Page 1

VRF Smart Gateway Installation Instructions

SI-VRFCBN02-0Sx

Part No. 24-10143-1183, Rev. B

Refer to the QuickLIT website for the most up-to-date version of this document.

Update Software

Important: A software update may be available for your

device. Visit VRFPro.com or contact your

nearest Johnson Controls representative

for the latest version. Refer to the VRF

Smart Gateway User's Guide

(LIT-12012385) for instructions on applying

updates.

Applications

The Johnson Controls® VRF Smart Gateway enables

the integration of the Hitachi VRF system with a building

automation system (BAS), such as the Metasys® system.

The VRF Smart Gateway performs this function by

communicating between the native H-Link

communications network of the Hitachi VRF system and

the open building standard BACnet®/IP network. The

VRF Smart Gateway intelligently provides the VRF device

and point data over the BACnet/IP network in a way that

the BAS can easily discover. The VRF Smart Gateway

therefore requires little or no post-integration configuration

within the BAS. The VRF Smart Gateway includes a

simple web server that provides a wireless mobile user

interface for configuring communication parameters and

performing VRF system discovery and device naming.

The wireless connection on the VRF Smart Gateway

allows users of a supported mobile device to be up to 30

m (100 ft, line of sight) away. Power must be supplied

using the provided external power supply.

North American Emissions Compliance

United States

This equipment has been tested and found to comply

with the limits for a Class A digital device pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference when this equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area may cause harmful interference, in which

case the users will be required to correct the interference

at their own expense.

RF Transmitters: Compliance Statement (Part 15.19)

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received,

including interference that may cause undesired

operation.

Warning (Part 15.21)

Changes or modifications not expressly approved by the

party responsible for compliance could void the user’s

authority to operate the equipment.

(barcode for factory use only)

Software Release 1.0

Issued April 2017

RF Exposure (OET Bulletin 65)

To comply with FCC RF exposure requirements for

mobile transmitting devices, this transmitter should only

be used or installed at locations where there is at least

20 cm separation distance between the antenna and all

persons.

1VRF Smart Gateway Installation Instructions

Page 2

Canada

Industry Canada Statement

The term IC before the certification/registration number

only signifies that the Industry Canada technical

specifications were met.

Le terme « IC » précédant le numéro

d'accréditation/inscription signifie simplement que le

produit est conforme aux spécifications techniques

d'Industry Canada.

Installation

Parts Included

• VRF Smart Gateway

• Installation Instructions

•

VRF Smart Gateway Quick Start Guide (Part No.

24-10737-156)

Note: A power adapter is available to order separately.

Contact the nearest Johnson Controls

representative to order.

Special Tools Needed

The unit supports both DIN rail and surface mounting

options. If the unit is permanently mounted to a vertical

surface without a DIN rail, you need screws to mount the

unit. The specific screw types depend upon the surface

to which the unit is mounted. The screw holes on the VRF

Smart Gateway can accommodate M3.5 and #6 screws.

To configure the VRF Smart Gateway using the gateway's

Wi-Fi access point, you need a mobile device (tablet or

smartphone) or computer (laptop or desktop) that

supports Wi-Fi.

Location Considerations

Observe the following guidelines when mounting a VRF

Smart Gateway:

• Mount the VRF Smart Gateway in areas free of

corrosive vapors and observe the environmental

limitations listed in the Technical Specifications

section of this document.

• Objects (including ductwork, cabinets, doors, and

glass) can impede the wireless signal. Minimize the

number of objects between the connected computer

or mobile device and the VRF Smart Gateway. Use

line of sight, if possible.

• Metal objects (such as cabinet doors, enclosures, and

pipes) and concrete objects (such as pillars, walls,

and ceilings) may limit Wi-Fi service. To

accommodate potential structural obstacles on site,

the VRF Smart Gateway can be mounted flush

against the wall or perpendicular to it.

• The VRF Smart Gateway is not rated for outdoor

mounting.

Mounting Locations

The VRF Smart Gateway can be attached to a 1-1/8 in.

(35 mm) DIN rail or a flat, vertical surface. Mounting the

unit on a ceiling or in a way that positions the front of the

unit facing down is not recommended.

Although the unit has two mounting clips, only the bottom

clip snaps inward. The top clip is permanently locked in

the outward position, and it can be used as an additional

hole for screwing the unit into place. If not utilized for DIN

rail or surface mounting, the top and bottom clips may

be removed from the unit.

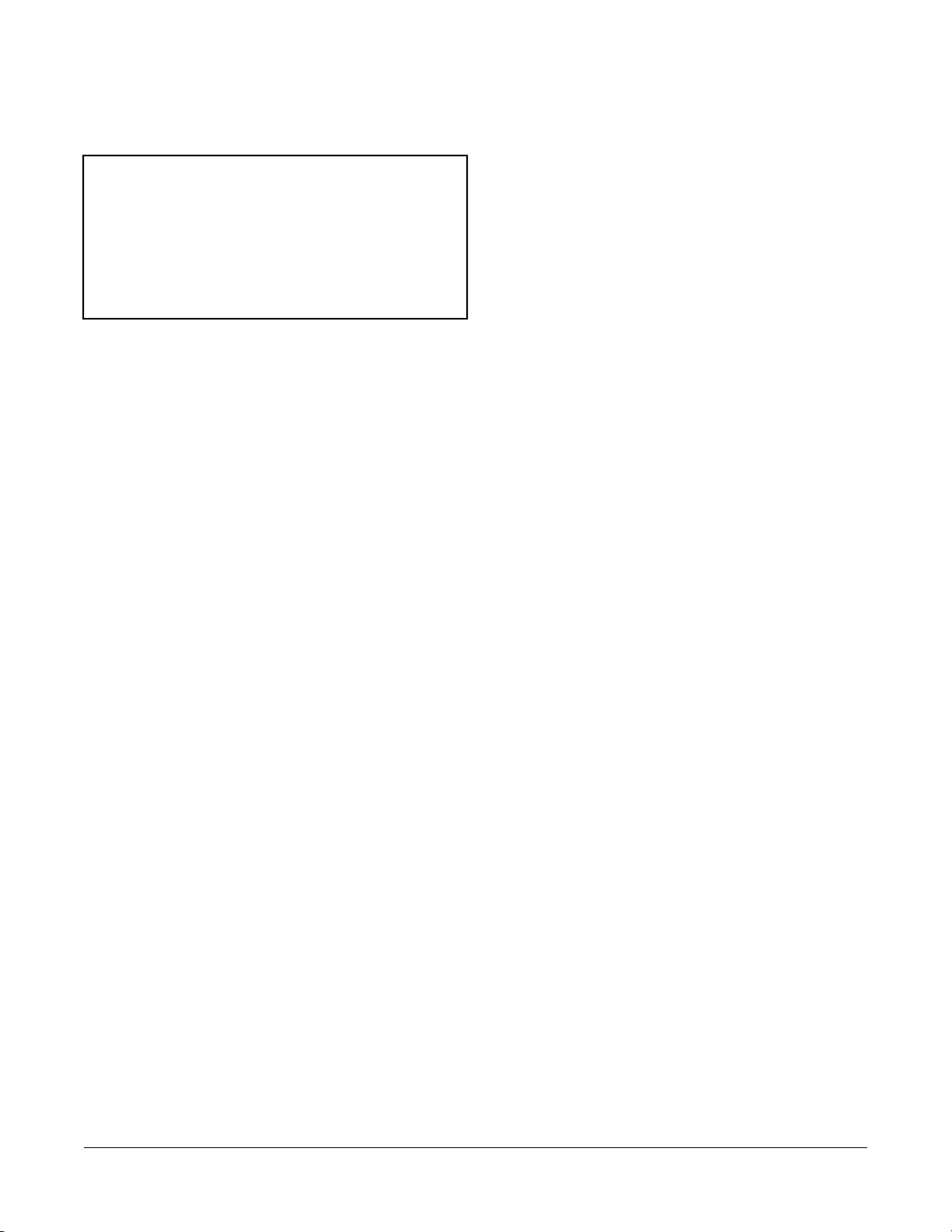

DIN Rail Mounting

To mount the unit on a DIN rail:

Mounting

We recommend mounting the unit either vertically (upright

and flush) or horizontally (sideways and flush). This

flexibility allows the unit to be mounted in a way that

minimizes spacial constraints and maximizes placement

options for optimal wireless signal strength.

The unit should be mounted in such a way that labels

can be read if they are visible. (For example, do not mount

the unit upside down, which puts the labels upside down.)

1. Securely mount a 3 in. (7.5 cm) or longer section of

1-1/8 in. (35 mm) DIN rail in the required space.

2. On the unit, pull the bottom mounting clip outward to

the extended position.

2VRF Smart Gateway Installation Instructions

Page 3

Figure 1: Positioning the Unit on a DIN Rail

Figure 2: Sample Permanent Mounting, Back-side

Screws

3. Hang the unit on the DIN rail by the hooks at the top

of the DIN rail channel (on the back of the bracket),

and position the unit snugly against the DIN rail.

4. Push the bottom-mounting clip inward to secure the

unit on the DIN rail.

Wall Mounting

The unit may be mounted using the holes in the DIN rail

clips. This orientation helps accommodate on-site

constraints. Screw hole locations are illustrated in Figure

3.

The screw types needed to mount the unit depend upon

the surface to which the unit is mounted. The screw holes

on the VRF Smart Gateway can accommodate M3.5 and

#6 screws.

For information on location considerations for maximizing

signal strength, see the Mounting section.

To mount the unit on a flat surface (such as a wall):

1. Pull the bottom mounting clip outward to the extended

position.

2. Mark mounting hole locations on the wall using the

dimensions shown in the following figure; or hold the

bracket against the wall and mark the hole locations

through the mounting clips.

Note: The position of the location holes depends on

whether the bracket is mounted horizontally

or vertically.

3VRF Smart Gateway Installation Instructions

Page 4

Figure 3: Mounting Holes, Flat Mounting, DIN

Rail Screws, in. (mm)

Wiring the H-Link Network

To wire the H-Link Network of the VRF Smart Gateway:

• Connect the two H-Link cable wires to the left

terminals indicated in the following figure.

• If the VRF Smart Gateway is connected at an

intermediate position of the H-Link network as

opposed to the end of the network segment, use the

right terminals shown in the following figure to

continue the H-Link network.

Figure 4: H-Link Cable Insert Position

Note: The screw holes on the VRF Smart Gateway

can accommodate M3.5 and #6 screws.

3. Drill holes in the wall based on the locations marked

in the preceding step, and insert wall anchors for each

hole (if necessary).

4. Hold the unit in place, insert the screws through the

mounting clips and into the screw holes, and then

carefully tighten all screws.

Important: Do not overtighten the mounting screws.

Overtightening the screws may damage

the mounting clips or bracket.

Wiring

Wiring Consideration and Guidelines

Observe the following guidelines when wiring the VRF

Smart Gateway:

• Do not allow the VRF Smart Gateway to hang from

a cable connection.

• Provide some slack in the cable between the VRF

Smart Gateway and the controller or other device to

which you are connecting.

To insert or remove the H-Link cable wires:

• Push the orange tabs using a small, flat screwdriver

or similar tool as indicated in the following figure.

• Then, insert or remove the wire and release the tab.

Figure 5: Inserting or Removing the H-Link Cable

Wires

Ethernet Port

The Ethernet port on the VRF Smart Gateway is an 8-pin

RJ-45 jack. The maximum allowable cable length is 328

ft (100 m). The Ethernet port on the VRF Smart Gateway

connects to the BAS by using an Ethernet switch or

similar networking equipment.

4VRF Smart Gateway Installation Instructions

Page 5

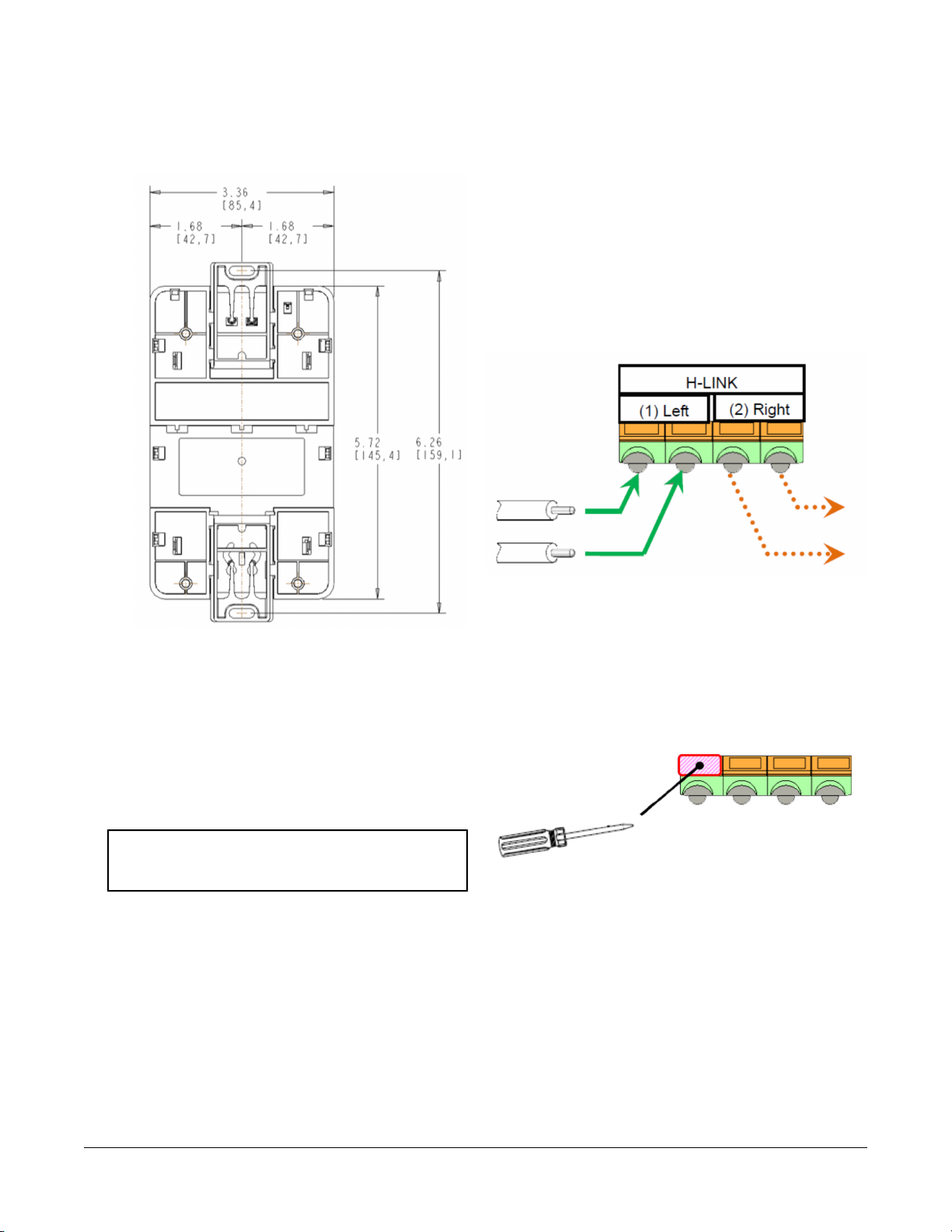

External Power Supply Connections

To connect the VRF Smart Gateway using the supplied

external power source:

1. Connect the 15 VDC output connector of the power

supply to the power supply port of the VRF Smart

Gateway.

Risk of Property Damage. Do not apply power to

the system before checking all wiring connections.

Short-circuited or improperly connected wires may

result in permanent damage to the equipment.

MISE EN GARDE:

Risque de dégâts matériels. Ne pas mettre le

système sous tension avant d'avoir vérifié tous les

raccords de câblage. Des fils formant un court-circuit

ou connectés de façon incorrecte risquent

d'endommager irrémédiablement l'équipement.

2. Connect the power supply to the supplied power cord.

3. Plug the power cord into a 100 to 240 VAC outlet.

Important: Power should only be applied and removed

by connecting and disconnecting the power

cord from the 100 to 240 VAC outlet.

Applying or removing power by connecting

or disconnecting the 15 VDC connector can

damage the unit.

Figure 6: VRF Smart Gateway with Sample External

Power Supply

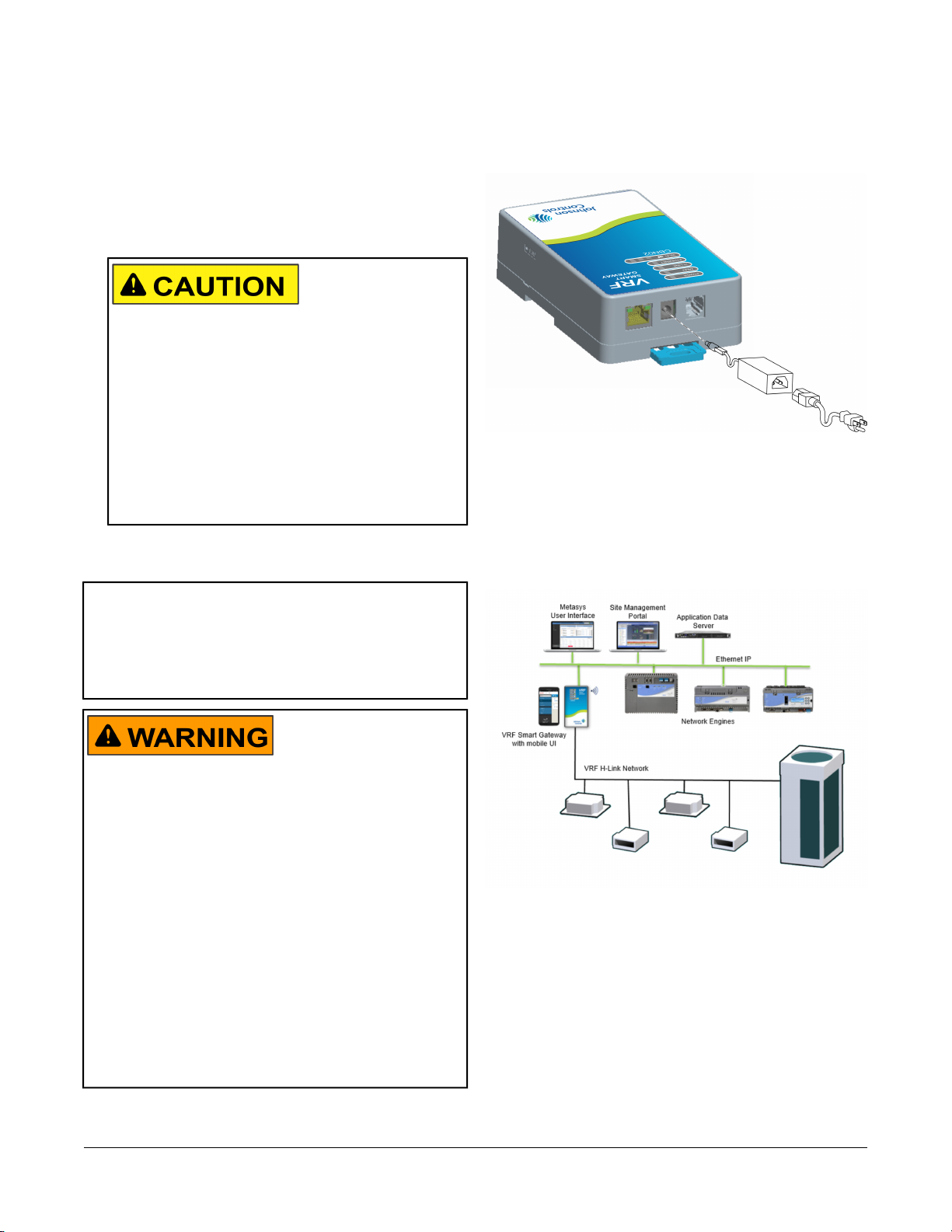

Operation

The easiest way to initially configure the VRF Smart

Gateway is by connecting to the gateway's Wi-Fi network.

Figure 7: Connecting VRF Equipment to the Metasys

System

Risk of Electric Shock. Disconnect or isolate all power

supplies before making electrical connections. More than

one disconnection or isolation may be required to

completely de-energize equipment. Contact with

components carrying hazardous voltage can cause

electric shock and may result in severe personal injury

or death.

AVERTISSEMENT:

Risque de décharge électrique. Débrancher ou isoler

toute alimentation avant de réaliser un branchement

électrique. Plusieurs isolations et débranchements sont

peut-être nécessaires pour -couper entièrement

l'alimentation de l'équipement. Tout contact avec des

composants conducteurs de tensions dangereuses

risque d'entraîner une décharge électrique et de

provoquer des blessures graves, voire mortelles.

Connecting to the VRF Smart Gateway Wi-Fi Network

1. In the Wi-Fi settings of your device or laptop, connect

to the VRF Smart Gateway Wi-Fi network using your

default credentials. These credentials are included

on a label in the VRF Smart Gateway Quick Start

Guide (Part No. 24-10737-156) that came with your

device.

2. Direct your browser to www.myvrfsg.com to open

the VRF Smart Gateway browser interface.

5VRF Smart Gateway Installation Instructions

Page 6

Note: VRF Smart Gateway ships with a private

myvrfsg.com SSL certificate installed to ensure

secure communication with the VRF Smart

Gateway. However, this certificate does not

indicate that it is trusted in a browser. If you

wish to install your own certificate, refer to

Adding a Private Key and Certificate to VRF

Smart Gateway in the VRF Smart Gateway

Network and IT Guidance Technical Bulletin

(LIT-12012341).

3. Read and accept the VRF Smart Gateway license

agreement.

4. The first time you log in to the VRF Smart Gateway,

the Change Password and Passphrase web page

appears. You must change the Admin password and

Wi-Fi passphrase.

Important: After you change the Wi-Fi passphrase

or SSID, the web server restarts and

you must rejoin the VRF Smart Gateway

Wi-Fi network using the new

passphrase. On some mobile devices,

you must select and forget the original

VRF Smart Gateway Wi-Fi network

before rejoining the network with the

new passphrase.

Change the default password in the New Admin

Password field. Confirm the change by entering the

new password in the Verify New Admin Password

field.

Change the Wi-Fi Passphrase in the New Wi-Fi

Passphrase field and click Save.

Once you have established Wi-Fi connection to the VRF

Smart Gateway, you can begin to configure the gateway

settings in the Settings menu as explained in the Users

Guide. When the gateway is physically connected to the

H-Link network, the VRF Smart Gateway automatically

starts to discover the VRF system and devices. View the

Device List from the VRF Smart Gateway UI to see the

discovered VRF devices.

Reset Button Operation and Descriptions

If you lose your password or if you want to restore the

unit to factory defaults, the VRF Smart Gateway offers

two reset functions: a Network Reset function that resets

Wi-Fi and Ethernet settings, and a Reset to Factory

Defaults function that resets all unit settings (including

user-configured VRF equipment names and descriptions).

Reset to Factory Defaults also resets your SSL certificate

to the Johnson Controls self-signed certificate that is in

the device when it comes from the factory.

For information on resetting the unit, see Table 1.

Important: To use a unit that is reset to factory defaults,

you must have the default login information

supplied in the Quick Start Guide that

shipped with the unit. The Reset to Factory

Defaults function does not change the

version of the application. If you did a

software upgrade, the VRF Smart Gateway

remains at the upgraded version rather than

resetting to the version that it was running

when it left the factory.

The reset button is on the side of the device, and it is

embedded into the VRF Smart Gateway housing so that

it cannot be activated by accident. To reach the reset

button, use a paper clip, pin, or similar tool.

Notes:

• If you are connected to the network, using the reset

button disconnects you.

• If you press the reset button for more than 9 seconds,

the reset operation is cancelled.

• If a fault condition already exists, the reset button is

disabled.

A software update may be available for your device. Visit

VRFPro.com or contact your nearest Johnson Controls

representative for the latest version. Refer to the VRF

Smart Gateway User's Guide (LIT-12012385) for

instructions on applying updates.

6VRF Smart Gateway Installation Instructions

Page 7

Figure 8: Using the Reset Button Table 1: Reset Button Operation and Descriptions

Reset

Reset Operation

2

Function

Reset Wi-Fi

and Ethernet

Settings

Reset to

Factory

Defaults

1. Press and hold the reset button for 2

seconds. The Fault LED displays Slow

Flicker behavior.

2. Release the reset button within 3

seconds. The Fault LED continues Slow

Flicker behavior.

3. Within 5 seconds, press the reset button

again, and then immediately release it to

confirm that you wish to reset Wi-Fi and

Ethernet settings. (If you do not press the

reset button to confirm within 5 seconds,

the reset operation is cancelled.)

The Wi-Fi (SSID and passphrase) and

Ethernet settings are reset to factory

defaults. The LEDs stop flickering for 2

seconds, and then the LEDs return to

normal operation, based on the current

state of the device.

1. Press and hold the reset button for 6

seconds. After 2 seconds, the Fault LED

1

displays Slow Flicker behavior. This

changes to Fast Flicker behavior after an

additional 4 seconds of holding the reset

button.

2. Release the reset button within 3 seconds

of seeing Fast Flicker behavior. The Fault

LED continues Fast Flicker behavior.

3. Within 5 seconds, press the reset button

again, and then immediately release it to

confirm that you wish to reset to factory

defaults. (If you do not press the reset

button to confirm within 5 seconds, the

reset operation is cancelled.)

4. All unit settings are reset to factory

defaults. The LEDs stop flashing for 2

seconds, and then the LEDs return to

normal operation, based on the current

state of the device.

1 Resets all unit settings, including user profiles.

2 For information on LED designations and flicker behavior,

see Table 2.

7VRF Smart Gateway Installation Instructions

Page 8

Status Indication LEDs

The VRF Smart Gateway communicates status using

LEDs to indicate the following functional states:

• power

• fault

• H-Link bus communication

• Ethernet communication

• Wi-Fi strength

See the following table for a comprehensive list of VRF

Smart Gateway LED functional information.

VRF Smart Gateway LED Designations and Descriptions

Table 2: LED Designations and Descriptions

Descriptions/Other

Conditions

Off = No power

On Steady = Power

supplied by primary

voltage

Off = No faults/normal

operation

On Steady = Missing

hardware, missing

software, operating

system has not yet

initialized, or reset is

in progress.

Slow Flicker (1 blink in

a second) = Software

upgrade in progress

Medium Flicker (2

blinks in a second) =

Startup sequence

Fast Flicker (5 blinks

in a second) = Fault

Off = No data

transmitting

Flicker = Discovering

VRF devices

On Steady =

Discovery complete

Name

NormalColorLED

GreenPower

On Steady

(no flashing)

OffRedFault

FlickerGreenH-Link Bus

Table 2: LED Designations and Descriptions

NormalColorLED

Name

On SteadyGreenEthernet

On SteadyYellowWi-Fi

Descriptions/Other

Conditions

Off = Communication

not established

On Steady =

Communication

established

Flicker = Data

transmission

Off = No Wi-Fi signal

or no devices currently

connected over Wi-Fi

Wi-Fi strength is

indicated by the

number of LEDs that

are lit, with one lit LED

indicating weak

wireless signal

strength (between 1%

and 49%) and three lit

LEDs indicating

excellent wireless

signal strength (at

least 75%).

LED Test Sequence at Startup

During startup, the VRF Smart Gateway automatically

initiates a self-test to verify proper operation of the unit.

Immediately after connecting supply power, the following

LED lighting sequence occurs:

1. The Power LED turns on, and stays lit.

2. The Fault LED indicator flashes for approximately 40

seconds, then turns off when the VRF Smart Gateway

is fully functional.

3. The Wi-Fi LEDs light up in succession (scanning),

indicating that the VRF Smart Gateway is waiting for

a device to join its Wi-Fi network.

Repair Information

If the VRF Smart Gateway fails to operate within its

specifications, replace it. The VRF Smart Gateway is not

a serviceable product; however, it does support software

updates to enable feature enhancements. For a

replacement unit, software updates, or accessories,

contact the nearest Johnson Controls representative.

Do not open the VRF Smart Gateway housing. The VRF

Smart Gateway has no user-serviceable parts inside.

8VRF Smart Gateway Installation Instructions

Page 9

The VRF Smart Gateway does not require periodic field

maintenance.

Troubleshooting

Table 3: Launch Issues Troubleshooting Information

ResolutionProblem

You are not directed to the VRF

Smart Gateway login page when

you launch a web browser.

Every time I install the SSL

certificate on my device, it asks me

to re-install it. What should I do?

When I install the SSL key or

certificate, I receive the message

Error Saving SSL Settings.

Reason

Device behavior can vary based on the device and Internet browser in use. For instance,

some devices cache browser information and do not automatically redirect users to the

VRF Smart Gateway login page when the browser is launched.

Resolution

Make sure that your device is connected to the VRF Smart Gateway's Wi-Fi network.

Direct your browser to www.myvrfsg.com.

If the login page is taking too long to load, try using the Ethernet connection instead.

Resolution

Check your web browser settings and verify that cookies are enabled.

When an SSL key or certificate is corrupted, the SSL page detects it and alerts you to the

corrupted key or certificate.

However, if the corruption is minor, for example, an extra space was copied while installing

the certificate or a character was missed, the UI does not detect the problem and allows

the corrupted key or certificate to be saved. The server detects the error and returns the

Error Saving SSL Settings message. While this correctly prevents the bad key or

certificate from being used, it does not inform you as to the source of the problem.

In this case, reinstall the SSL key or certificate as described in the VRF Smart Gateway

Network and IT Guidance Technical Bulletin (LIT-12012341).

Refer to the VRF Smart Gateway User's Guide (LIT-12012385) for information on Ethernet settings and SSL settings.

Technical Specifications

Table 4: VRF Smart Gateway

Product Code

Ambient Temperature

Conditions

Ambient Humidity

Conditions

Transmission Power

(Typical)

WLAN Receiver

Sensitivity (Typical)

1

SI-VRFCBN02-0Sx: VRF Smart Gateway (Includes VRF Smart Gateway and 100 to 240 VAC power

supply.)

12 to 15 VDC at 5.2 W maximumPower Consumption

Operating: 0 to 50°C (32 to 122°F)

Operating Survival: -30 to 60°C (-22 to 140°F)

Non-Operating: -40 to 70°C (-40 to 158°F)

Storage: 5 to 95% RH 30°C (86°F) maximum dew point conditions

Operating: 5 to 95% RH, 30°C (86°F) maximum dew point conditions

Wireless Local Area Network (WLAN) Transmission Power:

CE Compliant levels

+14.5 dBm, 54 Mbps

+12.5 dBm, 65 Mbps

-76 dBm, 10% packet error rate (PER ), 54 Mbps

-73 dBm, 10% PER, 65 Mbps

9VRF Smart Gateway Installation Instructions

Page 10

Table 4: VRF Smart Gateway

Transmission Speeds

Transmission Range

(Typical)

Wireless Security

Interfaces

(H x W x D)

Weight

Web Browser

Requirements for

Computers and

Handheld Devices

Control

Wireless Communication:

2.4 GHz ISM bands, 802.11 b/g/n, 11/22/54 Mbps

Channel 6 preconfigured, supported CH 1 to 11 for United States and Canada, and CH 1 to 12 for all

other countries

Serial Communication (H-Link Bus):

9600 bps

Ethernet Communication:

10, 100 Mbps

Ethernet Communication:

100 m (328 ft) cable length

H-Link Bus Communication:

1,000 m (3,280 ft) cable length

Wireless Communication:

30 m (98 ft) line-of-sight indoors

91 m (299 ft) line-of-sight outdoors

Channel 6 preconfigured, supported CH 1 to 11 for United States and Canada, and CH 1 to 12 for all

other countries

WLAN Range Performance:

0 to 50 ft = Excellent

50 to 100 ft = Good

100 to 300 ft = Weakest, approaching out of range

WPA2-PSK TKIP (Wi-Fi Protected Access Pre-Shared Key mode Temporal Key Integrity Protocol)

WPA2-EAP-PEAP

WPA2-EAP-TLS

One H-Link port (4-pin port)Network and Serial

145.4 x 85.4 x 40.1 mm (5.72 x 3.36 x 1.58 in. when used vertically)Dimensions

0.21 kg (0.46 lb)

Note: Weights do not include an external power supply.

Computer:

Windows® Internet Explorer® 10 and Windows Internet Explorer 11, Apple® Safari® 6.1 and later,

and Google® Chrome™

Handheld Device:

The handheld device must be running either Internet Explorer Mobile for Windows Mobile version 5

or version 6 operating system (OS); Apple® iPhone® and iPod touch® iOS version 7.0 or greater;

Android™ 4.0.3, 4.0.4, and 4.1+, or Google Chrome. Other web browsers may display the UI, but the

functionality is not guaranteed.

Operating controlPurpose of Control

Electronic Independently Mounted ControlConstruction of

10VRF Smart Gateway Installation Instructions

Page 11

Table 4: VRF Smart Gateway

TYPE 1TYPE 1 or TYPE 2

Action

Pollution Degree 2External Pollution

Situation

330 VRated Impulse Voltage

100º C (212º F)Ball Pressure

Temperature

Compliance

United States UL Listed File E107041, ANSI/UL 60730-1, UL Standard for Automatic Electrical Controls

for Household and Similar Use.

Transmission Complies with FCC Part 15.247 Regulations for Low Power Unlicensed Transmitters

Transmitter FCC Identification: OEJ-MAPWIFI

FCC Compliant to CFR 47, Part 15, Subpart B, Class A

Canada: cUL Listed File E107041, CAN/CSA-E60730-1, Canadian Standard for Automatic Electrical

Controls for Household and Similar Use

Industry Canada IC: 279A-MAPWIFI

IC: RSS-210, ICES-003

Europe: CE Mark – Johnson Controls declares that this product is in compliance with the essential

requirements and other relevant provisions of the RED Directive, the EMC Directive, and the Low

Voltage Directive (LVD).

CE Emission: EN61000-6-3; Generic standards for residential, commercial, and light-industrial

environments. ETSI EN 301 489-1, ETSI EN301 489-3 (Class 2), IEC 60730-1/ EN 60730-1

1 Last digit (x) represents non-US country requirements.

The performance specifications are nominal and conform to acceptable industry standard. For application at conditions

beyond these specifications, consult the local Johnson Controls office. Johnson Controls shall not be liable for

damages resulting from misapplication or misuse of its products.

BACnet Points

The following table lists the indoor units (IDUs) as exposed by the VRF Smart Gateway.

Table 5: VRF BACnet Points for Indoor Units

Contents of InformationObject TypeObject DescriptionObject NameBACnet

Instance

Number

0~255ValueAIIndoor Unit Capacity CodeUNIT-CAP4

–––EnableShutdownSettingBOUnit Enable ModeUNITEN-MODE5

AutoHeatFanDryCoolSettingMOCommand System ModeSYSTEM-MODE6

–––TrueFalseStatusBIHeat/Cool RequiredHtClg-REQ7

SF-SPEED-C8

Speed

0.0~100.0%ValueAIExpansion Valve PositionEXPV-%9

-50~99°C / -58~210°FValueAILiquid Pipe TemperatureLIQ-PIPE-T10

-50~99°C / -58~210°FValueAIGas Pipe TemperatureGAS-PIPE-T11

-50~99°C / -58~210°FValueAIReturn Air TemperatureRA-T12

–AutoHighMediumLowSettingMOCommanded Supply Fan

11VRF Smart Gateway Installation Instructions

Page 12

Table 5: VRF BACnet Points for Indoor Units

Instance

Number

ZNSP-LO33

Lockout

Contents of InformationObject TypeObject DescriptionObject NameBACnet

-50~99°C / -58~210°FValueAIDischarge Air TemperatureDA-T13

-127~127°C / -260~260°FValueAICoil Differential TemperatureDIFF-T14

17~30°C / 62~86°FSettingAOZone Temperature SetpointZN-SP15

-50~99°C / -58~210°FValueAIRemote Zone TemperatureRZN-T16

0~255 HzValueAIRequested Compressor SpeedCOMP~REQ17

0~255ValueAIUnit Stop CodeUNIT-STOP-CODE18

0~255ValueAIAlarm CodeALARM-CODE19

–––TrueFalseStatusBIOptional Room ThermostatRMT-OPT20

–––TrueFalseStatusBIDefrost StatusDEFROST-S21

–––TrueFalseStatusBIRemote Control ConnectedREM-CON22

–––OnOffStatusBISupply Fan StatusSF-S23

–––AlarmNormalStatusBIUnit Alarm StatusALARM-S24

–HeatFanDryCoolStatusMIActual System ModeSYSTEM-S25

––HighMediumLowStatusMIActual Supply Fan SpeedSF-SPD26

-50~99°C / -58~210°FValueAIZone TemperatureZN-T27

–––DirtyCleanStatusBIFilter StatusFILT-S28

–––DirtyCleanSettingBOFilter Status ResetFILT-S-RESET29

–––LockUnlockSettingBOUnit LockoutUNIT-LO30

–––LockUnlockSettingBOFan Command LockoutFANCMD-LO31

–––LockUnlockSettingBOSystem Mode LockoutSYSMODE-LO32

–––LockUnlockSettingBOZone Temperature Setpoint

–––LockUnlockSettingBOFan Speed LockoutFANSPD-LO34

–––LockUnlockSettingBOLouver Position LockoutLOUVER-LO35

The following table lists the IDU custom enum values for SYSTEM-MODE and SYSTEM-S.

Table 6: IDU System Mode

Metasys Enum StringMetasys Enum Value

Cool1

Dry2

Fan3

Heat4

Auto5

The following table lists the IDU custom enum values for SF-SPEED-C and SF-SPD.

Table 7: IDU Fan Speed

Metasys Enum StringMetasys Enum Value

Low1

Med2

12VRF Smart Gateway Installation Instructions

Page 13

Table 7: IDU Fan Speed

Metasys Enum StringMetasys Enum Value

High3

Auto4

The following table lists the outdoor units (ODUs) as exposed by the VRF Smart Gateway.

Table 8: VRF BACnet Points for Outdoor Units

Contents of InformationObject TypeObject DescriptionObject NameBACnet

Instance

Number

0~255ValueAIAlarm CodeALARM-CODE3

StatusMISystem StatusSYSTEM-S7

StatusMIHeat Exchanger StateHX-STATE8

StatusMIInverter StateINV-STATE9

StatusMIFan Controller StateFAN-STATE10

INV-HRS11

Runtime

INV-FREQ13

Frequency

BYPEXPV-%17

Position

INV2ND-A21

Secondary Current

INVPRI-A22

Primary Current

INVTOP-T24

Temperature

COMP2TOP-T25

Temperature

StatusMIProtection CodePROT-CODE26

Several Values (See the Following Tables

for Custom Enum Information)

Several Values (See the Following Tables

for Custom Enum Information)

Several Values (See the Following Tables

for Custom Enum Information)

Several Values (See the Following Tables

for Custom Enum Information)

0~655,350 HoursValueAIInverter Compressor 1

0~655,350 HoursValueAICompressor 2 RuntimeCOMP-HRS12

0~255 HzValueAIInverter Compressor

0~65,535 HzValueAITotal FrequencyTOTAL-FREQ14

0~100%ValueAIOutdoor Fan OutputFAN-%15

0~100%ValueAIExpansion Valve PositionEXPV-%16

0~100%ValueAIBypass Expansion Valve

0~3,698.5 psiValueAIDischarge PressureDISCH-P18

0~369.8 psiValueAISuction PressureSUCT-P19

-50~99°C / -58~210°FValueAIOutside Air TemperatureOA-T20

0~127.0 AValueAIInverter Compressor

0~127.0 AValueAIInverter Compressor

0~127.0 AValueAICompressor 2 CurrentCOMP2-A23

0~99°C / 32~210°FValueAIInverter Compressor Top

0~99°C / 32~210°FValueAICompressor 2 Top

Several Values (See the Following Tables

for Custom Enum Information)

AutoCoolHeatStatusMISystem ModeSYSTEM-MODE6

–OnOffStatusBIDefrost StatusDEFROST-S27

–OnOffStatusBIEmergency Run StatusEMERGRUN-S28

13VRF Smart Gateway Installation Instructions

Page 14

Table 8: VRF BACnet Points for Outdoor Units

Instance

Number

The following table lists the ODU custom enum values for SYSTEM-MODE.

Table 9: ODU System Mode

Metasys Enum StringMetasys Enum Value

Heat1

Cool2

Auto3

The following table lists the ODU custom enum values for SYSTEM-S.

Table 10: ODU System Status

Metasys Enum StringMetasys Enum Value

Thermo off1

Pump down2

SW on start3

Thermo on start4

After defrost5

Start control 16

Start control 27

Normal8

Oil return9

Defrost ready 110

Defrost ready 211

Differential pressure control12

Defrost13

Contents of InformationObject TypeObject DescriptionObject NameBACnet

–RunStopStatusBIInverter StatusINV-S29

–RunStopStatusBIFan StatusFAN-S30

The following table lists the ODU custom enum values for HX-STATE.

Table 11: ODU Heat Exchanger Status

Metasys Enum StringMetasys Enum Value

Evaporator Mode Low Pressure1

Condenser Mode High Pressure2

Evaporator Mode3

Condenser Mode4

The following table lists the ODU custom enum values for INV-STATE and FAN-STATE.

Table 12: ODU Inverter and Fan Status

Metasys Enum StringMetasys Enum Value

Normal stop1

Fault2

14VRF Smart Gateway Installation Instructions

Page 15

Table 12: ODU Inverter and Fan Status

Metasys Enum StringMetasys Enum Value

Over current3

Fin temp4

Electronic thermal5

Undervoltage6

Overvoltage7

Communication error8

Current sensor abnormality9

Instantaneous power failure10

Na011

MPU reset12

Earth fault voltage13

Phase loss14

Na115

Driving prohibited area16

Fan controller retry17

Control abnormality18

Na219

Na320

Loss of synchronism21

Na422

Na523

Normal acceleration24

Normal deceleration25

Constant speed26

Overload after the acceleration27

Overload after the deceleration28

Overload after constant speed29

Power supply unbalance30

Power supply phase loss31

Na632

The following table lists the ODU custom enum values for PROT-CODE.

Table 13: ODU Protection Code

Metasys Enum StringMetasys Enum Value

Pressure ratio1

Pd rise prevention2

Current protection3

INV module temp rise prevent4

Compressor top overheat prevent5

Ps drop or rise prevention6

15VRF Smart Gateway Installation Instructions

Page 16

Table 13: ODU Protection Code

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

Metasys Enum StringMetasys Enum Value

Na17

Na28

Pd drop prevention9

Current demand10

Na311

Na412

Ps rise prevention13

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

APAC Single Point of Contact:NA/SA Single Point of Contact:European Single Point of Contact:

JOHNSON CONTROLS

C/O CONTROLS PRODUCT

MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

Building Technologies & Solutions

507 E. Michigan Street, Milwaukee, WI 53202

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls.

All other marks herein are the marks of their respective owners.© 2017 Johnson Controls

www.johnsoncontrols.comPublished in U.S.A.

16VRF Smart Gateway Installation Instructions

Loading...

Loading...