Johnson Controls VG1xA5Gx, VG1xA5Kx, VG1xA5Lx, VG1xA5Jx, VG1xA5Hx Installation Instructions Manual

...Page 1

VG1000 Series Flanged Ball Valves

14- 1352-6, Rev. G

Installation Instructions

VG12A5xx, VG18A5xx

Refer to the QuickLIT website for the most up-to-date version of this document.

Part No. 14-1352-6, Rev. G

Issued October 2016

Applications

The VG1000 Series Flanged Ball Valves are designed

to regulate hot and chilled water , 50/50 glycol solutions,

and 25 psig steam in HVAC systems.

IMPORTANT: The VG1000 Series Flanged Ball

Valve is intended to control saturated steam, hot

water, and chilled water flow under normal operating

conditions. Where failure or malfunction of the ball

valve could lead to personal injury or property

damage to the controlled equipment or other

property, additional precautions must be designed

into the control system. Incorporate and maintain

other devices, such as supervisory or alarm systems

or safety or limit controls, intended to warn of or

protect against failure or malfunction of the ball

valve.

IMPORTANT: Le VG1000 Series Flanged Ball Valve

est destiné à réguler un débit saturated steam, hot

water, and chilled water dans des conditions

normales de fonctionnement. Lorsqu'une défaillance

ou un dysfonctionnement du ball valve risque de

provoquer des blessures ou d'endommager

l'équipement contrôlé ou un autre équipement, la

conception du système de contrôle doit intégrer des

dispositifs de protection supplémentaires. Veiller

dans ce cas à intégrer de façon permanente

d'autres dispositifs, tels que des systèmes de

supervision ou d'alarme, ou des dispositifs de

sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de

défaillance ou de dysfonctionnement du ball valve.

To minimize heat transfer in steam applications, wrap

the valve and piping with insulation. Allow at least 4 in.

(102 mm) of clearance from the top of the shaft to

remove the actuator (as noted in Table 1).

When mounting the actuator in the field and before

installing the actuator, use an adjustable wrench to

manually rotate the valve stem several times. This

rotation breaks the torque th at may have built up during

long-term storage.

IMPORTANT: Do not attempt to manually rotate the

drive shaft while the actuator is installed without fir st

releasing the actuator gears. Manually rotating the

drive shaft without releasing the actuator gears may

result in permanent damage to the actuator.

IMPORTANT: Take care to prevent foreign material

such as weld slag, thread burrs, metal chips, and

scale from entering the piping system. This de br is

can damage or severely impede the operation of the

valve by embedding itself in the seats, scoring the

valve, and ultimately resulting in seat leakage. If the

debris becomes embedded in the seats, subseque nt

flushing and filtering of the piping system with the

valve installed does not remedy the problem.

For detailed installation information about using

specific equipment, refer to the appropriate

documentation from the following list.

• M9108, M9116, M9124, and M9132 Series Ele ctric

Non-Spring Return Actuators Installation

Instructions (Part No. 34-636-399)

Installation

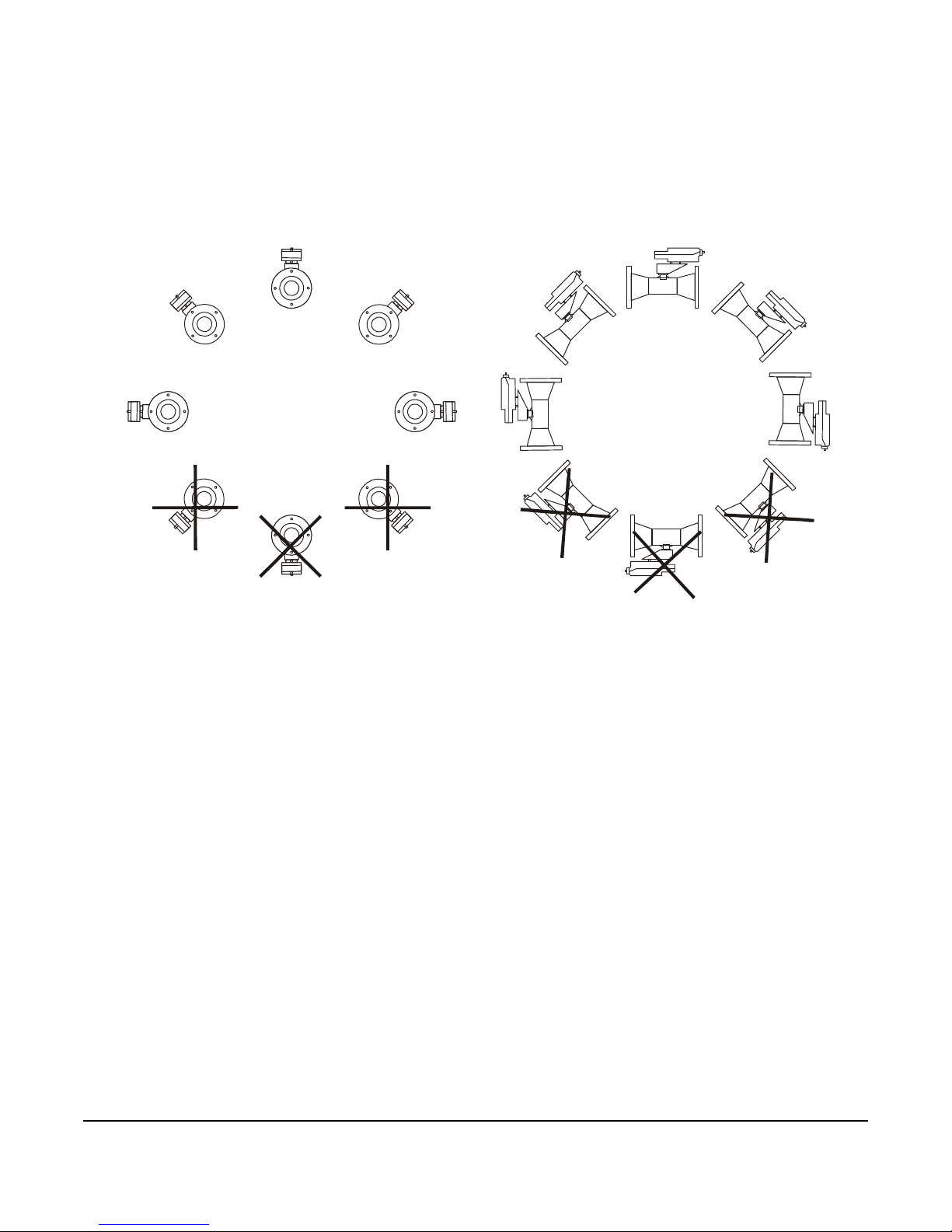

Install the VG1000 Series Flanged Ball Valves with the

actuator at or above the centerline of the horizontal

piping, as shown in Figure 1.

IMPORTANT: In steam applications, install the

valve with the stem horizontal to the piping. Failure

to follow these guidelines may shorten the life of the

actuator.

VG1000 Series Flanged Ball Valves Installation Instructions

• M9220-AGx-3 Series Floating Electric Spring

Return Actuators Installation Instructions

(Part No. 34-636-1689)

• M9220-Bxx-3 Series On/Off Electric Spring Return

Actuators Installation Instructions

(Part No. 34-636-1239)

• M9220-GGx-3 Series Proportional Electric Spring

Return Actuators Installation Instructions

(Part No. 34-636-1697)

1

Page 2

• M9000-330 and M9000-340 Series We ather Shield

Figure 1: Recommended Mounting Positions for Non-Steam Applications

F

I

G

.

V

G

1

0

0

0

-

i

i

0

1

A

AB

Enclosures Installation Instructions

(Part No. 14-1330-26)

• M9000-51x Series Valve Linkage Kits Installation

Instructions (Part No. 14-1201-13)

B

A

A

B

A

A

B

A

A

A

B

A

A

A

B

A

A

B

A

A

B

VG1000 Series Flanged Ball Valves Installation Instructions

2

Page 3

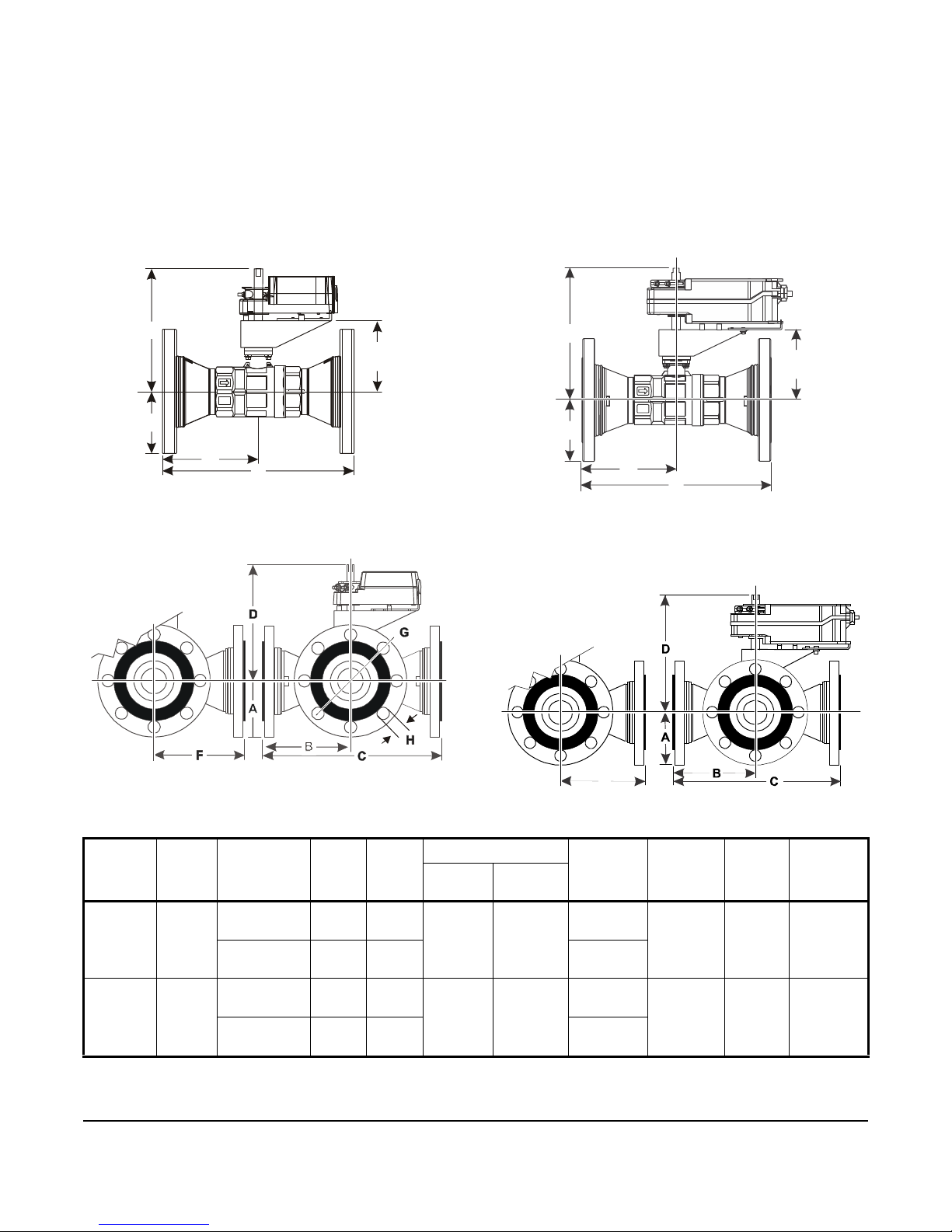

Dimensions

Figure 2: M9124 Actuated VG12A5xx

Two-Way Series Ball Valves, in. (mm)

FIG:M9000-ii02

A

B

C

D

Figure 3: M9124 Actuated

VG18A5xx Three-Way Series Ball Valves

FIG:VG1000 -1103

Figure 4: M9220 Actuated VG12A5x x

Two-Way Series Ball Valves, in. (mm)

5.17

(131)

A

B

C

D

FIG:VG1000-ii04

Figure 5: M9220 Actuated

VG18A5xx Three-Way Series Ball Valves

FIG:VG1000-1105

F

See Figure 2 for VG12A5xx Two-Way Series Flanged

Ball Valves with M9124 Series Actuators dimensions.

See Figure 3 for VG18A5xx Three-Way Series Flanged

Ball Valves with M9124 Series Actuators dimensions.

See Table 1 for specific model dimensions.

5.17

(131)

See Figure 4 for VG12A5xx Two-Way Series Flanged

Ball Valves with M9220 Series Actuators dimensions.

See Figure 5 for VG18A5xx Three-Way Series Flanged

Ball Valves with M9220 Series Actuators dimensions.

See Table 1 for specific model dimensions.

Table 1: VG1xA5xx Series Ball Valves Dimensions, in. (mm) (Part 1 of 2)

Valve

Size,

A Valve

Code

in. (DN)

2-1/2

(DN65)

3 (DN80) 3.75

3.50

(89)

(95)

VG1xA5Gx 5.71

VG1xA5Kx 3.60

VG1xA5Hx 6.10

VG1xA5Lx 4.30

VG1000 Series Flanged Ball Valves Installation Instructions

BC D F G

(Bolt

Circle)

5.50

(140)

6.00

(152)

(145)

(92)

(155)

(110)

1 1 .42

(290)

7.25

(184)

12.20

(310)

8.70

(220)

M9124

8.89

(226)

8.90

(226)

1

M9220

9.64

(245)

9.65

(245)

1

5.87

(149)

6.73

(171)

6.26

(159)

6.77

(172)

3

H Number

of Bolts

0.75

(19)

0.75

(19)

4

4

Page 4

Table 1: VG1xA5xx Series Ball Valves Dimensions, in. (mm) (Part 2 of 2)

Figure 6: Actuated VG12A5xx Two-Way Series

Ball Valves with M9000-3 30 Weathershield

Dimensions, in. (mm)

AAB

A

B

D

5.17

(131)

FIG-VG100 0-ii06

C

Figure 7: Actuated VG18A5xx Three-W ay Series

Ball Valves with M9000-330 Weathershield

F

Valve

Size,

in. (DN)

4

(DN100)

5

(DN125)

6

(DN150)

1. Allow a minimum of 4 in. clearance above the shaft to remove the actuator.

A Valve

4.50

(114)

5.00

(127)

5.50

(140)

VG1xA5Jx 6.89

VG1xA5MW 5.24

VG1xA5NY 6.25

VG1xA5PZ 7.25

Code

BC D F G

(175)

(133)

(159)

(184)

13.77

(350)

10.50

(266)

12.52

(318)

14.50

(368)

M9124

8.90

(226)

9.90

(251)

9.90

(251)

9.90

(251)

1

M9220

9.65

(245)

10.63

(270)

10.63

(270)

10.63

(270)

1

7.05

(179)

8.27

(210)

9.13

(232)

9.90

(251)

(Bolt

Circle)

7.50

(191)

8.50

(217)

9.50

(242)

H Number

of Bolts

0.75

(19)

0.87

(22)

0.87

(22)

8

8

8

See Figure 6 for VG12A5xx Two-Way Series Flanged

Ball Valves with the M9124 Series Non-Spring Return

Actuators dimensions. See Figure 7 for VG18A5xx

Three-Way Series Flanged Ball Valves with the M9124

Series Non-Spring Return Actuators dimensions. Each

drawing includes dimensions for the field-installed

M9000-330 Weathershield. See Table 2 for specific

model dimensions.

FIG-VG100 0-ii07

See Figure 8 for VG12A5xx Two-Way Series Flanged

Ball Valves with the M9220 Series Spring Return

Actuators dimensions. See Figure 9 for the VG18A5xx

Three-Way Series Flanged with the M9220 Series

Spring Return Actuators dimensions. Each drawing

includes dimensions for the field-installed M9000-340

Weathershield. See Table 2 for specific model

dimensions.

VG1000 Series Flanged Ball Valves Installation Instructions

4

Page 5

Figure 8: Actuated VG12A5xx Two-Way Series

Ball Valves with M9000-340 Weathershield

Dimensions, in. (mm)

AAB

5.17

(131)

A

B

D

C

FIG:VG1000-ii 08

Figure 9: Actuated VG18A5xx Three-Way Series

Ball Valves with M9000-340 Weathershield

FIG:VG1000-ii0 9

F

Table 2: VG1xA5xx Series Ball Valves Dimensions, in. (mm)

Valve

Size,

in. (DN)

2-1/2

(DN65)

3 (DN80) 3.75

4

(DN100)

5

(DN125)

6

(DN150)

A Valve

Code

3.50

(89)

(95)

4.50

(114)

5.00

(127)

5.50

(140)

VG1xA5Gx 5.71

VG1xA5Kx 3.60

VG1xA5Hx 6.10

VG1xA5Lx 4.30

VG1xA5Jx 6.89

VG1xA5MW 5.24

VG1xA5NY 6.25

VG1xA5PZ 7.25

BC D F G

1

M9220

9.64

(245)

10.24

(260)

10.24

(260)

10.24

(260)

11.25

(286)

11.25

(286)

11.25

(286)

(145)

(92)

(155)

(110)

(175)

(133)

(159)

(184)

11.42

(290)

7.25

(184)

12.20

(310)

8.70

(220)

13.77

(350)

10.50

(266)

12.52

(318)

14.50

(368)

M9124

8.89

(226)

9.10

(230)

9.10

(230)

9.10

(230)

10.10

(256)

10.10

(256)

10.10

(256)

1

5.87 (149) 5.50

6.73

(171)

6.26

(159)

6.77

(172)

7.05

(179)

8.27

(210)

9.13

(232)

9.90

(251)

(Bolt

Circle)

(140)

6.00

(152)

7.50

(191)

8.50

(217)

9.50

(242)

HNumber

of Bolts

0.75

(19)

0.75

(19)

0.75

(19)

0.87

(22)

0.87

(22)

4

4

8

8

8

1. Allow a minimum of 4 in. clearance above the shaft to remove the actuator.

VG1000 Series Flanged Ball Valves Installation Instructions

5

Page 6

Mounting

Figure 10: Typical VG1000 Series Flanged Ball Valves Piping Application

VG124x Two-Way Valve

Return

Supply

Port A Port B

VG184x Three -Way Valve

Return

Supply

Port A

Port C

F

I

G

:

V

G

1

0

0

0

p

i

p

a

p

p

Typical Two-Way Ball Valve Application

Typical Three-Way Ball Valve Application

Port B

Location Considerations

IMPORTANT: Protect the actuator from dripping

water, condensation, and other moisture. Water or

moisture could result in an electrical short, which

may damage or affect the operation of the actuator.

Piping

Be sure to wire the input lines to the electric actuator

correctly for the valve to move in the proper direction.

See Figure 10 for typical two- and three-way piping

configurations.

IMPORTANT: Use copper conductors only. Make

IMPORTANT: Do not cover the actuator with

thermal insulating material. High ambient

temperatures may damage the actuator, and a hot

all wiring connections in accordance with local,

national, and regional regulations. Do not exceed

the actuator’s electrical ratings.

water pipe, a steam pipe, or other heat source may

overheat it.

Note: Mount the valve downstream from the coil to minimize heat transfer to the actuator.

VG1000 Series Flanged Ball Valves Installation Instructions

6

Page 7

Setup and Adjustments

Figure 11: VG18A5 Series Three-Way Ball Valve

(Coil Port A Open to Common Port AB)

Port B Bypass

Port A

Coil

Port AB

Common

FIG:3W_AtoAB

Figure 12: VG18A5 Series Three-Way Ball Valve

(Bypass Port B Open to Common Port AB)

Port B Bypass

Port A

Coil

Port AB

Common

FIG:3W_BtoAB

!

!

Port A has the flow characterizing disk. Connect Port A

to the outlet from the coil. On three-way models, use

Port B as the bypass port.

Two-way VG1000 Series Ball Valves are fully open

when the electric actuator is fully counterclockwise

(CCW) and fully closed when the electric actuator is

fully clockwise (CW).

For three-way valves, the Coil Port A and Common

Port AB are fully open when the electric actuator is fully

CCW, as shown in Figur e 11. The Bypass Port B and

Common Port AB are fully open when the actuator is

fully CW, as shown in Figure 12.

For spring-to-close proportional control models in the

DA mode, a minimum control signal drives the electric

actuator to the fully CW position, while a maximum

control signal drives the electric actuator to the fully

CCW position.

T roubleshooting

Servicing the Actuator or Piping System

When servicing the electric actuator or the piping

system:

• disconnect the power supply to the actuator

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections. More

than one disconnection or isolation may be

required to completely de-energize

equipment. Contact with components

carrying hazardous voltage can cause

electric shock and may result in severe

personal injury or death.

AVERTISSEMENT : Risque de décharge

électrique.

Débrancher ou isoler toute alimentation

avant de réaliser un raccordement

électrique. Plusieurs isolations et

débranchements sont peut-être nécessa ires

pour -couper entièrement l'alimentation de

l'équipement. Tout contact avec des

composants porteurs de tensions

dangereuses risque d'entraîner une

décharge électrique et de provoquer des

blessures graves, voire mortelles.

For non-spring return and spring-to-open proportional

control models in the Direct Acting (DA) mode, a

minimum control signal drives the electric actuator to

the fully CCW position while a maximum control signal

drives the electric actuator in the fully CW position.

VG1000 Series Flanged Ball Valves Installation Instructions

• relieve the pressure in the piping system

CAUTION: Risk of Property Damage.

Do not apply power to the system before

checking all wiring connections. Short

circuited or improperly connected wires may

result in permanent damage to the

equipment.

MISE EN GARDE : Risque de dégâts

matériels.

Ne pas mettre le système sous tension

avant d'avoir vérifié tous les raccords de

câblage. Des fils formant un court-circuit ou

connectés de façon incorrecte risquent

d'endommager irrémédiablement

l'équipement.

7

Page 8

Repair Information

If the VG1000 Series Flanged Ball Valve fails to

operate within its specifications, replace the unit. For a

replacement valve, contact the nearest

Johnson Controls® representative.

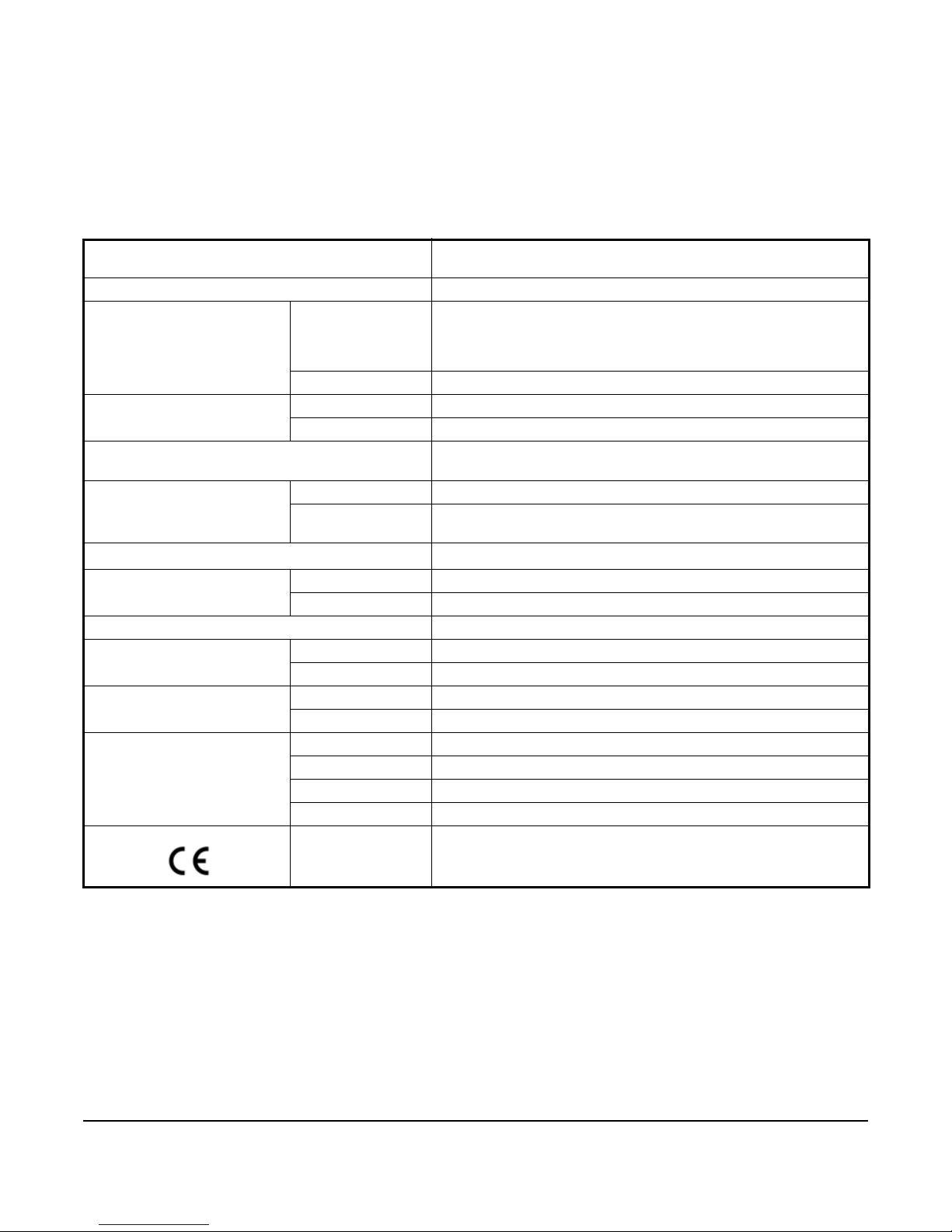

Technical Specifications

VG1000 Series Flanged Ball Valves

Service

Valve Fluid T e mpe r atu re Limits 0 to 284°F (-18 to 140°C)

Valve Body Pressure/

Temperature Rating

Maximum Closeoff Pressure Two-Way 100 psi (689 kPa)

Maximum Recommended Operating Pressure

Drop

Flow Characteristics Two-Way Equal Percentage

Rangeability

Leakage Two- or Three-Way 0.01% of maximum flow, control port, ANSI/FCI 70-2, Class 4

End Connections ASME Class 150 Flange

Minimum Ambient Operating

Temperature

Maximum Ambient

Operating Temperature

Materials Body Brass

Compliance

1

Water ASME Class 150

Steam 25 psig (172 kPa) saturated steam for HVAC systems

Three-Way 50 psi (345 kPa)

Three-Way Equal Percentage Flow Characteristics of In-line Port or

2

Three-Way 1% of maximum flow, bypass port

-4°F (-20°C) M9124 Series Non-Spring Return Actuators

-40°F (-40°C) M9220 Series Spring Return Actuators

3

122°F (50°C) M9124 Series Non-Spring Return Actuators

131°F (55°C) M9220 Series Spring Return Actuators

Flanges Ductile Iron

Ball 300 Series Stainless Steel

Stem 300 Series Stainless Steel

Europe CE Mark - Johnson Controls, Inc. declares that this product is in

Hot water, chilled water, 50/50 Glycol solutions, and 25 psig

(172 kPa) saturated steam for HVAC systems

250 psi at -20 to 100°F (-29 to 38°C)

235 psi at: 200°F (93°C)

218 psi at: 284°F (140°C)

30 psi (207 kPa) for quiet service

Linear Percentage Flow Characteristics of Angle Port

Greater than 500:1

compliance with the essential requirements and other relevant

provisions of the Pressure Equipment Directive (PED).

1. Refer to VDI 2035 Guideline for proper water treatment.

2. Rangeability is defined as the ratio of maximum controllable flow to minimum controllable flow.

3. In steam applications, install the valve with the stem horizontal to the piping, and wrap the valve and piping with insulation.

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

VG1000 Series Flanged Ball Valves Installation Instructions

8

Page 9

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

European Single Point of Contact: NA/SA Single Point of Contact: AP AC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MIL WAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

VG1000 Series Flanged Ball Valves Installation Instructions

Published in U.S.A. www.johnsoncontrols.com

9

Loading...

Loading...