Jokab Safety Control devices Catalog

CONTROL DEVICES 5– 1

—

Control devices

5– 2 Introduction and overview

5– 4 One- and two-hand devices

Safeball™

5– 10 Three-position device

JSHD4

5

5– 2 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Introduction and overview

Selection guide

ABB offers ergonomic control devices that allow operators to safely control

dangerous machinery.

Safeball JSHD4

Image

5

Type

Description

Application

Advantages

One or two-hand control device Tree-position device

Ergonomic and unique machine control Ergonomic hold-to-run device with extra

control buttons

Mainly used in pairs as a two-hand

control in applications where it must

be ensured that the operator has his

hands outside the hazardous area, e.g.

for starting a press cycle.

- Ergonomic design

- Several grip possibilities

- Flexible mounting

- Two opposing buttons minimize the

possibility to defeat

Used during e.g. troubleshooting, test

running and programming, in order

to allow the operator to be inside the

hazardous area without stopping the

machine, while ensuring limited movement and stop in case of danger.

- Ergonomic shape and operation

- Hand recognition prevents defeat

- Easy connection with M12 connectors

- Several models to suit multiple applications

- Extra buttons for e.g. machine control

CONTROL DEVICES 5– 3

—

Introduction and overview

Selection orientation

Different types of control devices

When to use a two-hand or one-hand control device

A two-hand control device is often used for machines with

manual loading or unloading. The operator uses the twohand control device to safely start a machine cycle. A twohand control must be used with a safety control device that

supervises that both buttons are pressed simultaneously,

i.e. both hands are on the control and therefore outside the

dangerous zone, in order to start the dangerous movement.

An one-hand control device can be used in applications

when the operator cannot reach the hazardous area with

his/her free hand, or on less dangerous machines.

When to use a three-position device

A three-position device (or hold-to-run device) is used to

allow a limited movement of the machine when the operator needs to be in the dangerous area without stopping the

dangerous machine, for example during troubleshooting,

test running or programming.

The operator pushes the larger black button to a middle

position in order to allow a movement. In case of danger, the

operator will either release the button or squeeze it to its

bottom position and the machine will stop.

Standards

The safety distance of two-hand control devices should be

calculated using EN ISO 13855.

When constructing a two-hand station for a machine, the

standard EN 574 about functional aspects and principles for

design needs to be followed.

5

5– 4 SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

One- and two-hand devices

Safeball™

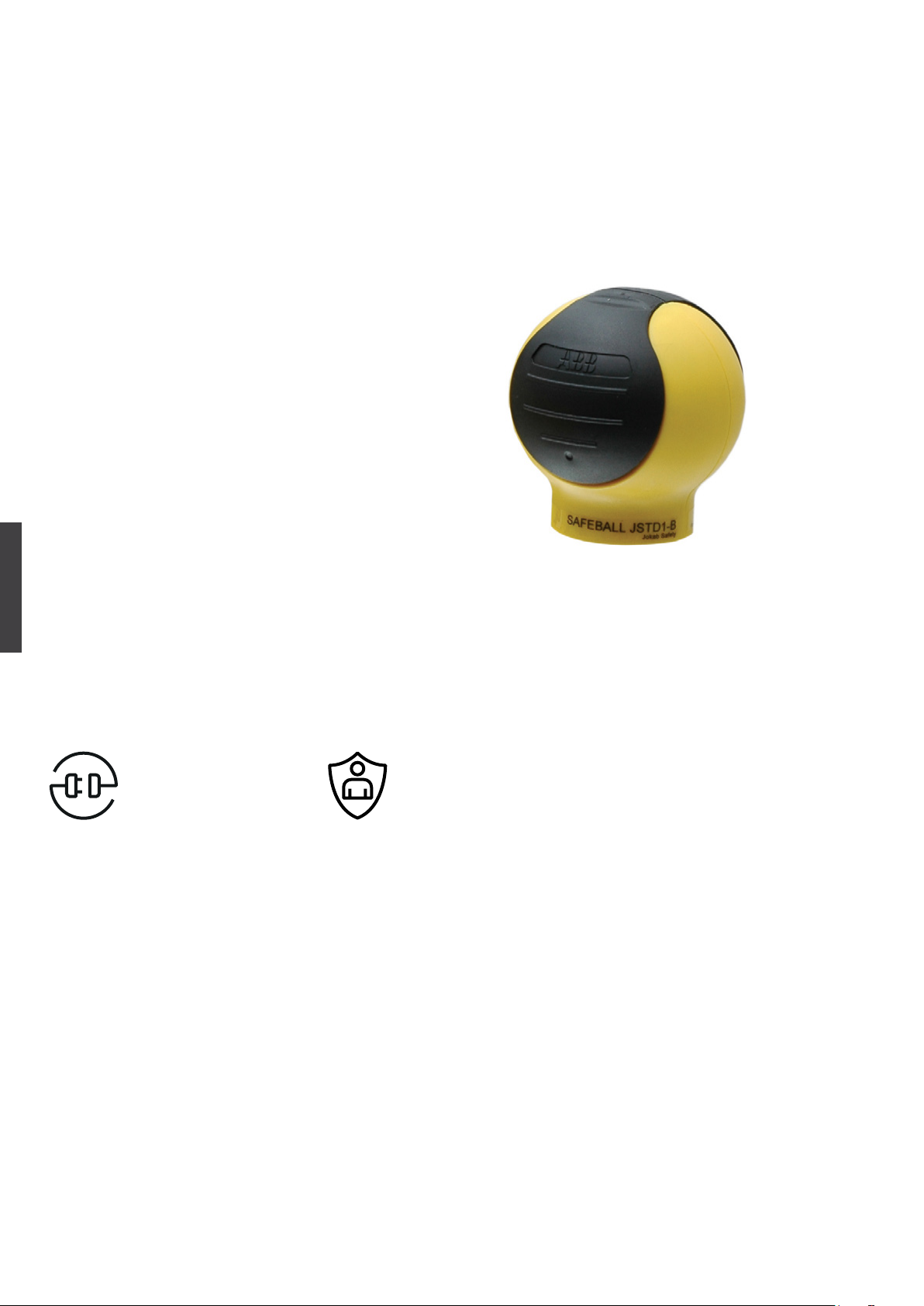

Safeball™ is an ergonomic control device

used for safe start and stop of machine

cycles. Usually two Safeball™ are used together to form a two-hand control.

Safeball™ consists of a spherical ball containing two embedded push button switches, one on each side of the ball. Both buttons

must be pressed in order to start and operate the machine. The risk of unintentional activation is thereby minimized and the device

is simple and ergonomic to use.

When two Safeball™ are used in a two-hand

device application, the operator must press

all four push buttons simultaneously in order

5

to operate the machine. If one or more of the

buttons are released, a stop signal is given

to the machine.

Optimum interface

Ergonomic design

The design of Safeball™ allows for

comfort of use for all hand sizes and

a great variety in gripping positions.

And there is no need for shrouding top

covers to prevent defeat, as there is for

two-hand devices with standard push

buttons.

Flexible mounting

With the JSM C5 mounting bracket,

Safeball™ can be orientated in the

most ergonomic position for the operator.

Safety and protection

Unique design

The unique design of Safeball

bines the highest level of safety with

the best ergonomics.

Highest safety level

Safeball

a dual switching function and shortcircuit supervision in each hand.

TM

provides the operator with

TM

com-

CONTROL DEVICES 5– 5

—

Applications and features

Safeball™

Applications

One-hand control device

One Safeball™ can be used as an ergonomic “hold to run”

button, i.e. the movement is allowed as long as both push

buttons on Safeball™ are pressed, usually when the operator cannot reach the hazardous area with his/her free hand,

or on less dangerous machines. Safeball

one-hand control device since it is very easy to locate and

activate.

TM

is a very practical

Two-hand control device

A two-hand control device is often used for machines with

manual loading or unloading. The operator uses the twohand

control device to safely start a machine cycle. A two-hand

control must be used with a safety control device that

makes sure that both buttons are pressed simultaneously,

i.e. both hands are on the control and therefore outside the

dangerous zone, in order to start the dangerous movement.

Using two Safeball

device.

TM

, it is easy to realize a custom two-hand

5

Features

Mounting methods

Safeball™ can be mounted in many different ways. It can

be mounted on a table, on the machine, on a support or

wherever suitable for ergonomic reasons. Safeball™ can be

mounted in a fixed position or on a tilting and/or rotating

support when used with a JSM C5. This flexibility in mounting enhances ergonomics and minimizes work-related musculoskeletal disorders.

When two Safeball™ are used as a two-hand device, no

shrouding top cover is necessary to prevent defeat, as it is

for two-hand devices with push buttons, since it is very difficult to push all 4 push buttons of the two Safeball™ with

e.g. a hand and an elbow.

Highest level of safety

When used as a two-hand control device, a safety controller for two-hand devices must be used, like an appropriate

Sentry safety relay or a Pluto programmable safety controller. The safety controller monitors that all four push buttons

(i.e. on each side of both Safeball™) are pressed within 0.5

second, in order to detect e.g. a short circuit or fraud, like

a rubber band around one device. Safeball™ is certified to

comply with type III C according to EN 574+A1:2008.

JSTD25

The JSTD25 control stations are pre-built two-hand devices

utilizing the good ergonomics of Safeball™. They can be

used as fixed devices that are easy to install, or as mobile

devices. All models are equipped with shields to protect the

buttons from accidental operation, and also protect from

damage if the device is dropped on the floor when used as

mobile device. All versions meet EN 574 and EN ISO 13849-1.

5– 6

SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—

Ordering information

Safeball™

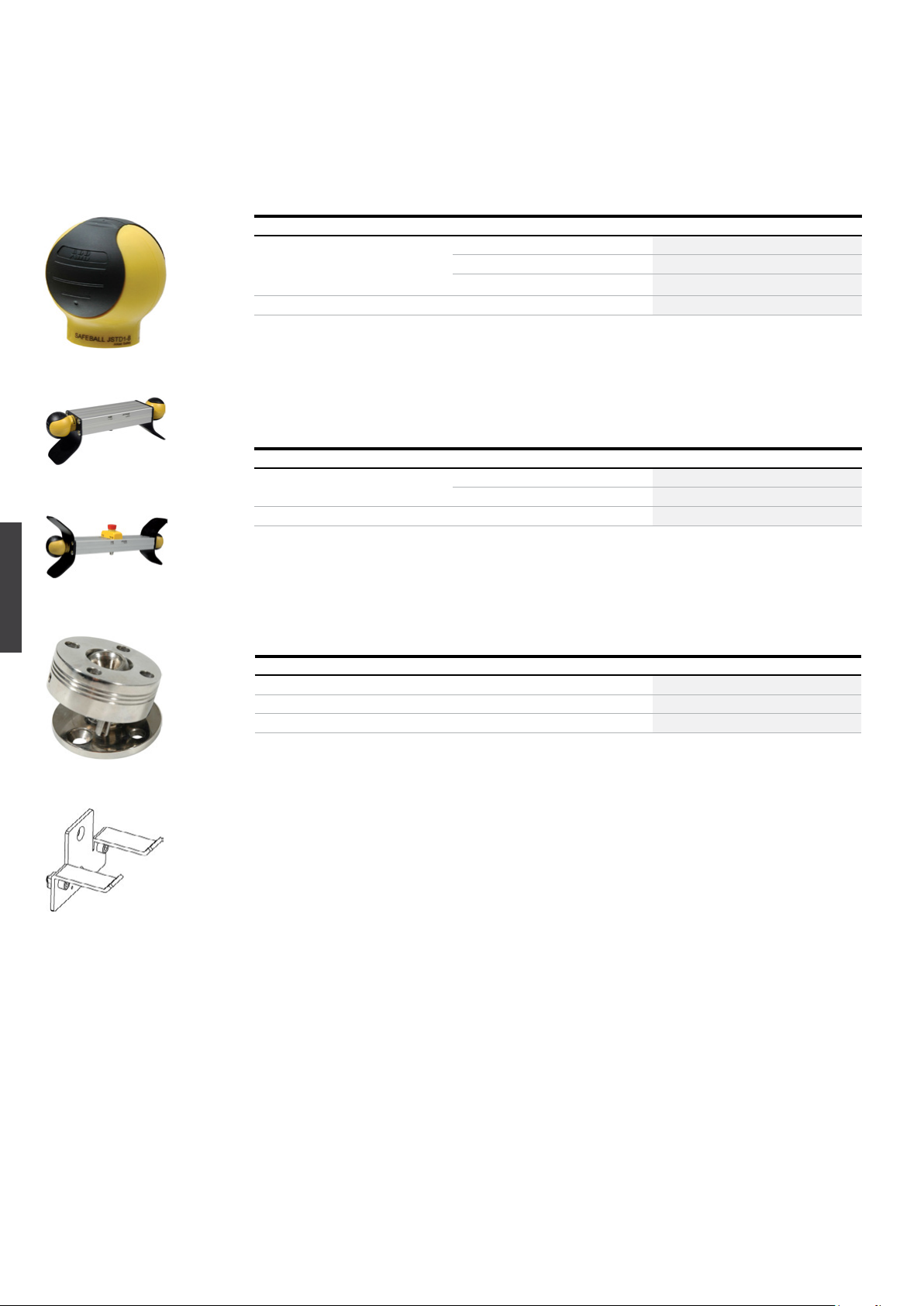

2TLC010041F0201

Safeball™

—

Safeball™ JSTD1

Types of switches Cable length Typ e Order code

1 NO + 1 NC 2 m JSTD1-A 2TLA020007R3000

0.2 m JSTD1-B 2TLA020007R3100

10 m JSTD1-C 2TLA020007R3200

2 NO 0.2 m JSTD1-E 2TLA020007R3400

—

Two-hand control devices JSTD25

2TLC172086F0201

JSTD25F

Extra feature Connector male Typ e Order code

None M12-5 JSTD25F 2TLA020007R6000

M12-8 JSTD25H 2TLA020007R6300

Pre-mounted Smile 10 EK emergency stop button

5

JSTD25K

2TLC172681F0201

—

Accessories

M12-8

JSTD25K 2TLA020007R6900

Description Typ e Order code

Mounting bracket for JSTD1 with orientation possibility (ball joint) JSM C5 2TLA020007R0900

Suspension shelf for JSTD25F/H/K JSM C7 2TLA020007R1200

Protection coat for Safeball Safeball coat 2TLA020007R1900

2TLC172194F0201

JSMC5

2TLC172195F0201

JSMC7

Loading...

Loading...