Page 1

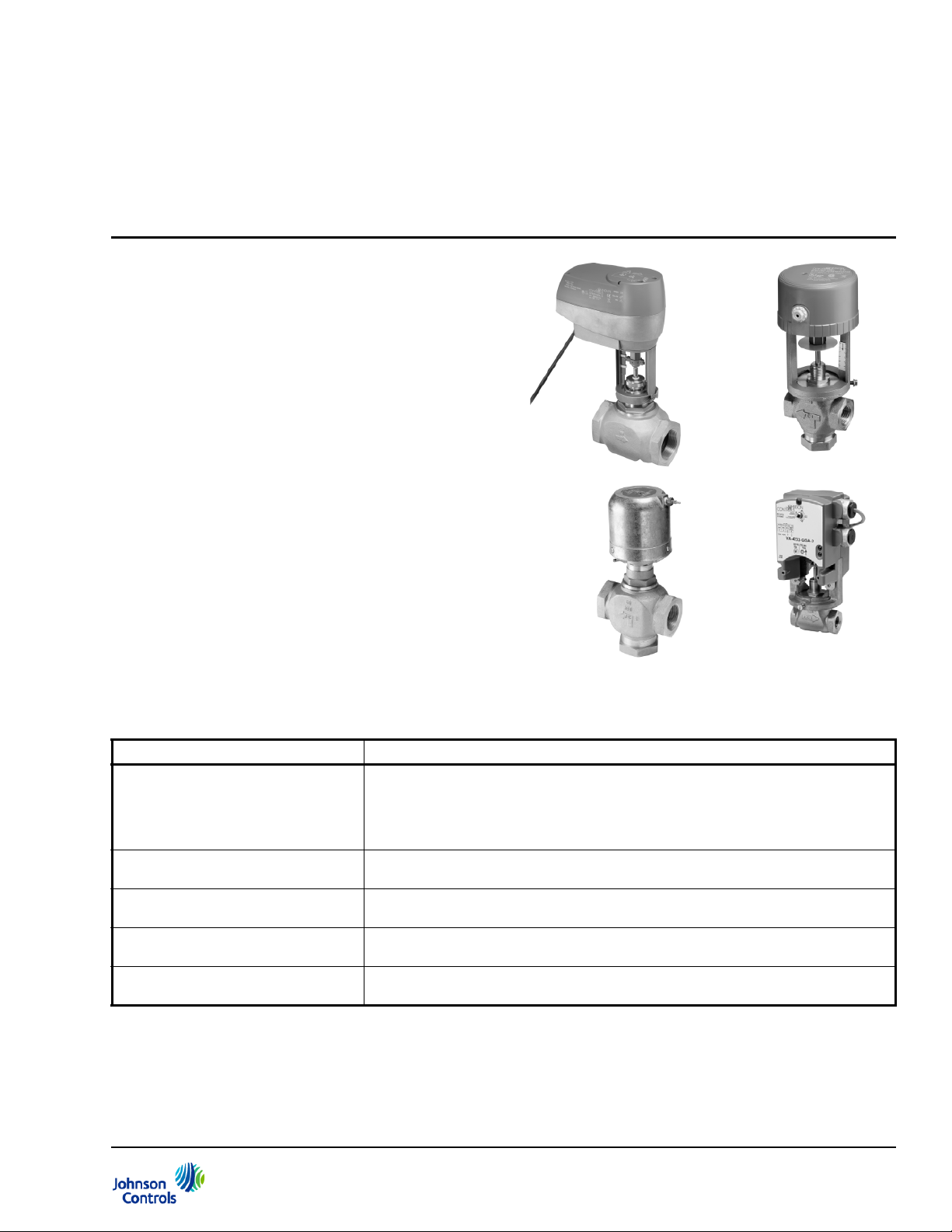

Figure 1: VG7000 Series Bronze Control Valves

VG7000 Series Bronze Control Valves

Product Bulletin

VG7000 Series

Refer to the QuickLIT website for the most up-to-date version of this document.

VG7000 Series Bronze Control Valves are designed

primarily to regulate the flow of water and steam in

response to the demand of a controller in Heating,

Ventilating, and Air Conditioning (HVAC) systems.

These valves are available in Normally Open (N.O.),

Normally Closed (N.C.), and three-way mixing

configurations. Both electric and pneumatic actuators

are available for factory or field mounting.

Code No. LIT-977140

Issued November 15, 2013

Supersedes March 29, 2013

Table 1: Features and Benefits

Features Benefits

Complete Family of 1/2 through

2 in. Bronze Valves, Brass and

Stainless Steel Trim, with Several

Styles of Electric and Pneumatic

Actuators

Flexible Features and Options

Ordering Matrix

Standard Johns on Controls®

Ring Pack Packings

Testing for Tight Shutoff of Every

Valve

Standard Bonnet and Stem Design Allows easy field retrofit, easy field mounting, and interchangeability of actuators with

Offers a broad selection to choose from, including electric spring return actuators, a

true 1-1/4 in. valve body, a 3/4 in. valve with small oval top actuator, and Stainless

Steel (SS) trim capable of 100 psig (690 kPa) saturated steam.

Suits your specific application via thousands of easy-to-select, factory-assembled

combinations.

Provides industry-leading reliability and operating life.

Provides energy conservation and ensures occupant comfort.

the use of standardized mounting kits.

VG7000 Series Bronze Control Valves Product Bulletin 1

Page 2

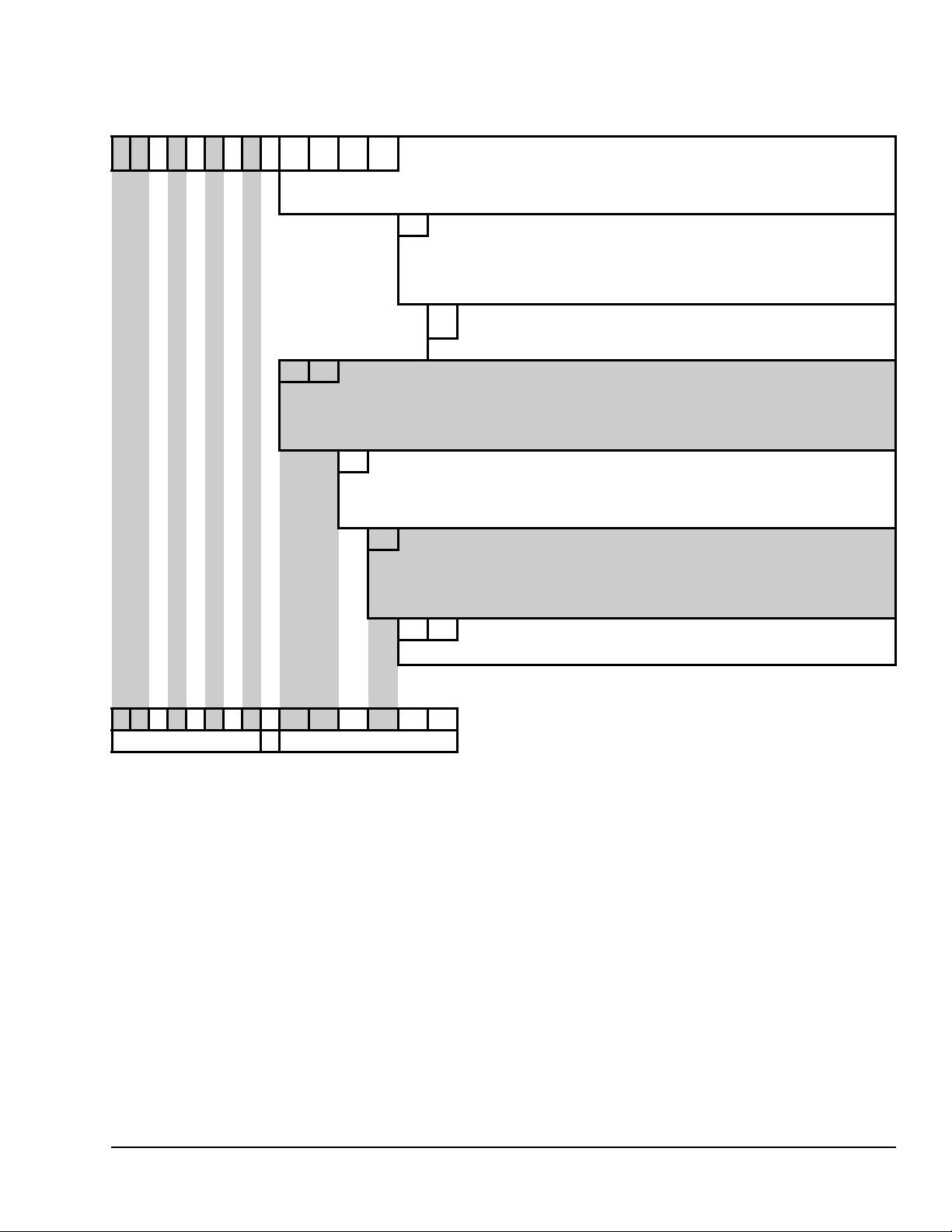

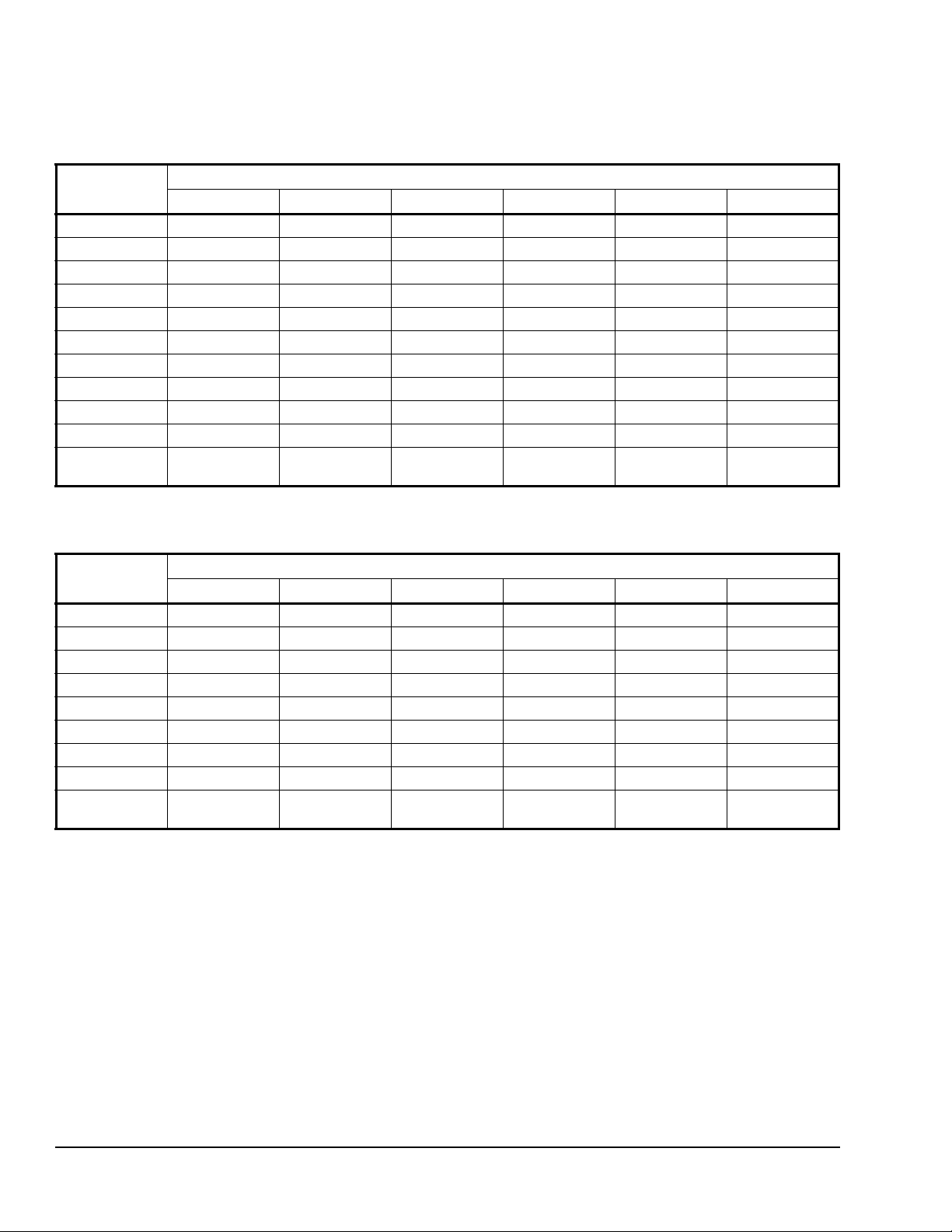

Ordering Data

Table 2: Ordering Data — VG7000 Series Bronze Control Valves

V G

1 2 7

3 2

4 4 = Two-Way, Normally Closed/Push-Down-to-Open

4

5 5 = Union Globe/Union Angle (1/2 through 1-1/2 in. Body

1

6 2 = Brass Linear (Three-Way Only)

L

7 E = 1/2 in., 1.8 Cv (1.6 Kv)

T

8 S = Slotted Stem and Small Bonnet (Factory-Mounted

+

9 (Leave Fields 9 through 15 blank for valve without

Valve Globa l

Product Family

Body Type

End Connections

Trim and Flow

Characteristics

Size and Cv (Kv)

Stem Type

Actuator

Mounting

7 = Cast Bronze

2 = Two-Way, Normally Open/Push-Down-to-Close

5 = Two-Way Angle, Normally Open/Push-Down-to-Close

8 = Three-Way Mixing

4 = Threaded National Pipe Thread (NPT)

Sizes, PDTC Only, Brass Trim Valves Only))

7 = Union Sweat, 3/8 in. Tubing (1/2 in. Body Size Only,

Brass Trim Valves Only))

8 = Union Sweat, Standard Tubing (Brass Trim Valves

Only)

9 = Union Sweat, 3/4 in. Tubing (1/2 in. Body Size Only,

Brass Trim Valves Only))

1 = Brass Equal Percentage (All Two-Way and 1/2 in.

Three-Way)

3 = Stainless Steel Equal Percentage (Two-Way Only)

4 = Stainless Steel Linear (Three-Way Only)

C = 1/2 in., 0.73 Cv (0.63 Kv)

G = 1/2 in., 4.6 Cv (4.0 Kv)

L = 3/4 in., 7.3 Cv (6.3 Kv)

N = 1 in., 11.6 Cv (10.0 Kv)

P = 1-1/4 in., 18.5 Cv (16.0 Kv)

R = 1-1/2 in., 28.9 Cv (25.0 Kv)

S = 2 in., 46.2 Cv (40.0 Kv)

T = Standard Threaded Stem (All Except V-3801, MP84,

VA-8x2x)

V-3801, VA-8x2x Only; Only Brass Trim Valves)

M = Large Threaded Stem (Factory-Mounted MP84 Only,

Only Stainless Steel Trim Valves)

+ = Factory-Mounted Actuator

(See Table 3 and Table 4.)

factory-mounted actuator. Valve without factory-mounted

actuator is available with standard threaded stem only.)

1

1 23456789101112131415 = Field

V G7 241LT + Example: Cast bronze valve, two-way, normally open/push-down-to-close,

Valve + Actuator

threaded (NPT) end connections, brass trim, equal percentage,

3/4 in., 7.3 Cv, standard threaded stem.

1. See Table 3 when adding a factory-mounted pneumatic actuator to a valve body. See Table 4 when adding a

factory-mounted electric actuator to a valve body. For valid valve and actuator combinations, see Table 16 and Ta ble 17.

VG7000 Series Bronze Control Valves Product Bulletin2

Page 3

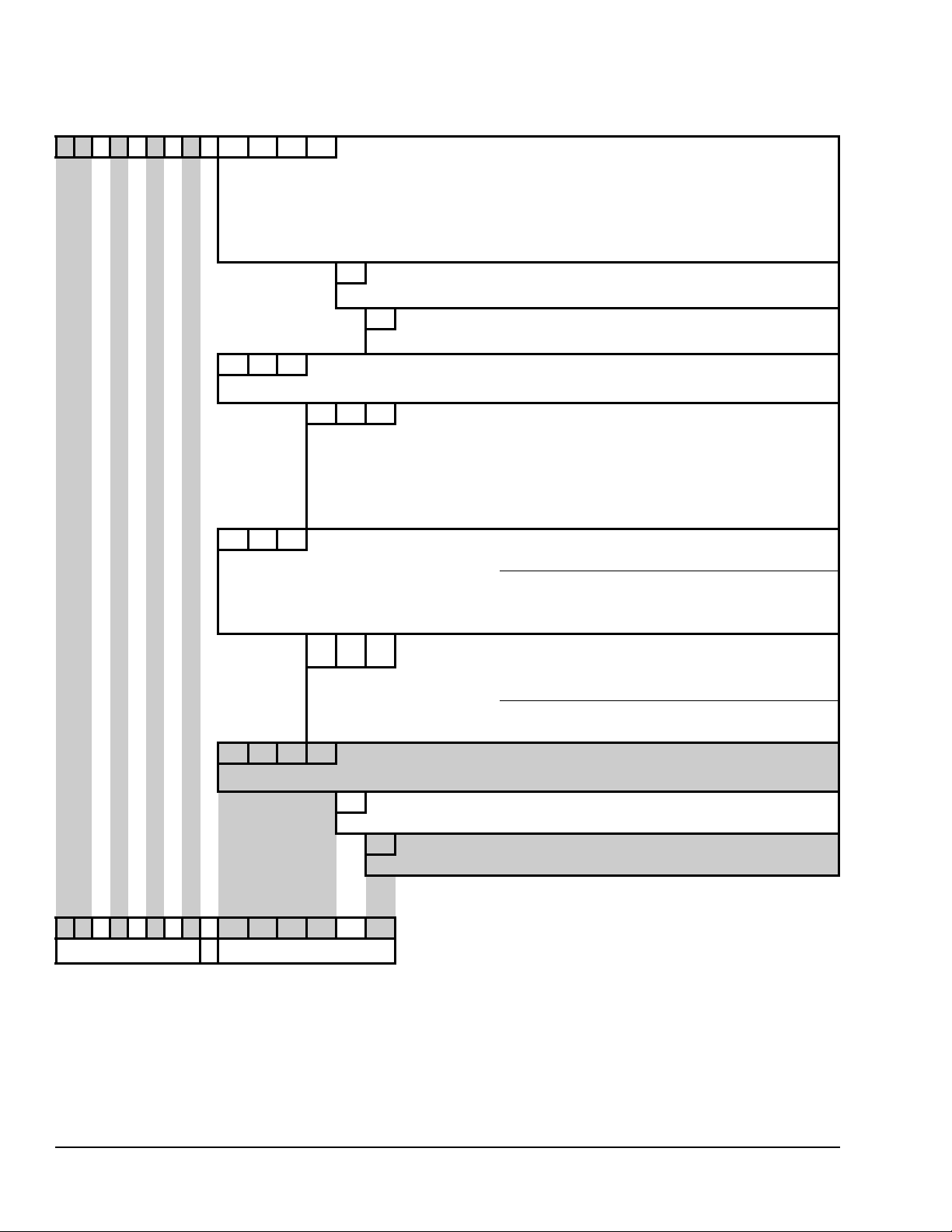

Table 3: Ordering Data — Adding a Factory-Mounted Pneumatic Actuator

V G7 243LT + 3 0 0 8 V-3000/V-3801

1 2345678 9 10 11 12 13 3008 = V-3000-8012 Exposed

B Spring Range

14 D = 4 to 8 psig (Suggested for Three-Way Valves with

8 2 MP8000 Series

10 11 84 = MP84, 50 sq in. Spring-Return-Up (SS Trim Only)

1Stroke

12 2 = 1/2 in. (1 or 1-1/4 in. Valves with MP82 Actuator Only)

C Spring Range

13 D = 4 to 8 psig (Suggested for Three-Way Valves with

0 1 Accessories

14 15 01 = V-9502 Positioner

Pneumatic

Actuator

(V-3000/V-3801)

P Accessories

(V-3000/V-3801)

15 Blank = None

Pneumatic

Actuator

(MP8000

Series)

(MP8000

Series)

(MP8000

Series)

2

2

3801 = V-3801-8001 Small Oval Top (Slotted Stem Only,

Brass Trim Valves Only, Must be Factory Assembled)

3003 = V-3000-8003 Enclosed

B = 3 to 6 psig (Suggested for N.O. Valves with Positioner)

Positioner)

E = 9 to 13 psig (Suggested for N.C. Valves with

Positioner)

P = V-9502 Positioner (Not Available with V-3801-8001 or

V-3000-8003)

82 = MP82, 25 sq in. Spring-Return-Up (SS or Brass Trim)

(Only spring-return-up models of MP8000 Series

Pneumatic Actuators are available factory-mounted to

VG7000 Series Bronze Control Valves.)

1 = 5/16 in. (1/2 or 3/4 in. Valves with MP82 Actuator Only)

3 = 3/4 in. (1-1/2 or 2 in. Valves with MP82 or MP84

Actuator)

C = 3 to 7 psig (Suggested for N.O. Valves with Positioner)

Positioner)

E = 9 to 13 psig (Suggested for N.C. Valves with

Positioner)

00 = None

1

1 2345678910 11 12 13 14 15 = Field

V G7 243LT+8 21C 0 1 Example: Cast bronze valve, two-way, normally open, threaded (NPT) end

Valve + Actuator

connections, stainless steel trim, equal percentage, 3/4 in., 7.3 Cv, standard

threaded stem, MP82 Series Pneumatic Actuator, 5/16 in. stroke, 3 to 7 psig

(21 to 48 kPa) spring range, with factory-mounted V-9502 Positioner.

1. See Table 2 when ordering a valve body only. See Table 4 when adding a factory-mounted electric actuator to a valve body.

For valid valve and actuator combinations, see Table 16 and Table 17.

2. Refer to the actuator product bulletin or product/technical bulletin.

VG7000 Series Bronze Control Valves Product Bulletin 3

Page 4

Table 4: Ordering Data — Adding a Factory-Mounted Electric Actuator

V G7 241LT + 7 1 5 0 VA-7150/

1 2345678 9 10 11 12 13 7152 = VA-7152-1001 Proportional, 0-10 VDC

VA-7200

Electric

Actuator

2, 3

7150 = VA-7150-1001 On/Off (Floating)

7153 = VA-7153-1001 On/Off (Floating), Feedback

1

7200 = VA-7200-1001 On/Off (Floating)

7202 = VA-7202-1001 Proportional, 0-10 VDC

7203 = VA-7203-1001 On/Off (Floating), Feedback

G Voltage

14

(VA-7150/

VA-7200)

Accessories

(VA-7150/

15

VA-7200)

4 2 3 VA-4233

10 11 12 423 = VA-4233-xGx-2, 24 VAC/VDC

A G A Features

13 14 15 AGC = Floating, 2 Auxiliary Switches

Electric

Actuator

(VA-4233)

2

4

G = 24 VAC

Blank = None

Spring Return Up

AGA = Floating

BGA = On/Off

BGC = On/Off, 2 Auxiliary Switches

GGA = Prop., 0-10 VDC, Feedback

GGC = Prop., 0-10 VDC, Feedback, 2 Auxiliary Switches

9 2 N VA7810

10 11 12 71C = VA7810-xGx-2, 24 VAC/VDC

VA7820/

VA7830

Electric

Actuator

5

2,6

Non-Spring Return

Spring Return

72C = VA7820-HGx-2, Spring-Return Stem Up 24 VAC

74C = VA7830-HGx-2, Spring-Return Stem Down 24 VAC

G G A Features

(VA78x0)

7

13 14 15 AGC = On/Off (Floating), 2 Auxiliary Switches

AGA = On/Off (Floating)

(Available only with VA7810 Actuator)

(Available only with VA7810)

HGA = Proportional, 0-10 VDC, Feedback

HGC = Proportional, 0-10 VDC, Feedback, 2

8 0 2 0 VA-8x2x

10 11 12 13 8122 = VA-8122-1, Proportional

G Voltage

14

Electric

Actuator

(VA-8x2x)

Accessories

(VA-8x2x)

15

2,3, 8

8020 = VA-8020-1, On/Off (Floating)

G = 24 VAC

Blank = None

1 2345678910 11 12 13 14 15 = Field

V G7 241LT+8 0 2 0G Example: Cast bronze valve, two-way, push-down-to-close, threaded (NPT)

Valve + Actuator

end connections, brass trim, equal percentage, 3/4 in., 7.3 Cv, standard

threaded stem, VA-8020-1 On/Off (Floating) Electric Actuator, 24 VAC supply.

1. See Table 2 when ordering a valve body only. See Table 3 when adding a factory-mounted pneumatic actuator to a valve body.

For valid valve and actuator combinations, see Table 16 and Table 17.

2. Refer to the actuator product bulletin or product/technical bulletin.

3. Available only for PDTC Two-Way and Three-Way body styles.

4. Available only for NPT (threaded) and Union Sweat End Connections body style.

5. VA7830 actuator is available only on Three-Way Mixing body style.

6. Available only for NPT (threaded) body style.

7. VA7820 and VA7830 Proportional Control Actuators have selectable switches for field conversion to On/Off or Floating Control.

8. Available only for 1/2 and 3/4 in. valves.

VG7000 Series Bronze Control Valves Product Bulletin4

Page 5

Application Overview

IMPORTANT: The VG7000 Series Bronze Control

Valves are intended to control saturated steam, hot

water, and chilled water flow under normal

equipment operating conditions. Where failure or

malfunction of the VG7000 Series Valve could lead

to personal injury or property damage to the

controlled equipment or other property, additional

precautions must be designed into the control

system. Incorporate and maintain other devices,

such as supervisory or alarm systems or safety or

limit controls, intended to warn of or protect against

failure or malfunction of the VG7000 Series Valve.

VG7000 Series Bronze Control Valves feature brass

and stainless steel trim, and are available in two-way

configurations with Push-Down-to-Close (PDTC)

(normally open if pneumatic or spring return) or

Push-Down-to-Open (PDTO) (normally closed if

pneumatic or spring return) with threaded (NPT), union

sweat, union globe, and union angle end connections.

The valve can be ordered with a variety of pneumatic

actuators: V-3000-8012 (exposed, with or without a

factory-mounted positioner), V-3000-8003 (enclosed),

V-38 01-8001 (oval top), and higher force MP8000

Series Actuators (with or without a factory-mounted

pneumatic positioner).

VG7000 Series Valves can also be ordered with any of

the following series electric actuators: VA-4233,

VA-7150, VA-7200, VA-8x2x, VA7810, VA7820, or

VA7830. All electric actuators are fully compatible with

Johnson Controls® controllers, reducing installation

costs. V alves without actu ators can be ordered with the

standard bonnet and threaded stem design, allowing

easy interchangeability of actuators with the use of

standardized mounting kits. See Table 2 through

Table 4 for ordering data and additional details. For

valid valve and actuator combinations, see Table 16

and Table 17.

The modulating valve plug of VG7000 Series Valves

provides an equal percentage flow characteristic for

two-way valves, and equal percentage or linear for

three-way valves. Tight shutoff is ensured using a

molded elastomeric disk in valves with brass trim, and

a precisely machined metal-to-metal seat for valves

with stainless steel trim. An arrow is cast on one side of

the valve body indicating the directio n of flow for proper

piping.

Pneumatic Actuator Selection

See Table 7, Table 9, Table 11, and Table 16.

Do not confuse the V-3000-8012, V-3000-8003, and

V-3801-8001 Pneumatic Actuators with the V-3000-1,

V-3000- 2, and V-3802-1 Pneumatic Actuators. Refer to

the V-3000-80 11 (Exposed) and V-3000-8003

(Enclosed) Pneumatic Valve Actuators Product/

Technical Bulletin (LIT-977252) for specifics regarding

interchangeability. The V-3801-8001 is not a direct

replacement for the V-3802-1 because V-3802-1 is not

compatible with VG7000 Series Valves.

V-3801-8001 Pneumatic Actuator

The V-3801-8001 is a low force, oval top actuator

designed specifically for 1/2 and 3/4 in. valves where

mounting space is restricted. The V-3801-8001 has

sufficient force to handle most seating pressures, and

the molded diaphragm design provides a constant

effective area (4 sq in.) throughout the valve stem

stroke. Due to the simplicity of the design, it is more

economical to replace the actuator than repair it. The

actuator assembly can be removed or repositioned by

loosening a single set screw without disturbing the rest

of the valve assembly.

Because the V-3801-8001 uses a unique slotted valve

stem for factory assembly (see the Stem Type section

in Table 2), the spring kits available are for field

mounting to standard threaded stem valves. See

Table 7 for mounting kit code numbers.

V-3000-8012 Pneumatic Actuator

The V-3000-8012 is a versatile, medium-force

pneumatic actuator that can be used in most HVAC

applications, including sequential control of valves. See

Table 9 and Table 11 for actuator sizing and selection.

The permanently captured, molded rolling diaphragm

of the V-3000-8012 provides a constant effective area

(8 sq in.) throughout the valve stem stroke. The

actuator assembly can be removed or repositioned by

loosening a single set screw without disturbing the rest

of the valve assembly.

The V-9502 Pneumatic Positioner is also available for

factory or field mounting to the V-3000-8012.

V-3000-8003 Pneumatic Actuator

The V-3000 -8003, operationally similar to the

V-3000-8012, is designed for enclosed installation in a

location where the actuator might be subjected to

tampering. The V -3000-8003 has a r eplaceable molded

diaphragm design.

VG7000 Series Bronze Control Valves Product Bulletin 5

Page 6

MP8000 Series Pneumatic Actuators

The higher force MP82 (25 sq in. effective diaphragm

area) and MP84 (50 sq in. effective diaphragm area)

Pneumatic Actuators are used where higher maximum

closeoff pressures are required, such as 1-1/2 and 2 in.

brass trim valves and 1/2 through 2 in. stainless steel

trim valves.

These actuators are equipped with a molded synthetic

rubber diaphragm contained in a sturdy, carbon-steel

housing that protects it against dirt and damage. The

actuator can be easily removed to perform inline

servicing to all parts of the valve. The MP8000

Actuators are available factory mounted or are easily

field mounted to VG7000 Series Valves. See Table 7

for the appropriate mounting kit.

The MP8000 Actuators are designed to allow for

reversing the action of the actuators in the field. If

desired, the action of the MP8000 on Normally Open

(N.O.) valves can be reversed from spring-return-up to

spring-return-down or vice versa. To field reverse the

actuator, refer to the MP8000 Pneumatic Valve

Actuators Technical Bulletin (LIT-977258).

The V-9502 Pneumatic Positio ner is also available for

factory or field mounting to MP8000 Series Pneumatic

Valve Actuators.

T-3000 Valve Top Thermostat Actuators

The T-3111 and T-3311 Series Valve Top Thermostat

Actuators are available for field mounting to all VG7000

Series Valves (N.O., N.C., and three-way). The valve

top thermostats are a combination of a pneumatic

thermostat and a pneumatic valve actuator. The T-311 1

and T-3311 are available in both direct an d reverse

acting models with various features and options. Refer

to the T-3111 Integral Thermostat a nd Piston Top V alve

Actuator Single Temperature, Single Pressure Product/

Technical Bulletin (LIT-7171137) and the T-3311

Integral Thermostat and Piston Top Valve Actuator

Dual Temperature, Dual Pressure Product/Technical

Bulletin (LIT-7171152) for specifications and ordering

information.

Note: A mounting kit is required to field mount T-3111

or T-3311 Valve Top Thermostats to a valve. See

Table 7 for the appropriate mounting kit code number.

Electric Actuator Selection

Factory-mounted electric actuators are available on

two-way PDTC and three-way mixing valve

configurations only. Actuators can be easily field

reversed if required. The actuators can be field

mounted on PDTO valves if desired. All proportional

electric actuator assemblies are factory calibrated for

nominal 0 to 10 VDC operation, to drive down with an

increase in signal. The VA-4233 and VA78x0 are

available on all valve styles: PDTO, PDTC, and threeway.

VA-4233 Series Electric Actuators

The VA-4233 Series Electric Actuators use a stepper

motor to accurately position the valve. In the event of a

power failure, a spring in the actuator automatically

returns the valve to the full stem-up position. These

direct-mount, spring return electric actuators provide a

minimum 61 lb force output for floating, on/off, or

proportional control, and can be factory mounted to

1/2 through 1-1/4 in. valve bodies with NPT (threaded)

and union sweat end connections.

Integral auxiliary switches are available for indicating

end stop position or to perform switching functions. On

proportional models, position feedback is also available

through a proportional DC voltage signal. All models

feature a hand crank for manual positioning of the

valve, independent of a power supply.

VA-7150 Series Electric Actuators

The VA-7150 Series Actuators use a reversible

synchronous motor and magnetic clutch to accurately

position the valve. This non-spring return actuator has

a 90 lb force output. The magnetic clutch maintains a

constant load at the end of travel, ensuring tight valve

shutoff and automatically compensating for seat wear.

This actuator is available in three models: floating

three-wire (VA-7150), floating with 0 to 2000 ohm

feedback (VA-7153), or 0 to 10 VDC proportional

control (VA-7152).

VA-7200 Series Electric Actuators

The VA-7200 Series Actuators use a reversible

synchronous motor and a magnetic clutch to accurately

position the valve. This non-spring return actuator has

a 180 lb force output. The magnetic clutch maintains a

constant load at the end of travel, which ensures tight

shutoff and automatically compensates for seat wear.

This actuator is available in three models: floating

three-wire (VA-7200), floating with 0 to 2000 ohm

feedback (VA-7203), or 0 to 10 VDC (0 to 20 mA)

proportional control (VA-7202).

VG7000 Series Bronze Control Valves Product Bulletin6

Page 7

VA-8x2x Series Electric Actuators

The VA-8x2x Series Actuators are synchronous

motor-driven, force sensor limited, non-spring return

actuators that feature a 22 lb seating force in a

compact design. The VA-8020 accepts floating control

from a three-wire, 24 VAC control signal. The VA-8122

typically accepts proportional control from a 0 to

10 VDC control signal; however, it can be field adjusted

to accept signals up to 20 VDC. In addition, the

V A-81 22 features a n input signal re versing fe ature that

allows it to be used in both heating and cooling

applications.

Note: The VA-8x2x is only available factory mounted

on 1/2 and 3/4 in. valves. Because the VA-8x2x

requires a unique slotted valve stem for factory

assembly, it is necessary to select the S option in the

Stem Type section of Table 2.

VA7810 Series Electric Actuators

The VA7810 Series is a line of motor driven, direct

mount, non-spring return actuators that operate on

24 VAC and are available for use with on/off (floating)

or proportional controllers. The actuator is available

factory mounted to 1/2 through 2 in. valve body styles

with NPT (threaded) end connections. The actuator is

available separately for field mounting to union sweat,

union globe, and union angle VG7000 Series valves.

The actuator delivers a minimum stem force of 180 lb.

Integral auxiliary switches are available for indicating

end-stop position or to perform switching functions. For

proportional models a 0 (2) to 10 VDC signal feedback

is available.

VA7820/VA7830 Series Electric Actuators

The VA7820/VA7830 Series is a line of motor driven,

direct mount, spring return actuators that operate on

24 VAC. The actuators ship alread y set for 0 to 10 VDC

Proportional control. With a simple change of DIP

switch settings, the actuator can be reconfigured in the

field for On/Off (Floating) Control. Position feedback is

available via switches or a 0 (2) to 10 VDC signal. The

actuator delivers a minimum stem force of 180 lb. If the

power fails, the automatic spring returns the valve stem

up for the VA7820 actuator or the valve stem down for

the V A7830 actu ator. A manual override allows manual

positioning of the valve when power is not available.

The actuator is available factory mounted to 1/2

through 2 in. valves body styles with NPT (threaded)

end connections. The actuator is available separately

for field mounting to union sweat, union globe, and

union angle VG7000 Series valves.

VG7000 Series Bronze Control Valves Product Bulletin 7

Page 8

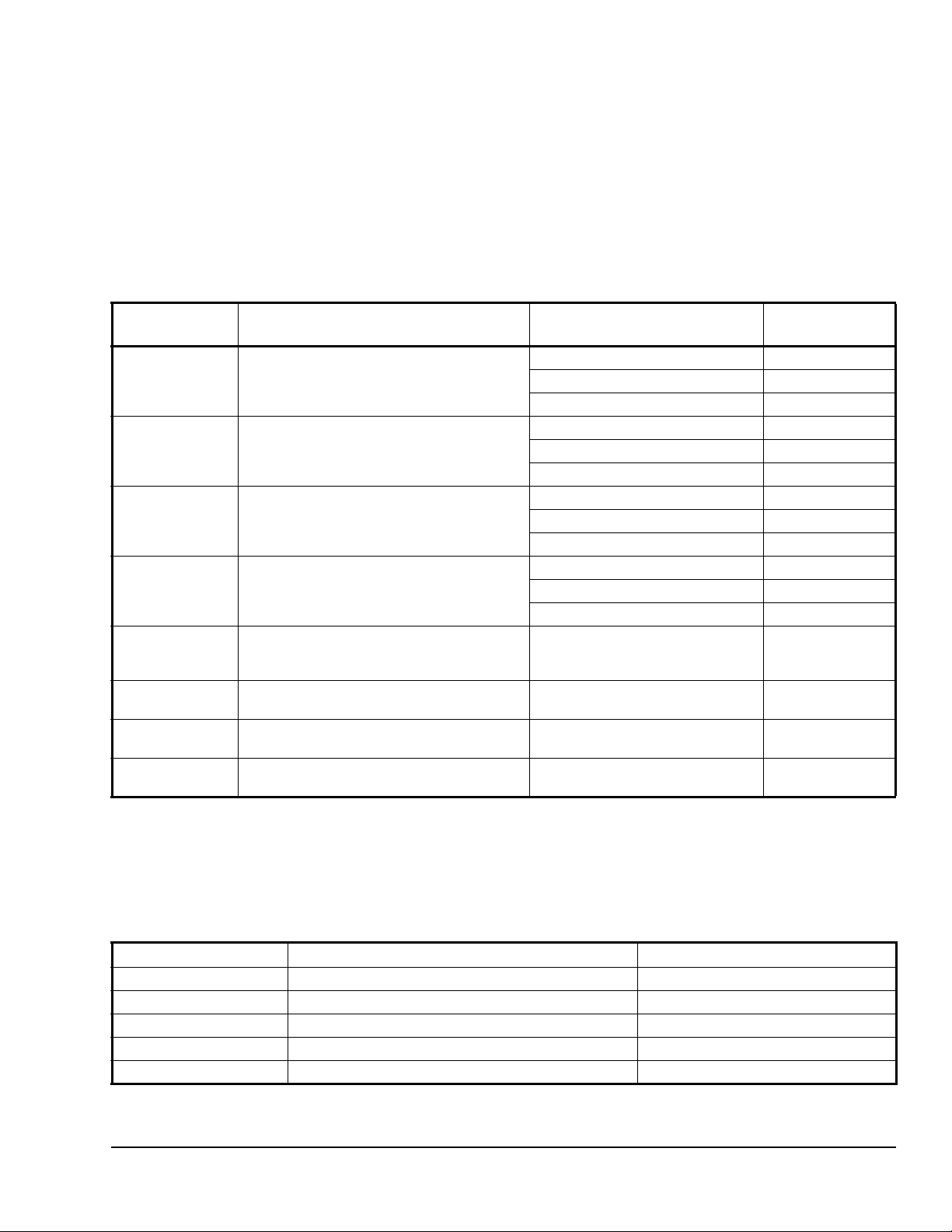

Shipping Weights

Table 5: Shipping Weights for Brass Trim Valves

Actuator Valve Weight, lb

1/2 3/4 1 1-1/4 1-1/2 2

V-3801-8001 2.5 3.1 --- --- --- --V-3000-8012 3.4 4.5 6.5 6.5 12.1 17.2

V-3000-8003 3.2 4.3 6.3 6.2 11.9 17.0

MP82 --- --- 14.0 16.0 19.0 24.0

MP84 --- --- --- --- --- --VA-4233 5.3 6.4 8.4 8.3 --- --VA-7150 3.9 5.0 7.0 6.9 12.6 17.7

VA-7200 --- --- 7.5 7.4 13.1 18.2

VA-8x2x 4.6 5.9 --- --- --- --VA7810 --- --- 6.2 6.2 11.8 16.9

VA7820/

VA7830

1. Weights are approximate and based on the heaviest valve. Add 2 lb (0.9 kg) for pneumatic assemblies with a positioner.

--- --- 7.9 7.9 13.5 18.6

1

Table 6: Shipping Weights for Stainless Steel Trim Valves

1

Actuator Valve Weight, lb

1/2 3/4 1 1-1/4 1-1/2 2

V-3000-8012 3.7 4.5 6.9 8.9 --- ---

V-3000-8003 3.5 4.2 6.7 8.7 --- ---

MP82 11.0 12.0 14.0 16.0 19.0 24.0

MP84 --- --- --- --- 32.0 37.0

VA-4233 5.3 5.6 8.0 10.0 --- ---

VA-7150 3.9 4.2 6.6 8.6 12.6 17.7

VA-7200 4.7 5.5 7.9 9.9 13.1 18.2

VA7810 3.1 4.2 6.6 8.6 11.8 16.9

VA7820/

VA7830

1. Weights are approximate and based on the heaviest valve. Add 2 lb (0.9 kg) for pneumatic assemblies with a positioner.

4.8 5.9 8.3 10.3 13.5 18.6

VG7000 Series Bronze Control Valves Product Bulletin8

Page 9

Field Mounting

A standard bonnet/stem design allows for easy field

mounting of actuators. See Table 2 to order valves

without actuators; Table 7, and Table 8 to order the

appropriate mounting kits; and Table 16 and Table 17

to identify compatible actuators. Refer to the

appropriate actuator product bulle tin fo r spe cif ic

actuator code number information.

Table 7: Field Mounting Kits for Pneumatic Actuators

Actuator Style

T-3x11

V-3000-8012

Valve Size, in. (DN)

1/2 or 3/4 (DN15 or DN20)

5/16 in. (8 mm) Stroke

V-3000-8003

T-3x11

V-3000-8012

1 or 1-1/4 (DN25 or DN32)

1/2 in. (13 mm) Stroke

V-3000-8003

T-3x11

V-3000-8012

1-1/2 or 2 (DN40 or DN50)

3/4 in. (19 mm) Stroke

V-3000-8003

V-3801-8001 1/2 or 3/4 (DN15 or DN20)

5/16 in. (8 mm) Stroke

V-3801-8001 1/2 or 3/4 (DN15 or DN20)

5/16 in. (8 mm) Stroke

MP82/MP83 1/2 or 3/4 (DN15 or DN20) with Stainless

Steel Trim

MP82/MP83 1 through 2 (DN25 through DN50) with 1/4 in.

Stem and Stainless Steel or Brass Trim

MP84/MP85 1-1/2 through 2 (DN40 through DN50) with

3/8 in. Stem and Stainless Steel Trim

2

1

Spring Range psig (kPa) Mounting Kit

Code Number

3 to 6 (21 to 41) VG7000-1001

4 to 8 (28 to 55) VG7000-1002

9 to 13 (62 to 90) VG7000-1003

3 to 6 (21 to 41) VG7000-1004

4 to 8 (28 to 55) VG7000-1005

9 to 13 (62 to 90) VG7000-1006

3 to 6 (21 to 41) VG7000-1007

4 to 8 (28 to 55) VG7000-1008

9 to 13 (62 to 90) VG7000-1009

3 to 6 (21 to 41) VG7000-1010

4 to 8 (28 to 55) VG7000-1011

9 to 13 (62 to 90) VG7000-1012

Kit with Three Springs:

3 to 6, 4 to 8, and 9 to 13 (Includes

hardware to adapt one valve only.)

Not Applicable MP8000-6701

Not Applicable MP8000-6702

Not Applicable MP8000-6703

VG7000-1015

3

3

3

3

3

3

3

3

3

3

3

3

3

4

4

5

1. Use all mounting kits with valves with standard threaded stem design only.

2. DN is the European designation for body size in metric units (mm).

3. The mounting kits include: upper spring seat, spring, stem extension, stem locking screw (or set screw), and a

bonnet adaptor for the V-3801-8001. Use this only on valves with threaded stems.

4. The mounting kits include: stem nut (1), stem extender nuts (2), stem extender (1), and yoke nut (1).

5. The mounting kit includes: stem nuts (2) and yoke nut (1).

Table 8: Field Mounting Kits for Electric Actuators

1

Actuator Style Valve Size, in. (DN) Mounting Kit Code Number

VA-4233 1/2 through 1-1/4 (DN15 through DN32) None Required

VA-715x 1/2 through 2 (DN15 through DN50) None Required

VA-720x 1 through 2 (DN25 through DN50) None Required

VA-8x2x 1/2 and 3/4 in. (DN15 and DN??) VA-8020-100 (Refit only)

VA78x0 1/2 through 2 (DN15 through DN50) None Required

1. Use all mounting kits with valves with standard threaded stem design only.

VG7000 Series Bronze Control Valves Product Bulletin 9

Page 10

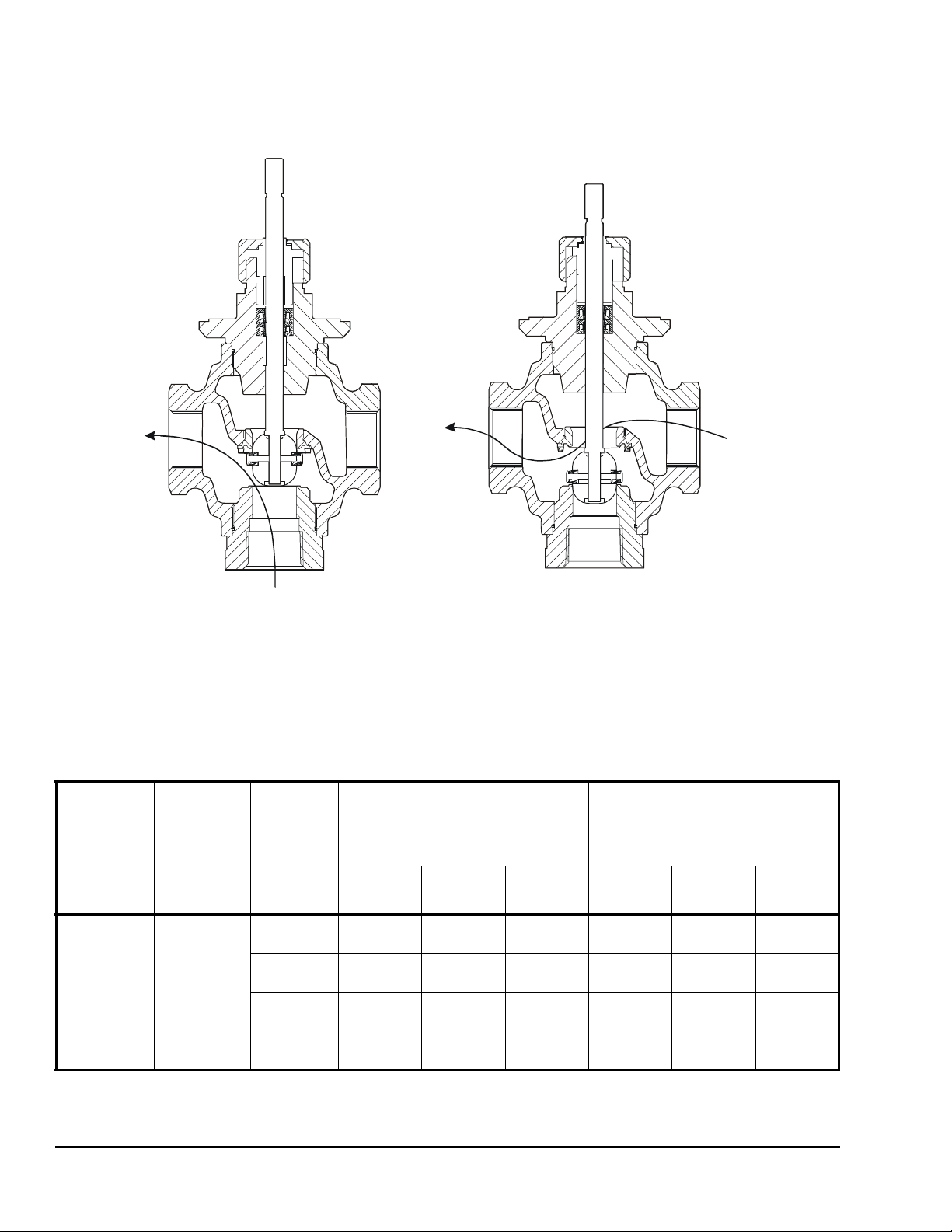

Stem Up Position

the lower port (N.O.) is open

to the Common port (C).

C

C

Stem Down Position

the inline port (N.C.) is open

to the Common port (C).

N.O.

(PDTC)

N.O.

(PDTC)

N.C.

N.C.

(PDTO)

F

I

G

:

V

G

7

F

G

0

2

P

Figure 2: Three-Way Mixing Valves Fluid Flow Direction and Port Designation

(PDTO)

With the stem in the up position,

With the stem in the down position,

Table 9: Brass Trim – Maximum Closeoff Pressures, psig (kPa) for Pneumatically Actuated Valves (Part 1

of 2)

Actuator

Style

V-3801-8001

(248°F

[120°C])

Valve Size,

in. (DN)

Brass Trim

1/2

(DN15)

3/4

(DN20)

Maximum

Cv (Kv)

Factor

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

Two-Way Normally Open or

Three-Way N.O. Port

(with 20 psig Supply)

Spring Range (psig

2

3 to 6

(21 to 41)

186

(1,282)

186

(1,282)

105

(723)

67

(462)

4 to 8

(28 to 55)

157

(1,082)

157

(1,082)

89

(613)

56

(386)

(62 to 90)

1

)

9 to 13

84

(579)

84

(579)

48

(331)

30

(207)

Two-Way Normally Closed or

Three-Way N.C. Port

(with 0 psig Supply)

Spring Range (psig)

2

3 to 6

(21 to 41)

37

(255)

37

(255)

18

(124)

11

(76)

4 to 8

(28 to 55)

57

(393)

57

(393)

28

(193)

16

(110)

1

9 to 13

(62 to 90)

158

(1,089)

158

(1,089)

76

(524)

45

(310)

VG7000 Series Bronze Control Valves Product Bulletin10

Page 11

Table 9: Brass Trim – Maximum Closeoff Pressures, psig (kPa) for Pneumatically Actuated Valves (Part 2

of 2)

Actuator

Style

V-3000-8012

(284°F

[140°C])

and

V-3000-8003

(248°F

[120°C])

MP82

(284°F

[140°C])

Valve Size,

in. (DN)

Brass Trim

1/2

(DN15)

3/4

(DN20)

1

(DN25)

1-1/4

(DN32)

1-1/2

(DN40)

2

(DN50)

1

(DN25)

1-1/4

(DN32)

1-1/2

(DN40)

2

(DN50)

Maximum

Cv (Kv)

Factor

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

11.6

(10)

18.5

(16)

28.9

(25)

46.2

(40)

11.6

(10)

18.5

(16)

28.9

(25)

46.2

(40)

Two-Way Normally Open or

Three-Way N.O. Port

(with 20 psig Supply)

Spring Range (psig

2

3 to 6

(21 to 41)

365

(2,515)

365

(2,515)

225

(1,550)

144

(992)

90

(620)

55

(379)

35

(241)

22

(152)

279

(1,924)

170

(1,172)

109

(752)

70

(483)

4 to 8

(28 to 55)

339

(2,336)

339

(2,336)

192

(1,323)

122

(841)

76

(524)

47

(324)

30

(207)

19

(131)

257

(1,772)

157

(1,082)

100

(689)

64

(441)

(62 to 90)

1

)

9 to 13

191

(1,316)

191

(1,316)

108

(744)

69

(475)

42

(289)

26

(179)

16

(110)

11

(76)

148

(1,020)

90

(621)

58

(400)

37

(255)

Two-Way Normally Closed or

Three-Way N.C. Port

(with 0 psig Supply)

Spring Range (psig)

2

3 to 6

(21 to 41)

100

(689)

100

(689)

49

(338)

29

(200)

17

(117)

10

(69)

6

(41)

4

(28)

70

(483)

40

(276)

25

(172)

16

(110)

(28 to 55)

4 to 8

142

(978)

142

(978)

68

(469)

41

(282)

25

(172)

14

(96)

9

(62)

6

(41)

96

(662)

55

(379)

34

(234)

21

(145)

1

9 to 13

(62 to 90)

348

(2,398)

348

(2,398)

168

(1,158)

100

(689)

(448)

(255)

(158)

(96)

223

(1,536)

128

(883)

(545)

(345)

65

37

23

14

79

50

1. The recommended spring ranges for use with a V-9502 Positioner are: 3 to 6 psig (21 to 41 kPa) and 3 to 7 psig

(21 to 48 kPa) for N.O. valves, 9 to 13 psig (62 to 90 kPa) for N.C. valves, and 4 to 8 psig (28 to 55 kPa) for three-way valves.

2. 3 to 7 psig (21 to 48 kPa) for MP82 Actuators.

Table 10: Brass Trim – Maximum Fluid Temperature for Pneumatically Actuated Valves

Actuator Style Water Saturated Steam

V-3801-8001 248°F (120°C) 15 psig (103 kPa)

V-3000-8012 284°F (140°C) 38 psig (262 kPa)

V-3000-8003 248°F (120°C) 15 psig (103 kPa)

MP82 284°F (140°C) 38 psig (262 kPa)

VG7000 Series Bronze Control Valves Product Bulletin 11

Page 12

Table 11: Stainless Steel Trim – Maximum Closeoff Pressure, psig (kPa) for Pneumatically Actuated Valves

Actuator

Style

V-3000-8012

and

V-3000-8003

(338°F

[170°C])

MP82

(338°F

[170°C])

MP84

(338°F

[170°C])

3

3

3

Valve

Size, in.

(DN)

SS Trim

1/2

(DN15)

3/4

(DN20)

1

(DN25)

1-1/4

(DN32)

1/2

(DN15)

3/4

(DN20)

1

(DN25)

1-1/4

(DN32)

1-1/2

(DN40)

2

(DN50)

1-1/2

(DN40)

2

(DN50)

Maximum

Cv (Kv)

Factor

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

11.6

(10)

18.5

(16)

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

11.6

(10)

18.5

(16)

28.9

(25)

46.2

(40)

28.9

(25)

46.2

(40)

Two-Way Normally Open or

Three-Way N.O. Port

(with 20 psig Supply)

Spring Range (psig

2

3 to 6

(21 to 41)

299

(2,060)

299

(2,060)

169

(1,164)

108

(744)

67

(462)

41

(282)

308

(2,124)

308

(2,124)

308

(2,124)

308

(2,124)

209

(1,440)

128

(882)

82

(565)

52

(358)

165

(1,137)

106

(730)

4 to 8

(28 to 55)

255

(1,757)

255

(1,757)

144

(992)

92

(634)

57

(393)

35

(241)

308

(2,124)

308

(2,124)

308

(2,124)

304

(2,095)

193

(1,330)

118

(813)

75

(517)

48

(331)

152

(1,047)

97

(668)

(62 to 90)

1

)

9 to 13

143

(985)

143

(985)

81

(558)

52

(358)

32

(220)

19

(131)

308

(2,124)

308

(2,124)

275

(1,895)

175

(1,206)

111

(765)

68

(469)

43

(296)

28

(193)

88

(606)

56

(386)

Two-Way Normally Closed or

Three-Way N.C. Port

(with 0 psig Supply)

Spring Range (psig)

2

3 to 6

(21 to 41)

75

(517)

75

(517)

36

(248)

22

(152)

13

(90)

7

(48)

280

(1,929)

280

(1,929)

135

(930)

81

(558)

53

(365)

30

(207)

19

(131)

12

(83)

39

(269)

24

(154)

(28 to 55)

4 to 8

106

(730)

106

(730)

51

(351)

31

(214)

19

(131)

11

(76)

308

(2,124)

308

(2,124)

183

(1,261)

109

(751)

72

(496)

41

(282)

25

(172)

16

(110)

53

(365)

33

(227)

1

9 to 13

(62 to 90)

(1,798)

(1,798)

(868)

(517)

(338)

(193)

(2,124)

(2,124)

(2,124)

(136)

(1,158)

(661)

(407)

(255)

(834)

(524)

261

261

126

75

49

28

308

308

308

252

168

96

59

37

121

76

1. The recommended ranges for use with a V-9502 Positioner are: 3 to 6 psig (21 to 41 kPa) and 3 to 7 psig (21 to 48 kPa) for

N.O. valves, 9 to 13 psig (62 to 90 kPa) for N.C. valves, and 4 to 8 psig (28 to 55 kPa) for three-way valves.

2. 3 to 7 psig (21 to 48 kPa) for MP82 and MP84 Actuators.

3. The maximum closeoff pressure listed is limited to the maximum allowable American Nati onal Standards Institute (ANSI)

valve body rating corresponding to the maximum temperature rating (308 psig [2,122 kPa] at 338°F [170°C]) of the valve.

VG7000 Series Bronze Control Valves Product Bulletin12

Page 13

Table 12: Brass Trim – Maximum Closeoff Pressures, psig (kPa) for PDTC Two-Way and PDTC Port for

1

3/4

(DN20)

1

(DN25)

2

1-1/4

(DN32)

1-1/2

(DN40)

2

(DN50)

Valve

Size,

Three-Way Electrically Actuated Valves

284°F (140°C) Maximum Fluid Temperature

1/2

(DN15)

in. (DN)

Maximum

Cv (Kv)

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

11.6

(10.0)

18.5

(16.0)

28.9

(25.0)

46.2

(40.0)

Factor

VA-715x 345

(2,377)

VA-720x --- --- --- --- 179

VA-4233 345

(2,377)

VA78x0 --- --- --- --- 182

VA-8x2x 112

(772)

1. The maximum closeoff pressure listed is limited to the maximum allowable ANSI valve body rating corresponding to the

maximum temperature rating (345 psig [2,377 kPa] at 281°F [138°C]) of the valve, except for VA-8x2x Actuators that are

limited to 195°F (91°C) maximum temperature and 381 psig (2,625 kPa) pressure rating.

The maximum closeoff pressures listed are for actuators coupled to the appropriate mounting kits listed in Table 7 and

Table 8. See Table 16 and Table 17 for valid factory-mounted combinations, and Table 7 and Table 8 for available field

mounting kits.

2. The maximum fluid temperature is 284°F (140°C) water to 38 psig (262 kPa) saturated steam except for the following:

VA-4233 Actuators are limited to 35 to 250°F (2 to 121°C) water to 15 psig (103 kPa) saturated steam.

VA-8x2x Actuators are limited to 195°F (91°C) water, and are not rated for steam applications.

345

(2,377)

345

(2,377)

80

(551)

216

(1,488)

208

(1,433)

45

(310)

138

(951)

132

(909)

29

(200)

86

(593)

(1,233)

63

(434)

(1,254)

--- --- --- ---

52

(358)

109

(751)

38

(262)

111

(765)

34

(234)

70

(482)

--- ---

71

(489)

21

(145)

45

(310)

46

(317)

Table 13: Brass Trim – Maximum Closeoff Pressures, psig (kPa) for PDTO Two-Way and PDTO Port for

Three-Way Electrically Actuated Valves

1,2

Not Available Factory Coupled for PDTO Two-Way — Field Mounting Only

3

1-1/4

(DN32)

1-1/2

(DN40)

2

(DN50)

Valve

Size,

284°F (140°C) Maximum Fluid Temperature

1/2

(DN15)

3/4

(DN20)

(DN25)

1

in. (DN)

Maximum

Cv (Kv)

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

11.6

(10.0)

18.5

(16.0)

28.9

(25.0)

46.2

(40.0)

Factor

VA-715x 345

(2,377)

VA-720x --- --- --- --- 209

VA-4233 345

(2,377)

VA78x0 --- --- --- --- 213

VA-8x2x 345

(2,377)

345

(2,377)

345

(2,377)

112

(772)

257

(1,171)

173

(1,192)

54

(372)

153

(1,054)

103

(710)

32

(220)

100

(690)

(1,440)

66

(455)

(1,468)

--- --- --- ---

57

(393)

120

(827)

38

(262)

122

(841)

36

(248)

74

(510)

--- ---

76

(524)

22

(152)

46

(317)

47

(324)

VG7000 Series Bronze Control Valves Product Bulletin 13

Page 14

1. The maximum closeoff pressure listed is limited to the maximum allowable ANSI valve body rating corresponding to the

maximum temperature rating (345 psig [2,377 kPa] at 281°F [138°C]) of the valve, except for VA-8x2x Actuators that are

limited to 195°F (91°C) maximum temperature and 381 psig (2,625 kPa) pressure rating.

The maximum closeoff pressures listed are for actuators coupled to the appropriate mounting kits listed in Table 7 and

Table 8. See Table 16 and Table 17 for valid factory-mounted combinations, and Table 7 and Table 8 for available field

mounting kits.

2. The VA-715x, VA-720x, and VA-8x2x are not available factory coupled for PDTO two-way. These are available for field

mounting only.

3. The maximum fluid temperature is 284°F (140°C) water to 38 psig (262 kPa) saturated steam except for the following:

VA-4233 Actuators are limited to 35 to 250°F (2 to 121°C) water to 15 psig (103 kPa) saturated steam. VA-8x2x Actuators

are limited to 195°F (91°C) water, and are not rated for steam applications.

Table 14: Stainless Steel Trim – Maximum Closeoff Pressures, psig (kPa) for PDTC Two-Way and PDTC

Valve

Size,

Port for Three-Way Electrically Actuated Valves

338°F (170°C) Maximum Fluid Temperature

1/2

(DN15)

(DN20)

3/4

1

1

(DN25)

2

1-1/4

(DN32)

1-1/2

(DN40)

2

(DN50)

in. (DN)

Maximum

Cv (Kv)

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

11.6

(10.0)

18.5

(16.0)

28.9

(25.0)

46.2

(40.0)

Factor

VA-715x 239

(1,647)

VA-720x 308

(2,122)

VA-4233 230

(1,585)

VA78x0 308

(2,122)

1. The maximum closeoff pressure listed is limited to the maximum allowable ANSI valve body rating corresponding to the

maximum temperature rating (308 psig [2,122 kPa] at 338°F [170°C]) of the valve.

The maximum closeoff pressures listed are for actuators coupled to the appropriate mounting kits listed in Table 7 and

Table 8. See Table 16 and Table 17 for valid factory-mounted combinations, and Table 7 and Table 8 for available field

mounting kits.

2. The maximum fluid temperature is 338°F (170°C) water to 100 psig (690 kPa) saturated steam except for the following:

VA-4233 Actuators are limited to 35 to 250°F (2 to 121°C) water to 15 psig (103 kPa) saturated steam.

239

(1,647)

308

(2,122)

230

(1,585)

308

(2,122)

135

(930)

278

(1,915)

130

(896)

283

(1,950)

86

(593)

177

(1,220)

82

(565)

180

(1,240)

54

(372)

112

(772)

39

(269)

114

(785)

33

(227)

68

(469)

24

(165)

70

(482)

21

(145)

44

(303)

--- ---

45

(310)

13

(90)

28

(193)

28

(193)

VG7000 Series Bronze Control Valves Product Bulletin14

Page 15

Table 15: Stainless Steel Trim – Maximum Closeoff Pressures, psig (kPa) for PDTO Two-Way and PDTO

Port for Three-Way Electrically Actuated Valves

1,2

Not Available Factory Coupled for PDTO Two-Way — Field Mounting Only

3

1-1/4

(DN32)

1-1/2

(DN40)

2

(DN50)

Valve

Size,

338°F (170°C) Maximum Fluid Temperature

1/2

(DN15)

3/4

(DN20)

(DN25)

1

in. (DN)

Maximum

Cv (Kv)

0.73

(0.63)

1.8

(1.6)

4.6

(4.0)

7.3

(6.3)

11.6

(10.0)

18.5

(16.0)

28.9

(25.0)

46.2

(40.0)

Factor

VA-715x 308

(2,122)

VA-720x 308

(2,122)

VA-4233 224

(1,543)

VA78x0 308

(2,122)

1. The maximum closeoff pressure listed is limited to the maximum allowable ANSI valve body rating corresponding to the

maximum temperature rating (308 psig [2,122 kPa] at 338°F [170°C]) of the valve.

The maximum closeoff pressures listed are for actuators coupled to the appropriate mounting kits listed in Table 7 and

Table 8. See Table 16 and Table 17 for valid factory-mounted combinations, and Table 7 and Table 8 for available field

mounting kits.

2. The VA-715x, VA-720x, VA-8x2x are not available factory coupled for PDTO two-way. These are available for field mounting

only.

3. The maximum fluid temperature is 338°F (170°C) water to 100 psig (690 kPa) saturated steam except for the following:

VA-4233 Actuators are limited to 35 to 250°F (2 to 121°C) water to 15 psig (103 kPa) saturated steam.

308

(2,122)

308

(2,122)

224

(1,543)

308

(2,122)

161

(1,109)

308

(2,122)

108

(744)

308

(2,122)

96

(661)

197

(1,357)

64

(441)

201

(1,385)

63

(434)

131

(903)

41

(282)

133

(916)

36

(248)

75

(517)

24

(165)

76

(524)

22

(152)

46

(317)

--- ---

47

(324)

14

(97)

29

(200)

30

(207)

VG7000 Series Bronze Control Valves Product Bulletin 15

Page 16

Table 16: Pneumatic Actuated Valves – Available Factory-Mounted Combinations1 (Part 1 of 2)

Actuator V-3801-8001

Spring

3-6 4-8 9-13 3-6 4-8 9-13 3-6 4-8 9-13 3-6 4-8 9-13 3-6 4-8 9-13

V-3000-8012

2

V-3000-8003

MP82

2

Range

Valve Size,

in. (DN)

1/2 in.

(DN15)

3/4 in.

(DN20)

1 in.

(DN25)

1-1/4 in.

(DN32)

1-1/2 in.

(DN40)

2 in.

(DN50)

Valve Size,

in. (DN)

1/2 in.

(DN15)

3/4 in.

(DN20)

1 in.

(DN25)

1-1/4 in.

(DN32)

1-1/2 in.

(DN40)

2 in.

(DN50)

Valve Size,

in. (DN)

1/2 in.

(DN15)

3/4 in.

(DN20)

1 in.

(DN25)

1-1/4 in.

(DN32)

1-1/2 in.

(DN40)

2 in.

(DN50)

Valve Size,

in. (DN)

1/2 in.

(DN15)

X X X X X X X X X --- --- --- --- --- ---

X X X X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- X X X X X X X X X --- --- ---

--- --- --- --- --- --- --- --- --- X X X X X X

--- --- --- --- --- --- --- --- --- X X X X X X

X X X X X X X X X --- --- --- --- --- ---

X X X X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X --- --- --- --- --- ---

VG7271, VG7291, VG7872, and VG7892 Valves – Brass Trim, Union Sweat End Connections

X X X X X X X X X --- --- --- --- --- ---

VG7241, VG7441, and VG7842 Valves – Brass Trim, NPT End Connections

VG7243, VG7443, and VG7844 Valves – Stainless Steel Trim, NPT End Connections

VG7281, VG7481, and VG7882 Valves – Brass Trim, Union Sweat End Connections

MP84

2

VG7000 Series Bronze Control Valves Product Bulletin16

Page 17

Table 16: Pneumatic Actuated Valves – Available Factory-Mounted Combinations1 (Part 2 of 2)

Actuator V-3801-8001

Spring

3-6 4-8 9-13 3-6 4-8 9-13 3-6 4-8 9-13 3-6 4-8 9-13 3-6 4-8 9-13

V-3000-8012

2

V-3000-8003

MP82

2

Range

Valve Size,

in. (DN)

1/2 in.

(DN15)

3/4 in.

(DN20)

1 in.

(DN25)

1-1/4 in.

(DN32)

1-1/2 in.

(DN40)

1. Stainless steel trim is available only with NPT (i nternal) end connections.

Items shown as --- are not available factory mounted, and not recommended for field assembly.

2. Available with or without a positioner.

X X X X X X X X X --- --- --- --- --- ---

X X X X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X --- --- --- --- --- ---

--- --- --- X X X X X X --- --- --- --- --- ---

VG7251, VG7451 (1/2 in. Only), and VG7551 Valves – Brass Trim, Union Globe

and Union Angle End Connections (No Factory-Mounted Pos it ion e rs Available)

MP84

2

VG7000 Series Bronze Control Valves Product Bulletin 17

Page 18

Table 17: Electrically Actuated Valves – Available Factory-Mounted Combinations

Actuator Non-Spring Return

V A-7150-1001

V A-7152-1001

V A-7153-1001

Valve Size,

in. (DN)

1/2 in. (DN15) X --- X X X ---

3/4 in. (DN20) X --- X X X ---

1 in. (DN25) XX X---X X

1-1/4 in. (DN32) XX X---X X

1-1/2 in. (DN40) X X X --- --- X

2 in. (DN50) X X X --- --- X

Valve Size,

in. (DN)

1/2 in. (DN15) XX X---X X

3/4 in. (DN20) XX X---X X

1 in. (DN25) XX X---X X

1-1/4 in. (DN32) XX X---X X

1-1/2 in. (DN40) X X X --- --- X

2 in. (DN50) X X X --- --- X

Valve Size,

in. (DN)

1/2 in. (DN15) X --- --- X X ---

3/4 in. (DN20) X --- --- X X ---

1 in. (DN25) X X --- --- X ---

1-1/4 in. (DN32) X X --- --- X ---

1-1/2 in. (DN40) X X --- --- --- ---

2 in. (DN50) X X --- --- --- ---

Valve Size,

in. (DN)

1/2 in. (DN15) X --- --- X X ---

Valve Size,

in. (DN)

1/2 in. (DN15) X --- --- --- --- ---

3/4 in. (DN20) X --- --- --- --- ---

1 in. (DN25) X X --- --- --- ---

1-1/4 in. (DN32) X X --- --- --- ---

1-1/2 in. (DN40) X X --- --- --- ---

VG7271, VG7291, VG7872, and VG7892 Valves – Brass Trim, Union Sweat End Connections

VG7251 and VG7551 Valves – Brass Trim, Union Globe and Union Ang le End Connections

V A -7200-1001

V A -7202-1001

V A -7203-1001

VG7241 and VG7842 Valves – Brass Trim, NPT End Connections

VG7243 and VG7844 Valves – Stainless Steel Trim, NPT End Connections

VG7281 and VG7882 Valves – Brass Trim, Union Sweat End Connections

V A7810 -AGA-2

V A7810 -AGC-2

V A7810 -HGA-2

V A7810 -HGC-2

V A-8020-1

V A-8122-1

VA -4233-AGA-2

VA -4233-AGC-2

VA -4233-BGA-2

VA -4233-BGC-2

V A -4233-GGA-2

V A -4233-GGC-2

1

Spring Return

VA7820-HGA-2

VA7820-HGC-2

VA7830-HGA-2

VA7830-HGC-2

2

1. Items shown as --- are not available factory mounted, and not recommended for field assembly. Electric actuators are

available on two-way PDTC and three-way mixing valves only (except the VA-4233-xGx-2 Series, which is available on all

body styles).

2. The VA-4233 Series is available with spring return stem-up only.

VG7000 Series Bronze Control Valves Product Bulletin18

Page 19

Operation

V-3000, V-3801-8001, and MP8000 Series Pneumatic Actuators

Air pressure from a pneumatic controller is applied to

the diaphragm of the actuator, which moves the piston

against the forces of the internal spring and the fluids.

The piston moves the valve plugs to a position where

the diaphragm pressure and the spring force balance

against the fluid forces. These fluid forces cause the

operating ranges to shift from the nominal spring range.

Reducing the air pressure to the diaphragm of the

actuator allows the spring to return the valve plug to its

normal position.

For applications requiring stable, accurate control and

sequencing, the V-3000-8012, MP82, and MP84 are

available with a V-9502 Pneumatic Positioner. The

V-9502 Pneumatic Positioner compensates for the

spring range shift, and the valve operates within the

published range. Refer to the Operation section of the

V-9502 Pneumatic Valve Actuator Positioners Product

Bulletin (LIT-977265) for more details.

To ensure installed performance quality and optim a l

maximum closeoff pressure when using the positioner,

the following spring ranges are recommended:

Normally Open Valve: 3 to 6 psig

(3 to 7 psig for MP82/MP84)

Normally Closed Valve: 9 to 13 psig

Three-Way Mixing Valve:4 to 8 psig

Positioners are factory calibrated to match the nominal

spring range of the actuator and valve assembly.

VA-715x and VA-720x Series Electric Valve Actuators

The V A-715x and V A -720x Series Actuators operate on

24 VAC, and are available for on-off/floating control

action or proportional control. A reversible synchronous

motor and a magnetic clutch are used to accurately

position the valve. The actuator maintains position

even if power to the actuator is removed. The magnetic

clutch maintains a constant load at the end of travel,

which ensures tight valve shutoff and compensates for

seat wear. Refer to the appropriate electric valve

actuator literature for specifications and available

options.

VA-8x2x Series Electric Valve Actuators

The V A- 8x2x Series Actuators ope rate o n 24 VAC, and

are available for on/off, floating, or proportional contr ol.

The signal drives the actuator motor, causing the valve

stem to move in the desired direction. Once the valve

stem reaches the end of travel, a shutoff force builds

up. When the force reaches its maximum, a lever within

the actuator trips a force sensor, which stops the motor .

Field calibration of the force sensor is not required. The

actuator maintains the shutoff force even if power to

the controller is lost. Valve stem positioning can be

accomplished manually by turning the adjustment knob

on the lower right portion of the actuator. Rotating the

adjustment knob counterclockwise moves the valve

stem up. Refer to the appropriate electric valve

actuator literature for specifications and available

options.

VA7810 Series Electric Actuators

The VA7810 Series of non-spring return actuators

operates on 24 VAC and are available for use with

on/off (floating) or proportional controllers. Models are

available with two auxiliary switches and all

proportional models include a 0 (2) to 10 VDC

feedback signal. Proportional models are

self-calibrating and can also be used as an on/off and

floating actuator with a change of switch settings.

The direct mount series of actuators features a manual

override as standard, an IP54 enclosure, a status

Light-Emitting Diode (LED) and a brushless motor for

long life. Refer to the VA7800 Series Electric Valve

Actuators Product Bulletin (LIT-1201 1474) for

specifications and available options.

VA7820/VA7830 Series Electric Actuators

The VA7820 spring return stem up or VA7830 spring

return stem down series of actuators operates on

24 VAC. Actuators are shipped already set for

proportional control but with a simple change of switch

settings, can be changed to on/off or floating control.

The actuators are self-calibrating and come standard

with a 0 (2) to 10 VDC feedback signal, manual

override, an IP54 enclosure, a status LED, and a

brushless motor for long life.

Models with two auxiliary switches are available. Refer

to the VA7800 Series Electric Valve Actuators Product

Bulletin (LIT-12011 474) for specificatio ns and available

options.

VG7000 Series Bronze Control Valves Product Bulletin 19

Page 20

VA-4233 Series Electric Actuators

!

!

!

The VA-4233 Series Electric Actuators operate on

24 VAC or VDC power, and are available for use with

on/off, floating, or proportional controllers. These

actuators incorporate a stepper moto r to accura te ly

position the valve. In the event of a power failure, a

spring in the actuator automatically returns the valve to

the full stem-up position. All models feature a hand

crank for manual positioning of the valve, independent

of a power supply.

Proportional models include an AUTO stroke

calibration feature that enables the actuator to redefine

the selected input signal and feedback proportionally

across the actual valve stroke. Initial application of a

power signal drives the actuator and valve assembly to

the full stem-up position and then the full stem-down

position, and stores these positions in nonvolatile

memory (retains data when power is lost or removed).

The actuator then drives to the position determined by

the applied control signal.

Installation and Servicing

We recommend that the VG7000 Series Valves be

mounted in an upright position in a conveniently

accessible location. Sufficient clearance must be

allowed for actuator removal. See the Dimensions

section for more details. The valve must be piped with

the flow in the direction indicated by the arrow, so that

the plug seats against the flow.

On electrically actuated valve assemblies, input lines to

the actuator must be wired correctly for the valve to

move in the proper direction.

IMPORTANT: Take care to prevent foreign material

such as weld slag, thread burrs, metal chips, and

scale from entering the piping system. This de br is

can damage or severely impede the operation of the

valve by embedding itself in the seats, scoring the

valve, and ultimately resulting in seat leakage. If the

debris becomes embedded in the seats, subseque nt

flushing and filtering of the piping system with the

valve installed does not remedy the problem.

Before servicing a VG7000 Series Bronze Control

Valve, isolate or disconnect the pneumatic supply or

electrical power to the actuator, allow sufficient

clearance for actuator removal from the valve, and note

the following:

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnect or isolation

may be required to completely

de-energize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

WARNING: Risk of Personal Injury.

Shut off the liquid supply and relieve

pressure in the line before servicing the

valve. Contents of liquid lines could be

under pressure and the release of liquid

under pressure may cause severe

personal injury.

Note: VG7000 Serie s Valves should not be used for

fluid service other than those indicated in the Technical

Specifications section.

IMPORTANT: Protect the actuator from dripping

water, condensation, and other moisture. Water or

moisture could result in an electrical short, which

may damage or affect the operation of the actuator.

IMPORTANT: Do not cover the actuator with

thermal insulating material. High ambient

temperatures may damage the actuator, and a hot

water pipe, steam pipe, or other heat source may

overheat it.

VG7000 Series Bronze Control Valves Product Bulletin20

CAUTION: Risk of Property Damage.

Do not apply power to the system before

checking all wiring connections. Short

circuited or improperly connected wires

may result in permanent damage to the

equipment.

IMPORTANT: Make all wiring connections in

accordance with local, national, and regional

regulations. Do not exceed the electrical ratings of

the VG7000 Series Bronze Control Valve.

Page 21

Dimensions

Figure 3: Two-Way and Three-Way Valve Dimensions

Table 18: National Pipe Thread (Internal NPT) Valve Dimensions, in. (mm)

1

Valve Size, in. (DN) A B

N.O./N.C./Three-Way N.O. N.C. Three-Way

1/2 (DN15) 3 (76) 13/16 (21) 1-9/16 (39) 1-13/16 (46)

3/4 (DN20) 3-7/32 (81) 15/16 (24) 1-5/8 (41) 2-1/8 (54)

1 (DN25) 4-1/8 (104) 1-5/32 (29) 1-3/4 (44) 2-9/16 (65)

1-1/4 (DN32) 4-23/32 (119) 1-11/32 (34) 2 (51) 2-25/32 (70)

1-1/2 (DN40) 5-1/8 (130) 2-5/32 (55) 2-3/4 (70) 3-3/8 (85)

2 (DN50) 5-29/32 (150) 2-1/8 (53) 2-27/32 (72) 3-3/4 (95)

1. See Table 22 for overall assembly height C and clearance D dimen s ions.

VG7000 Series Bronze Control Valves Product Bulletin 21

Page 22

Figure 4: Two-Way Union Globe Valve Dimensions

E

F

Fig:unionglobe

G

Table 19: Two-Way Union Globe Valve Dimensions, in. (mm)

1

Valve Size, in. (DN) E F G

1/2 (DN15) N.O./PDTC 1-1/2 (38) 2-21/32 (68) 13/16 (20)

1/2 (DN15) N.C./PDTO 1-1/2 (38) 2-21/32 (68) 1-17/32 (39)

3/4 (DN20) N.O./PDTC

1 (DN25) N.O./PDTC

2

1-1/4 (DN32) N.O./PDTC

1-1/2 (DN40) N.O./PDTC

2

2

2

1-9/16 (40) 3-3/32 (79) 15/16 (24)

2-1/16 (53) 4-1/32 (102) 1-5/32 (29)

2-3/8 (60) 4-19/32 (117) 1-11/32 (34)

2-9/16 (65) 4-27/32 (123) 2-5/32 (55)

1. See Table 22 for overall assembly height C and clearance D dimen sions.

2. Sizes greater than 1/2 in. (DN15) are available in N.O./PDTC Only.

VG7000 Series Bronze Control Valves Product Bulletin22

Page 23

Figure 5: Two-Way Union Angle Valve Dimensions

E

F

Fig:unionangle

G

Table 20: Two-Way Union Angle Valve Dimensions, in. (mm)

1

Valve Size, in. (DN) E F G

1/2 (DN15) N.O./PDTC 1-23/32 (44) 2-21/32 (68) 1-7/8 (48)

3/4 (DN20) N.O./PDTC 1-9/16 (40) 3-3/32 (79) 2- 1/8 (54)

1 (DN25) N.O./PDTC 2-1/16 (53) 4-1/32 (102) 2-9/16 (65)

1-1/4 (DN32) N.O./PDTC 2-3/8 (60) 4-19/32 (117) 2-25/32 (70)

1-1/2 (DN40) N.O./PDTC 2-9/16 (65) 4-27/32 (123) 3-3/8 (85)

1. See Table 22 for overall assembly height C and clearance D dimen s ions.

VG7000 Series Bronze Control Valves Product Bulletin 23

Page 24

Figure 6: Union Sweat Valve Dimensions

A

Fig:unionsweat

B

Table 21: Union Sweat Valve Dimensions, in. (mm)

1

Valve Size, in. (DN) A B

Two-Way N.O./

PDTC

1/2 (DN15), 3/8 in. Tubing 4-3/16 (106) 13/16 (20) 1-17/32 (39) 2-17/32 (64)

1/2 (DN15), 1/2 in. Tubing 4-3/16 (106) 13/16 (20) 1-17/32 (39) 2-17/32 (64)

1/2 (DN15), 3/4 in. Tubing 4 -2 5/32 (122) 13/16 (20) 1-17/32 (39) 2-17/32 (64)

3/4 (DN20) 5-1/16 (129) 15/16 (24) 1-9/16 (40) 3 - 1/4 (82)

1 (DN25) 6-3/32 (155) 1-5/32 (29) 1-3/4 (44) 3-23/32 (94)

1-1/4 (DN32) 7-9/32 (185) 1-11/32 (34) 2 (51) 4-3/32 (104)

1-1/2 (DN40) 8-19/32 (218) 2-5/32 (55) 2-3/4 (70) 4-29/32 (125)

2 (DN50) 9-7/16 (240) 2-1/8 (53) 2-27/32 (72) 5-19/32 (142)

1. See to Table 22 for overall assembly height C and clearance D dimensions.

Two-Way N.C./

PDTO

Three-Way

Mixing

VG7000 Series Bronze Control Valves Product Bulletin24

Page 25

Table 22: Valve Assembly Dimensions, in. (mm)

Actuator

Type

Brass Trim Valve Assemblies

V-3000-8012

V-3000-8003

V-3801-8001

MP82xx,

MP83xx

VA-4233

VA-715x

VA-720x

VA-8x2x

VA78x0 --- ---

Stainless Steel Trim Valve Assemblies

V-3000-8012

V-3000-8003

MP82xx

MP83xx

MP84xx

MP85xx

VA-4233

VA-715x

VA-720x

VA78x0

1/2 in.

(DN15)

4-3/4

(120)

5-11/32

(135)

4

(102)

--- --- 12-23/32

8-15/32

(215)

7-11/16

(195)

--- --- 10-7/16

6-7/16

(164)

5-7/16

(138)

6-1/16

(153)

12-3/4

(324)

12-21/64

(313)

--- --- --- --- 17-7/32

--- --- --- --- 15-61/64

8-23/32

(221)

8-13/32

(214)

9-3/32

(231)

11-15/32

(291)

3/4 in.

(DN20)

4-3/4

(120)

5-11/32

(135)

4

(102)

8-15/32

(215)

7-11/16

(195)

6-7/16

(164)

2

5-7/16

(138)

6-1/4

(158)

13-17/64

(337)

12-35/64

(319)

8-15/16

(227)

8-5/8

(219)

9-5/16

(236)

11-11/16

(297)

1in.

(DN25)

5-31/32

(151)

6-9/16

(166)

(323)

9-7/16

(240)

8-21/32

(220)

(265)

11-23/32

(298)

(152)

6-19/32

(167)

13-39/64

(346)

12-7/8

(327)

9-9/32

(236)

8-31/32

(228)

9-21/32

(245)

12-19/32

(320)

1

C

1-1/4 in.

(DN32)

5-7/8

(149)

6-19/32

(167)

--- --- --- --- 2-3/8

12-27/32

(326)

9-9/16

(243)

8-25/32

(223)

10-17/32

(268)

--- --- --- --- 1-1/2

11-27/32

(301)

6

6-1/4

(158)

6-27/32

(173)

13-27/32

(352)

13-1/8

(333)

9-13/16

(249)

9-7/32

(234)

9-7/8

(251)

12-27/32

(326)

1-1/2 in.

(DN40)

5-13/16

(147)

6-13/32

(162)

13-13/32

(341)

--- --- 1-1/2

9-11/32

(238)

11-1/8

(283)

12-13/32

(315)

--- --- 3-9/16

--- --- 3-9/16

14-1/32

(356)

13-19/64

(338)

(437)

(405)

--- --- 1-1/2

9-13/32

(239)

10-3/32

(256)

13-1/32

(331)

2in.

(DN50)

6-3/16

(157)

6-13/16

(172)

13-13/16

(351)

9-3/4

(248)

11-1/2

(293)

12-13/16

(325)

14-15/64

(361)

13-1/2

(343)

17-27/64

(443)

16-5/32

(410)

9-5/8

(244)

10-9/32

(261)

13-1/4

(336)

1

D

3-9/16

(90)

3-9/16

(90)

(60)

3-1/2

(89)

(38)

2-1/2

(64)

4-1/2

(114)

(38)

4-1/2

(114)

(90)

(90)

3-1/2

(89)

3-1/2

(89)

3-1/2

(89)

3-1/2

(89)

(38)

2-1/2

(64)

4-1/2

(114)

4-1/2

(114)

1. Dimension C is the overall height above the centerline of the valve body and dimension D is the clearance required for

actuator removal (as illustrated in Figure 3).

2. An extended bonnet comes as standard equipment on VG7000 Series Bronze Control Valves with stainless steel trim,

to allow for higher fluid temperatures (100 psig [689 kPa] saturated steam at 338°F [170°C]).

VG7000 Series Bronze Control Valves Product Bulletin 25

Page 26

Repair Information

If the VG7000 Series Bronze Control Valve fails to

operate within its specifications, see the Maintenance

and Accessories and Reconditioning Kits sections for a

Maintenance and Accessories

The maintenance parts available for the

VG7000 S er ies Valves are listed in Table 23. See

Table 24 for a list of available accessories.

list of repair parts and recondition ing kits available. For

a replacement valve, contact the nearest

Johnson Controls representative.

Table 23: Maintenance Parts (Order Separately)

Code Number Description

VG7000-6001 Ring Pack Packing Kits for Brass Trim Valves:

Single Pack for 1/4 in. Stem (1/2 or 3/4 in. Valves)

Kit Includes: two ring packs (U-cup with installed O-ring), one stem wiper, one insertion/

removal tool, one bullet, one grease tube, and one 3 in. (76 mm) strip of crocus cloth

VG7000-6002 Single Pack for 3/8 in. Stem (1 through 2 in. Valves)

Kit includes: two ring packs (U-cup with installed O-ring), one stem wiper, one stem guide, one

insertion/removal tool, one sleeve packing installer, one grease tube, and one 3 in. (76 mm)

strip of crocus cloth

VG7000-6011 PTFE V-Ring Packing Kits for Stainless Steel Trim Valves:

Single Pack for 1/4 in. Stem, SS Trim (1/2 or 3/4 in. Valves)

Kit includes: two Teflon® V-rings, one rubber V-ring, two Teflon stem wipers, one Teflon stem

guide, one Teflon bushing, one steel washer, one spring, one insertion/removal tool, one

bullet, one grease tube, and one 3 in. (76 mm) strip of crocus cloth

VG7000-6012 Single Pack for 3/8 in. Stem, SS Trim (1 through 2 in. Valves)

Kit includes: two Teflon V-rings, one rubber V-ring, two Teflon stem wipers, one Teflon stem

guide, one Teflon bushing, one steel washer, one spring, one insertion/removal tool, one

sleeve packing installer, one grease tube, and one 3 in. (76 mm) strip of crocus cloth

VG7000 Series Bronze Control Valves Product Bulletin26

Page 27

Table 24: Accessories (Order Separately)

1

Code Number Description

--- For specific actuator code numbers, refer to appropriate product bulletins.

--- For mounting and linkage kits, see Tables 6, 7, 8, and 9 in this document.

EP-8000-1 EP Transducer, Low Volume, 0.5 to 9 VDC

EP-8000-2 EP Transducer, High Volume, 0.25 to 9.5 VDC

EP-8000-3 EP Transducer, Low Volume, 4 to 20 mA DC

EP-8000-4 EP Transducer, High Volume, 4 to 20 mA DC

EP-8000-101 EP-8000 Electro-Pneumatic Transducer Mounting Kit

R-3710 0.007 in. Restrictor (Required for Low Volume EP-8000 Models)

A-4000-1037 Inline Air Filter (Required for all EP-8000 Models)

JC 5361 Hypodermic Needle Test Probe Assembly

G-2010 0 to 30 psig (0 to 207 kPa) Gauge

VA-8000-102 Valv e Position Indicator for Electrically Actuated Valves with VA-805x Actuators Only

VG7000-1016 Bonnet Adaptor for V-3000 Style Linkages on 1 through 2 in. VG7000 Series Valves

V-3000-600 Replacement Diaphragm for V-3000-8012

V-3000-6001 Replacement Diaphragm for V-3000-8003

V-9502-90 Pne umatic Positioner (Less Spring) for V-3000-8012

V-9502-91 Pne umatic Positioner (Less Spring) for V-3000-8001

V-9502-6801 5/16 in. (8 mm) Stroke for 1/2 or 3/4 in. Valve – 3 psig (21 kPa) Span

V-9502-6802 5/16 In. (8 mm) Stroke for 1/2 or 3/4 in. Valve – 8 psig (55 kPa) Span

V-9502-6801 1/2 in. (13 mm) Stroke for 1 or 1-1/4 in. Valve – 5 psig (34 kPa) Span

V-9502-6802 1/2 in. (13 mm) Stroke for 1 or 1-1/4 in. Valve – 12 psig (83 kPa) Span

V-9502-6801 3/4 in. (19 mm) Stroke for 1-1/2 or 2 in. Valve – 10 psig (69 kPa) Span

V-9502-6803 3/4 in. (19 mm) Stroke for 1-1/2 or 2 in. Valve – 4 psig (28 kPa) Span

V-9502-95 Pne umatic Positioner (Less Spring and Mounting Hardware)

MP8000-6002 V-9502 Pneumatic Positioner Mounting Kit with Springs

EPP-1000-8 Electro-Pneumatic Positioner (Less Mounting Hardware)

MP8000-6003 EPP-1000 Electro-Pneumatic Positioner Mounting Kit

V-9502-76 Pneumatic Positione r (Less Spring)

V-9502-8100 5/16 in. (8 mm) Stroke for 1/2 or 3/4 in. Valve – Adjustable 3 to 12 psig (21 to 83 kPa) Span

V-9502-8102 1/2 in. (13 mm) Stroke for 1 or 1-1/4 in. Valve – Adju stable 3 to 12 psig (21 to 83 kPa) Span

V-9502-8106 3/4 in. (19 mm) Stroke for 1-1/2 or 2 in. Valve – Adjustable 3 to 12 psig (21 to 83 kPa) Span

(Required when Converting from an M100 Series Actuator to an M9x16, VA-4233, VA-715x,

or VA-720x Series Actuator)

Positioners for V-3000-8001 and V-3000-8012:

Positioner Feedback Springs for V-3000-8001 and V-3000-8012:

Positioners and Positioner Accessories for MP8000 Series Actuators:

Positioner and Feedback Springs for V-400 and V-500 Actuators:

1. Positioner accessory kits include positioner and all the appropriate mounting hardware, ex cluding the positioner feedback

spring that must be ordered separately.

VG7000 Series Bronze Control Valves Product Bulletin 27

Page 28

Reconditioning Kits

Table 25: Ordering Data – VG7000 Series Reconditioning Kits

V G Valve Global

1 2 7 Product Family 7 = Cast Bronze

3 4 Body Type 2 = Two-Way, Normally Open/Push-Down-to-Close

4 4 = Two-Way, Normally Closed/Push-Down-to-Open

8 = Three-Way Mixing

K Reconditioning K = Inner Valve Reconditioning Kits

5 Kits (Includes: bonnet, bonnet nut, packing, stem, plug, disk, and seat; replaceable

1 Trim and Flow 1 = Brass Equal Percentage (All Two-Way and 1/2 in. Three-Way)

6 Characteristic 2 = Brass Linear (Two-Way Union Angle and All Three-Way)

RSize andC = 1/2 in., 0.73 Cv (0.63 Kv)

7 Cv (Kv) E = 1/2 in., 1.8 Cv (1.6 Kv)

T Stem Type T = Standard Threaded Stem (All Except V-3801, V-500, MP84, VA-8x2x)

8 S = Slotted Stem and Small Bonnet (Factory-Mounted V-3801, VA-8x2x Only)

+Optional+ = Lower Body Option (For 1-1/2 and 2 in. Bodies Only)

9 Lower Body (Leave Fields 9 and 10 blank for 1/2 through 1-1/4 in. kits and for 1-1/2 and

W N.C. Valve W = Two-Way Bottom Cap

10 Bottom Cap (For 1-1/2 and 2 in. valves, it is recommended that a new bottom cap is ordered

4 Three-Way 4 = NPT

10 Lower Body (For 1-1/2 and 2 in. valves, it is recommended that a lower body with matching

seat is available for stainless steel trim valves only.)

3 = Stainless Steel Equal Percentage (Two-Way Only)

4 = Stainless Steel Linear (Three-Way Only)

G = 1/2 in., 4.6 Cv (4.0 Kv)

L = 3/4 in., 7.3 Cv (6.3 Kv)

N = 1 in., 11.6 Cv (10.0 Kv)

P = 1-1/4 in., 18.5 Cv (16.0 Kv)

R = 1-1/2 in., 28.9 Cv (25.0 Kv)

S = 2 in., 46.2 Cv (40.0 Kv)

L = Large Threaded Stem (Factory-Mounted V-500 Only)

M = Large Threaded Stem (Factory-Mounted MP84 Only)

2 in. kits without lower body.)

with the reconditioning kit.)

end connection is ordered with the reconditioning kit.)

1 2345678910 = Field Example: Cast bronze valve, two-way, normally closed/push-down-to-open,

V G7 4K1RT+4

Reconditioning Kit + 1-1/2 or 2 in. Bottom Cap/

Lower Body

brass trim, equal percentage, 1-1/2 in., 28.9 Cv, standard threaded stem, with a

three-way lower body.

VG7000 Series Bronze Control Valves Product Bulletin28

Page 29

The reconditioning kits for VG7000 Series Valves

include all the components necessary to return a valve

to near new condition. These kits are available

according to the convenient features and options

format shown in Table 25. This section provides a list of

the components included in each kit. Note that

1-1/2 and 2 in. two-way N.C. and three-way valves

incorporate a stem guide in the bottom body of the

valve.

For N.O./PDTC valves with brass trim, the kit contains

the bonnet, packing, and stem and plug assembly.

For N.O./PDTC valves with stainless steel trim, the kit

contains:

• preassembled bonnet, packin g, and stem and plu g

assembly

• stainless steel seat

For N.C./PDTO and three-way valves with stainless

steel trim, the kit contains:

• bonnet, packing, stem and plug assembly

• stainless steel seat (two for three-way valves)

For N.C./PDTO and three-way valves with brass trim,

the kit contains the bonnet, packing, and stem and plug

assembly.

Technical Specifications

VG7000 Series Bronze Control Valves1 (Part 1 of 3)

Service

Valve Body Size/Cv (kv) 1/2 in. 0.73 (0.63), 1.8 (1.6), and 4.6 (4.0)

Valve Stroke 5/16 in. (8 mm) for 1/2 or 3/4 in. Valves

Valve Body Rating Meets Requirements of ANSI B16.15, Class 250 (EN 12360).

Valve Ambient Operating

Temperature Limits

Valve Assembly Maximum

Allowable Pressure/

Temperature

Leakage Brass Trim 0.01% of Maximum Flow per ANSI/FCI 70-2, Class 4

2

3/4 in. 7.3 (6.3)

1 in. 11.6 (10)

1-1/4 in. 18.5 (16)

1-1/2 in. 28.9 (25)