Jokab Safety all products Product Guide

Product Profile

ABB Jokab Safety

Safety

Contact us

ABB AB

Jokab Safety

Tel. +46 300-67 59 00

www.abb.com/lowvoltage

2TLC172001B0201, ABB Jokab Safety, 2011

We develop innovative products and

solutions for machine safety

We make it simple to build safety systems. Developing innovative products and solutions for machine

safety has been our business idea since the company Jokab Safety, now ABB AB, was founded in

Sweden in 1988. Our vision is to become “Your partner for machine safety – globally and locally”.

Many industries around the world, have discovered how much easier it has become to build protection and safety systems with our components and guidance.

Experience

We have great experience of practical application of safety requirements andstandards from both authorities and

production. We represent Sweden instandardisation organisations for machine safety and we work daily with the

practical application of safety requirements in combination with production requirements. You can use our experience for training and advice.

Systems

We deliver everything from a safety solution to complete safety systems for single machines or entire production

lines. We combine production demands with safety demands for production-friendly solutions.

Products

We market a complete range of safety products, which makes it easy to build safety systems. We develop these

innovative products continuously, in cooperation with our customers Our extensive program of products, safety

solutions and our long experience in machine safety makes us a safe partner.

Jokab Safety - a member of the ABB Group

Jokab Safety is now a member of the ABB Group, which

gives us extra strength and a world wide sales network

in 120 countries. Our goal is to become even better

at providing service to you by cooperation within ABB

globally and locally.

Do you need to learn about the new safety requirements for

robots? If so, please contact us.

M

a

c

h

i

n

e

s

a

f

e

t

y

Standards and

regulations

We help to develop standards

Directives and standards are very important to machinery and safety component manufacturers. We therefore

participate in several international committees that develop standards, for among other things industrial robots,

safety distances and control system safety features. This

is experience that we absorb so that the standards will

present requirements that benefit production efficiency

allied to a high level of safety. We are happy to share our

knowledge of standards with our customers.

2

PRODUCT PROFILE

ABB

Our products revolutionise the market

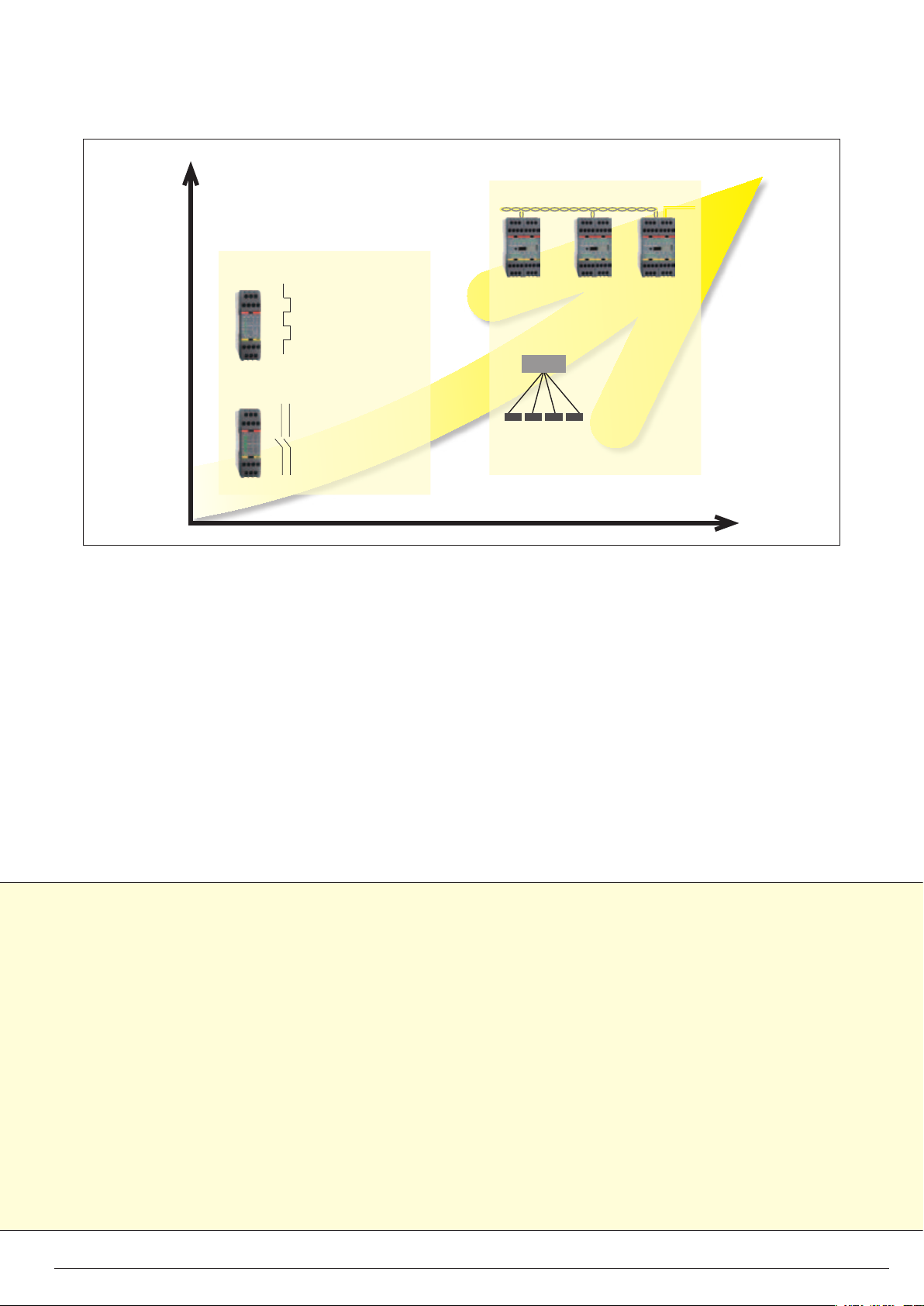

Flexibility

Programmable

Not programmable

Pluto

AS-i

Vital

Dynamic "doubled up"

safety signal that tests a

sensor, for example, 200

times per second.

Safety relay

Double static inputs that

only test the switches

each time they are used.

Our dynamic safety circuits and our comprehensive

safety PLC are probably the most revolutionary ideas

that have happened in the safety field in the control and

supervision of protection, in many respects:

•They save on inputs: a dual safety circuit with one

conductor instead of two. In addition, many protection devices can be connected to the same input

while maintaining the highest level of safety.

•Reliability is better. Our electronic sensors have

much longer lives than mechanical switches

•They are safer, since the dynamic safety sensors are

checked 200 times per second. Switches on a door

can only be checked each time they are used, for

example once per hour or even once a month.

Pluto All-Master

Safety PLC with static and dynamic

safety inputs.

Master

Slaves

Traditional safety PLC

Master-Slave with static inputs

Number of machines/different stops

•With the All-Master Safety PLC it is easy to connect

and disconnect machinery from a safety viewpoint.

Common emergencystop circuits and sensors can

be created as soon as the buses are interconnected

between our safety PLCs.

We are continuously designing safety systems for difficult environments and also to create new safety solutions where practical solutions are missing. New technical improvements give new possibilities and therefore

we continuously develope new products.

We train both machine builders

and machine operators

Do you construct machinery?

We can provide the training you need to construct machinery that meets the requirements. Example subjects:

•Practicalimplementationoftherequirementsinthenew

Machinery Directive2006/42/EC, which is valid for machines that was delivered/put into service from the 29th

of december2009

•Riskanalysis–intheoryandpractice

•Controlsystemssafety,standardsENISO13849-1

and EN 62061

ABB

Do you purchase and use machinery?

As a machinery user it is your responsibility to ensure

thatthecorrectrequirementsarecompliedwith–regardless of whether your machinery is “new” or “old”, i.e.

CE-labelled or not. Unfortunately many have purchased

CE-labelled machinery that does not meet the requirements. This must not be used. Having it brought into

compliance by the supplier can take a long time and be

expensive in terms of loss of production, etc. We can educate you on this and help you to set the right demands

when buying new or even second-hand machinery.

PRODUCT PROFILE

3

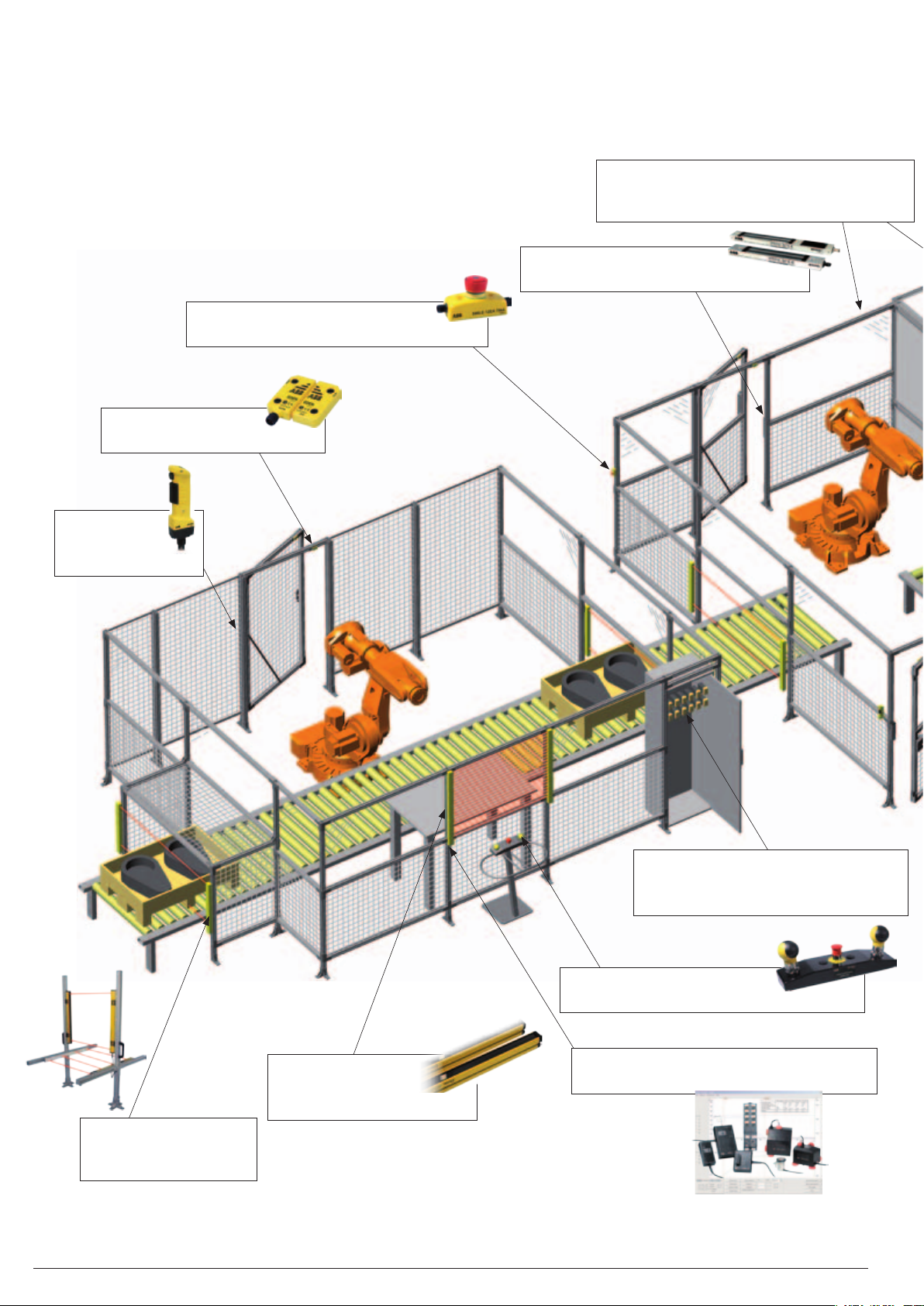

Production-friendly safety systems

from ABB Jokab Safety

Quick-Guard fencing system

prevents unauthorised access and offers

noise reduction

Magne magnetic lock

to keep doors closed during a process

Smile emergency stop

to stop machinery when there is a hazard

The Eden sensor

monitors that doors are closed

3-position

device

for troubleshooting

Pluto Safety PLC, Vital and

safety relays

for monitoring protection

Safeball control device

for ergonomic and safe two-handed control

Focus light

curtain

with finger detection

Smart stopping timer

to assist in determining protection locations

Focus light beam

to provide protection

when entering an area

4

PRODUCT PROFILE

ABB

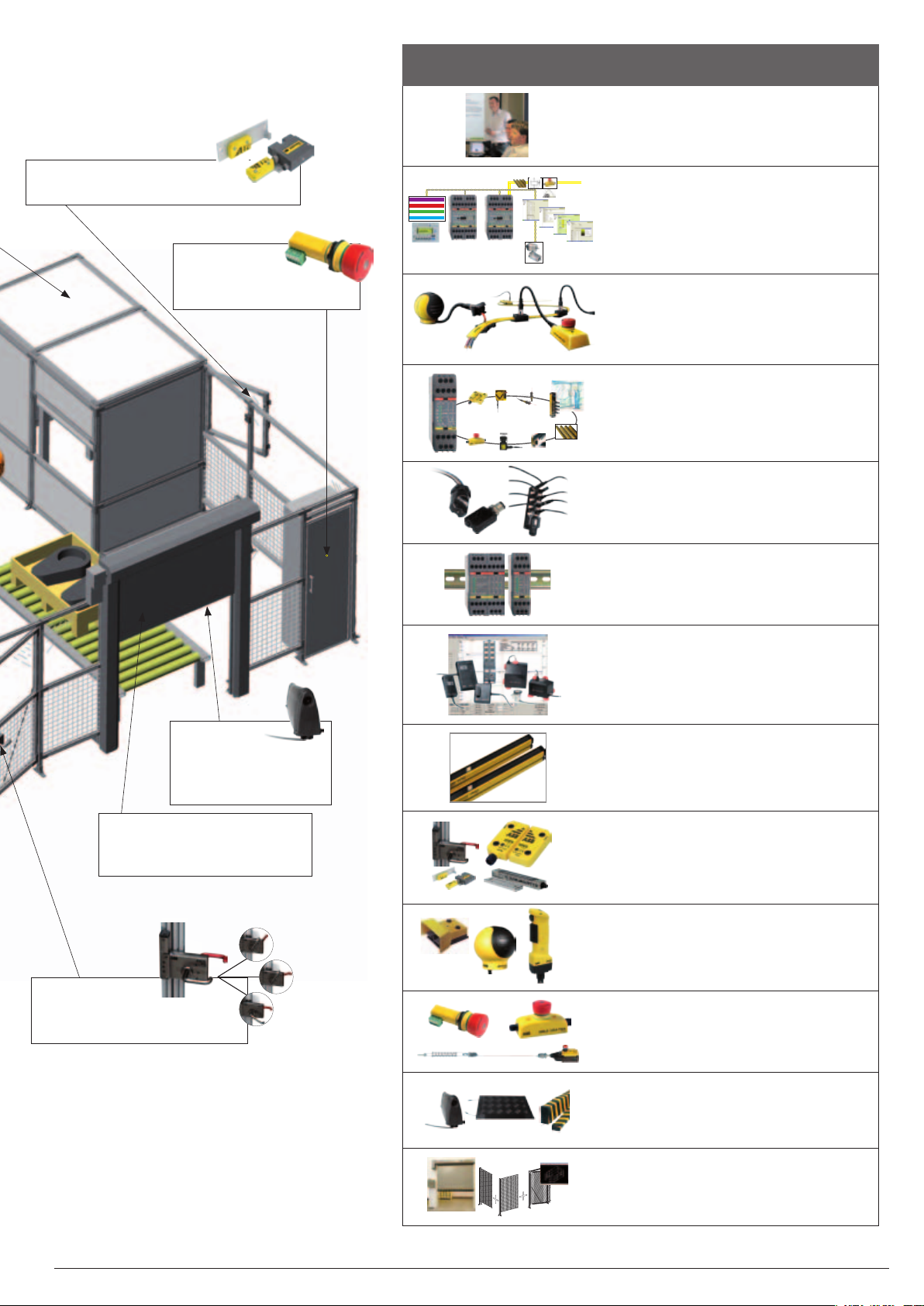

Dalton process lock

to keep doors closed during a process

Emergency

stop Inca

for enclosure installation

Profibus DP

DeviceNet

CANopen

Ethernet

HMI

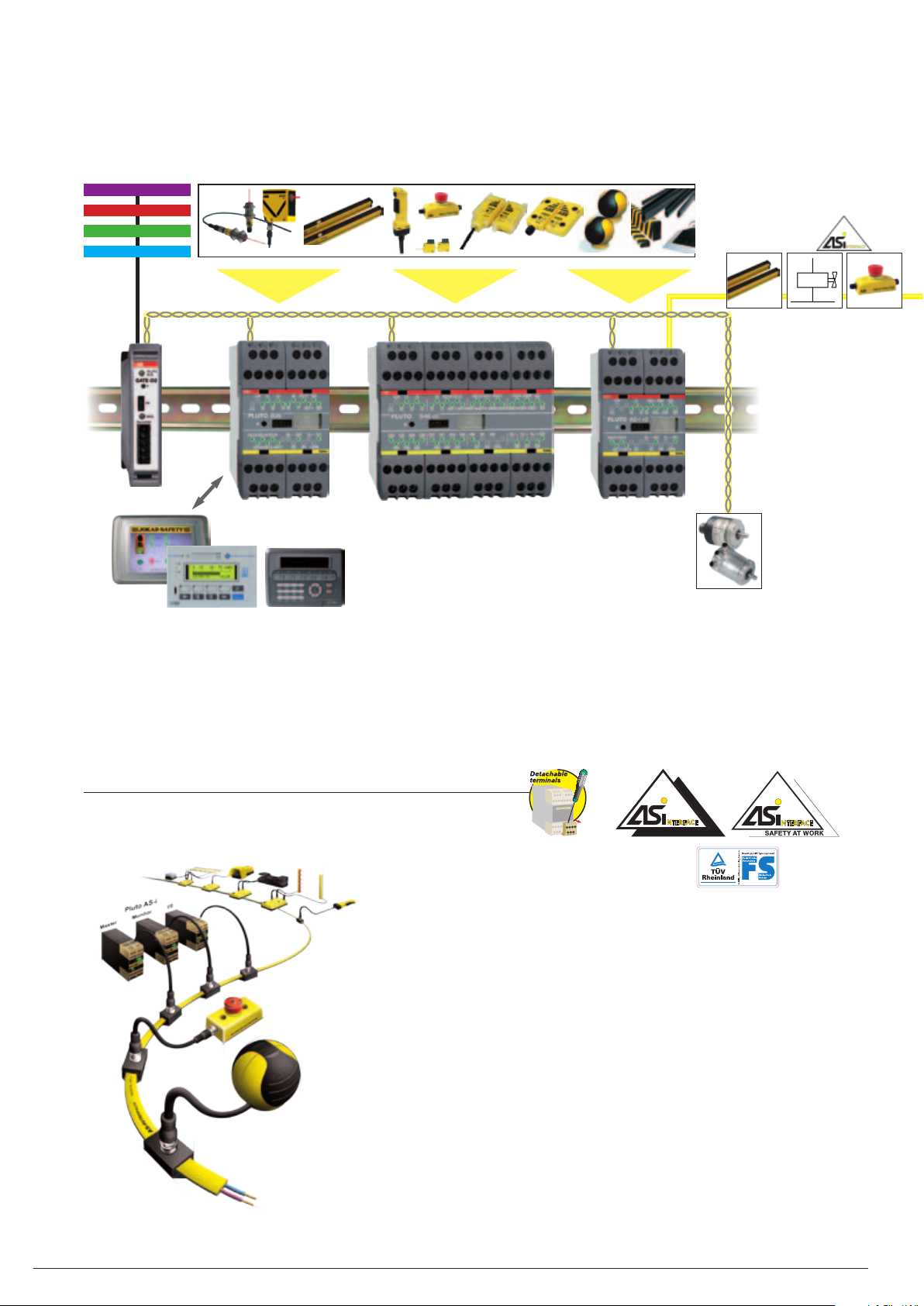

Product groups

Training & Advice

Practical application of standards and

regulations, along with CE-labelling.

AS-i

Pluto Safety PLC

A unique All-Master safety PLC for

dynamic and static safety circuits.

Pluto AS-i

Programmable safety system AS-i where all

units are connected to the same bus cable

and the function of the unit is determined in

the PLC program.

Vital safety controller

Dynamic safety circuit for multiple protection

according to the highest safety category.

Tina adapter units

Transformation of static signals to dynamic

safety signals, etc.

Sensitive

edges

prevents against

trapping injuries

Roller doors

for short protection distances

and noise reduction

Knox

safety lock

ensures that doors are locked

Operational mode

locked and reset

Reset

Openable

Open

Safety relays

The market’s most flexible safety

relays for different protection

purposes and categories.

Stopping time & machinery diagnosis

Used for stopping time measurement,

annual maintenance and for trouble shooting machinery.

Light curtain/light beam/scanner

Complete range of light beams, light curtains and scanners.

Sensors/switches/locks

Dynamic non-contact sensors, safety

switches, magnetic switches and locks.

Control devices

Ergonomic three-position control units,

two-handed control units and foot pedals.

Emergency stop devices

Emergency stop devices for dynamic and

static safety circuits.

ABB

Contactstrips/Bumpers/Safety mats

Sensitive edges, bumpers and

safety mats.

Fencing systems/SafeCAD/Roller

doors

A stable and flexible fencing system

that is easy to install.

PRODUCT PROFILE

5

Programmable safety systems

Safety PLC Pluto

Profibus DP

DeviceNet

CANopen

Ethernet

20 I/O 46 I/O

12 I/O

(A/D)

Pluto AS-i

HMI

Pluto Safety PLC enables freely programmable functions

•Save I/O's by connecting several sensors in series to one input while maintaining the highest safety level

•Write your own programme or use TÜV approved function blocks

•All-Mastersystemwithupto32Plutosononebus

Pluto AS-i

AS-i two-wire bus simplifies function and installation

•Easy to add, remove and move units on the bus

•Power, data and control in the same cable

•Pluto AS-i as master, monitor or safe I/O

6

PRODUCT PROFILE

ABB

Loading...

Loading...