vital chapters.

Tina 4A 2TLA020054R0300

Tina 8A 2TLA020054R0500

Tina 3A* 2TLA020054R0200

6

M12-C61

M12-C61HE

2TLC010003F0201

—

Cable with connectors

Connector Female/male Length Special feature Type Order code

M12-5 Female 3 m M12-C31 2TLA020056R0500

6 m M12-C61 2TLA020056R0000

Harsh environment, halogen free M12-C61HE 2TLA020056R8000

10 m M12-C101 2TLA020056R1000

Harsh environment, halogen free M12-C101HE 2TLA020056R8100

2TLC172951F0201

20 m M12-C201 2TLA020056R1400

Female + male 0.3 m M12-C0312 2TLA020056R5800

0.06 m M12-C00612 2TLA020056R6300

1 m M12-C112 2TLA020056R2000

3 m M12-C312 2TLA020056R2100

6 m M12-C612 2TLA020056R2200

10 m M12-C1012 2TLA020056R2300

Angled female connector M12-C1012V2 2TLA020056R6700

16 m M12-C1612 2TLA020056R5400

20 m M12-C2012 2TLA020056R2400

Male 6 m M12-C62 2TLA020056R0200

10 m M12-C102 2TLA020056R1200

EMERGENCY STOPS AND PILOT DE VICES 6– 1 1

—

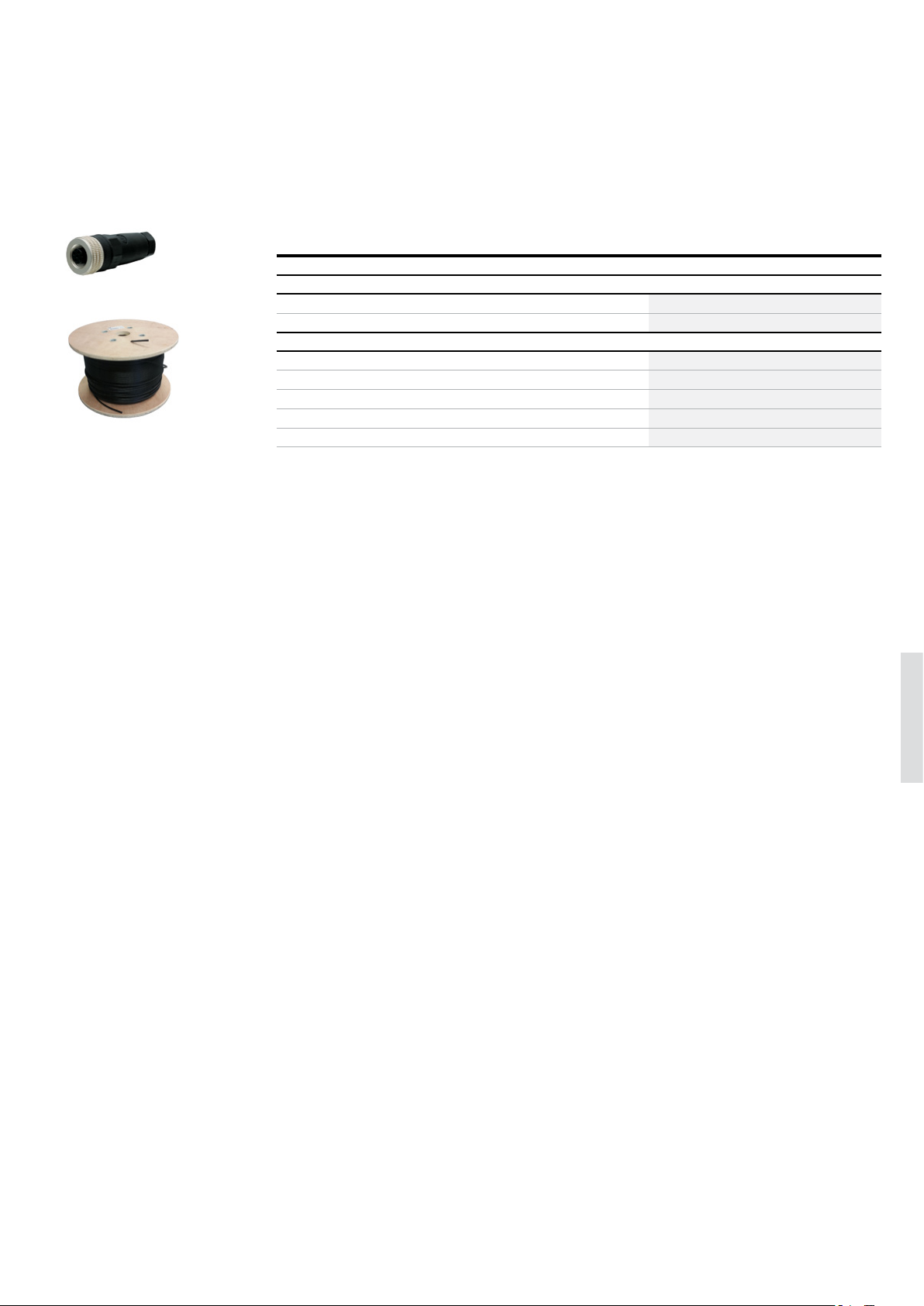

Separate cables and connectors

M12-C01

C5 cable

2TLC172657F0201

2TLC010038F0201

Description Typ e Order code

Connectors

M12-5 pole female, straight M12-C01 2TLA020055R1000

M12-5 pole male, straight M12-C02 2TLA020055R1100

Cable with 5 conductors

10 m cable with 5 x 0.34 shielded conductors C5 cable 10 m 2TLA020057R0001

50 m cable with 5 x 0.34 shielded conductors C5 cable 50 m 2TLA020057R0005

100 m cable with 5 x 0.34 shielded conductors C5 cable 100 m 2TLA020057R0010

200 m cable with 5 x 0.34 shielded conductors C5 cable 200 m 2TLA020057R0020

500 m cable with 5 x 0.34 shielded conductors C5 cable 500 m 2TLA020057R0050

6

6– 1 2 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Technical data

Emergency stop buttons

Technical data

Approvals

Smile, INCA

Conformity

6

Functional safety data

Smile Tina, INCA Tina

Smile AS-i

EStrong

Compact

Smile, INCA

Smile Tina, INCA Tina

Smile AS-i

EStrong

Compact

EN 61508:2010 Up to SIL3, depending on system architecture

EN 62061:2005 Up to SILCL3, depending on system architecture

EN ISO 13849-1:2008 Up to Cat. 4, PL e, depending on system architecture

Smile, INCA B10

Smile Tina, INCA Tina PFH

Smile AS-i PFHD = 1.69 x 10

EStrong B10

Compact B10

TÜV NORD

TÜV NORD

2006/42/EC – Machinery

2011/65/EU - RoHS

EN ISO 12100:2010, EN ISO 13849-1:2008/AC:2009, EN 60204-1:2006+A1:2008, EN ISO 13850:2008

2006/42/EC - Machinery

2004/108/EC - EMC

EN ISO 12100:2010, EN ISO 13849-1:2008, EN 62061:2005, EN 60204-1:2006+A1:2009, IEC 60664-1:2007, EN 61000-6-2:2005, EN 61000-64:2007, EN 60947-5-5:2005, EN ISO 13850:2006

2006/42/EC - Machinery

EN ISO 12100:2010, EN ISO 13849-1:2008/AC:2009,EN ISO 13849-2:2012, EN 60204-1:2007+A1, EN ISO 13850:2008, IEC 60947-5-5:2005

2006/42/EG – Machinery

2011/65/EU - RoHS

EN ISO 12100:2010, EN ISO 13850:2015, EN 60204-1:2006:+A1:2009+AC:2010, EN 60947-5-5:1997:+A1:2017, EN 60947-5-1:2004:+A1:2009

2006/42/EC - Machinery

2014/30/EU - EMC

EN 60947-1:2007/A1:2011/A2:2014, EN 60947-5-1:2004/A1:2009, EN 60947-5-5:1997/A1:2005/A11:2013, EN ISO 13850:2008

= 100 000

d

= 4.66 x 10

D

= 1 500 000

d

= 250 000

d

-9

-9

EMERGENCY STOPS AND PILOT DE VICES 6– 1 3

—

Technical data

Emergency stop buttons

Technical data

Electrical data

Operating voltage

Smile, INCA 17-27 VDC ± 10%

Smile Tina, INCA Tina +24 VDC +15% -25%

Smile AS-i +30 VDC from the AS-i bus. Tolerances 26.5 - 31.6 VDC

EStrong 230 VAC / +24 VDC (the LED is +24 VDC originally, but can be replaced with a 230 VAC accessory)

Compact 230 VAC / +24 VDC

Mechanical data

Mechanical life >50 000 operations

Operating temperature

Smile, INCA -10…+55 °C

EStrong -25…+80 °C

Compact -25…+70 °C

Protection class

Smile, INCA IP65

EStrong IP67, IP69K

Compact IP66, IP67, IP69K

Weight

Smile 65 g

INCA 45 g

EStrong 820 g

Compact 108 g, 124 g (with shroud)

Material

Smile Polyamide PA66, Macromelt, polybutylenterephthalate PBT, Polypropene PP, UL 94 V0

INCA Polyamide PA66, Macromelt, polybutylenterephthalate PBT, Polypropene PP, UL 94 V0

EStrong Stainless steel 316 housing

Compact Polycarbonate

6

More information

Fore more information, e.g. the complete technical information, see product manual for:

Smile 2TLC172097M0201

INCA 2TLC172163M0201

EStrong 2TLC172247M0201

Compact 1SFC151005C0201

6– 14 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

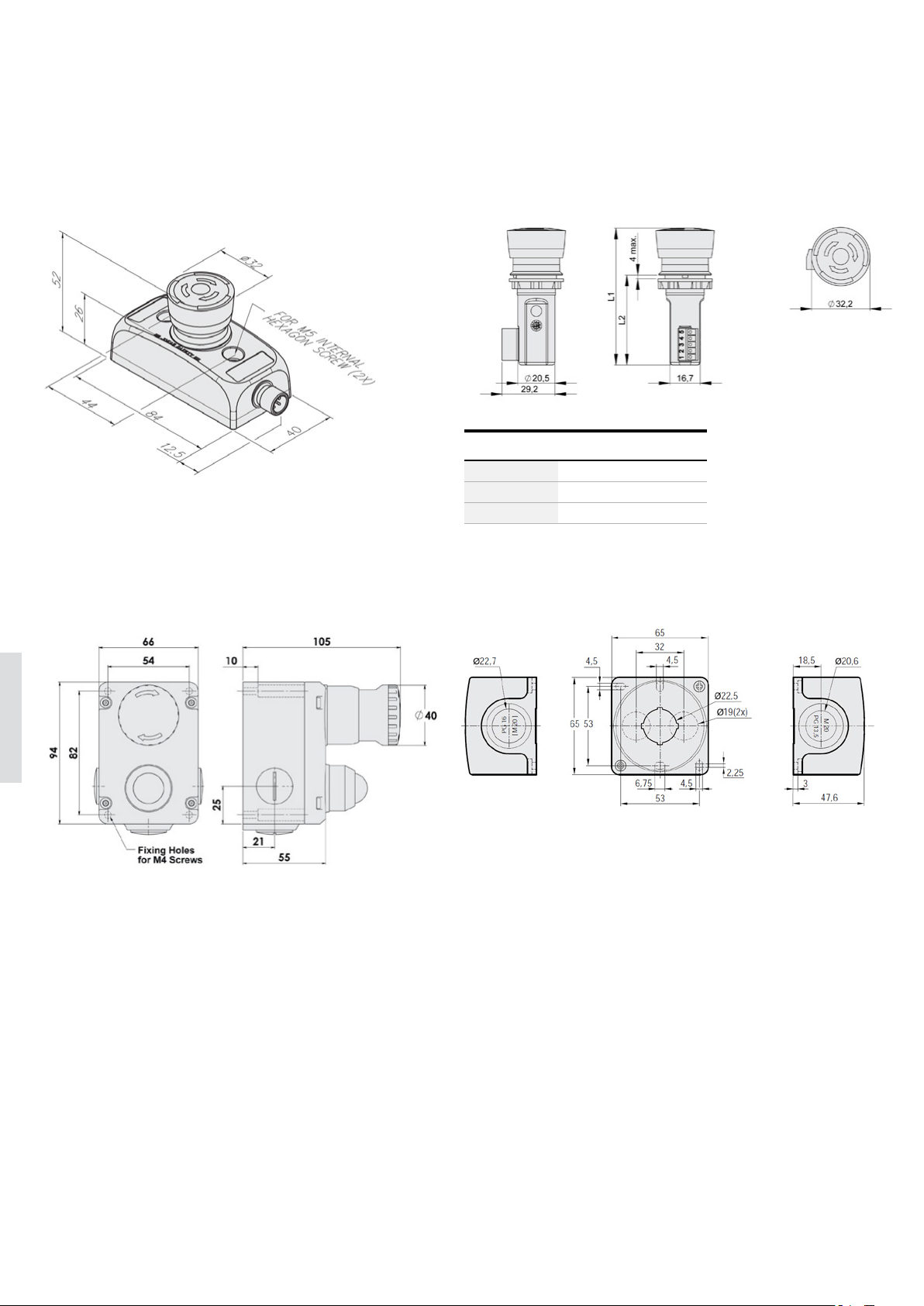

Dimension drawings

Emergency stop buttons

Smile

INCA

Typ e L1

mm

INCA 1 EC Tina 75.5 49.5 ± 0.5

INCA 1 80 54 ± 0.5

INCA 1 Tina 80 54 ± 0.5

EStrong Compact (housing only)

L2

mm

6

All dimensions in mm

EMERGENCY STOPS AND PILOT DE VICES 6– 1 5

6

Loading...

Loading...