Page 1

ECHNICAL BULLETIN

T

LONW

Systems Manual 1162

ORKS

VMA1200 Section

Issue Date 0501

Variable Air Volume Modular Assembly (VMA) 1200 Series

Overview and Engineering Guidelines

VMA1200 Series Overview and Engineering Guide......................... *3

Introduction........................................................................................................*3

Key Concepts.....................................................................................................*4

VMA1200 Series Models...............................................................................................*4

Definition of Terms........................................................................................................*6

Theory of Operation.......................................................................................................*9

Establish Zones.............................................................................................................12

Room Sensor Placement...............................................................................................12

Pressure Independent VMA...........................................................................................13

VMA Airflow Rate........................................................................................................*13

Power Source.............................................................................................................. *14

ONWORKS

L

Network Topology..................................................................................... *17

Inputs and Outputs...................................................................................................... *19

CablePRO................................................................................................................... *21

CVTPRO.....................................................................................................................*21

Software Too ls ............................................................................................................ *21

Related Documentation............................................................................................... *22

Procedure Overview......................................................................................... 23

Detailed Procedures ........................................................................................*24

Determining VAV Box Requirements........................................................................... *24

Establishing the Room Schedule...................................................................................25

Developing Bills of Material and Placing Orders............................................................26

Configuring the VMA .....................................................................................................27

*Indicates those sections where changes have occurred since the last printing.

© 2001 Johnson Controls, Inc. www.johnsoncontrols.com

Code No. LIT-1162350

Page 2

2

VMA1200

Appendix A: Reference Information ............................................... *28

Introduction....................................................................................................... 28

VMA Wiring List........................................................................................................... *29

VMA Wiring Interface Diagram....................................................................................*31

VMA Parts List............................................................................................................. *32

FCC Part 15 Label.........................................................................................................33

VMA Specifications ..................................................................................................... *34

Fabricating Your Own Interconnection Cable...............................................................*38

Sensor Interface.......................................................................................................... *39

Appendix B: Application Example.................................................. *42

Single Duct Application Example................................................................................. *42

*Indicates those sections where changes have occurred since the last printing.

Page 3

VMA1200 Series Overview and Engineering Guidelines

VMA1200 Series Overview and

Engineering Guide

Introduction

The Variable Air Volume Modular Assembly (VMA) 1200 Series is a

configurable, integrated module that includes a Variable Air Volume

(VAV) controller, actuator, and differential pressure sensor. The VMA

is offered as two models: cooling only and cooling with reheat. The

models, which use the LonTalk protocol, are designed for pressure

independent, single duct systems. The reheat model can be used with

parallel or series fan powered boxes.

3

This manual is a reference tool for engineering VMA1200 installations

and applications. It is also a training tool to learn about the

VMA1200 Series controllers. It is task oriented for easy reference to

specific tasks. Refer to the appendixes at the end of this document for

wiring tables and diagrams, a parts list, specifications, and an

application example.

This document describes how to:

• determine VAV box requirements

• establish the room schedule

• develop bills of material and place orders

• configure the VMA

Page 4

4

VMA1200

Key Concepts

VMA1200 Series Models

Table 1 lists VMA1200 Series features. Table 2 shows available

VMA1200 models.

Table 1: Feature Checklist

VMA Features Comments

Applications

Pattern Recognition Adaptive Control (PRAC)

on Zone Proportional Plus Integral (PI)

Temperature Loops

Adaptive Flow Control Loops No manual tuning, improved control and energy savings

Single Duct, Pressure Independent VAV Meets most VAV applications.

Side Loops without Interlocking Single Analog Input (AI) to Analog Output (AO)/Binary

Fan Powered Boxes Series or parallel

Incremental, Proportional, and Three Stages

of Box Heat

Incremental, Proportional Two Position, or

One Stage Supplemental Heat

Damper Actuator

Clockwise (CW)/Counterclockwise (CCW)

Rotation Selection

Software/Tools

Ability to Download Code Firmware Firmware code is upgradeable without removing the VMA.

Diagnostics

Moving Average Flow/Temperature

Diagnostic

Actuator Duty Cycle Diagnostic Indicates shaft slippage.

Commissioning

Balancing Tool with Automatic K-factor

Calculation

Hardware

24 VAC Isolation Eliminates 24 to 24 VAC transformer and polarity concerns.

Multiple VMAs Powered by a 100 VA

Transformer

Isolated Communication, Binary Outputs, and

24 VAC

Ability to Drive Low Current Relays Down to

25 mA

13-Bit Analog Input/8-Bit Analog Output

Resolution

Analog Input Jumpers Eliminated All analog inputs are preset reducing labor.

Continued on next page . . .

Eliminates manual tuning and seasonal retuning.

Output (BO)

Up to three stages or normally open/closed valves

Normally open or closed valves

Set via M-Pro software, VMA1200 Balancing Tool (VBT)

software, or network management tool for either direction

to close.

Provides standard measure of control loop performance

over time.

Palm compatible handheld device (Version 2.0 or later

operating system) on Zone Bus

Up to 14 cooling only. Number of reheat/fan units depends

on power consumption of valve/fan relays.

Saves installed cost and improved electrical noise

rejection.

Eliminates relay chatter.

High accuracy and good device control

Page 5

VMA1200 Series Overview and Engineering Guidelines

VMA Features (Cont.) Comments

Differential Pressure Transducer

Dead Ended Transducer No filters or maintenance required.

Capacitive Technology Improved stability

Industry Accepted Flow Measurement

Accuracy

Temperature Sensors

Variety of Sensors Nickel, 1K platinum, 2.25K NTC

Temporary Occupied Button On TMZ1600, TE-6700, TE-7000 (Europe only) Series

Temporary Occupied Light-Emitting Diode

(LED)

LED Indicator for Operation

Power/Communication

Physical

Small, One Piece Assembly

102 x 153 x 102 mm (4 x 6 x 4 in.)

Plenum Plastic Housing Rating UL 94-5VB plenum flammability may eliminate metal box

Removable Input/Output (I/O) Screw

Terminals

Node Installation

Service Pin Message Local pushbutton and remote access from Palm compatible

Wink Function

Bar Code Label

Even for flows below 250 fpm (1.25 m/s) typical

room sensors

On TMZ1600, TE-6700, TE-7000 (Europe only) Series

room sensors for Occupied and Unoccupied modes

Verifies operation and power connections.

Prewired to reduce installed cost.

(check local codes).

Two or three position accessory kits

handheld device

Initiate via Palm compatible handheld device or network

management tool.

Two removable bar code labels printed with Neuron ID

5

Page 6

6

VMA1200

Table 2: VMA1200 Series Models

Inputs/Outputs Points Rating VMA1210

(Cooling

Only)

Analog Inputs:

Zone Temperature

Zone Setpoint

Humidity, Dewpoint, or Sideloop

Supply Air Temperature or

Supplemental Heat Temperature

Velocity Pressure

Binary Inputs:

Temporary Occupied/

Standby/Room Sensor LED

Occupied

Off or Window or Shutdown

Analog Outputs:

Proportional Heat AO-1 0-10 VDC @ 10 mA

Binary Outputs:

Fan

Box Heat--Incremental Valve or

1-3-stage Electric

Supplemental Heat--Incremental

Valve or 1-3-stage Electric

Actuator Motor

AI-1

AI-2

AI-3

AI-4

Internal

BI-1

BI-2

BI-3

BO-1 to

BO-5

Internal

1K Ni or Pt or 2.25K NTC

1.6K ohm Potentiometer (Pot.)

0-10 VDC

1K Ni or Pt or 2.25K NTC

0-1.75 inch W.C. (0-436 pa)

Dry contact

Dry contact

Dry contact

24 VAC triac @ 0.5A

✔

✔

✔

✔

✔

✔

✔✔

VMA1220

(Cooling

w/Reheat)

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

Definition of Terms

Auto Calibration

The VMA has an Auto Calibration mode that runs periodically to

adjust the pressure sensor calibration due to offset tolerance and

mounting position.

Binding

A process performed by a network management tool that connects

Network Variable Outputs (NVOs) and Network Variable Inputs

(NVIs). These connections provide for peer-to-peer data transfers.

Commissioning

Verification of controller inputs and outputs and modification of the

controller configuration properties to meet installation specifications.

Configuration Properties

Data stored in non-volatile memory (Flash) in the controller that is

accessible from a network management tool.

Page 7

VMA1200 Series Overview and Engineering Guidelines

Configuring

Building an application within the controller to establish the required

control sequence, setting the functionality of the controller.

Downloading

Writing the Heating, Ventilating, and Air Conditioning (HVAC)

application data and configuration properties to the controller. This is

accomplished using a software tool with a Personal Computer (PC).

7

LONW

Network management system protocol for LONW

ORKS

Network Services (LNS

) Protocol

ORKS

devices.

LONWORKS FTT-10A Transceiver

The Free Topology Transceiver (FTT) interface between the

VMA1200 and the physical network.

M-Pro

A software tool used to configure and download controllers.

M-Pro software is part of the System Tools in M-Tool.

Neuron

The microprocessor used in the VMA. Each neuron has a unique

48-bit ID for node identification.

NVI/NVO

LONM

term for Network Variable Inputs/Outputs. These

ARK

variables may be read/written by network management tools. They

may be bound to other network variables in a system.

Palm Compatible Handheld Device

A handheld computer that uses software to configure and balance the

VMA1200. The PalmPilot unit is an example of this device.

SCPT/UCPT

LONM

Configuration Property Type.

SNVT/UNVT

LONM

A SNVT/UNVT defines the units, structure, and resolution of the

configuration properties, NVIs and NVOs.

terms for Standard Configuration Property Type and User

ARK

term for Standard/User Network Variable Types.

ARK

Page 8

8

VMA1200

Test and Balance (TAB)

Test and Balance (TAB) is a function performed to ensure the installed

system operates to design specifications. Balancing of the VMA zone

indicates whether the VAV terminal box achieves minimum/maximum

airflow settings. TAB must also be performed for the air handler and

the air duct distribution to the VAV box.

Variable Air Volume (VAV) Controller

An Application Specific Controller (ASC) used for digital control of

single duct, dual duct, fan powered, and supply/exhaust VAV box

applications.

Variable Air Volume Modular Assembly (VMA)

Includes a digital controller with integrated pressure transducer and

actuator.

Zone Bus

A local interface between the controller and the room sensor. By

connecting a Palm compatible handheld device with the proper

software to the CablePRO or CVTPROx00-0 and room sensor, the

Zone Bus allows you to monitor and commission directly through the

room sensor.

Page 9

Theory of Operation

VAV systems are most easily understood by considering them as

cooling applications. As the zone temperature increases due to heat

produced by people, computers, or other heat sources, the VMA opens

the VAV box damper and lets cooler air in. The size of the space and

the internal and external heat loads dictate the volume of air required

to maintain a zone temperature setpoint. In addition, since the size of

the VAV box dictates its maximum cooling capacity, VAV box

performance is dependent upon the design engineer sizing the box for

each zone. If the installed unit is too small, insufficient cooling results,

and excessive flow rates cause audible noise. If the installed unit is too

large, proper control is difficult to maintain, since a small change in

damper position causes excessive airflow change. Boxes are

sometimes oversized to ensure quiet operation or to reserve cooling

capacity as zone usage changes.

A cooling only VAV system maintains a constant zone temperature

while varying the flow of air to the space. This is unlike a constant

volume system that maintains a constant volume of airflow to the

space but varies the temperature of the air stream in response to space

temperature changes. VAV systems are predominantly single duct, but

some are dual duct designs. The VMA can be configured for most

single duct pressure independent VAV applications. The M-Pro

software (part of M-Tool Release 2.0) is used to configure and

download VMA1200 applications.

VMA1200 Series Overview and Engineering Guidelines

9

The actuator drives the damper from full open to full closed in

90 seconds. The VMA incorporates flow feedback to accurately

position the damper and to minimize position hunting and motor

runtime. Control performance metrics are recorded and are available

via network variables to the Metasys Operator Workstation (OWS).

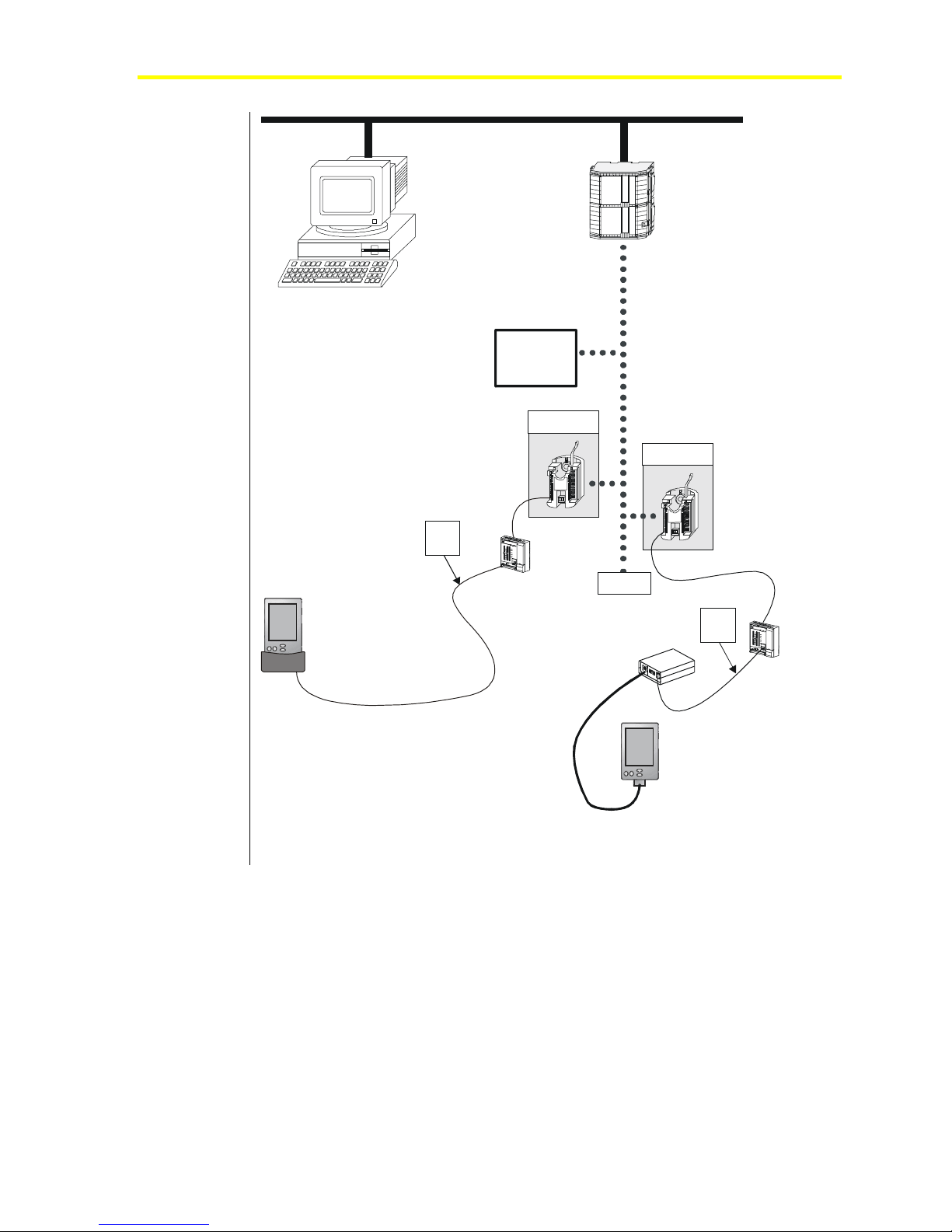

Figure 1 shows the VMA1200 in the Metasys Network. Figure 2 is a

functional block diagram of the VMA1200.

Page 10

10

VMA1200

Operator Workst at i on

(with OWS, M-Pro,

and LNS S of tware)

LW

ON ORKS

Compatible

Devices

VMA1200

N1 LAN

Network Control Module (NCM)

LW

ON ORKS

Network

Bus

VMA1200

Zone

Bus

Room

Sensor

Palm Compatible

Handheld Device

CVTPRO

Converter

FTT-10

CablePRO

Converter

Zone

Bus

Room

Sensor

Palm Compatible

Handheld Device

MNET

Figure 1: VMA1200 Controllers in Metasys Network Diagram

Page 11

VMA1200 Series Overview and Engineering Guidelines

ON ORKS

L W Network

FTT-10

Interface

11

Window Open

Occupancy Sensor

Temp Occ Button

Space Temperature

Space Set point

Auxiliary Temperature

Auxiliary 0-10V

Low

Neuron

Digital

Inputs

x3

Analog

Inputs

x5

Hi

Differential

Pressure

(DP) Sensor

Application

Processor

COP8

IO Processor

Isolated

Phone

Jack

Zone

Bus

Analog

Output

x1

Triac

Outputs

x7

CW CCW

Actuator

Motor

Fblock2

TE-670 0, TMZ1600, or

Palm Compatible

Handheld Device

Heating Valve

Five 24 VAC Outputs for

Fan, Staged Heating, etc.

Figure 2: VMA1200 Functional Block Diagram

Page 12

12

VMA1200

Establish Zones

When designing VMA systems, establishing zones correctly is critical

to take maximum advantage of the VMA’s exceptional accuracy and

rapid response capabilities.

The designer strives for the most uniform indoor environmental

conditions possible. A single thermostatic device (room sensor)

controls each area. A zone could also be thought of as an area where

the load is considered the same for every square foot of floor space.

HVAC system zones fall into two major categories: exterior zones and

interior zones. Exterior zones are spaces directly affected by outdoor

weather conditions. Heat losses or outdoor air conditions do not

influence interior zones. Interior zones usually have cooling or

ventilation requirements only.

Further divisions of interior/exterior zones may be required to

accommodate different occupancy schedules and/or solar loads.

Variations in internal loading dictate the selection of separate zones.

For example, in a restaurant, the kitchen has vastly different heating

and cooling requirements from the seating area.

Room Sensor Placement

Consider room sensor placement for each zone, making sure to:

• Verify that the room sensor is the correct one for the application.

• Review architectural requirements such as furniture height and

location, aesthetics, and type of mounting. Wall plates are required

if mounting on a conduit handibox.

• Review room sensor location. The best room sensor location is on

an interior wall, about five feet above the floor, out of direct

sunlight, out of the direct path of supply air from the diffuser, away

from heat sources, such as equipment, machines, and perimeter

radiation, and away from doors and other draft sources. Mounting

height may be affected by local codes or the accessibility needs of

persons with disabilities.

• Do not locate a sensor near zone boundaries where primary

influence is from an adjacent zone.

Page 13

VMA1200 Series Overview and Engineering Guidelines

Pressure Independent VMA

The pressure independent VMA employs patented self-tuning,

cascaded proportional/integral control loops. The zone temperature

loop samples space temperature and resets the airflow setpoint

between the minimum and maximum flow settings. Since inlet duct

static pressure influences the amount of air passing through the

VAV box, the VMA airflow loop samples airflow via a flow pickup in

the box inlet. It modulates the damper to control the flow. Thus, the

VAV box flow is independent of duct static pressure.

The engineering basis for this method of control is that the temperature

of a space with a constant load is linearly proportional to the flow of

conditioned air into the space. The engineer must accurately determine

the required maximum and minimum flow for each space based on

heating, cooling, and ventilation loads.

VMA Ai r fl o w Ra t e

The VMA determines airflow rate by dynamic pressure measurement.

The VMA contains a Differential Pressure Transmitter (DPT) to sense

differential pressure in pressure independent VAV applications.

13

The DPT is connected to the VAV box airflow pickups. It measures

differential pressure and generates a proportional voltage signal. The

voltage signal from the DPT is read by the VMA and converted to

airflow in cubic feet per minute (cfm) or liters per second.

The DPT provides maintenance-free performance within the control

range of 1.25 to 18 m/s (250 to 3500 feet per minute [fpm]) when used

as recommended.

The minimum 1.25 m/s (250 fpm) velocity and the gain of the airflow

pickup produce an accurately measured pressure difference.

The VMA Auto Calibration function helps reduce the temperature

effect error by zeroing offset errors. As the ambient temperature

swings relative to the temperature at which the Auto Calibration

occurred, an offset error may occur (typically ±0.179 Pa/°C

[±0.0004 inch W.C./°F]). When calibration occurs, this error becomes

zero.

The error envelope becomes smaller with increased airflow pickup

gain and with smaller ambient temperature deviations at the

transmitter location.

Page 14

14

Power Source

VMA1200

You can use one 24 VAC power trunk to power multiple VMAs. In

this case, transformers of up to 100 VA are centrally located, and the

secondary run is without conduit and without concern about polarity.

Notes: The 24V power transformer must be UL/CSA listed as

NEC Class 2 Power Limited.

See NEC Article 725/Class 2 (30 VRMS maximum) and

(100 VA maximum).

The VMA1210 draws 7 VA including the internal damper actuator.

Therefore, 14 VMAs can be powered from one 100 VA transformer

without conduit. The number of VMA1220s is dependent on the

binary output loads and reheat actuators. The reheat actuators must be

added to the 7 VA of the controller, then divided into the 100 VA

transformer power. For example, the VMA1220 draws 7 VA without

loads. If there were only a single VA-8020 reheat valve per VMA, its

4 VA must be added to the VMA for a total of 11 VA. Then

nine VMA/VA8020s can be powered from one 100 VA transformer.

Table 3 shows the power rating for several cooling/heating coil valve

actuators. The valve power plus the VMA power must not exceed

100 VA. If a device is not listed in the following table, refer to the

product literature for that device.

Table 3: Actuator VA Power Rating

Actuator Type Power Rating

VA-8020

VA-8050

VA-7200

J Series Electric Zone Valve

VA-8022

VA-8052

VA-7202

VA-7450

VA-7452

VA-7050

VA-7310

VA-7312

VA-7010

VA-7150

VA-7152

Incremental 4 VA

Incremental 6 VA

Incremental 6.7 VA

On Off 7 VA

Voltage (0 to 10 VDC) 4 VA

Voltage (0 to 10 VDC) 6 VA

Voltage (0 to 10 VDC) 6.7 VA

Incremental 2.5 VA

Voltage (0 to 10 VDC) 2.5 VA

Thermal (DAO) 3 VA

Incremental 2 VA

Voltage (0 to 10 VDC) 2 VA

On/Off 7 VA

Incremental 2.7 VA

Voltage (0 to 10 VDC) 4.7 VA

Page 15

24 V A C

100 VA

VMA1200 Series Overview and Engineering Guidelines

When using a single transformer and running 24 VAC to multiple

VMAs, use a wire gauge large enough for the load. The voltage drop

on the 24 VAC cabling is much higher than for line voltage wiring for

the same power draw. For a 100 VA (equivalent to 100 watt) load at

120 VAC, only 0.8 ampere is required. However, at 24 VAC, over

four amperes are needed. Current draw determines the wire size.

Two connection methods are available. In the first method, individual

spade lugs accept a single 10 to 22 American Wire Gauge

(AWG)/4 mm2 to 0.8 mm wire and still fit on 6 mm (1/4 inch) tabs. In

the second method, optional screw terminals are assembled over the

spade lugs. The screw terminals accept up to a single 12 AWG

(4 mm2) wire or two 14 AWG (2.5 mm2) wires. When two wires are

crimped into one spade lug, a larger spade lug barrel is needed.

Alternately, a wire nut can connect two heavy wires to a short 152 mm

(6 inch) thinner wire.

< 88 ft of 14 AWG >

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

15

VMA

Example 1:

< 176 ft of 14 AWG >

VMA

VMA

VMA

VMA

VMA

VMA

VMA

Example 2:

Figure 3: Power Cable Lengths

A standard 14 AWG (2.5 mm2) wire (top example in Figure 3) is

All VMA s are at one end.

100 VA

24 V A C

< 176 ft of 14 AWG >

Transformer is centered.

VMA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

Cablelength

limited to 27m (88 feet) with 14 cooling only VMAs when the VMAs

are all located at one end of the cable. If the transformer is centered

(bottom example in above figure) with seven VMAs on the left and

seven VMAs on the right, the distance in each direction can be

increased. This is because the current (and voltage drop) are halved in

each direction. In this example, both the left and the right legs can be

increased to 54m (176 feet) from the transformer, creating a 108m

(352 foot) total length.

Page 16

16

VMA1200

Table 4 and Table 5 indicate the relationship between wire length and

power at the end of wires.

Table 4: Maximum Wire Length for Given Power/Gauge (U.S. Measurements)

Wire Size

8 Gauge 10 Gauge 12 Gauge 14 Gauge 16 Gauge 18 Gauge

Power (VA) at

End of Wire

10

20

30

40

50

60

70

80

90

100

Wire Length (Feet)

3520 2200 1400 880 550 350

1760 1110 700 440 275 175

1173 740 467 293 183 117

880 555 350 220 138 88

704 444 280 176 110 70

587 370 233 147 92 58

503 317 200 126 79 50

440 278 175 110 69 44

391 247 156 98 61 39

352 222 140 88 55 35

Table 5: Maximum Wire Length for Given Power/

Wire Gauge (Metric Measurements)

Wire Size

2.5 mm

268

134

89

67

54

45

38

34

30

27

2

Power (VA) at

End of Wire

10

20

30

40

50

60

70

80

90

100

2

4 mm

Wire Length (Meters)

427

213

142

107

85

71

61

53

48

43

1.5 mm

168

84

56

42

34

28

24

21

19

17

2

Page 17

VMA1200 Series Overview and Engineering Guidelines

17

LONW

ORKS

Network Topology

The LONW

network topologies. Table 6 describes free topologies, and Figures 4

and 5 show supported topologies. For more information, see the

LONW

Table 6: Free Topologies

Category Free Topology

Architecture

Termination

Connection

ORKS

FTT-10A used by the VMA1200 supports free

ORKS

Network Layout Technical Bulletin (LIT-1162150).

Bus, star, ring, or mixed

Single termination for star, ring, or mixed

Double termination for bus

Connected by stub/multi-drop

Free Topology (Tree or Star)

Legend:

L W Compatible Device

ON ORKS

(Including NCM350/361)

Free Topology Terminator

Figure 4: Free Topology

Free_Top

Page 18

18

VMA1200

Daisy-chained TopologyBus

Stub-wired TopologyBus

Legend:

ON ORKS

L W Compatible Device

(Including NCM350/361)

Bus End- of - Line (EO L) Terminator

Bus_Top

Figure 5: Bus Topology

Table 7 contains a specification example for the FTT-10A Transceiver.

This is just one example of the many available wiring styles. For more

complete information, refer to Echelon Corporation

LONW

FTT-10A Transceiver User’s Guide.

ORKS

Table 7: FTT-10A Transceiver Specification Example

Transceiver

Topology

Bit Rate

Maximum Node to Node Distance

Maximum Total Wire Length

Maximum Nodes

Node Application Current

* Belden 85102, 8471 Cable

FTT-10/FTT-10A

Free

78 kbps

500m (1640 ft)*

500m (1640 ft)*

64

NA

Page 19

Inputs and Outputs

For specific input/output range, wire length, wire size issues, refer to

the VMA Wiring List in Appendix A: Reference Information at the back

of this document.

VMA1200 Series Overview and Engineering Guidelines

19

Note: All terminals are spade lug type except the LONW

ORKS

Network Bus terminals, which are removable screw terminals.

Optional two or three position kits can be ordered to convert

the spade lugs to removable screw terminals. See Table 12.

Binary Inputs

There are three dry contact binary inputs on the VMA1200. A manual

override button on the room sensor initiates a Temporary Occupancy

mode of operation. The TE-6700 room sensor includes an LED in

series with the button to show the occupancy mode. The switch can be

pushed for as little as 0.2 seconds to detect a change.

The binary inputs on the VMA are inactive when open. They are

active when a contact closure to binary input common (COM) is

applied.

Binary Outputs

The VMA has zero (VMA1210) or five (VMA1220) user accessible

binary outputs. The damper actuator is wired internal to the VMA.

Each load is connected between the BO terminal and BCOM common

terminal. When required to meet codes, the 24 VAC terminal of the

VMA/transformer can be earth grounded. In this situation, the binary

outputs switch the transformer’s low side to the relays and actuators.

Analog Outputs

There is one analog output on the VMA1220. The VMA1210 has no

analog outputs. The load is connected between the analog output and

analog output common (COM) terminals. The output is controlled to

generate a proportional voltage output of 0 to 10 VDC. The maximum

load for each output is 10 mA with a minimum load resistance of

1000 ohms.

Page 20

20

VMA1200

Analog Inputs

There are two external and one internal analog inputs on the

VMA1210 and four external and one internal analog inputs on the

VMA1220. They are preset for either temperature, setpoint, or voltage.

There are no jumpers to set. Shielding is not required, but if used, earth

ground the shield only at the VMA. You may use 24 AWG (0.6 mm)

twisted pair wire; however, this reduces the allowable wire length due

to the resistance. To minimize sensor error caused by field wiring, the

total resistance of the nickel or platinum resistive sensor wiring should

be less than 3 ohms. The NTC sensor accepts a larger wire resistance.

This wiring error effect is corrected through configuration properties

using a commissioning tool.

Do not share the temperature or setpoint common wire with voltage or

current transmitters on the Zone Bus. The maximum voltage drop on

the common wire must be less than 1 mV.

Zone Bus

The Zone Bus is a 2-wire local communications bus that allows a

Palm compatible handheld device with Johnson Controls VMA1200

Balancing Tool (VBT) software to commission and balance the VMA.

The Zone Bus connector also provides 15 VDC power to the

CablePRO or CVTPRO. The bus sustains no damage in the presence

of fault voltages of 15 VDC or 24 VAC.

Table 8: Zone Bus Specifications

Type

Speed

Recommended Cable Type

Maximum Bus Length

Voltages

Logic High Voltage

Logic Low Voltage

Data Tra nsmission

Isolation

Multi-drop serial communications bus

1200 baud (bits per second)

1.5 mm2 (18 AWG) with or without shield

(Belden 8760) or

0.6 mm (24 AWG) without shield (unshielded

telephone cable)

150 meters (500 feet) with 1.5 mm2 (18 AWG)

cable or

15 meters (50 feet) with 0.6 mm (24 AWG)

cable

4 VDC minimum (approximately)

1 VDC maximum (approximately)

1 Start Bit (low level)

8 Data Bits (least significant bit first)

1 Stop Bit (high level)

Isolated from 24 VAC, Binary Outputs (BO),

and L

ONWORKS

Network Bus

Page 21

CablePRO

CVTPRO

VMA1200 Series Overview and Engineering Guidelines

CablePRO (AS-CBLPRO) is an interface device used between a

21

Palm compatible handheld device and the VMA. It is used for box

balancing or commissioning via the Zone Bus communication port.

When used with a VMA, the CablePRO is strictly an electrical

interface between the serial RS-232 port of the Palm compatible

handheld device and the Zone Bus. CablePRO operates on 15 VDC,

drawn from a VMA through the Zone Bus phone jack. The data rate on

both the RS-232 and the Zone Bus is 1200 baud.

The connection to the RS-232 COM port of the Palm compatible

handheld device is by means of a DB9 or DB25 connector supplied

with the CablePRO.

Refer to the Auxiliary Gear Technical Bulletin (LIT-6363080) for

more information on the CablePRO.

Software Tools

CVTPRO (AS-CVTPROx00-0) is a Zone Bus/N2 interface device that

is used between a Palm compatible handheld device and the VMA. It

is used for box balancing or commissioning via the Zone Bus

communication port.

When used with a VMA, the CVTPRO is strictly an electrical interface

between the serial RS-232 port of the Palm compatible handheld

device and the Zone Bus. CablePRO operates on 15 VDC, drawn from

a VMA through the Zone Bus phone jack. The data rate on both the

RS-232 and the Zone Bus is 1200 baud.

Refer to the Auxiliary Gear Technical Bulletin (LIT-6363080) for

more information on the CVTPRO.

M-Tool software tools allow you to commission, configure, and

balance the VMA1200. Use M-Pro software to configure and

download applications. The VMA1200 Balancing Tool (VBT)

software allows you to balance and perform limited commissioning.

The Comm Pro commissioning tool performs commissioning

operations, such as reading and writing network variables and

configuration properties or downloading new firmware to the

controller.

In addition, a number of third-party network management tools (e.g.,

LonMaker software) allow you to read/write network variables and

configuration properties and bind network variables. See Table 13 in

Appendix A: Reference Information for additional software details.

Page 22

22

Related Documentation

VMA1200

Table 9 lists related VMA1200 documentation.

Table 9: Related Documentation

For Information on This Use This Document:

Sales and Marketing

information

Installing the VMA

Downloading and

Commissioning Details

Mounting and Wiring

Information

Troubleshooting VMA1200

Connecting to the

NCM/Workstation

Installing M-Pro and VBT

Configuring the VMA1200

Balancing the VMA1200

Working with LONW

Networks and Devices

ORKS

VMA1200 Series Controller Product Bulletin (LIT-1162300) in the

Metasys Network Sales Resource Manual (FAN 635) and the L

Systems Manual (FAN 1162)

VMA1200 Installation Bulletin, Part No. 24-9310-5 (Packed with product)

Downloading and Commissioning VMA1200 Series Controllers Technical

Bulletin (LIT-1162370)

Comm Pro User’s Guide (LIT-1162550)

Mounting and Wiring VMA1200 Series Controllers Technical Bulletin

(LIT-1162360)

Troubleshooting VMA1200 Series Controllers Technical Bulletin (LIT-1162380)

Metasys Network Technical Manual (FAN 636)

M-Tool Manual (FAN 693)

M-Pro User’s Guide (LIT-693300)

Variable Air Volume Modular Assembly (VMA) 1200 Series Controllers

Application Note (LIT-1162500)

Using the VMA1200 Balancing Tool (VBT) Software Technical Bulletin

(LIT-1162400)

ORKS

LONW

Compatible Devices Supported by NCM350 Technical Bulletin (LIT-1162100).

Network Layout Technical Bulletin (LIT-1162150) and LONW

ONWORKS

ORKS

Page 23

VMA1200 Series Overview and Engineering Guidelines

Procedure Overview

Table 10: Engineering the VMA Procedure Overview

To Do This Follow These Steps:

Determine VAV Box

Requirements

Establish the Room Schedule

Develop Bills of Material and

Place Orders

Configure the VMA

Select the VMA.

Establish sensor placement in zones.

Coordinate and authorize mounting.

Develop application configuration files.

Determine control strategy.

Select room sensors.

Create source power drawings.

Determine quantity needed of all components.

Make sure all items are included.

Coordinate parts ordering and delivery.

Reference appropriate room schedules.

Select control sequences using M-Pro.

Create configuration files.

Archive and document applications.

Download applications.

23

Page 24

24

Detailed Procedures

Determining VAV Box Requirements

VMA1200

To determine VAV box requirements:

1. Select the VMA based on control sequence, Input/Output (I/O),

side loops, and flow measurement accuracy requirements for

single duct boxes. Refer to the discussion of VMA Airflow Rate in

the Key Concepts section of this document.

2. Establish sensor placement in zones.

3. Contact box manufacturer’s representative to authorize mounting

or mount on site.

Notes: Damper shafts must protrude 44 mm (1-3/4 in.) or more

from the box. The VMA accommodates damper shafts

greater than 44 mm (1-3/4 in.) in length from the box exit.

Shaft bushings may interfere with flat mounting of the

VMA. If needed, use a spacer to keep the VMA parallel to

the mounting surface.

Things to consider:

• project install date

• plans and specifications

• wiring diagrams and specifications to box manufacturer

• who does what including: mounting, connecting, downloading,

testing, and shipping

• who provides which parts including: control enclosure and

transformer

4. Coordinate field or factory mounting.

Page 25

VMA1200 Series Overview and Engineering Guidelines

Establishing the Room Schedule

To establish the room schedule:

1. Develop application configuration files based on project

requirements.

For flow calculation constants, refer to the Variable Air Volume

Modular Assembly (VMA) 1200 Series Controllers Application

Note (LIT-1162500).

2. Determine control strategy.

Note: The VMA1200 is for single duct applications only. Use other

standard Johnson Controls VAV controllers for dual duct

and supply/exhaust applications.

3. Select appropriate room sensors based on project specifications.

Typically, each VMA requires a room sensor.

4. Create source power drawings. Determine such things as line

length, transformer count and layout, and power distribution.

25

5. Determine number of:

• VMAs

• other control devices

• room sensors

• valves

• valve actuators

• transformers

• phone cables

• accessories such as screw terminal kits

Page 26

26

VMA1200

Developing Bills of Material and Placing Orders

To write up the bill of material and place orders:

1. Make sure the following items are included as required:

• valves

• valve actuators

• room sensors (one per VMA)

• VMAs

• cables

• transformers

• box fan speed controllers - for information about the

Johnson Controls S66 Series Electronic Fan Speed Control,

refer to the S66 Series Electronic Fan Speed Control

Product/Technical Bulletin (LIT-121605) Part No. 24-8374-8

in the Installation Sheets Manual (FAN 121).

Notes: The differential pressure sensor and the damper actuator are

included as part of the VMA.

Room sensors cannot be hardwired/shared between VMAs;

however, sensors may be shared by connecting network

variables using a LONM

network management tool.

ARK

2. Coordinate parts ordering and delivery, including:

• placing orders through Johnson Controls Customer Service

• determining shipping destinations

• coordinating VMA manufacturing and delivery issues

• coordinating box manufacturer issues

• coordinating boxes with VMAs delivered to job

• determining status of software, documentation, and drawings

Note: The VMA can be shipped in individual packages or bulk

shipped (maximum ten VMAs per box).

Page 27

Configuring the VMA

Configure the VMA as specified in room schedules.

To configure the VMA:

1. Refer to the appropriate room schedule for room specifications.

2. Select control sequences using M-Pro software. Refer to

M-Pro User’s Guide (LIT-693300).

3. Create individual configuration files for each device or each set of

similar devices.

4. Archive and document the applications and VMA configuration

as needed. Downloading can be performed through the

LONW

Refer to the M-Pro User’s Guide (LIT-693300) for additional

configuration information.

VMA1200 Series Overview and Engineering Guidelines

ORKS

Network Bus.

27

Page 28

28

VMA1200

Appendix A: Reference

Information

Introduction

The following tables are to be used for wiring, parts, and specification

reference.

Page 29

VMA Wiring List

Table 11 provides a wiring list for the VMA1200. Figure 6 highlights

the electronic isolation of the VMA1200.

Note: All field terminals are power limited when powered by a

Table 11: VMA Wiring List

VMA1200 Series Overview and Engineering Guidelines

Class 2 transformer.

29

Point Description Range Input or

Load

Impedance

AI-1*

AI-2*

AI-3*

AI-4*

AI-5*

BI-1*

BI-2*

BI-3*

AO-1*

* Isolated from 24 VAC

Continued on next page . . .

Zone

Temperature

Zone

Setpoint

Humidity

Transmitter

or CO

2

Sensor

Perimeter

Temperature

or Supply Air

Temperature

Velocity

Pressure

(internal)

Temporary

Occupied

Comfort

(occupied)

Window, Off

(shutdown)

Proportional

Heat/

Humidity Fan

Speed

1K ohm

Nickel,

or Pt

2.25K ohm

NTC

1.6K ohm

2-wire Pot.

0-10 VDC 1.1M ohm 16.5 VDC 15 uA 0.6 mm to

1K ohm

Nickel,

or Pt

2.25K ohm

NTC

0 to 1.75 in.

W.C./0.5 to

2.0 VDC

0-5 VDC,

3V trigger

0-15 VDC,

2.5V trigger

0-15 VDC,

2.5V trigger

0-10 VDC 1K-10M ohm 10 VDC 10 mA

10K ohm 5 VDC 0.5 mA

10K ohm 5 VDC 0.5 mA 0.6 mm to

10K ohm 5 VDC 0.5 mA

10K ohm 5 VDC 0.5 mA

10K ohm 5 VDC 0.5 mA 0.6 mm to

100K ohm 5 VDC 20 uA NA Internal

440 ohm 5 VDC 10 mA

47K ohm 17 VDC 0.1 mA 0.6 mm to

47K ohm 17 VDC 0.1 mA 0.6 mm to

Maximum

Voltage

Maximum

Current

Wire Size in

2

mm

or mm

(AWG)

Cable

Length

in

Meters

(Feet)

1.5 mm2 (18) 150 (500)

0.6 mm (24) 30 (100)

1.5 mm

(24 to 18)

1.5 mm2 (18) 150 (500)

0.6 mm (24) 30 (100)

1.5 mm

(24 to 18)

1.5 mm2 (18) 150 (500)

0.6 mm (24) 30 (100)

1.5 mm

(24 to 18)

1.5 mm2 (18) 150 (500)

0.6 mm (24) 30 (100)

1.5 mm

(24 to 18)

1.5 mm

(24 to 18)

1.5 mm2 (18) 150 (500)

0.6 mm (24) 60 (200)

2

2

2

2

2

150 (500)

150 (500)

150 (500)

150 (500)

150 (500)

Page 30

30

VMA1200

Point

(Cont.)

Description Range Input or

Load

Impedance

BO-1,

2,3,4,5^

AM-1^

Network

Bus*^

Zone

Bus*

Room

Sensor

Cable*

+15

VDC*

24 VAC

Power

In^

Notes:

* Isolated from 24 VAC

^ Isolated from AI, BI, AO, Zone Bus, 15 VDC

+

See LONW

~

Length using 100 VA

Fan, Box/

Supplemental

24 VAC @

25-500 mA

48-1000 ohm 30 VAC 100 mA

Heat, Electric

Heat,

Lighting

Actuator

motor

24 VAC

4 VA

144 ohm 30 VAC 100 mA NA Internal

(internal)

Networking

Bus

±5V

transmit,

200 ohm line 5 VDC 100 mA 0.6 mm to

±0.2V

receive

Local Room

0 to 5V >3000 ohm 5 VDC 100 mA 1.5 mm2 (18) 150 (500)

Sensor Bus

AI-1, AI-2,

See above. 0.6 mm (24)

BI-1, Zone

Bus, and

+15 VDC

DC Output

14-18 VDC 1K-10M ohm 18 VDC 35 mA

Supply

AC Supply

22-30 VAC 12-48 ohm 30 VAC 0.3 ampere

Voltage

ORKS

Network Layout Technical Bulletin (LIT-1162150).

Maximum

Voltage

Maximum

Current

100 mA

500 mA

500 mA

for

VMA1210;

1.3 ampere

for

VMA1220

Wire Size in

2

mm

or mm

(AWG)

Cable

Length

in

Meters

(Feet)

2

1.5 mm

(18)

0.6 mm (24)

2

1.5 mm

(18)

0.6 mm (24)

1.5 mm

2

(24 to 18)

0.6 mm (24) 30 (100)

eight conductor

phone cable

1.5 mm2 (18) 150 (500)

0.6 mm (24) 60 (200)

6 mm2 (10) 67 (222)

6 mm2 (12) 42 (140)

2.5 mm2 (14) 27 (88)

1.5 mm2 (16) 17 (55)

2

1.5 mm

(18) 11 (35)

150 (500)

30 (100)

30 (100)

6 (20)

+

See

7.5 (25)

15 (50)

22.5 (75)

30 (100)

~

~

~

~

~

VMA1200

AI BI

Microprocessor

+15 VDC

Power Supply

24 VAC,

Motor,

BO

AO ZB

Figure 6: VMA Electronic Isolation

LW

ON ORKS

Communications

Circuit

Isolation

Page 31

VMA1200 Series Overview and Engineering Guidelines

VMA Wiring Interface Diagram

s

7

1

r

-

-

e

2

1

b

B

B

m

T

T

u

)

e

r

g

u

n

i

s

b

s

u

e

r

T

p

c

l

i

t

a

i

a

t

n

m

e

u

O

L

I

H

p

o

t

S

d

n

E

W

C

r

e

e

f

n

f

i

P

D

(

)

d

e

R

(

N

w

8

6

e

r

c

S

M

1

-

I

B

)

8

1

(

M

2

3

-

-

O

O

I

C

)

9

1

(

I

B

C

B

)

)

)

0

1

2

2

2

2

(

(

(

3

8

4

2

-

-

-

-

1

2

1

1

B

B

B

B

T

T

T

T

1

4

5

2

*

C

C

D

D

V

V

M

5

O

1

C

+

)

)

3

4

2

2

(

(

M

1

2

5

-

-

O

I

I

1

+

A

C

A

)

)

)

)

5

6

7

8

2

2

2

2

(

(

(

(

31

0

6

5

-

-

2

2

B

B

T

T

3

7

*

*

*

*

M

M

M

3

4

-

-

O

O

O

I

I

C

A

C

A

)

9

2

(

L

L

SHLD

C

)

)

)

)

0

1

2

3

3

3

3

3

(

(

(

(

O

B

N

A

N

O

e

)

0

p

y

0

l

o

r

7

n

-

u

O

E

E

(

T

*

*

*

0

0

7

6

E

T

M

+

O

B

C

Z

)

)

5

4

3

3

(

(

h

0

c

0

t

i

7

w

6

-

S

E

P

T

I

r

D

o

f

d

e

n

r

o

r

i

t

e

i

f

s

e

o

r

P

P

*

*

*

3

N

2

O

1

S

K

s

R

u

O

B

k

W

r

N

o

O

w

L

t

e

o

N

T

)

2

m

m

G

5

W

.

1

A

-

8

1

m

-

4

m

2

8

.

0

(

w

e

r

c

S

t

e

S

.

)

l

d

a

n

n

*

*

C

C

G

o

i

*

*

M

A

V

r

e

l

p

u

o

C

p

o

t

W

S

C

d

C

n

E

4

2

)

1

(

d

n

u

o

r

G

h

t

r

a

E

d

*

*

e

t

r

i

e

2

m

i

m

s

r

L

s

o

f

y

a

l

s

g

r

n

C

e

a

r

n

T

E

t

A

h

1

t

p

V

r

O

a

4

(

2

E

)

)

2

3

(

(

M

O

C

B

C

A

V

4

2

y

C

C

r

A

A

a

V

V

m

i

0

7

r

2

7

P

1

2

-

2

-

-

O

O

C

O

B

B

B

)

)

)

4

5

6

(

(

(

n

e

p

O

y

n

a

l

a

e

F

R

*

*

M

M

3

-

O

O

C

O

C

B

B

B

)

)

)

7

8

9

(

(

(

e

s

o

l

C

l

a

t

r

n

o

t

e

e

e

r

v

a

i

l

m

u

a

w

t

e

-

c

V

r

3

c

A

n

I

*

*

*

*

*

*

M

M

4

5

1

-

O

O

C

B

B

)

)

0

1

1

1

(

(

e

n

s

e

o

p

l

O

C

d

r

a

e

r

o

i

b

w

e

-

s

3

a

B

M

O

C

M

-

-

O

O

O

C

O

B

B

A

C

)

)

)

)

2

3

4

5

1

1

1

1

(

(

(

(

t

a

e

H

l

a

r

n

o

o

i

t

t

a

r

u

o

t

p

c

o

A

r

P

e

v

e

l

r

i

a

V

w

-

2

.

d

e

r

u

g

i

f

y

l

n

r

o

e

c

p

t

o

o

r

n

p

s

g

i

n

i

e

t

l

a

b

r

a

t

e

p

k

n

r

o

o

o

i

r

t

e

w

l

t

p

l

i

e

o

r

r

n

c

t

s

n

e

o

e

h

D

C

T

g

n

i

e

k

t

n

a

f

i

f

t

l

S

O

B

r

o

l

)

o

e

c

C

i

v

r

D

d

e

E

e

S

L

R

(

n

D

d

e

e

R

k

r

o

w

t

e

N

a

r

o

o

r

P

m

m

o

C

e

s

U

D

E

e

E

r

L

L

G

e

m

h

o

t

r

f

e

r

u

g

i

f

n

o

c

o

t

l

o

o

t

t

n

e

m

e

g

a

n

a

M

l

d

o

n

o

a

t

m

S

m

N

o

L

c

r

o

k

,

n

i

o

r

W

P

o

t

m

.

e

r

m

s

e

o

l

n

l

C

o

o

r

,

p

t

T

s

n

e

B

o

c

R

V

f

s

f

k

O

n

i

l

n

e

B

h

t

3

t

S

e

e

x

l

K

c

i

e

b

i

R

v

t

N

O

e

a

o

p

D

W

T

m

N

o

O

L

C

.

l

a

k

,

y

l

l

a

m

r

.

o

e

r

n

a

g

w

n

i

m

n

m

r

i

n

e

f

l

u

r

b

w

o

s

e

r

i

n

p

n

r

d

o

i

e

a

t

l

l

o

a

l

o

c

r

n

i

t

l

n

w

p

o

o

p

C

D

A

g

n

i

k

n

i

n

l

B

O

n

e

e

r

G

v

c

r

e

t

n

i

d

n

o

c

e

s

e

n

o

t

a

s

k

n

i

l

b

D

E

L

)

g

n

i

n

n

u

R

(

w

f

e

i

e

h

t

i

n

C

n

.

a

u

g

d

e

n

i

a

h

n

t

o

l

n

n

e

u

c

r

w

a

t

o

l

o

d

p

n

e

d

s

R

n

i

.

a

n

n

r

o

o

i

e

i

t

t

w

a

a

c

o

c

i

i

l

p

l

p

p

e

p

p

h

A

t

a

f

n

f

O

O

e

p

o

r

u

E

.

n

y

i

r

r

a

.

y

e

s

l

s

n

m

e

r

O

c

o

f

e

0

s

n

2

n

2

a

r

1

T

A

n

M

o

i

V

t

a

n

l

o

o

s

d

I

e

y

d

t

u

e

l

f

c

a

n

I

S

*

*

*

Figure 7: VMA Wiring Interface

Page 32

32

VMA1200

VMA Parts List

Table 12 lists hardware accessories. Table 13 lists software

requirements and options.

Table 12: Hardware Accessories (Order Separately)

Transformer

Screw Terminal Kit

Room Sensors

8-pin Room Sensor

Communication Cables

Electronic Fan Speed Controller

Handheld Interface

(for Balancing Tool software)

Converter (for Handheld

Interface)

Interface Accessories (for

Converter)

Table 13: Software

AS-XFR050 AS-XFR100 Y63 through Y66 Series

AP-TBK1002-0 Removable 2-position screw terminal kit (100 pcs)*

AP-TBK1003-0 Removable 3-position screw terminal kit (100 pcs)*

AP-TBK3COMM-0 Replacement L

screw terminal kit (10 pcs)

* These terminals fit over the existing I/O spade lugs.

TMZ-1600, TE-6700, TE-7000 (Europe only)

See the Room Sensor with LCD Display (TMZ1600) Technical Bulletin

(LIT-6363110) and the TE-6700 Series 2nd Generation Temperature

Elements Product Bulletin (LIT-216331) for information on room sensor

accessories.

S66AA-1C or S66DC-1C. See S66 Series Electronic Fan Speed

Control Product/Technical Bulletin (LIT-121605) for specifications.

Palm compatible handheld device (Version 2.0 or later operating

system). See Using the VMA1200 Balancing Tool (VBT) Software

Technical Bulletin (LIT-1162400) for more information on device

compatibility.

AS-CBLPRO-2 or AS-CVTPROx00-0

Required for AS-CBLPRO-2 only: Palm V Travel Kit cable (for the

Palm V) or Palm HotSync cable (for all other Palm models),

DB9M/DB9F Null Modem Adapter, DB9M/DB9M Gender Changer.

ONWORKS

Network Bus 3-position

Item Comments

Microsoft Windows 95,

Windows 98, or Windows NT

software

VMA1200 Balancing Tool (VBT)

M-Pro software

Comm Pro Commissioning Tool

LONW

(LNS) Network Management Tool

(Optional)

Network Services

ORKS

Platform

Used for Balancing. Part of M-Tool.

(Required for Configuration.) Can be used as a plug-in with third-party

network management tools or standalone. Part of M-Tool.

Can be used to commission a VMA1200 controller. Part of M-Tool.

Use a network management tool (e.g., LonMaker software) for

commissioning tasks.

Page 33

FCC Part 15 Label

This equipment has been tested and found to comply with the limits

for a Class A digital device pursuant to Part 15 of Federal

Communications Commission (FCC) rules. These limits are designed

to provide reasonable protection against harmful interference when

this equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the

interference at his/her own expense.

This device complies with Part 15 of the FCC rules. Operation is

subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference that may cause undesired

VMA1200 Series Overview and Engineering Guidelines

operation.

33

This Class A and B digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Page 34

34

VMA1200

VMA Specifications

Table 14: Basic VMA Specifications

Product Name

Product Code Number

Supply Voltage

Optional Fuse Current

Power Consumption

Ambient Operating

Conditions

Ambient Storage

Conditions

Terminations

Optional Terminations

Network Interfaces

LONW

Addressing

Communications

Protocols

Mounting

Housing

Dimensions (L x W x H)

Actuator Rating

Shipping Weight

Electrical Inputs

Velocity Pressure

Outputs

Standards Compliance

ORKS

Controller

Variable Air Volume Modular Assembly (VMA)

-0 (cooling only) or AP-VMA

AP-VMA

20 to 30 VAC at 50 or 60 Hz

0.3 ampere for VMA

7 VA maximum (relay and valve requirements not included)

0 to 50°C (32 to 122°F)

10 to 90% RH non-condensing, limited by a 30°C (86°F) maximum dewpoint

-40 to 70°C (-40 to 158°F)

6.3 mm (1/4 inch) spade lugs. (Communications has removable screw

terminals included.)

2 or 3 position screw terminals that plug into spade lugs (accessories)

L

Unique 48-bit ID

LON

Zone Bus between VMA controller and room sensor (8 pin phone jack or wire

to spade lugs)

One screw mounts the VMA to the VAV box.

One screw attaches damper shaft to the actuator 8 mm (5/16 inch) square

head set screw with 44 N.m (375 lb.in) of axial holding torque for up to 13 mm

(1/2 inch) round damper shafts.

Minimum damper shaft length is 44.5 mm (1 3/4 inch).

Plastic housing for controller, sensor and actuator with UL 94-5V Plenum

Flammability Rating

152.4 x 101.6 x 101.6 mm (6 x 4 x 4 inch)

4 N.m (35 lb.in) minimum

13.1 kg (29 lb) for a box of ten; 1.3 kg (2.8 lb) each

Analog Inputs: (Input configurations vary based on model type)

- Nickel (1K ohm Johnson Controls), or Platinum (1K ohm DIN 385) or

Binary Inputs: dry contacts

Velocity Pressure for 0 to 436 Pascal (0 to 1.75 inch W.C.)

No outputs on AP-VMA

Binary Outputs: 24 VAC triac switched; 25 to 500 mA loads

Damper Actuator: 90° rotation in 90 seconds

Analog Output: 0 to 10 VDC at 10 mA

CSA 22.2 No. 205

UL 916 UL 864 (UUKL) UL 94-5VB

FCC Part 15, Subpart B, Class A and B

CISPR 22, Residential Class B

CE Directive (89/336/EEC, EN50081/1, EN50082/2) Industrial and Residential

IEEE 472 ANSI C62.41 A/B (IEEE 587 Category A/B)

C-tick Australia/NZ, AS/NZS 4251.1

IEC 950 IEC 1000-4, -2, -3, -4, -5, -6

Refer to the Metasys Smoke Control Wiring Technical Bulletin (LIT-636331) in

the Metasys Network Technical Manual (FAN 636) for details on smoke

control compliance requiremen ts.

1210

1.3 ampere for a VMA

1210,

ONWORKS

NTC (2.25K ohm Fenwal) room sensors

- 1.6K ohm setpoint potentiometer (2-wire)

- Voltage Input for 0 to 10 VDC (humidity, dewpoint sensor, or sideloop)

Combination contact input w/LED driver for temporary occupancy on

TE-6700

Network Bus and Zone Bus

W

Network Bus between VMA controller and NCM (2-wire)

ORKS

-0, except internal damper actuator

1210

-0 (cooling with reheat/fan)

1220

fully loaded

1220

Page 35

VMA1200 Series Overview and Engineering Guidelines

All specifications are for the VMA controller pressure sensor and

actuator only, measured at the midpoint of each range within 90 days

of calibration at room temperature.

Table 15: Additional Detailed VMA Specifications

Power Input

Voltage Range 20 to 30 VAC; 50 or 60 Hz

Input Current 0.3 ampere without relays or valves

Transient Protection Control circuitry is transformer isolated from input power.

Common and Normal mode capacitor

LONW

Communications

Bus Type and Voltage FTT-10A, 2.5V differential signal

Bus Speed 78k Baud

Transient Protection Transformer isolated from 24 VAC, BOs, AI, BI, AO, ZBus, +15 VDC;

Zone Bus

Communications

Bus Type and Voltage Single-ended 5 VDC

Bus Speed 1200 Baud

Transient Protection Isolated from 24 VAC, BOs, and LONW

Microprocessor/Memory

Microprocessor

Memory 56K byte Flash

DC Supply Output

Voltage Range 14 to 18 VDC

Load Current 0 to 35 mA

Overload and Transient

Protection

Pressure Input (AI-5)

Range 0 to 435 Pascal (0 to 1.75 inch W.C.)

Proof Pressure 6895 Pascal (1 psi)

Burst Pressure 68940 Pascal (10 psi)

Resolution 0.0234 Pascal (0.000094 inch W.C.)

Non-repeatability and

Hysteresis

Non-linearity (Best Fit) ±2 Pascal (±0.008 inch W.C. maximum) for 0 to 249 Pa (0 to 1 inch W.C.)

Thermal Effect on Zero* ±0.179 Pascal per degree C (±0.0004 inch W.C. per degree F maximum)

Thermal Effect on Span ±0.179 Pascal per degree C (±0.0004 inch W.C. per degree F maximum)

Position Effect on Zero* ±0.623 Pascal (±0.0025 inch W.C. maximum)

Position Effect on Full Span ±0.623 Pascal (±0.0025 inch W.C. maximum)

Long Term Zero Drift* ±2.49 Pascal per year (±0.01 inch W.C. per year maximum)

Long Term Span Drift ±2.49 Pascal per year (±0.01 inch W.C. per year maximum)

Sample Time One second

Continued on next page . . .

Network Bus

ORKS

Spark gaps, series blocking capacitors, clamping diodes, transformer

communications circuit;

ORKS

PTC+Transorb; Common mode capacitors

Neuron 3150 processor operating at 10 MHz

Current Foldback; Isolated from 24 VAC, BOs, and LONW

communications circuit; Common mode capacitors

±0.187 Pascal (±0.00075 inch W.C. maximum)

±3 Pascal (±0.012 inch W.C. maximum) above 249 Pa (>1 inch W.C.)

ORKS

35

Page 36

36

VMA1200

Additional Specifications (Cont.)

Temperature Inputs

(AP-VMA

(AI-1, AI-2, AI-4)

Range

NTC: 0 to 40°C (32 to 104°F)

Platinum: 0 to 40°C (32 to 104°F)

Nickel: 0 to 40°C (32 to 104°F)

Setpoint: 18 to 30°C (65 to 85°F)

Resolution (13 bit)

NTC: 0.0028°C (0.0050°F)

Platinum: 0.0589°C (0.1060°F)

Nickel: 0.0430°C (0.0774°F)

Setpoint: 0.0015°C (0. 0027°F)

Non-repeatability and

Hysteresis (estimate)

NTC: ±0.009°C (±0.016°F) maximum

Platinum: ±0.189°C (±0.340°F)

Nickel: ±0.138°C (±0.248°F)

Setpoint: ±0.005°C (±0.009°F) maximum

Measurement Accuracy

NTC: ±0.03°C (±0.05°F) maximum

Platinum: ±0.68°C (±1.23°F) maximum

Nickel: ±0.50°C (±0.90°F) maximum

Setpoint: ±0.15°C (±0.27°F) maximum

Thermal Tolerance

±0.020% per °C (±0.036% per °F) maximum

Long Term Drift ±0.07% per year maximum

Sample Time One second

Transient Protection

Isolated from 24 VAC, BOs, and LON

Normal mode RC; Common mode capacitors

Temporary Occupied

100 mS

Response Time (AI-1)

Voltage Input (AI-3)

(AP-VMA

Range 0 to 10.0 VDC (0 to 2000 PPM CO2)

Resolution (13 bit) 0.750 mV (0.15 PPM CO2)

Non-repeatability and

±0.012 V maximum (±2.4 PPM CO2)

Hysteresis (estimate)

Measurement Accuracy ±75 mV maximum (±15 PPM CO2)

Thermal Tolerance

±0.028% per °C (±0.050% per °F) maximum

Long Term Drift ±0.7% per year maximum

Sample Time One second

Transient Protection Isolated from 24 VAC, BOs, and LONW

Normal mode RC; Common mode capacitors

Binary Inputs

Voltage Range and

Trigger Level

BI-1: 0 to 5 VDC with 3.1 VDC threshold

BI-2 and BI-3: 0 to 5 VDC with 2.5 VDC threshold

Sample Time 50 mS pulse width (10 Hz maximum)

Transient Protection Isolated from 24 VAC, BOs, and LONW

Normal mode RC; Common mode capacitors

Continued on next page . . .

only for AI-4)

1220

only)

1220

W

communications circuit;

ORKS

communications circuit;

ORKS

communications circuit

ORKS

Page 37

VMA1200 Series Overview and Engineering Guidelines

Additional Specifications (Cont.)

Analog Output (AO-1)

Voltage Range 0 to 10 VDC

Load Current 0 to 10 mA

Voltage Resolution

(8 bit)

Linearity and Hysteresis ±0.04 VDC maximum

Voltage Accuracy ±3% full scale

Thermal Tolerance

Long Term Drift ±0.7% per year maximum

Time Constant one second (seven seconds for steady state)

Transient Protection Isolated from 24 VAC, BOs, and LONW

Binary Outputs

(BO-1 through BO-5)

Voltage Range 20 to 30 VAC

Load Current 25 to 500 mA

Time Constant 50 mS

Transient Protection Isolated from AI, BI, AO, ZBus, +15 VDC, and LONW

Motor Actuator Output

Rated Running Torque

Unpowered Holding

Torque

Stall Torque

Stroke 93±3 degrees maximum

Angular Velocity 1 degree per second nominal

Full Stroke Life 100,000 cycles minimum

Reposition Stroke Life 2,500,000 cycles minimum

Reposition Accuracy ±1 degree maximum

Acoustic Noise 30 dBA at one meter maximum

* Use the Auto Calibration function to correct. Specifications are deemed accurate but are subject to change.

(AP-VMA1220 only)

0.04 VDC

±0.005% per °C (±0.009% per °F) maximum

communications circuit;

ORKS

Common mode capacitors

(AP-VMA1220 only)

communications

ORKS

circuit; Common mode capacitors; Normal mode capacitors and resistors

4 N⋅m (35 lb⋅in) minimum

5.1 N⋅m (45 lb⋅in) minimum

9.1 N⋅m (80 lb⋅in) maximum

37

Page 38

38

VMA1200

Fabricating Your Own Interconnection Cable

You must construct any fabricated interconnection cable, so the same

color wire on both ends of the cable align with Pin 1 in the plug. This

provides a consistent field assembly of the cable. Figure 8 illustrates

the interconnection cable.

8

7

6

5

4

3

2

1

VMA1200

Controller

Phone Plug

BI-1

AI-2

AI-1

AI-1 COM

+15 VDC

ZB COM

AI COM

ZB+

1234567

TE-670 0 R oom Sens or

Phone Plug

Figure 8: Interconnection Cable

8

Phone Connector s

(Clip Side Out)

Cblfab_1

Note: This is not typical of preassembled phone cable purchased in

retail stores. A telephone system cable is wired opposite of

the Zone Sensor requirements.

Page 39

Sensor Interface

AI-1 (Zo ne Temperature)

+15/Zone Bus COM (Not BCOM)

VMA1200 Series Overview and Engineering Guidelines

39

Figures 9, 10, and 11 show interfaces between room sensors and the

VMA1200. For more information on the TE-6700 room sensor

(including Dual Inline Package (DIP) switch settings), see the TE-6700

Series 2nd Generation Temperature Elements Installation Bulletin

(LIT-216332).

8-pin P hone Jack

on TE-6700

BI-1

AI-2 (Setpoint)

AI COM

+15 Volts DC

AI-COM

Zone Bus/N 3+

Screw

Terminals

1

8

4

2

3

1

2

4

5

5

6

6

7

3

7

8

LED*

Sensor

Manual

Override

1K ohm

1.6K ohm

Setpoint Potentiometer

6-pin P hone Jack

on TE-6700

1

2

3

4

5

6

+15 Volts DC

COM

Zone Bus

TE6X

Figure 9: TE-6700 Phone Jack Interface to VMA1200

Page 40

40

VMA1200

VMA

(18) BI-1*

(19) COM

(20) BI-2

(21) COM

(22) BI-3

(23) COM

(24) +1 5 VD C

(25) +1 5 VD C

(26) AI-1

(27) COM

(28) AI-2

(29) COM

(30) AI-3

(31) COM

(32) AI-4

(33) COM

(34) ZB+

(35) ZB-

AI

COMAICOM

AI1

1

8

ZB+ COM 15 VDC

BI-1

AI2

4

5

O N

Preferred DIP Switch

Position for TE-6700

1 2 3

screw term

Figure 10: TE-6700 Interface to VMA1200 (Terminal Block)

Page 41

VMA

VMA1200 Series Overview and Engineering Guidelines

TE-7000 (Europe Only)

Terminal Blocks (TBs)

TB1 TB2

1234 5678

(18) BI-1

(19) COM

(20) BI-2

(21) COM

(22) BI-3

(23) COM

(24) +1 5 VD C

(25) +1 5 VD C

(26) AI-1

(27) COM

(28) AI-2

(29) COM

(30) AI-3

(31) COM

(32) AI-4

(33) COM

(34) ZB+

(35) ZB-

41

TE7000

Figure 11: TE-7000 (Europe Only) Interface to

VMA1200 (Terminal Blocks)

Note: The IU-9100 converter is not compatible with the VMA1200

Zone Bus.

Page 42

42

VMA1200

Appendix B: Application Example

This example is provided as a basic overview of wiring locations you

might expect to see. It does not define all applications available or all of

the possible questions and answers. For more information on VMA1200

applications, see the Variable Air Volume Modular Assembly (VMA)

1200 Series Controllers Application Note (LIT-1162500).

Single Duct Application Example

Table 16: Single Duct Application Example Questions

M-Pro Questions Configuration Selections

VAV Box Type

Fan Type (R1)

Baseboard Heat Type

Box Heat Type (HTG)

Pressure Independent

Series/On-Off

None

2-stages

Note: The Orig inal Equ ipment Man ufactur er (OE M) bo x manufa c turer

typically supp lies t he fan re lay s and e lectr ic hea t rel ay s.

R2

Plenum

Supply

DPT1

R3

H

T

G

Discharge

DA1

R1

C

1

Figure 12: Single Duct Application Example

TE

1

Sample1

Mechanical Flow Diagram

Page 43

VMA1200 Series Overview and Engineering Guidelines

Table 17: Single Duct Application Example Bill of Materials

Component Description Part Number

C1, DPT1, DA1

TE1

R1

R2, R3

* Box OEM manufacturers typically furnish fan relays and electric heat relays.

Power

Transformer

120 VAC 24 V A C

Fan Relay

Stage 1 Relay

Stage 2 Relay

R1

R2

R3