Page 1

Product Bulletin

Issue Date November 15, 2013

Supersedes October 30, 2012

VG2000 Series Cast Iron Flanged Globe Valves

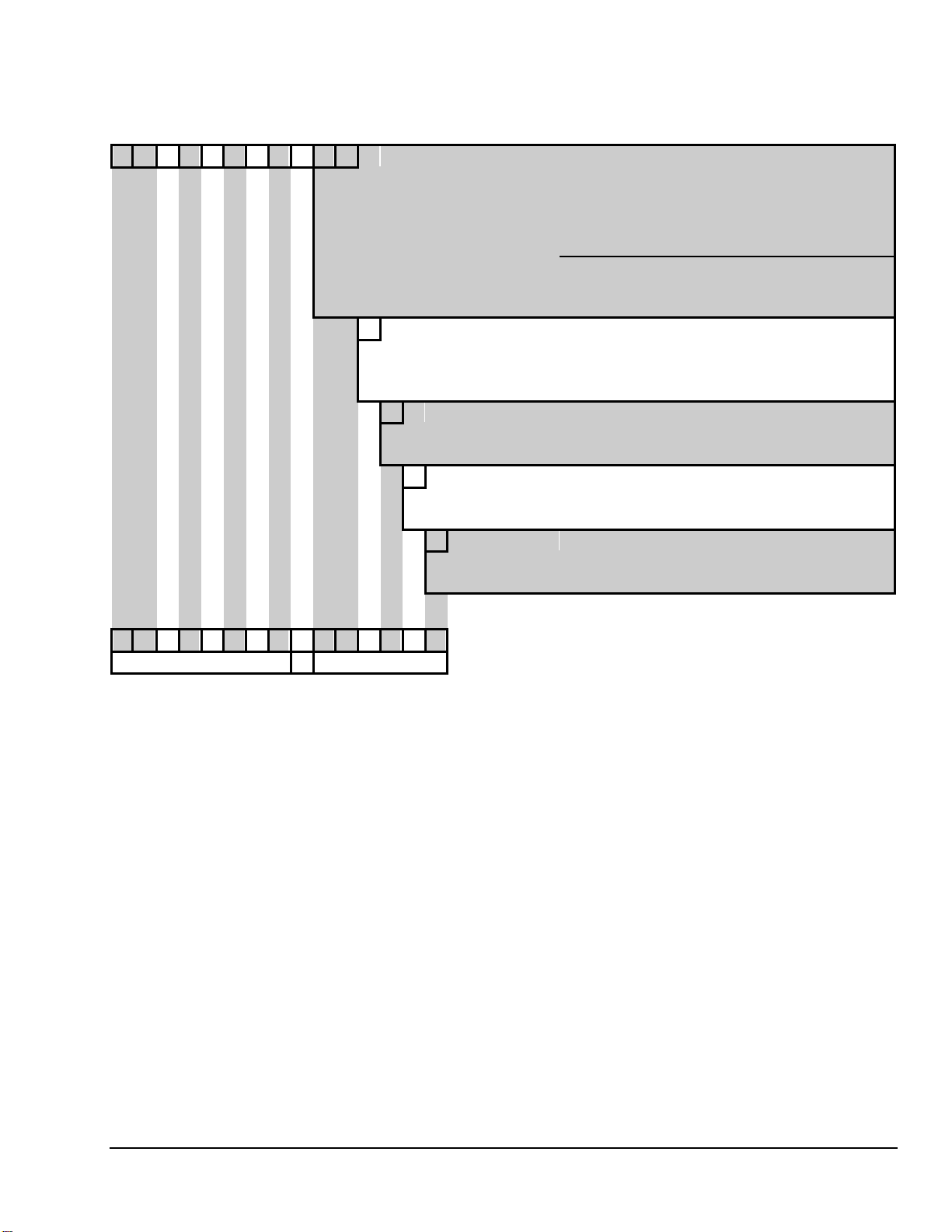

VG2000 Series Cast Iron Flanged Globe Valves are

designed primarily to regulate the flow of water and

steam in response to the demand of a controller in

Heating, Ventilating, and Air Conditioning (HVAC)

systems. Available in sizes 2-1/2 through 6 in., these

ANSI Class 125 valves are available in Normally Open

(N.O.), Normally Closed (N.C.), and three-way mixing

configurations. Both electric and pneumatic actuators

are available for factory or field mounting.

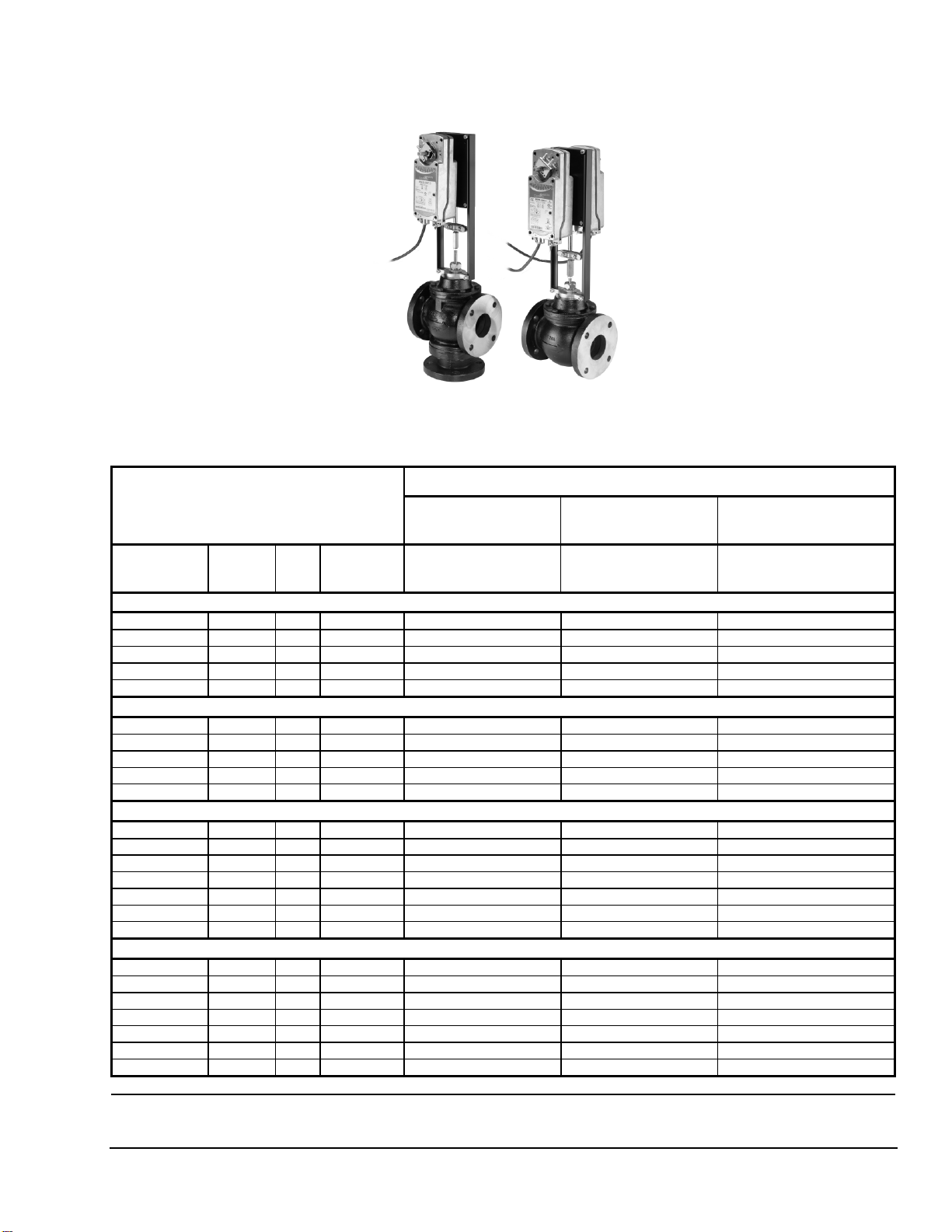

Figure 1: VG2000 Series

Cast Iron Flanged Globe Valves

Features and Benefits

Complete Family of 2-1/2

through 6 in. Cast Iron

Flanged Globe Valves,

Brass Trim, with Several

Styles of Electric and

Pneumatic Actuators

Flexible Features and

Options Ordering Matrix

Standard

Johnson Controls®

Ring Pack Packings

Every Valve Tested for

Leakage

Offers a broad selection from which to choose

Allow engineering to suit your specific

application from thousands of easy-to-select,

factory-assembled combinations

Provide industry-leading reliability and

operating life

Provides energy conservation and ensures

occupant comfort

© 2013 Johnson Controls, Inc. 1

Code No. LIT-977133 www.johnsoncontrols.com

Page 2

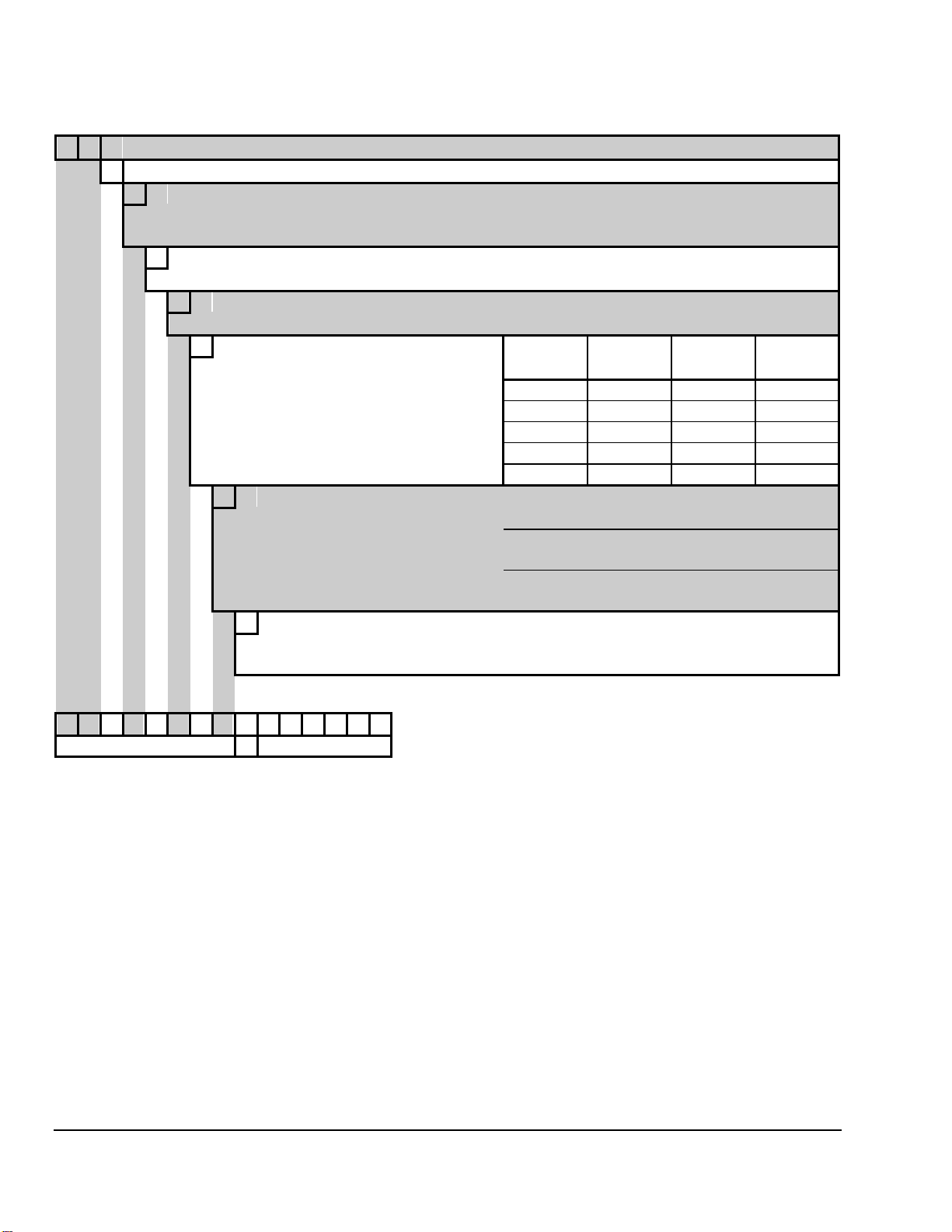

Table 1: Ordering Data — VG2000 Series Cast Iron Flanged Globe Valves

y

V G Valve Global

1 2

2 Product Family

3

2 Body Type

4

3

5

1

6

End

Connections

Trim and Flow

Characteristics

T Size and Cv

7

(Kv = Cv x 0.857)

M Stem Type

8

+

9

Actuator

Mounting

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 = Field

V G 2 2 3 1 T M +

Valve + Actuator

Example: Cast iron valve; two-way, normally open/push-down-to-close;

flat-faced flanged end connections; brass trim; modified linear;

2-1/2 in.; 51.0 Cv, 3/8 in. threaded stem.

Note: See Table 2 when adding a factory-mounted pneumatic actuator to a valve body. See Table 3 and Table 4

when adding a factor

-mounted electric actuator to a valve body. For valid actuator and valve combinations, see Table 5.

2 = Cast Iron

2 = Two-Way, Normally Open/Push-Down-To-Close

4 = Two-Way, Normally Closed/Push-Down-To-Open

8 = Three-Way Mixing

3 = ANSI Class 125 Flat-Faced Flanged

1 = Brass, Modified Linear

Valve Two-Way Two-Way Three-Way

Size N.O./PDTC N.C./PDTO Mixing

T = 2-1/2 in. 51.0 54.0 54.0

U = 3 in. 83.0 83.0 80.0

V = 4 in. 150.0 150.0 157.0

W = 5 in. 240.0 237.0 238.0

Y = 6 in. 350.0 344.0 347.0

L = 3/8 in. Threaded Stem

(2-1/2 and 3 in. N.O. Valves with MP82 Actuator Only)

M = 3/8 in. Threaded Stem

(2-1/2 through 4 in. Valves Only)

N = 1/2 in. Threaded Stem

(3 through 6 in. Valves Only)

+ = Factory-Mounted Actuator (See Tables 2 and 3.)

(Leave fields 9 through 15 blank for valve without a

factory-mounted actuator.)

2 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 3

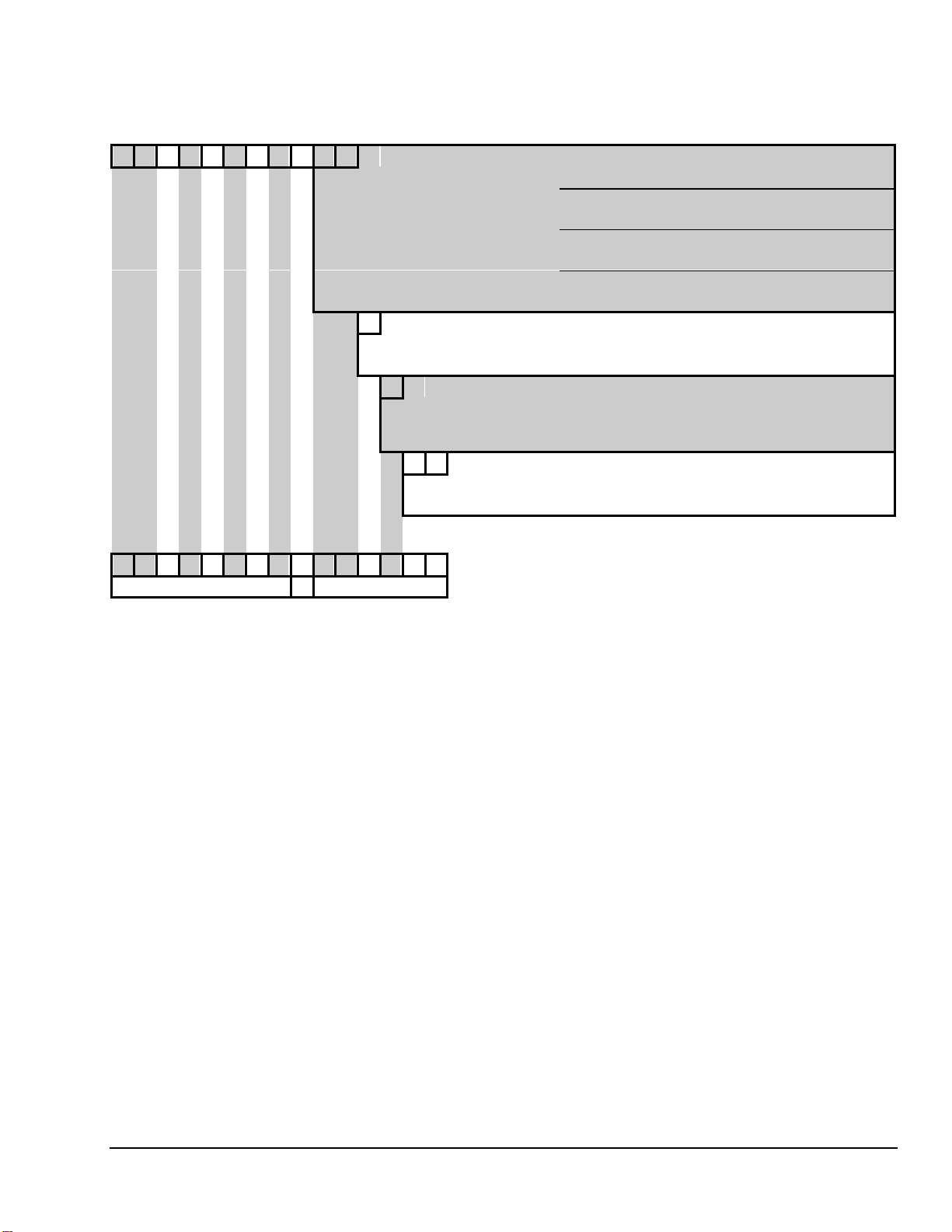

Table 2: Ordering Data — Adding a Factory-Mounted Pneumatic Actuator

V G 2 2 3 1 T L + 8 2 MP8000 Series

1 2 3 4 5 6 7 8 9 10 11

Pneumatic

Actuator

(See Actuator

Product Bulletin.)

3 Stroke

12

(MP8000 Series)

C Spring Range

13

(MP8000 Series)

0 1 Accessories

14 15

(MP8000 Series)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 = Field

V G 2 2 3 1 T L + 8 2 3 C01

Valve + Actuator

Example: Cast iron valve; two-way, normally open; flat-faced flanged

end connections; brass trim; modified linear; 2-1/2 in.; 51.0 Cv; 3/8 in.

threaded stem; MP82 Pneumatic Actuator; 3/4 in. stroke; 3 to 7 psig

spring range with factory-mounted V-9502 Positioner.

Note: See Table 1 when ordering a valve body only. See Table 3 and Table 4 when adding a factory-mounted electric

actuator to a valve body. For valid actuator and valve combinations, see Table 5 through Table 12.

82 = MP82, 25 sq. in., Spring-Return-Up

(2-1/2 and 3 in. N.O. Valves with “L” Stem)

84 = MP84, 50 sq. in., Spring-Return-Up

(All 2-1/2 through 4 in. Valves with “M” Stem)

86 = MP86, 100 sq. in., Spring-Return-Up

(All 3 through 6 in. Valves with “N” Stem)

(Note: Only spring-return-up models of MP8000 Series Actuators are

available factory mounted to VG2000 Series Cast Iron Valves.)

3 = 3/4 in.

5 = 1-1/8 in.

7 = 1-1/2 in.

(2-1/2 and 3 in. Valves with MP82 or MP84 Actuators Only)

(3 and 4 in. Valves with MP84 or MP86 Actuators Only)

(5 and 6 in. Valves with MP86 Actuator Only)

C = 3 to 7 psig (Suggested for N.O. Valves with Positioner)

D = 4 to 8 psig (Suggested for Three-Way Valves with

Positioner)

E = 9 to 13 psig (Suggested for N.C. Valves with Positioner)

00 = None

01 = V-9502 Pneumatic Positioner

02 = EPP-1000 Electro-Pneumatic Positioner

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 3

Page 4

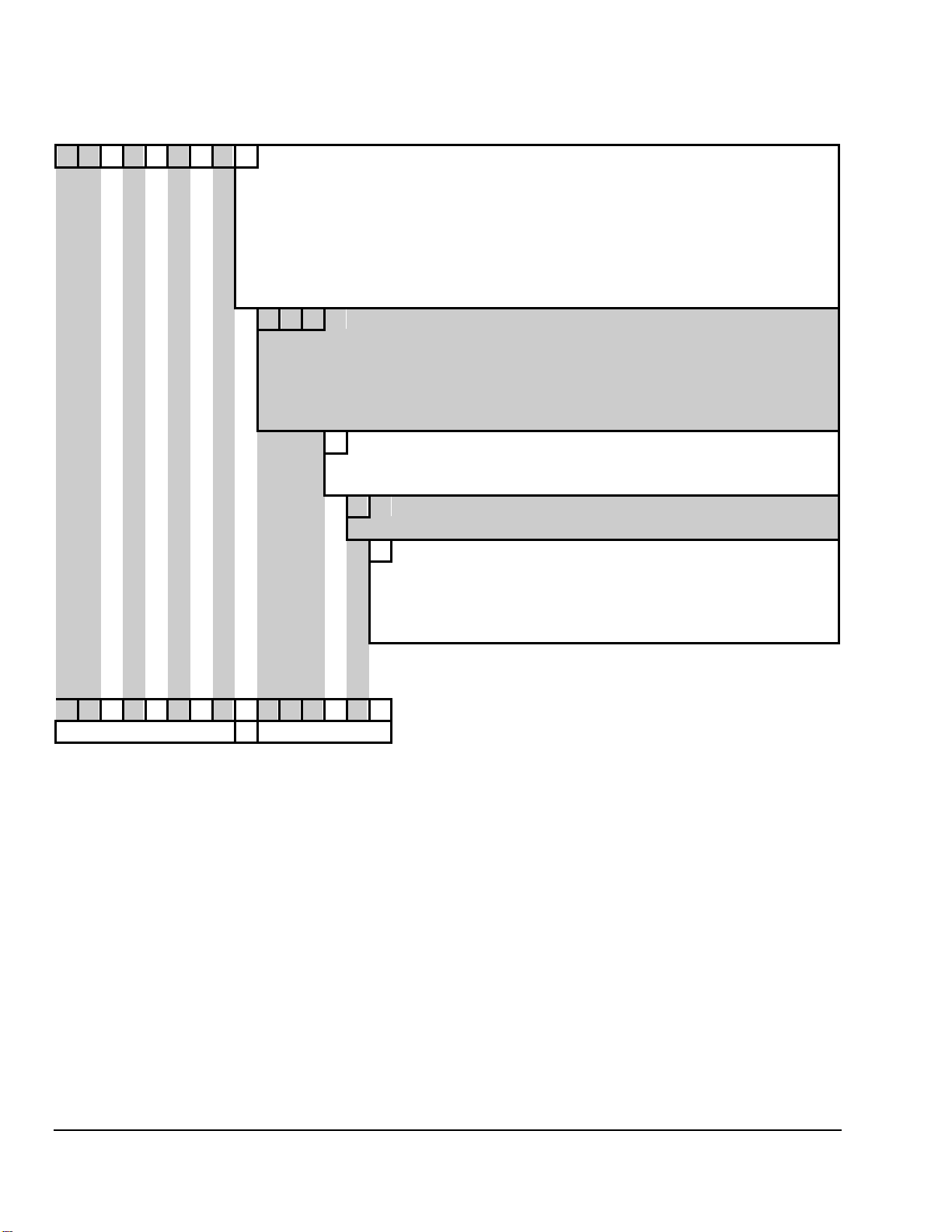

Table 3: Ordering Data — Adding a Factory-Mounted Electric Actuator

A

A

V G 2 2 3 1 U M 2

1 2 3 4 5 6 7 8 9

9 2 6

10 11 12

Series Electric

A

13

G

14

C

15

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 = Field

V G 2 2 3 1 U M 2 9 2 N A G C

Valve + Actuator

Factory

Mounted

Actuator

M91xx/M9220

Actuator

(See Actuator

Product Bulletin.)

Control

Type

Supply

Voltage

Feedback

Example: Cast iron valve; two-way, push-down-to-close; flat-faced

flanged end connections; brass trim; modified linear; 3 in.; 80.0 Cv;

3/8 in. threaded stem with one Spring Return M9220-AGC-3

Proportional Electric Actuator; 24 VAC supply; with two auxiliary

switches; and one M9220-AGA-3 Spring Return Proportional Electric

Actuator; 24 VAC supply without auxiliary switches.

Note: See Table 1 when ordering a valve body only. See Table 2 when adding a factory-mounted pneumatic actuator to a

valve body. For valid actuator and valve combinations, see Table 5 through Table 12.

+ = Single Actuator

2 = Tandem Actuators

(Tandem Actuators can only be factory mounted on

VG2231UM, VG2231VM, VG2231WN, VG2231YN

VG2831UM, VG2831VM, VG2831WN, VG2831YN

Valves Only)

(M9124-xGx-2 or M9220-xGx-3 only)

Non-Spring Return

916 = M9116-xGx-2 (VG2231TM and VG2831TM only)

924 = M9124-xGx-2

Spring Return

92N = M9220-xGx-3 (Spring to Open, Stem Up)

94N = M9220-xGx-3 (Spring to Close, Stem Down)

= Floating, 24 VAC/VDC (M91xx and M9220)

B = On/Off, 24 VAC/VDC

(M9220 only)

G = Proportional, 0-10 VDC or 0-20 mA

G = 24 VAC

= 0-10 VDC (Proportional only); No Feedback (All others)

C = 0-10 VDC

(Proportional only); 2 Aux. Sw. (All Models)

Note: When ordering Option “C” on tandem

factory mounted actuators, only one

actuator will have auxiliary switches.

4 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 5

Table 4: Ordering Data — Adding a Factory-Mounted Electric Actuator

A

A

V G 2 2 3 1 T M + 3 0

1 2 3 4 5 6 7 8 9

VA-610x Series

Electric

0

12

VA-310x or

Actuator

(See Actuator

Product/Technical

Bulletin.)

Actuator

Mounting

(VA-310x or

VA-610x Series)

A Actuator Input

13

(VA-310x or

VA-610x Series)

G Voltage

14

VA-610x Series)

(VA-310x or

C Accessories

15

(VA-310x or

VA-610x Series)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 = Field

V G 2 2 3 1 T M + 3 0 0 AGC

Valve + Actuator

Example: Cast iron valve; two-way, push-down-to-close; flat-faced

flanged end connections; brass trim; modified linear; 2-1/2 in.; 51.0 Cv;

3/8 in. threaded stem; VA-3100-AGC Non-Spring Return On/Off

(Floating) Electric Actuator; 24 VAC supply with two auxiliary switches.

Note: See Table 1 when ordering a valve body only. See Table 2 when adding a factory-mounted pneumatic actuator to a

valve body. For valid actuator and valve combinations, see Table 5 through Table 12.

Non-Spring Return

30 = VA-310x (Available on 2-1/2 through 4 in. Two-Way PDTC

and Three-Way Mixing Valves with “M” Stem, and 5 and 6 in.

Two-Way PDTC and Three-Way Mixing Valves with “N”

Stem)

60 = VA-610x (Available on 4 through 6 in. Two-Way PDTC

and Three-Way Mixing Valves with “N” Stem)

0 = 2-1/2 in. Valves with 3/8 in. Threaded Stem

1 = 3 and 4 in. Valves with 3/8 in. Threaded Stem

2 = 3 through 6 in. Valves with 1/2 in. Threaded Stem

= On/Off (Floating)

H = Proportional, 0 to 10 VDC

G = 24 VAC

= None (VA-310x Series Only)

C = Two Auxiliary Switches

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 5

Page 6

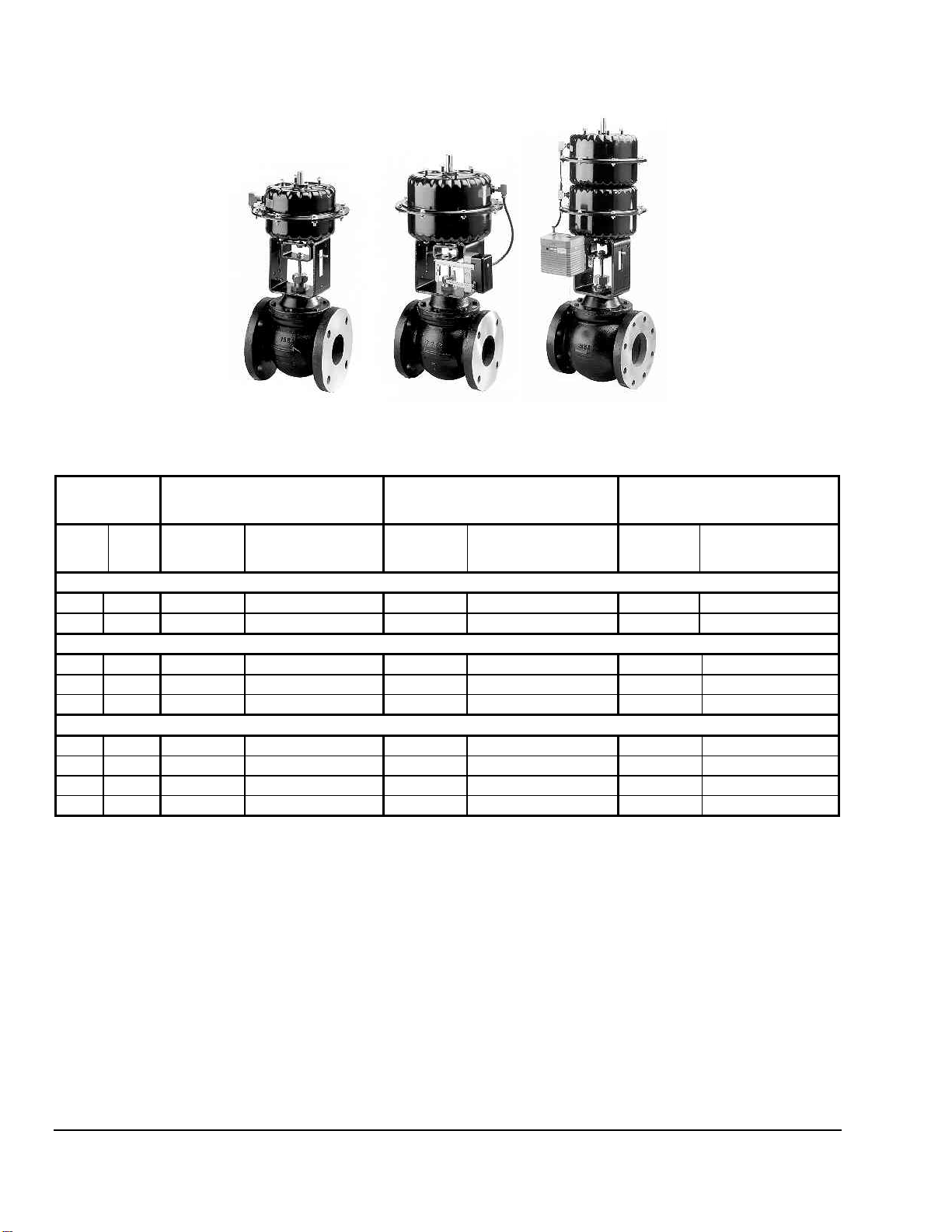

Figure 2: VG2231 Two-Way Normally Open Valves with MP8000 Series Pneumatic Valve Actuators

Table 5: VG2231 Two-Way Normally Open Valves with Pneumatic Actuators

Spring

Range

Size,

in.

Cv

Closeoff

psig

3 to 7 psig 4 to 8 psig 9 to 13 psig

Code Number

Closeoff

psig

Code Number

Closeoff

psig

Code Number

MP82 Series Actuators – 25 sq. in. Effective Diaphragm Area

2-1/2 51 53 VG2231TL+823C00 49 VG2231TL+823D00 28 VG2231TL+823E00

3 83 37 VG2231UL+823C00 34 VG2231UL+823D00 19 VG2231UL+823E00

MP84 Series Actuators – 50 sq. in. Effective Diaphragm Area

2-1/2 51 109 VG2231TM+843C00 100 VG2231TM+843D00 58 VG2231TM+843E00

3 83 75 VG2231UM+845C00 70 VG2231UM+845D00 40 VG2231UM+845E00

4 150 42 VG2231VM+845C00 39 VG2231VM+845D00 23 VG2231VM+845E00

MP86 Series Actuators – 100 sq. in. Effective Diaphragm Area

3 83 152 VG2231UN+865C00 140 VG2231UN+865D00 81 VG2231UN+865E00

4 150 86 VG2231VN+865C00 79 VG2231VN+865D00 46 VG2231VN+865E00

5 240 55 VG2231WN+867C00 51 VG2231WN+867D00 29 VG2231WN+867E00

6 350 38 VG2231YN+867C00 35 VG2231YN+867CD0 20 VG2231YN+867E00

To add an optional positioner to the valve assembly, change the 00 at the end of the code number to 01 for a V-9502-95

pneumatic positioner or to 02 for an EPP-1000-8 Electro-pneumatic positioner.

Example: VG2231TM+843C01 for a V-9502-95 pneumatic positioner, or

VG2231TM+843C02 for an EPP-1000-8 Electro-pneumatic positioner.

6 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 7

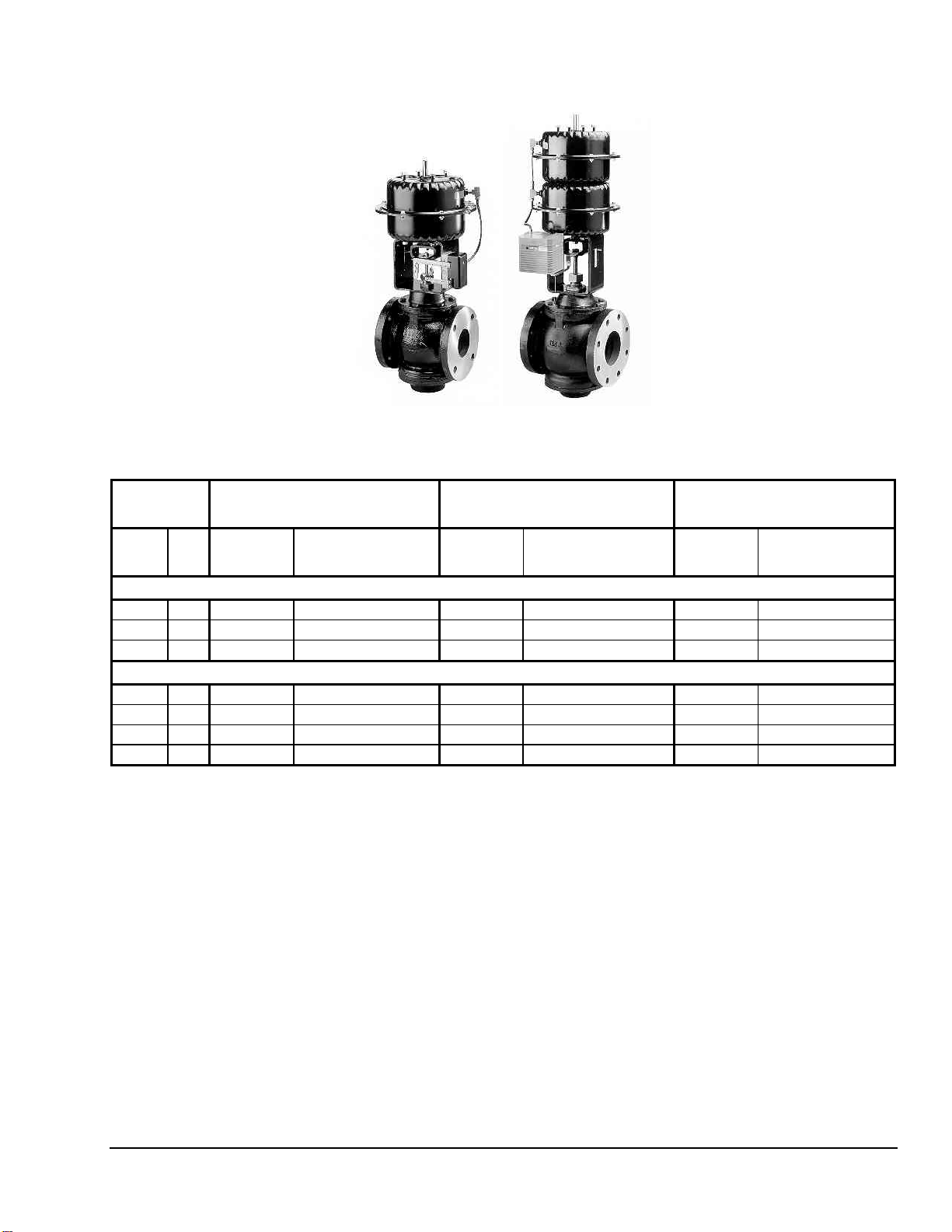

Figure 3: VG2431 Two-Way Normally Closed Valves with MP8000 Series Pneumatic Valve Actuators

Table 6: VG2431 Two-Way Normally Closed Valves with Pneumatic Actuators

Spring

Range

Size,

in.

2-1/2 54 24 VG2431TM+843C00 32 VG2431TM+843D00 75 VG2431TM+843E00

3 83 17 VG2431UM+845C00 22 VG2431UM+845D00 52 VG2431UM+845E00

4 150 9 VG2431VM+845C00 13 VG2431VM+845D00 29 VG2431VM+845E00

3 83 34 VG2431UN+865C00 46 VG2431UN+865D00 105 VG2431UN+865E00

4 150 19 VG2431VN+865C00 26 VG2431VN+865D00 59 VG2431VN+865E00

5 237 12 VG2431WN+867C00 17 VG2431WN+867D00 38 VG2431WN+867E00

6 344 9 VG2431YN+867C00 11 VG2431YN+867D00 26 VG2431YN+867E00

To add an optional positioner to the valve assembly, change the 00 at the end of the code number to 01 for a V-9502-95

pneumatic positioner or to 02 for an EPP-1000-8 Electro-pneumatic positioner.

Example: VG2431TM+843C01 for a V-9502-95 pneumatic positioner, or

Closeoff

Cv

psig

VG2431TM+843C02 for an EPP-1000-8 Electro-pneumatic positioner.

3 to 7 psig 4 to 8 psig 9 to 13 psig

Code Number

MP84 Series Actuators – 50 sq. in. Effective Diaphragm Area

MP86 Series Actuators – 100 sq. in. Effective Diaphragm Area

Closeoff

psig

Code Number

Closeoff

psig

Code Number

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 7

Page 8

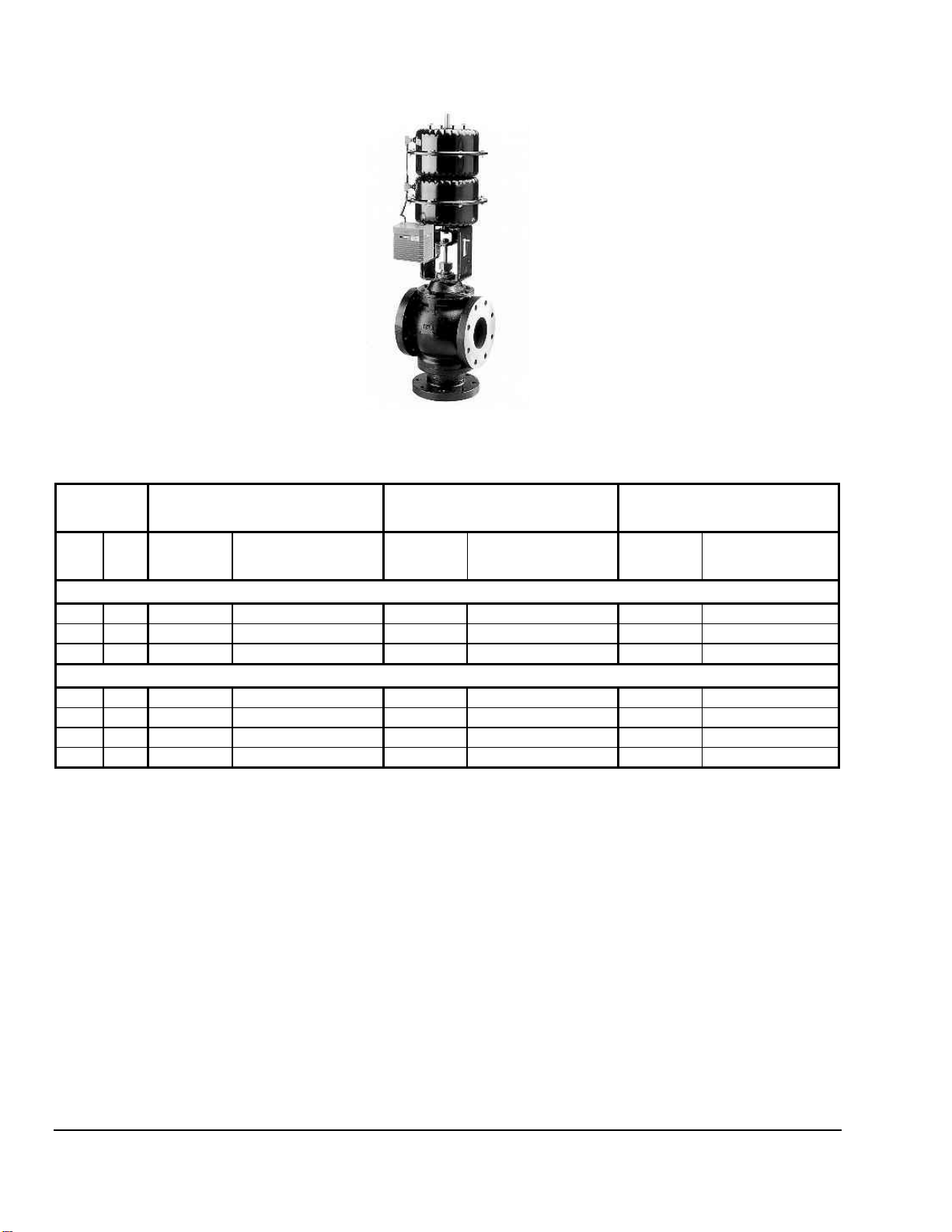

Figure 4: VG2831 Three-Way Mixing Valve with MP8000 Series Pneumatic Valve Actuator

Table 7: VG2831 Three-Way Mixing Valves with Pneumatic Actuators

Spring

Range

Size,

in.

2-1/2 54 65/14 VG2831TM+843C00 60/19 VG2831TM+843D00 35/45 VG2831TM+843E00

3 83 45/10 VG2831UM+845C00 42/13 VG2831UM+845D00 24/31 VG2831UM+845E00

4 150 25/6 VG2831VM+845C00 23/8 VG2831VM+845D00 14/18 VG2831VM+845E00

3 83 91/21 VG2831UN+865C00 84/28 VG2831UN+865D00 49/63 VG2831UN+865E00

4 150 51/12 VG2831VN+865C00 47/16 VG2831VN+865D00 27/35 VG2831VN+865E00

5 237 33/7 VG2831WN+867C00 30/10 VG2831WN+867D00 18/23 VG2831WN+867E00

6 344 23/5 VG2831YN+867C00 21/7 VG2831YN+867CD0 12/16 VG2831YN+867E00

To add an optional positioner to the valve assembly, change the 00 at the end of the code number to 01 for a V-9502-95

pneumatic positioner or to 02 for an EPP-1000-8 Electro-pneumatic positioner.

Example: VG2831TM+843C01 for a V-9502-95 pneumatic positioner, or

Closeoff

Cv

psig

VG2831TM+843C02 for an EPP-1000-8 Electro-pneumatic positioner.

3 to 7 psig 4 to 8 psig 9 to 13 psig

Code Number

MP84 Series Actuators – 50 sq. in. Effective Diaphragm Area

MP86 Series Actuators – 100 sq. in. Effective Diaphragm Area

Closeoff

psig

Code Number

Closeoff

psig

Code Number

8 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 9

Figure 5: VG2x31 Valves with M9220 Series Spring Return Electric Valve Actuators – No Switches

Table 8: VG2x31 Valves with M9220-xGA-3 Actuators – Spring Return without Switches

Spring Return

Floating without

Switches

On/Off without

Switches

Proportional without

Switches

Valve Size,

in.

Cv Closeoff

psig

M9220-AGA-3 M9220-BGA-3 M9220-GGA-3

Two-Way – Spring Return Normally Open – Valve Stem Up

VG2231TM 2-1/2 51 76 VG2231TM+92NAGA VG2231TM+92NBGA VG2231TM+92NGGA

VG2231UM 3 83 33 VG2231UM+92NAGA VG2231UM+92NBGA VG2231UM+92NGGA

VG2231UM 3 83 66 VG2231TM292NAGA* VG2231UM292NBGA* VG2231UM292NGGA*

VG2231VM 4 150 37 VG2231UM292NAGA* VG2231VM292NBGA* VG2231VM292NGGA*

VG2231WN 5 240 20 VG2231WN292NAGA* VG2231WN292NBGA* VG2231WN292NGGA*

Two-Way – Spring Return Normally Closed – Valve Stem Down

VG2231TM 2-1/2 51 76 VG2231TM+94NAGA VG2231TM+94NBGA VG2231TM+94NGGA

VG2231UM 3 83 33 VG2231UM+94NAGA VG2231UM+94NBGA VG2231UM+94NGGA

VG2231UM 3 83 66 VG2231TM294NAGA* VG2231UM294NBGA* VG2231UM294NGGA*

VG2231VM 4 150 37 VG2231UM294NAGA* VG2231VM294NBGA* VG2231VM294NGGA*

VG2231WN 5 240 20 VG2231WN294NAGA* VG2231WN294NBGA* VG2231WN294NGGA*

Three-Way Mixing – Spring Return – Valve Stem Up – Side Inlet Port Closed

VG2831TM 2-1/2 54 45 VG2831TM+92NAGA VG2831TM+92NBGA VG2831TM+92NGGA

VG2831UM 3 80 20 VG2831UM+92NAGA VG2831UM+92NBGA VG2831UM+92NGGA

VG2831UM 3 80 40 VG2831UM292NAGA* VG2831UM292NBGA* VG2831UM292NGGA*

VG2831VM 4 157 11 VG2831VM+92NAGA VG2831VM+92NBGA VG2831VM+92NGGA

VG2831VM 4 157 22 VG2831VM292NAGA* VG2831VM292NBGA* VG2831VM292NGGA*

VG2831WN 5 238 12 VG2831WM292NAGA* VG2831WN292NBGA* VG2831WN292NGGA*

VG2831YN 6 347 7 VG2831YN292NAGA* VG2831YN292NBGA* VG2831YN292NGGA*

Three-Way Mixing – Spring Return – Valve Stem Down – Side Inlet Port Open

VG2831TM 2-1/2 54 45 VG2831TM+94NAGA VG2831TM+94NBGA VG2831TM+94NGGA

VG2831UM 3 80 20 VG2831UM+94NAGA VG2831UM+94NBGA VG2831UM+94NGGA

VG2831UM 3 80 40 VG2831UM294NAGA* VG2831UM294NBGA* VG2831UM294NGGA*

VG2831VM 4 157 11 VG2831VM+92NAGA VG2831VM+94NBGA VG2831VM+94NGGA

VG2831VM 4 157 22 VG2831VM294NAGA* VG2831VM294NBGA* VG2831VM294NGGA*

VG2831WN 5 238 12 VG2831WM294NAGA* VG2831WN294NBGA* VG2831WN294NGGA*

VG2831YN 6 347 7 VG2831YN294NAGA* VG2831YN294NBGA* VG2831YN294NGGA*

* Valve assemblies require two actuators mounted in tandem.

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 9

Page 10

Figure 6: VG2x31 Valves with M9220 Series Spring Return Electric Valve Actuators – with Switches

Table 9: VG2x31 Valves with M9220-xGC-3 Actuators – Spring Return with Switches

Spring Return

Valve Size,

Cv Closeoff

in.

psig

Floating with Two

Switches

On/Off with Two

Switches

Proportional with Two

Switches

M9220-AGC-3 M9220-BGC-3 M9220-GGC-3

Two-Way – Spring Return Normally Open – Valve Stem Up

VG2231TM 2-1/2 51 76 VG2231TM+92NAGC VG2231TM+92NBGC VG2231TM+92NGGC

VG2231UM 3 83 33 VG2231UM+92NAGC VG2231UM+92NBGC VG2231UM+92NGGC

VG2231UM 3 83 66 VG2231TM292NAGC* VG2231UM292NBGC* VG2231UM292NGGC*

VG2231VM 4 150 37 VG2231UM292NAGC* VG2231VM292NBGC* VG2231VM292NGGC*

VG2231WN 5 240 20 VG2231WN292NAGC* VG2231WN292NBGC* VG2231WN292NGGC*

Two-Way – Spring Return Normally Closed – Valve Stem Down

VG2231TM 2-1/2 51 76 VG2231TM+94NAGC VG2231TM+94NBGC VG2231TM+94NGGC

VG2231UM 3 83 33 VG2231UM+94NAGC VG2231UM+94NBGC VG2231UM+94NGGC

VG2231UM 3 83 66 VG2231TM294NAGC* VG2231UM294NBGC* VG2231UM294NGGC*

VG2231VM 4 150 37 VG2231UM294NAGC* VG2231VM294NBGC* VG2231VM294NGGC*

VG2231WN 5 240 20 VG2231WN294NAGC* VG2231WN294NBGC* VG2231WN294NGGC*

Three-Way Mixing – Spring Return – Valve Stem Up

VG2831TM 2-1/2 54 45 VG2831TM+92NAGC VG2831TM+92NBGC VG2831TM+92NGGC

VG2831UM 3 80 20 VG2831UM+92NAGC VG2831UM+92NBGC VG2831UM+92NGGC

VG2831UM 3 80 40 VG2831UM292NAGC* VG2831UM292NBGC* VG2831UM292NGGC*

VG2831VM 4 157 11 VG2831VM+92NAGC VG2831VM+92NBGC VG2831VM+92NGGC

VG2831VM 4 157 22 VG2831VM292NAGC* VG2831VM292NBGC* VG2831VM292NGGC*

VG2831WN 5 238 12 VG2831WM292NAGC* VG2831WN292NBGC* VG2831WN292NGGC*

VG2831YN 6 347 7 VG2831YN292NAGC* VG2831YN292NBGC* VG2831YN292NGGC*

Three-Way Mixing – Spring Return – Valve Stem Down

VG2831TM 2-1/2 54 45 VG2831TM+94NAGC VG2831TM294NBGC VG2831TM294NGGC

VG2831UM 3 80 20 VG2831UM+94NAGC VG2831UM294NBGC VG2831UM294NGGC

VG2831UM 3 80 40 VG2831UM294NAGC* VG2831UM294NBGC* VG2831UM294NGGC*

VG2831VM 4 157 11 VG2831VM+94NAGC VG2831VM+94NBGC VG2831VM+94NGGC

VG2831VM 4 157 22 VG2831VM294NAGC* VG2831VM294NBGC* VG2831VM294NGGC*

VG2831WN 5 238 12 VG2831WM294NAGC* VG2831WN294NBGC* VG2831WN294NGGC*

VG2831YN 6 347 7 VG2831YN294NAGC* VG2831YN294NBGC* VG2831YN294NGGC*

* Valve assemblies require two actuators mounted in tandem. On tandem assemblies with switches, only one actuator is

required to have switches.

10 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 11

Figure 7: VG2x31 Valves with M91xx Series Non-Spring Return Electric Valve Actuators

Table 10: VG2x31 Valves with M91xx-xGx-2 Actuators – Non-Spring Return

Non-Spring Return

On/Off Floating

with Two

Switches

M9116-AGC-2

M9124-AGC-2

Proportional with

Two Switches

M9116-GGC-2

M9124-GGC-2

Size,

in.

Cv

Closeoff

psig

On/Off Floating

without Switches

M9116-AGA-2

M9124-AGA-2

Proportional

without Switches

M9116-GGA-2

M9124-GGA-2

Two-Way, Push-Down-To-Close

2-1/2 51 62 VG2231TM+916AGA VG2231TM+916GGA VG2231TM+916AGC VG2231TM+916GGC

2-1/2 51 101 VG2231TM+924AGA VG2231TM+924GGA VG2231TM+924AGC VG2231TM+924GGC

3 83 27 VG2231UM+916AGA VG2231UM+916GGA VG2231UM+916AGC VG2231UM+916GGC

3 83 43 VG2231UM+924AGA VG2231UM+924GGA VG2231UM+924AGC VG2231UM+924GGC

3 83 88 VG2231UM2924AGA* VG2231UM2924GGA* VG2231UM2924AGC* VG2231UM2924GGC*

4 150 24 VG2231VM+924AGA VG2231VM+924GGA VG2231VM+924AGC VG2231VM+924GGC

4 150 49 VG2231VM2924AGA* VG2231VM2924GGA* VG2231VM2924AGC* VG2231VM2924GGC*

5 240 26 VG2231WN2924AGA* VG2231WN2924GGA* VG2231WN2924AGC* VG2231WN2924GGC*

6 350 16 VG2231YN2924AGA* VG2231YN2924GGA* VG2231YN2924AGC* VG2231YN2924GGC*

Three-Way, Mixing

2-1/2 54 37 VG2831TM+916AGA VG2831TM+916GGA VG2831TM+916AGC VG2831TM+916GGC

2-1/2 54 60 VG2831TM+924AGA VG2831TM+924GGA VG2831TM+924AGC VG2831TM+924GGC

3 80 16 VG2831UM+916AGA VG2831UM+916GGA VG2831UM+916AGC VG2831UM+916GGC

3 80 26 VG2831UM+924AGA VG2831UM+924GGA VG2831UM+924AGC VG2831UM+924GGC

3 80 53 VG2831UM2924AGA* VG2831UM2924GGA* VG2831UM2924AGC* VG2831UM2924GGC*

4 157 9 VG2831VM+916AGA VG2831VM+916GGA VG2831VM+916AGC VG2831VM+916GGC

4 157 14 VG2831VM+924AGA VG2831VM+924GGA VG2831VM+924AGC VG2831VM+924GGC

4 157 30 VG2831VM2924AGA* VG2831VM2924GGA* VG2831VM2924AGC* VG2831VM2924GGC*

5 238 7 VG2831WN+924AGA VG2831WN+924GGA VG2831WN+924AGC VG2831WN+924GGC

5 238 15 VG2831WN2924AGA* VG2831WN2924GGA* VG2831WN2924AGC* VG2831WN2924GGC*

6 347 4 VG2831YN+924AGA VG2831YN+924GGA VG2831YN+924AGC VG2831YN+924GGC

6 347 9 VG2831YN2924AGA* VG2831YN2924GGA* VG2831YN2924AGC* VG2831YN2924GGC*

* Valve assemblies require two actuators mounted in tandem. On tandem assemblies with switches, only one actuator is

required to have switches. M9116-AGx-2 actuators are not designed for tandem operation.

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 11

Page 12

Figure 8: VG2x31 Valves with VA-3100 Series Non-Spring Return Electric Valve Actuators

Table 11: VG2x31 Valves with VA-3100-xGx Series Non-Spring Return Actuators

Non-Spring Return

On/Off Floating

without Switches

On/Off Floating

with Two Switches

Proportional with Two

Switches

Valve

VG2231TM

VG2231UM

VG2231VM

VG2231WN

VG2231YN

VG2831TM

VG2831UM

VG2831VM

VG2831WN

VG2831YN

Size,

in.

2-1/2 51 115

3 83 79

4 150 45

5 240 29

6 350 20

2-1/2 54 69

3 80 48

4 157 27

5 238 17

6 347 12

Cv

Closeoff

psig

VA-3100-AGA VA-3100-AGC VA-3100-HGC

Two-Way Push-Down-To-Close

VG2231TM+300AGA

VG2231UM+301AGA

VG2231VM+301AGA

VG2231WN+302AGA

VG2231YN+302AGA

VG2231TM+300AGC VG2231TM+300HGC

VG2231UM+301AGC VG2231UM+301HGC

VG2231VM+301AGC VG2231VM+301HGC

VG2231WN+302AGC VG2231WN+302HGC

VG2231YN+302AGC VG2231YN+302HGC

Three-Way Mixing

VG2831TM+300AGA

VG2831UM+301AGA

VG2831VM+301AGA

VG2831WN+302AGA

VG2831YN+302AGA

VG2831TM+300AGC VG2831TM+300HGC

VG2831UM+301AGC VG2831UM+301HGC

VG2831VM+301AGC VG2831VM+301HGC

VG2831WN+302AGC VG2831WN+302HGC

VG2831YN+302AGC VG2831YN+302HGC

12 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 13

Figure 9: VG2x31 Valves with VA-6100 Series Non-Spring Return Electric Valve Actuators

Table 12: VG2x31 Valves with VA-6100-xGx Series Non-Spring Return Actuators

Non-Spring Return

On/Off Floating

with Two Switches

Proportional

with Two Switches

Valve

VG2231VN

VG2231WN

VG2231YN

VG2831VN

VG2831WN

VG2831YN

Size,

in.

Cv

Closeoff

psig

VA-6100-AGC VA-6100-HGC

Two-Way Push-Down-To-Close

4 150 89 VG2231VN+602AGC VG2231VN+602HGC

5 240 57 VG2231WN+602AGC VG2231WN+602HGC

6 350 40 VG2231YN+602AGC VG2231YN+602HGC

Three-Way Mixing

4 157 54 VG2831VN+602AGC VG2831VN+602HGC

5 238 34 VG2831WN+602AGC VG2831WN+602HGC

6 347 24 VG2831YN+602AGC VG2831YN+602HGC

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 13

Page 14

Table 13: Shipping Weights for Two-Way N.O. (PDTC) Valve Assemblies, lb (kg)

Actuator Valve Size, in.

2-1/2 3 4 5 6

MP82

MP84

MP86

M9116

M9124

M9124 (Tandem)

M9220

M9220 (Tandem)

VA-310x

VA-610x

Note: Weights are approximate and based on the heaviest valve. Add 2.0 lb (0.9 kg) for assemblies with a

factory-mounted positioner. The weights given for the M9220 actuated assemblies are for the M9220-AGx and M9220-GGx

models. For assemblies with M9220-Bxx On/Off actuators, add 1.2 lb (0.55 kg) for single assembly actuators and 2.4 lb (1.1

kg) for tandem actuated assemblies to the weights listed previously.

47.0 (21.3) 64.0 (29.1) --- --- ---

57.0 (25.9) 80.0 (36.3) 119.0 (54.0) --- ---

--- 104.0 (47.2) 129.0 (58.6) 163.0 (74.0) 198.0 (89.9)

47 (21.3) 61 (27.7) --- --- --47 (21.3) 61 (27.7) 95 (43.1) --- ---

--- 64 (29.0) 98 (44.5) 138 (62.6) 145 (65.8)

50 (22.7) 64 (29.0) --- --- ---

--- 71 (32.2) 105 (47.6) 145 (65.8) ---

44.0 (20.0) 61.0 (27.7) 97.0 (44.0) 136.0 (61.7) 158.0 (71.7)

--- --- 104.0 (47.2) 146.0 (66.3) 170.0 (77.2)

Table 14: Shipping Weights for Two-Way N.C. (PDTO) Valve Assemblies, lb (kg)

Actuator Valve Size, in.

2-1/2 3 4 5 6

MP84

MP86

Note: Weights are approximate and based on the heaviest valve. Add 2.0 lb (0.9 kg) for assemblies with a

factory-mounted positioner.

76.0 (34.5) 90.0 (40.9) 127.0 (57.7) --- ---

--- 113.0 (51.3) 149.0 (67.6) 168.0 (76.3) 224.0 (101.7)

Table 15: Shipping Weights for Three-Way Mixing Valve Assemblies, lb (kg)

Actuator Valve Size, in.

2-1/2 3 4 5 6

MP84

MP86

M9116

M9124

M9124 (Tandem)

M9220

M9220 (Tandem)

VA-310x

VA-610x

Note: Weights are approximate and based on the heaviest valve. Add 2.0 lb (0.9 kg) for assemblies with a

factory-mounted positioner. The weights given for the M9220 actuated assemblies are for the M9220-AGx and

M9220-GGx models. For assemblies with M9220-Bxx On/Off actuators, add 1.2 lb (0.55 kg) for single assembly actuators

and 2.4 lb (1.1 kg) for tandem actuated assemblies to the weights listed previously.

86.0 (39.0) 104.0 (47.2) 149.0 (67.6) --- ---

--- 126.0 (57.2) 170.0 (77.2) 209.0 (94.9) 254.0 (115.3)

68 (30.8) 87 (39.5) 116 (52.6) --- --68 (30.8) 87 (39.5) 116 (52.6) 182 (82.6) 221 (100.2)

--- 90 (40.8) 119 (54.0) 185 (83.9) 224 (101.6)

78 (35.4) 90 (40.8) 119 (54.0) 185 (83.9) 224 (101.6)

--- 97 (44.0) 126 (57.2) 192 (87.1) 231 (104.8)

64.0 (29.1) 82.0 (37.2) 130.0 (59.0) 180.0 (81.7) 220.0 (99.9)

--- --- 137.0 (62.2) 193.0 (87.6) 228.0 (103.5)

14 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 15

Application Overview

VG2000 Series Cast Iron Flanged Globe Valves

feature brass trim and are available in two-way

Push-Down-To-Close ([PDTC] – normally open if

pneumatically actuated) or Push-Down-To-Open

([PDTO] – normally closed if pneumatically actuated)

and three-way mixing configurations. These iron

valves can be ordered with MP8000 Series Pneumatic

Actuators (with or without a factory-mounted

pneumatic or electro-pneumatic positioner). VG2000

Series Valves can also be ordered with any of the

following series of electric actuators: M9116, M9124,

M9220, VA-310x, or VA-610x. All electric actuators are

fully compatible with Johnson Controls controllers,

reducing installation costs. Valves without actuators

can be ordered with the standard bonnet and stem

design, allowing easy interchangeability of actuators

with the use of standardized mounting kits. See Tables

1, 2, 3, and 4 for ordering data and additional details.

For valid valve and actuator combinations, see Tables

5 through 12.

The modulating valve plug of VG2000 Series Valves

provides a modified linear flow characteristic. An arrow

is cast on both sides of the valve body indicating the

direction of flow for proper piping.

Pneumatic Actuator Selection

(See Tables 1 and 2.)

MP8000 Series Pneumatic Actuators

The MP82 (25 sq. in. effective diaphragm area),

MP84 (50 sq. in. effective diaphragm area), and

MP86 (100 sq. in. effective diaphragm area) are

equipped with a molded synthetic rubber diaphragm

contained in a sturdy, carbon-steel housing that

protects it against dirt and damage. The actuator can

be easily removed to perform inline servicing to all

parts of the valve. MP8000 Series Pneumatic

Actuators are available factory mounted or are easily

field mounted to VG2000 Series Valves.

MP8000 Series Pneumatic Actuators are designed to

allow for reversing the action of each actuator in the

field. If desired, the action of the MP8000 Series

Actuator can be reversed from spring-return-up to

spring-return-down or vice versa. For instructions on

field reversing the action, refer to the MP8000 Series

Pneumatic Valve Actuators Technical Bulletin

(LIT-977258). The V-9502 Pneumatic Positioner and

the EPP-1000 Electro-Pneumatic Positioner are also

available for factory or field mounting to MP8000

Series Pneumatic Valve Actuators.

Electric Actuator Selection

(See Tables 1, 3, and 4.)

Factory-mounted electric actuators are available on

two-way PDTC and three-way mixing valve

configurations only. These same actuators can be field

mounted on PDTO valves if desired. All electric

actuators used with VG2000 Series Cast Iron Flange

Globe Valves can be easily field reversed if required.

All proportional electrically actuated assemblies are

factory calibrated for nominal 0 to 10 VDC operation to

drive down with an increase in signal.

M9100 Series Electric Actuators

The M9100 Series is a line of motor driven, non-spring

return actuators that operate on 24 VAC or VDC

power and are available for use with floating or

proportional controllers. When coupled with the

M9000-53x Series of Valve Linkages, the rotary

motion of this actuator is converted into linear motion

that operates 2-1/2 through 6 in. VG2000 Series

Valves. Integral auxiliary switches are available for

indicating end-stop position or performing switching

functions. Position feedback is available via switches,

or a 0 to 10 VDC signal. For more information on

M91xx Series Electric Actuators, refer to the M9108,

M9116, M9124, and M9132

Return Actuators Product Bulletin (LIT-2681058).

M9220 Series Electric Actuators

The M9220 Series is a line of motor driven, spring

return actuators that operate on 24 VAC or VDC

power and are available for use with on/off, floating, or

proportional controllers. The 120 and 230 VAC models

are available for field mounting for use with on/off

controllers. When coupled with the M9000-53x Series

of Valve Linkages, the rotary motion of this actuator is

converted into linear motion that operates 2-1/2

through 6 in. VG2000 Series Valves. Integral auxiliary

switches are available for indicating end-stop position

or performing switching functions. Position feedback is

available via switches or a 0 to 10 VDC signal. For

more information on M9220 Series Electric Actuators,

refer to the M9220-xxx-3 Electric Spring Return

Actuators Product Bulletin (LIT-12011057).

Series Electric Non-spring

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 15

Page 16

VA-310x Series Electric Actuators

The VA-310x Series uses a synchronous motor to

accurately position valves in HVAC and industrial

applications. This non-spring return actuator has a

675 lb (3,000 N) force output for on/off (floating) or

proportional control. Integral auxiliary switches are

available for indicating end-stop position or performing

switching functions.

VA-610x Series Electric Actuators

The VA-610x Series uses a synchronous motor to

accurately position valves in HVAC and industrial

applications. This non-spring return actuator has a

1,350 lb (6,000 N) force output for on/off (floating) or

proportional control. Integral auxiliary switches are

available for indicating end-stop position or performing

switching functions.

For more information on VA-310x Series Electric

Actuators, refer to the VA-3100 Series Electric Valve

Actuators Product Bulletin (LIT-977283).

For more information on VA-610x Series Electric

Actuators, refer to the VA-6100 Series Electric Valve

Actuators Product Bulletin (LIT-977284).

Table 16: Mounting Kits for Field Mounting M91xx and M9220 Series Electric Actuators

Mounting Kit

Code Number

M9000-530

M9000-531

M9000-532

M9000-533

M9000-534

M9000-535

M9000-536

M9000-537

Valve Valve Size Valve Stroke

VG2x31TM 2-1/2 in. 3/4 in “M” Stem (3/8 in.) Single

VG2x31UM and

VG2x31VM

VG2x31UM and

VG2x31VM

VG2x31WN 5 in. 1-3/8 in. “N” Stem (1/2 in.) Single

VG2x31WN 5 in. 1-3/8 in. “N” Stem (1/2 in.) Dual

VG2x31YN 6 in. 1-1/2 in. “N” Stem (1/2 in.) Single

VG2x31YN 6 in. 1-1/2 in. “N” Stem (1/2 in.) Dual

VG2x31UN and

VG2x31VN

3 and 4 in. 1-1/8 in. “M” Stem (3/8 in.) Single

3 and 4 in. 1-1/8 in. “M” Stem (3/8 in.) Dual

3 and 4 in. 1-1/8 in. “N” Stem (1/2 in.) Dual

Stem Type

(Diameter)

Number of

Actuator(s)

16 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 17

Table 17: Mounting Kits for Field Mounting MP8000 Series Pneumatic Valve Actuators

Mounting Kit Code

Actuator Style Valve Size Stem Type (Diameter)

Number

MP8000-6201

MP8000-6203

MP82/MP83/MP84/MP85 2-1/2 through 4 in. “L” Stem (3/8 in.) or

“M” Stem (3/8 in.)

MP86/MP87 3 through 6 in. “N” Stem (1/2 in.)

Table 18: Mounting Kits for Field Mounting VA-310x Series Electric Valve Actuators

Mounting Kit Code Number Valve Size Stem Type (Diameter)

VA-3100-500

VA-3100-501

2-1/2 through 4 in. “M” Stem (3/8 in.)

5 and 6 in. “N” Stem (1/2 in.)

Table 19: Mounting Kits for Field Mounting VA-610x Series Electric Valve Actuators

Mounting Kit Code Number Valve Size Stem Type (Diameter)

VA-3100-501

4 through 6 in. “N” Stem (1/2 in.)

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 17

Page 18

Table 20: Maximum Closeoff Pressures, psig (kPa) for Factory-Assembled Pneumatically Actuated

Two-Way Valves

Two-Way N.O.

(with 20 psig Supply)

Actuator

Style

Valve

Size

in.

Spring Range, psig (kPa)*

3 to 7

(21 to 48)

MP82

MP84

MP86

* To maximize closeoff, the recommended spring ranges for use with a positioner are 3 to 7 psig (21 to 48 kPa) for

two-way N.O. valves and 9 to 13 psig (62 to 90 kPa) for two-way N.C. valves.

Note: The maximum fluid temperature is 281F (138C) water or 35 psig (241 kPa) saturated steam.

2-1/2 53 (365) 49 (338) 28 (193) --- --- ---

3 37 (255) 34 (234) 19 (131) --- --- ---

2-1/2 109 (751) 100 (689) 58 (400) 24 (165) 32 (220) 75 (517)

3 75 (517) 70 (482) 40 (276) 17 (117) 22 (152) 52 (358)

4 42 (289) 39 (269) 23 (158) 9 (62) 13 (90) 29 (200)

3 152 (1,047) 140 (965) 81 (558) 34 (234) 46 (317) 105 (723)

4 86 (592) 79 (544) 46 (317) 19 (131) 26 (179) 59 (407)

5 55 (379) 51 (351) 29 (200) 12 (83) 17 (117) 38 (262)

6 38 (262) 35 (241) 20 (138) 9 (62) 11 (76) 26 (179)

4 to 8

(28 to 55)

9 to 13

(62 to 90)

3 to 7

(21 to 48)

Two-Way N.C.

(with 0 psig Supply)

Spring Range, psig (kPa)*

4 to 8

(28 to 55)

9 to 13

(62 to 90)

Table 21: Maximum Closeoff Pressures, psig (kPa) for Factory-Assembled Pneumatically Actuated

Three-Way Mixing Valves

Three-Way Mixing N.O. Port

(with 20 psig Supply)

Actuator

Style

MP84

MP86

* To maximize closeoff, the recommended spring range for use with a positioner is 4 to 8 psig (28 to 55 kPa) for

three-way mixing valves.

Note: The maximum fluid temperature is 281F (138C) water or 35 psig (241 kPa) saturated steam.

Valve

Size in.

2-1/2 65 (448) 60 (413) 35 (241) 14 (96) 19 (131) 45 (310)

3 45 (310) 42 (289) 24 (165) 10 (69) 13 (90) 31 (214)

4 25 (172) 23 (158) 14 (96) 6 (41) 8 (55) 18 (124)

3 91 (627) 84 (579) 49 (338) 21 (145) 28 (193) 63 (434)

4 51 (351) 47 (324) 27 (186) 12 (83) 16 (110) 35 (241)

5 33 (227) 30 (207) 18 (124) 7 (48) 10 (69) 23 (158)

6 23 (158) 21 (145) 12 (83) 5 (34) 7 (48) 16 (110)

Spring Range, psig (kPa)*

3 to 7

(21 to 48)

4 to 8

(28 to 55)

9 to 13

(62 to 90)

Three-Way Mixing N.C. Port

(with 0 psig Supply)

Spring Range, psig (kPa)*

3 to 7

(21 to 48)

4 to 8

(28 to 55)

9 to 13

(62 to 90)

18 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 19

Table 22: Maximum Closeoff Pressures, psig (kPa) for Factory-Assembled Electrically Actuated Two-Way

and Three-Way Valves

Valve Size, in.

Actuator 2-1/2 3 4 5 6

Two-Way, Push-Down-To-Close

M9116

M9124

M9124 (Tandem)

M9220

M9220 (Tandem)

VA-3100

VA-6100

62 (427) 27 (186) --- --- --101 (696) 43 (296) 24 (165) --- ---

--- 88 (606) 49 (337) 26 (179) 16 (110)

76 (524) 33 (227) --- --- ---

--- 66 (456) 37 (255) 20 (138) ---

115 (792) 79 (544) 45 (310) 29 (200) 20 (138)

--- --- 89 (613) 57 (393) 40 (276)

Three-Way, Mixing

M9116

M9124

M9124 (Tandem)

M9220

M9220 (Tandem)

VA-3100

VA-6100

Note: The maximum fluid temperature is 281F (138C) water or 35 psig (241 kPa) saturated steam.

37 (255) 16 (110) 9 (62) --- --60 (413) 26 (179) 14 (96) 7 (48) 4 (28)

--- 53 (365) 30 (206) 15 (103) 9 (62)

45 (310) 20 (138) 11 (76) --- ---

--- 40 (276) 22 (152) 12 (83) 7 (48)

69 (475) 48 (331) 27 (186) 17 (117) 12 (83)

--- --- 54 (372) 34 (234) 24 (165)

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 19

Page 20

E

E

A

A

B

D

C

MP82/84 Actuated

B

D

C

MP86 Actuated

Figure 10: MP8000 Actuated Two-Way N.O. Valve Dimensions

(See Table 23)

Table 23: MP8000 Actuated Two-Way N.O. Valve Dimensions, in. (mm)

Actuator

Style*

MP82

MP84

MP86

* Allow 3-3/4 in. (95 mm) clearance for MP82/MP84 actuator removal and 4-3/4 in. (121 mm) clearance for

MP86 actuator removal.

Valve Size,

in.

2-1/2 15-3/16 (386) 4-21/32 (118) 7-1/4 (184) 7 (178) 8-21/32 (220)

3 15-13/16 (402) 5-3/16 (132) 8-5/8 (219) 7-1/2 (191) 8-21/32 (220)

2-1/2 18-17/32 (471) 4-21/32 (118) 7-1/4 (184) 7 (178) 10-7/8 (276)

3 19-3/16 (487) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 10-7/8 (276)

4 20-5/16 (516) 6-7/16 (164) 10-1/2 (267) 9 (229) 10-7/8 (276)

3 27-1/4 (692) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 10-7/8 (276)

4 28-3/8 (721) 6-7/16 (164) 10-1/2 (267) 9 (229) 10-7/8 (276)

5 28-13/16 (732) 6-7/8 (175) 12-1/2 (318) 10 (254) 10-7/8 (276)

6 30-1/8 (765) 8-3/16 (208) 14-1/2 (368) 11 (279) 10-7/8 (276)

A B C D E

20 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 21

F

F

A

A

B

D

E

D

C

MP84 Actuated

B

E

C

MP86 Actuated

Figure 11: MP8000 Actuated Two-Way N.C. Valve Dimensions

(See Table 24)

Table 24: MP8000 Actuated Two-Way N.C. Valve Dimensions, in. (mm)

Actuator

Style*

MP84

MP86

* Allow 3-3/4 in. (95 mm) clearance for MP84 actuator removal and 4-3/4 in. (121 mm) clearance for MP86 actuator

removal.

Valve

Size,

A B C D E F

in.

2-1/2 18-17/32 (471) 4-21/32 (118) 7-1/4 (184) 7 (178) 4-21/32 (118) 10-7/8 (276)

3 19-3/16 (487) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 5-5/16 (135) 10-7/8 (276)

4 20-5/16 (516) 6-1/16 (152) 10-1/2 (267) 9 (229) 6-1/16 (152) 10-7/8 (276)

3 27-1/4 (692) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 5-5/16 (135) 10-7/8 (276)

4 28-3/8 (721) 6-7/16 (164) 10-1/2 (267) 9 (229) 6-7/16 (164) 10-7/8 (276)

5 28-13/16 (732) 6-7/8 (175) 12-1/2 (318) 10 (254) 6-7/8 (175) 10-7/8 (276)

6 30-1/8 (765) 8-3/16 (208) 14-1/2 (368) 11 (279) 8-3/16 (208) 10-7/8 (276)

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 21

Page 22

F

F

A

B

D

E

C

MP84 Actuated

MP86 Actuated

C

Figure 12: MP8000 Actuated Three-Way Mixing Valve Dimensions

(See Table 25)

A

B

E

Table 25: MP8000 Actuated Three-Way Mixing Valve Dimensions, in. (mm)

Actuator

Style*

MP84

MP86

* Allow 3-3/4 in. (95 mm) clearance for MP84 actuator removal and 4-3/4 in. (121 mm) clearance for MP86 actuator

removal.

Valve

Size,

A B C D E F

in.

2-1/2 18-17/32 (471) 4-21/32 (118) 7-1/4 (184) 7 (178) 6-25/32 (172) 10-7/8 (276)

3 19-3/16 (487) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 6-13/16 (173) 10-7/8 (276)

4 20-5/16 (516) 6-7/16 (164) 10-1/2 (267) 9 (229) 8-1/16 (205) 10-7/8 (276)

3 27-1/4 (692) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 6-13/16 (175) 10-7/8 (276)

4 28-3/8 (721) 6-7/16 (164) 10-1/2 (267) 9 (229) 8-1/16 (205) 10-7/8 (276)

5 28-13/16 (732) 6-7/8 (175) 12-1/2 (318) 10 (254) 9-5/32 (233) 10-7/8 (276)

6 30-1/8 (765) 8-3/16 (208) 14-1/2 (368) 11 (279) 9-15/16 (252) 10-7/8 (276)

22 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 23

A

A

B

C

D

Two-Way

PDTC

Three-Way

Mixing

Figure 13: M9000 Actuated Valve Dimensions, in. (mm)

(See Table 26)

Table 26: M9000 Actuated VG2000 Series Cast Iron Flanged Valve Dimensions, in. (mm)

Actuator

Style

M9000

Valve Size,

in.

2-1/2 16-13/16 (427) 4-21/32 (118) 7-1/4 (184) 7 (178) 6-25/32 (172)

3 16-13/16 (427) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 6-13/16 (175)

4 16-13/16 (427) 6-7/16 (164) 10-1/2 (267) 9 (229) 8-1/16 (205)

5 17-3/8 (441) 6-7/8 (175) 12-1/2 (318) 10 (254) 9-5/32 (233)

6 17-3/8 (441) 8-3/16 (208) 14-1/2 (368) 11 (279) 9-15/16 (252)

A B C D E

B

E

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 23

Page 24

A

A

B

B

D

E

C

Two-Way

PDTC

Figure 14: VA-310x Actuated Valve Dimensions

(See Table 27)

Table 27: VA-310x Actuated Valve Dimensions, in. (mm)

Actuator

Style*

VA-310x

* Allow 6-5/16 in. (160 mm) clearance for VA-310x actuator removal.

Valve Size

A B C D E

in.

2-1/2 18-23/32 (475) 4-21/32 (118) 7-1/4 (184) 7 (178) 6-25/32 (172)

3 19-3/8 (492) 5-5/16 (135) 8-5/8 (219) 7-1/2 (191) 6-13/16 (175)

4 20-1/2 (521) 6-7/16 (164) 10-1/2 (267) 9 (229) 8-1/16 (205)

5 20-15/16 (532) 6-7/8 (175) 12-1/2 (318) 10 (254) 9-5/32 (233)

6 22-1/4 (565) 8-3/16 (208) 14-1/2 (368) 11 (279) 9-15/16 (252)

D

Three-Way

Mixing

24 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 25

A

A

B

B

E

C

Two-Way

PDTC

Figure 15: VA-610x Actuated Valve Dimensions

(See Table 28)

Table 28: VA-610x Actuated Valve Dimensions, in. (mm)

Actuator

Style*

VA-610x

* Allow 7-29/32 in. (201 mm) clearance for VA-610x actuator removal.

Valve Size,

in.

4 27-21/32 (702) 6-7/16 (164) 10-1/2 (267) 9 (229) 8-1/16 (205)

5 28-3/32 (714) 6-7/8 (175) 12-1/2 (318) 10 (254) 9-5/32 (233)

6 29-13/32 (747) 8-3/16 (208) 14-1/2 (368) 11 (279) 9-15/16 (252)

A B C D E

D

Three-Way

Mixing

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 25

Page 26

Figure 16: Flange and Bolt Circle

Table 29: Flange and Bolt Circle Dimensions, in. (mm)

Valve Size, in. Diameter of

Flange

2-1/2

3

4

5

6

7 (178) 11/16 (17) 5-1/2 (140) 3/4 (19) 4

7-1/2 (191) 3/4 (19) 6 (152) 3/4 (19) 4

9 (229) 1 (25) 7-1/2 (191) 3/4 (19) 8

10 (254) 1 (25) 8-1/2 (216) 7/8 (22) 8

11 (279) 1 (25) 9-1/2 (241) 7/8 (22) 8

Thickness of

Flange

Diameter of

Bolt Circle

Diameter of

Bolt Holes

Number of Bolt

Holes

Table 30: Positioners and Positioner Mounting Kits for MP8000 Series Pneumatic Valve Actuators

(Order Separately)

Code Number Description

V-9502-95

MP8000-6002

EPP-1000-8

MP8000-6003

Pneumatic Valve Actuator Positioner (Less Spring and Mounting

Hardware)

Mounting Kit for V-9502-95 Pneumatic Valve Actuator Positioner (Kit

includes all necessary mounting hardware and six springs)

Electro-Pneumatic Valve Actuator Positioner (Less Mounting

Hardware)

Mounting Kit for EPP-1000-8 Electro-Pneumatic Valve Actuator

Positioner (Kit includes all necessary mounting hardware.)

Shipping Weight,

lb

0.9 (0.41)

1.3 (0.59)

1.6 (0.73)

1.5 (0.68)

26 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 27

Table 31: Accessories for M9000 Series Electric Actuators (Order Separately)

Code Number Description Shipping Weight, lb*

M9000-100

M9000-103

M9000-104

M9000-105

M9000-106

M9000-310

M9000-320

M9000-610

* lb x 0.454 = kg

Conduit Adapter Kit 0.4

14 VA Transformer, 120/24 VAC, 60 Hz, Class 2 1.4

14 VA Transformer, 230/24 VAC, 60 Hz, Class 2 1.4

Pluggable 3-terminal block 0.5

Pluggable 4-terminal block 0.5

NEMA 3R weather shield enclosure for M9214 (two weather shield

enclosures required for tandem assemblies)

NEMA 3R weather shield enclosure for M9220 (two weather shield

enclosures required for tandem assemblies)

Tandem Adapter Kit (Converts Single Actuator Valve Linkage into

Tandem Actuator Linkage) includes: Shaft with Spring Clip, Cable,

Strain Relief, Anti-rotation bracket with screws and two plug-in

terminal blocks

2.0

3.3

2.0

Table 32: Tool Kit for VA-310x Series Electric Actuators (Order Separately)

Code

Number

VA-3100-101

* lb x 0.454 = kg

Description Shipping Weight,

lb*

Auxiliary Switch Cam Adjusting Wrench (Used on VA-310x Series

Electric Actuators – One wrench is supplied with each actuator.)

0.1

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 27

Page 28

Table 33: Maintenance and Repair Parts (Order Separately)

Code Number Description

Shipping

Weight, lb*

Packing Kits

V-9999-613

V-5252-668

For 2-1/2 through 4 in. Valves with 3/8 in. Stem. Kit includes: two Ring Packs

(U-Cup with O-Ring installed), one Follower, one Spacer, Insertion/Removal Tool,

one Grease Tube, and one 3 in. (76 mm) strip of Crocus Cloth.

For 3 through 6 in. Valves with 1/2 in. Stem. Kit includes: two Ring Packs (U-Cup

with O-Ring installed), one Follower, one Spacer Insertion/Removal Tool, one

Grease Tube, and one 3 in. (76 mm) strip of Crocus Cloth.

0.1

0.2

Packing Nut Kits (Pneumatically Actuated Assemblies Only)

V-4510-6019

V-5252-609

* lb x 0.454 = kg

For 2-1/2 through 4 in Valves with 3/8 in. Stem 0.1

For 3 through 6 in. Valves with 1/2 in. Stem 0.4

Table 34: Valve Reconditioning Kits (Order Separately)

Code Number Description Shipping

Weight, lb*

V-5252-6001

V-5252-6002

V-5252-6003

V-5252-6004

V-5252-6005

V-5252-6006

V-5252-6007

V-5252-6008

V-5462-6001

Continued on next page . . .

Reconditioning Kit, 2-1/2 in. N.O. Flanged Valve, “M” Stem (3/8 in.), for

use with MP84 Pneumatic Actuator or Electric Actuator, Cv = 51.0;

Includes: Bonnet and Packing Items, Stem and Disk Assembly, Packing

Tools, Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 2-1/2 in. N.O. Flanged Valve, “L” Stem (3/8 in.), for

use with MP82 Pneumatic Actuator, Cv = 51.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 3 in. N.O. Flanged Valve, “M” Stem (3/8 in.), for use

with MP84 Pneumatic Actuator or Electric Actuator, Cv = 83.0; Includes:

Bonnet and Packing Items, Stem and Disk Assembly, Packing Tools,

Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 3 in. N.O. Flanged Valve, “L” Stem (3/8 in.), for use

with MP82 Pneumatic Actuator; Cv = 83.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 4 in. N.O. Flanged Valve, “M” Stem (3/8 in.), for use

with MP84 Pneumatic Actuator or Electric Actuator, Cv = 150.0;

Includes: Bonnet and Packing Items, Stem and Disk Assembly, Packing

Tools, Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 4 in. N.O. Flanged Valve, “N” Stem (1/2 in.), for use

with MP86 Pneumatic Actuator, Cv = 150.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 5 in. N.O. Flanged Valve, “N” Stem (1/2 in.), for use

with MP86 Pneumatic Actuator, Cv = 240.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 6 in. N.O. Flanged Valve, “N” Stem (1/2 in.), for use

with MP86 Pneumatic Actuator, Cv = 350.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 2-1/2 in. N.C. Flanged Valve, “M” Stem (3/8 in.), for

use with MP84 Pneumatic Actuator or Electric Actuator, CV = 54.0;

Includes: Bonnet and Packing Items, Stem and Disk Assembly, Packing

Tools, Gasket and Screw Set, and Grease Packet.

15.0

16.5

22.0

30.6

7.0

6.9

9.5

9.5

7.4

28 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Page 29

Code Number (Cont.) Description Shipping

Weight, lb*

V-5462-6002

V-5462-6003

V-5462-6004

V-5462-6005

V-5462-6006

V-5462-6007

V-5842-6001

V-5842-6002

V-5842-6003

V-5842-6004

V-5842-6005

V-5842-6006

V-5842-6007

* lb x 0.454 = kg

Reconditioning Kit, 3 in. N.C. Flanged Valve, “M” Stem (3/8 in.), for use

with MP84 Pneumatic Actuator or Electric Actuator, Cv = 83.0; Includes:

Bonnet and Packing Items, Stem and Disk Assembly, Packing Tools,

Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 3 in. N.C. Flanged Valve, “N” Stem (1/2 in.), for use

with MP86 Pneumatic Actuator, Cv = 83.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 4 in. N.C. Flanged Valve, “M” Stem (3/8 in.), for use

with MP84 Pneumatic Actuator or Electric Actuator, Cv = 150.0;

Includes: Bonnet and Packing Items, Stem and Disk Assembly, Packing

Tools, Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 4 in. N.C. Flanged Valve, “N” Stem (1/2 in.), for use

with MP86 Pneumatic Actuator, Cv = 150.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 5 in. N.C. Flanged Valve, “N” Stem, (1/2 in.), for use

with MP86 Pneumatic Actuator, Cv = 237.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 6 in. N.C. Flanged Valve, “N” Stem (1/2 in.), for use

with MP86 Pneumatic Actuator, Cv = 344.0; Includes: Bonnet and

Packing Items, Stem and Disk Assembly, Packing Tools, Gasket and

Screw Set, and Grease Packet.

Reconditioning Kit, 2-1/2 in. Three-Way Mixing Flanged Valve, “M” Stem

(3/8 in.), for use with MP84 Pneumatic Actuator or Electric Actuator, Cv

= 54.0; Includes: Bonnet and Packing Items, Stem and Disk Assembly,

Packing Tools, Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 3 in. Three-Way Mixing Flanged Valve, “M” Stem

(3/8 in.), for use with MP84 Pneumatic Actuator or Electric Actuator,

Cv = 80.0; Includes: Bonnet and Packing Items, Stem and Disk

Assembly, Packing Tools, Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 3 in. Three-Way Mixing Flanged Valve, “N” Stem (1/2

in.), for use with MP86 Pneumatic Actuator, Cv = 80.0; Includes: Bonnet

and Packing Items, Stem and Disk Assembly, Packing Tools, Gasket

and Screw Set, and Grease Packet.

Reconditioning Kit, 4 in. Three-Way Mixing Flanged Valve, for use with

Electric Actuator, Cv = 157.0; Includes: Bonnet and Packing Items, Stem

and Disk Assembly, Packing Tools, Gasket and Screw Set, and Grease

Packet.

Reconditioning Kit, 4 in. Three-Way Mixing Flanged Valve, “N” Stem (1/2

in.), for use with MP86 Pneumatic Actuator, Cv = 157.0; Includes:

Bonnet and Packing Items, Stem and Disk Assembly, Packing Tools,

Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 5 in. Three-Way Mixing Flanged Valve, “N” Stem (1/2

in.), for use with MP86 Pneumatic Actuator, Cv = 238.0; Includes:

Bonnet and Packing Items, Stem and Disk Assembly, Packing Tools,

Gasket and Screw Set, and Grease Packet.

Reconditioning Kit, 6 in. Three-Way Mixing Flanged Valve, “N” Stem (1/2

in.), for use with MP86 Pneumatic Actuator, Cv = 347.0; Includes:

Bonnet and Packing Items, Stem and Disk Assembly, Packing Tools,

Gasket and Screw Set, and Grease Packet.

9.9

12.7

16.3

17.4

23.7

31.1

8.1

10.8

12.3

16.6

17.8

22.0

31.9

VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin 29

Page 30

Technical Specifications

Product

Models and Ordering Data

Service*

Valve Body Size/Cv (Kv)

Valve Stroke

2-1/2 and 3 in. Valves

3 and 4 in. Valves

5 in. Valves

6 in. Valves

Valve Body Rating

Valve Assembly

Maximum Allowable

Steam

Water

Pressure/Temperature

Leakage

Inherent Flow Characteristics

Rangeability**

2-1/2 in. Valves

3 in. Valves

4 in. Valves

5 in. Valves

6 in. Valves

Spring Ranges (MP8000 Series Actuators)

Maximum Recommended Operating Pressure Drop

Maximum Actuator Supply Pressure (Pneumatically

Actuated Valves Only)

Maximum Closeoff Pressures

Materials

Body

Stem

Plug

Packing

Valve Fluid Operating Temperature Limits

Actuator Ambient Operating Temperature Limits

Accessories (Order Separately)

Compliance CRN: 0C1100.9087YTN

* Proper water treatment is recommended; refer to VDI 2035 Guideline.

** Rangeability is defined as the ratio of maximum flow to minimum controllable flow.

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

VG2000 Series Cast Iron Flanged Globe Valves

See Tables 1, 2, 3, and 4.

Hot Water, Chilled Water, 50% Glycol Solutions, or Steam for

HVAC Systems

See Table 1.

3/4 in. (19 mm)

1-1/8 in. (29 mm)

1-3/8 in. (35 mm)

1-1/2 in. (38 mm)

Meets Requirements of ASME B16.1, Class 125.

35 psig (241 kPa) at 281F (138C)

175 psig (1,206 kPa) up to 150F (66C),

Decreasing to 125 psig (861 kPa) at 281F (138C)

0.1% of Maximum Flow

Modified Linear

6.5:1

7.7:1

9.3:1

10.7:1

10.4:1

3 to 7, 4 to 8, and 9 to 13 psig

(21 to 48, 28 to 55, and 62 to 90 kPa)

35 psig (241 kPa) for All Valve Sizes

25 psig (172 kPa) Maximum

See Tables 21 through 24.

Cast Iron with Black Lacquer Finish

316 Stainless Steel

Brass

Ethylene Propylene Terpolymer (EPT) Ring Packs

35 to 281F (2 to 138C),

35 psig (241 kPa) Saturated Steam

Refer to the appropriate actuator product bulletin.

See Tables 32 through 35.

Building Efficiency

507 E. Michigan Street

P.O. Box 423 Published in U.S.A.

Milwaukee, WI 53201 www.johnsoncontrols.com

30 VG2000 Series Cast Iron Flanged Globe Valves Product Bulletin

Loading...

Loading...