Page 1

Product Bulletin VF Series Butterfly Valves

Issue Date August 15, 2014

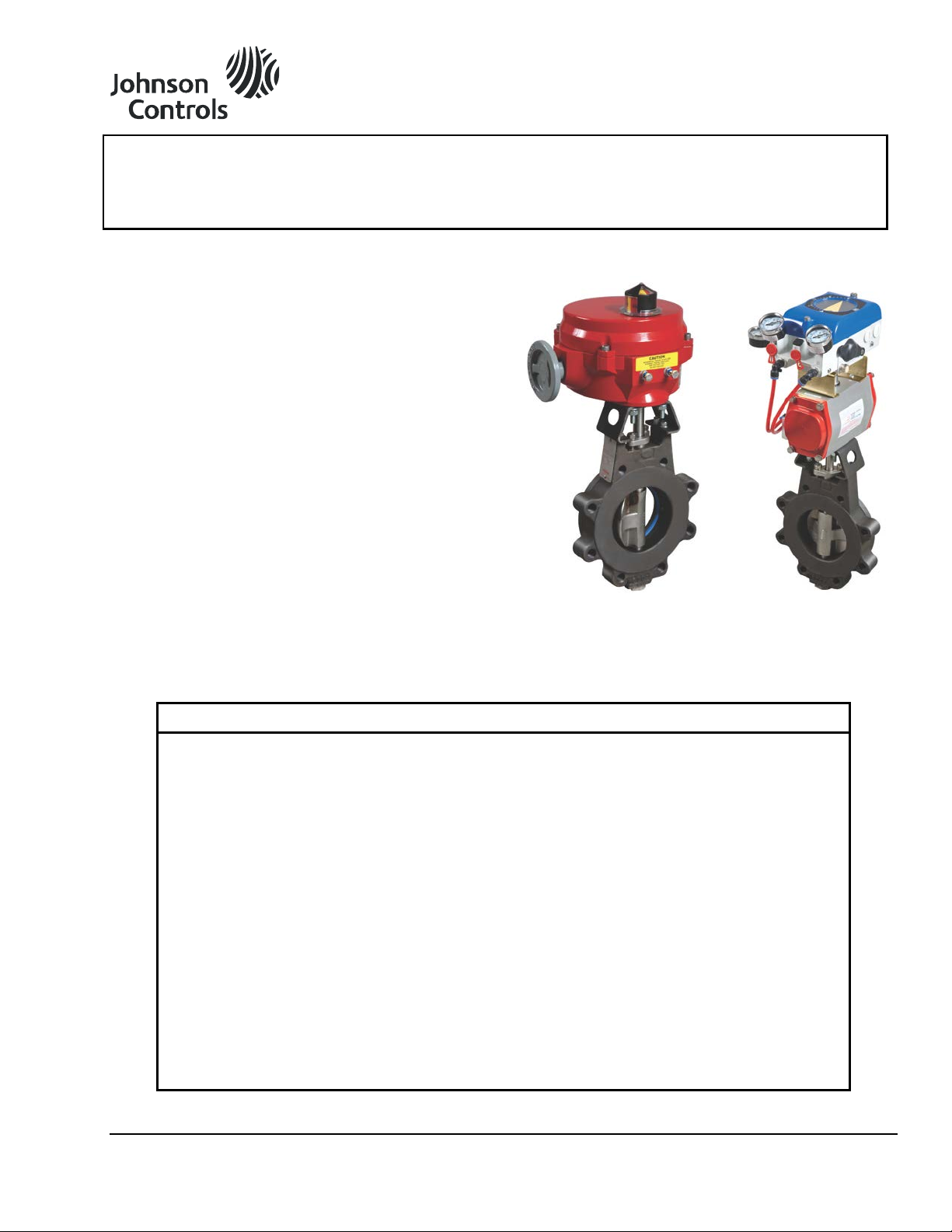

VF Series High-Pressure,

High-Temperature Butterfly Valve Assemblies

VF Series High-Press ur e, High-T e mp er ature But ter fly

Valve Assemblies are specifically designed for a wide

range of Heating, Ventilating, and Air Conditioning

(HVAC) applications including two-position and

modulating/throttling control of hot water, chilled water,

condenser water, and steam. Refer to the VF Ser i es

High-Pressure, High-Temperature Butter f l y Valves for

Steam Service Application Note (LIT-977321) for more

information on steam app lic atio ns . T hese lu g-style

valves offer bidirectional shutoff at fully rated American

National Standards Institute (ANSI) Class 150 and 300

operating pressures, increasing the range of

applications – particularly in high-rise building HVAC

control applications. ANSI Class 150 and 300 models

are also suitable for steam applications.

ANSI Class 150 Butterfly Valves are avai lab le in

two-way configurations, in sizes ranging from

2-1/2 through 16 in. ANSI Class 300 Butterfly Valves

are available in two-way configurations , in sizes

ranging from 2-1/2 through 14 in. ANSI Class 150

valves are rated for 240 psig at 250°F, and ANSI

Class 300 valves are rated for 550 psig at 250°F.

Features and Benefits

Compatible with All Types of ANSI

150/300 Slip-On and Weld-Neck Flanges

High-Pressure, High-Temperature Design

Bidirectional Shutoff, Dead-End Service Provides positive closure in both directions to

Live-Loaded Seat Design with Fully

Encased O-Ring

Double Offset Stem Design Reduces seat wear to significantly extend

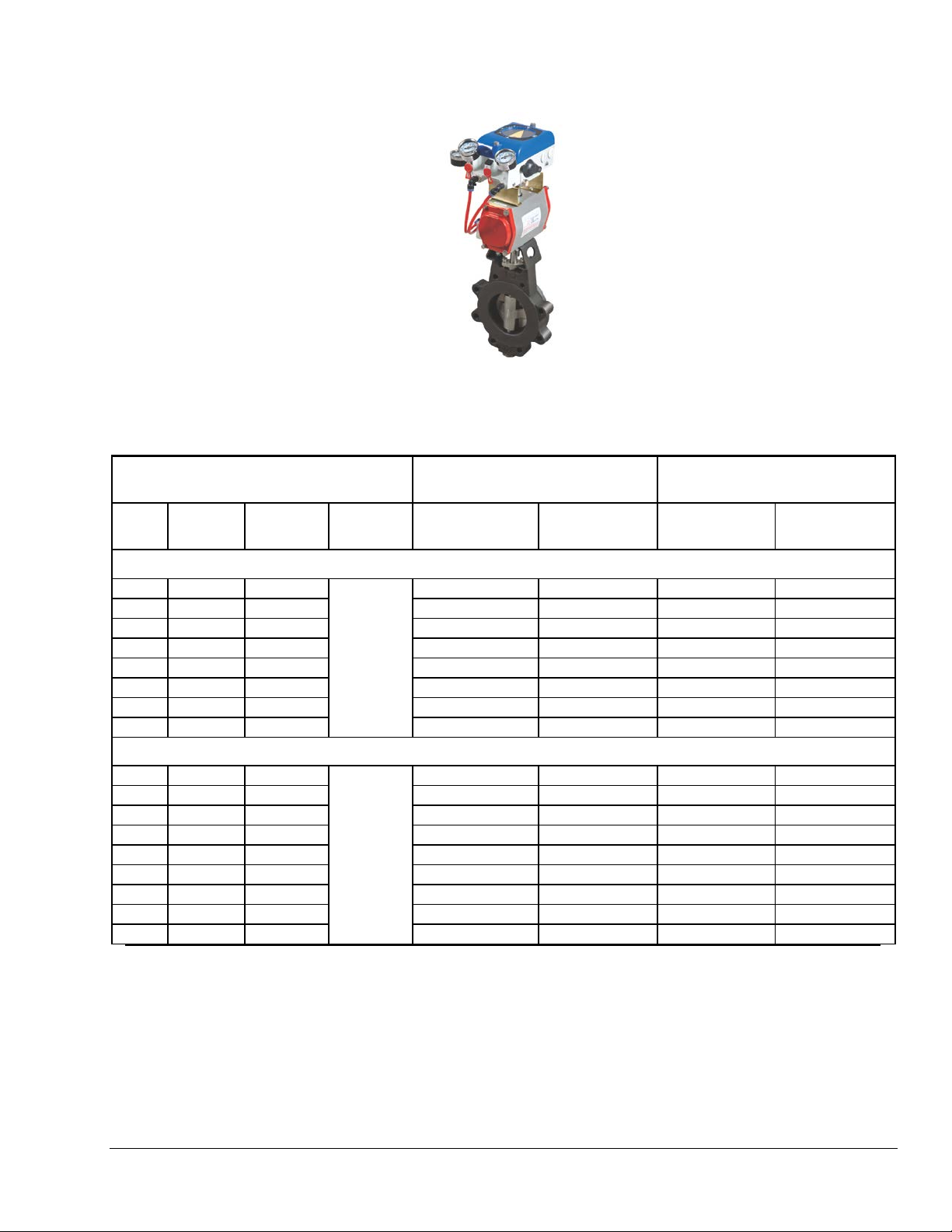

Figure 1: VF Series High-Pressure,

High-Temperature Butterfly Valve Assemblies

Enables field configuration with readily

available standard fittings

Increases the range of applications,

particularly in high-rise building HVAC control

applications

full ANSI pressure ratings

Offers superior sealing and long service life

cycle life

Broad Range of Compact Pre-Assembled

Actuators Available

Provides a wide selection for new and

replacement electric and pneumatic actuators

Direct Actuator-to-Stem Mounting Reduces hysteresis and simplifies installation

© 2014 Johnson Controls, Inc. 1

Code No. LIT-977208 www.johnsoncontrols.com

Page 2

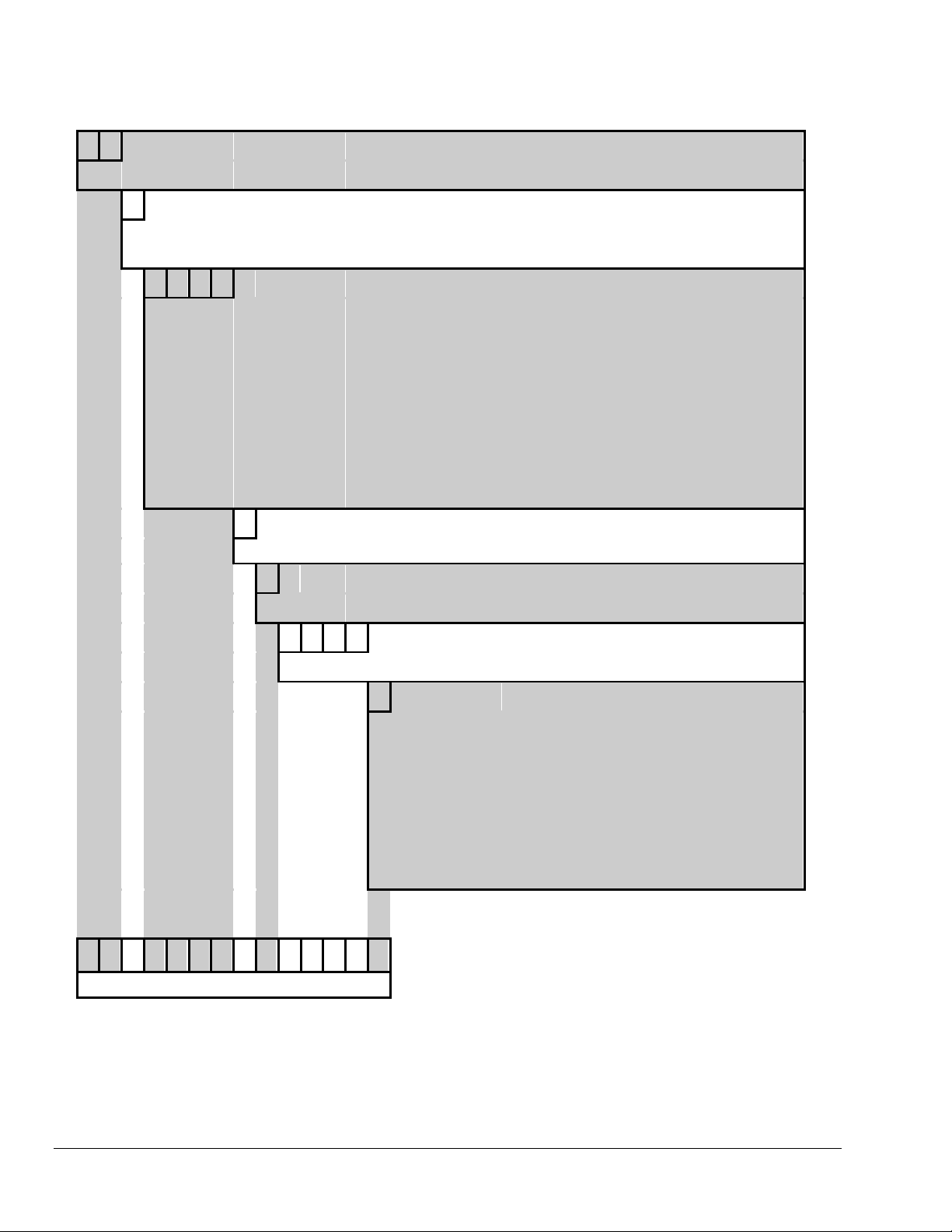

Table 1: Ordering Data

C = Two

M = Manually Operated

N = Two

025 = 2

030 = 3 in.

040 = 4 in.

050 = 5 in.

060 = 6 in.

080 = 8 in.

100 = 10 in.

120 = 12 in.

140 = 14 in.

160 = 16 in.

V = ANSI Class 150

Z = ANSI Class 300

E = 17

See

11

B = High Pressure Positioner

C = 120 VAC Solenoid with Speed Controls

D = Thermostat/Heater Kit for On/Off

E = 24 VAC Solenoid with Speed Controls

G = Gear-Operated Manual Hand Wheel

M = Ten

N = Thermostat/Heater Kit for Proportional

Example: Two

in.,

ANSI

stem, proportional non

actuator, and thermostat/heater kit.

V F

Butterfly

1 2

C

3

– 1 0 0

4 5 6 7

V

8

E

9

Valve

Body Type

Valve Size

Flange

Stem

Material

-Way, Normally Closed (N.C.)

-Way, Normally Open (N.O.)

-1/2 in.

-4 PH Stainless Steel

– 7 0 7

10

1 2 3 4 5 6 7 8 9 10 11 12 13 14 = Field

V F C

–

1 0 0 V E

Butterfly Valve Assembly

–

7 0 7

12 13

Actuator

Accessories

N

14

N

Table 2.

Electric Actuators

-Position Manual Handle

Electric Actuators

-way normally closed valve, 10

Class 150 with 17-4 PH stainless steel

-spring return electric

2 VF Series High-Pressure, High-Tem perat ure Butt er f l y Valves Product Bulle tin

Page 3

707

=

VA-9077-01

432

=

V-9194-23

=

724

=

VA-9075-02

550

=

V-9195-15

080 = V-9098-1

Table 2: Ordering Data – Adding a Factory-Mounted Industrial-Grade

Pneumatic or Electric Actuator

Note: See Table 3, Table 4, Table 5, and Table 6 for valid factory assemblies.

Electric, Proportional, Non-Spring Return High Pressure Pneumatic, Spring Return

702 = VA-9072-01 340 = V-9193-14

703 = VA-9075-01 360 = V-9193-16

704 = VA-9075-01

705 = VA-9075-01 422 = V-9194-22

706 = VA-9076-01 430 = V-9194-13

702N4 = VA-9072-11

705N4 = VA-9075-11 440 = V-9194-14

707N4 = VA-9077-11 442 = V-9194-24

907 = VA-907A-01 452 = V-9194-25

908 = VA-907B-01

Electric, On/Off, Non-Spring Return

722 = VA-9072-02

723 = VA-9075-02 530 = V-9195-13

462

V-9194-26

725 = VA-9075-02

726 = VA-9076-02 630 = V-9196-13

727 = VA-9077-02 650 = V-9196-15

722N4 = VA-9072-12 660 = V-9196-16

725N4 = VA-9075-12

727N4 = VA-9077-12 730 = V-9197-13

750 = V-9197-15

927 = VA-907A -02

928 = VA-907B -02

High Pressure Pneumatic,

Non-Spring Return

030 = V-9093-1 820 = V-9198-12

040 = V-9094-1 830 = V-9198-13

042 = V-9094-2 840 = V-9198-14

050 = V-9095-1 850 = V-9198-15

060 = V-9096-1

070 = V-9097-1

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 3

Page 4

3

185

123

VFC-030ZE-722D

VFC-030ZE-702N

VFC-030ZE-722D4

VFC-030ZE-702N4

4

375

250

VFC-040ZE-723D

VFC-040ZE-703N

VFC-040ZE-725D4

VFC-040ZE-705N4

5

790

360

VFC-050ZE-725D

VFC-050ZE-705N

VFC-050ZE-725D4

VFC-050ZE-705N4

6

1,000

530

VFC-060ZE-726D

VFC-060ZE-706N

VFC-060ZE-727D4

VFC-060ZE-707N4

8

2,000

950

VFC-080ZE-727D

VFC-080ZE-707N

VFC-080ZE-727D4

VFC-080ZE-707N4

10

2,650

1,025

VFC-100ZE-927D

VFC-100ZE-907N

–––

–––

12

4,000

1,690

VFC-120ZE-927D

VFC-120ZE-907N

–––

–––

14

4,100

1,770

VFC-140ZE-928D

VFC-140ZE-908N

–––

–––

Two-Way, Normally Closed – ANSI Class 150 Flanges

3

2-1/2

160

78

VFC-025VE-722D

VFC-025VE-702N

VFC-025VE-722D4

VFC-025VE-702N4

3

185

123

VFC-030VE-722D

VFC-030VE-702N

VFC-030VE-722D4

VFC-030VE-702N4

4

375

250

VFC-040VE-722D

VFC-040VE-702N

VFC-040VE-722D4

VFC-040VE-702N4

5

790

360

VFC-050VE-724D

VFC-050VE-704N

VFC-050VE-725D4

VFC-050VE-705N4

6

1,350

510

VFC-060VE-725D

VFC-060VE-705N

VFC-060VE-725D4

VFC-060VE-705N4

8

2,800

1,060

VFC-080VE-725D

VFC-080VE-705N

VFC-080VE-725D4

VFC-080VE-705N4

10

4,300

1,630

VFC-100VE-726D

VFC-100VE-706N

VFC-100VE-727D4

VFC-100VE-707N4

12

6,650

2,530

VFC-120VE-727D

VFC-120VE-707N

–––

–––

14

7,650

2,900

VFC-140VE-927D

VFC-140VE-907N

–––

–––

16

9,800

3,170

VFC-160VE-927D

VFC-160VE-907N

–––

–––

1.

2.

3

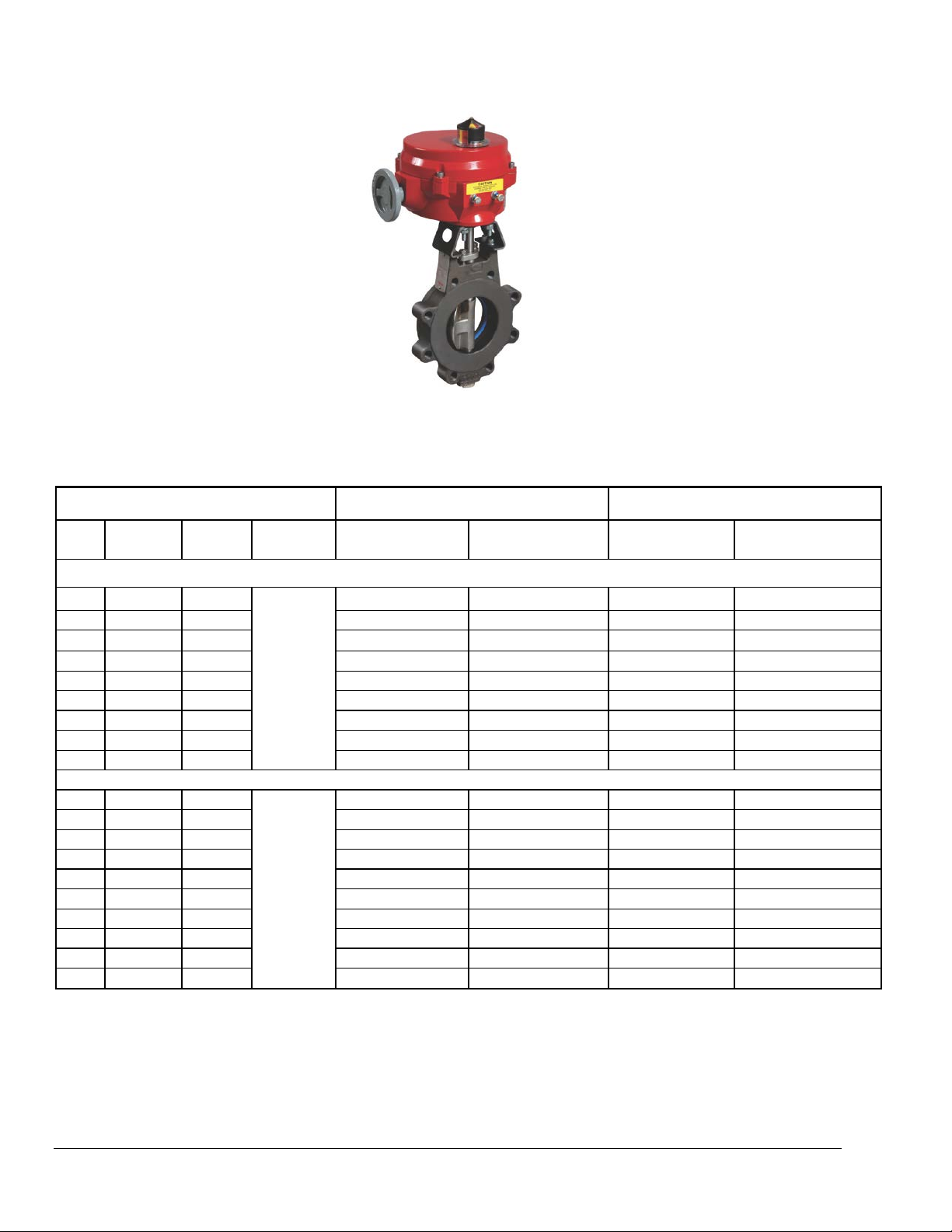

Figure 2: Two-Way Valve with Industrial-Grade,

Non-Spring Return, VA-907X Series Electric Actuator

Table 3: Two-Way Valves with Indust rial-Grade, Non-Spring Return,

VA-907X Series Electric Actuators

Actuator

AC 120 V Powered Actuator AC 24 V Powered Actuator

Size,

2-1/2 160 78

in.

Cv at 90

Degrees

Cv at 60

Degrees

Closeoff

Pressure

1

On/Off

0 to 10 VDC

Proportional

Two-Way, Normally Closed – ANSI Class 300 Flanges

VFC-025ZE-722D VFC-025ZE-702N VFC-025ZE-722D4 VFC-025ZE-702N4

550 psig

240 psig

On/Off

2

0 to 10 VDC

Proportional

Close-off pressures are dimensioned for a valve seat retainer that is oriented upstr ea m.

Maximum closeoff pressure for ANSI Class 300 valves is 740 psig (5102.1 kPa) for fluid temperatures below 100°F (37.8°C),

and 550 psig (3,790 kPa) for fluid temperatures at 250°F (121.1°C). Maximum steam pressure is 150 psig (1034.2 kPa) for

On/Off service, and 50 psig (344.8 kPa) for proportional service.

. Maximum closeoff pressure for ANSI Class 150 valves is 285 psig (1965 kPa) for fluid temperatures below 100°F (37.8°C), and

240 psig (1654.8 kPa) for fluid temperatures at 250°F (121.1°C). Maximum steam pressure is 150 psig (1034.2 kPa) for On/Off

service, and 50 psig (344.8 kPa) for proportional service.

4 VF Series High-Pressure, High-Tem perat ure Butt er f l y Valves Product Bulle tin

Page 5

2-1/2

160

78

VFC-024ZE-432C

VFN-025ZE-422C

VFC-025ZE-432B

VFN-025ZE-422B

3

185

123

VFC-030ZE-442C

VFN-030ZE-422C

VFC-030ZE-442B

VFN-030ZE-422B

4

375

250

VFC-040ZE-452C

VFN-040ZE-432C

VFC-040ZE-452B

VFN-040ZE-432B

5

790

360

VFC-050ZE-650C

VFN-050ZE-630C

VFC-050ZE-650B

VFN-050ZE-630B

6

1,000

530

VFC-060ZE-660C

VFN-060ZE-630C

VFC-060ZE-660B

VFN-060ZE-630B

8

2,000

950

VFC-080ZE-750C

VFN-080ZE-730C

VFC-080ZE-750B

VFN-080ZE-730B

10

2,650

1,200

VFC-100ZE-840C

VFN-100ZE-830C

VFC-100ZE-840B

VFN-100ZE-830B

12

4,000

1,450

VFC-120ZE-850C

VFN-120ZE-840C

VFC-120ZE-850B

VFN-120ZE-840B

2-1/2

160

78

VFC-025VE-360C

VFN-025VE-340C

VFC-025VE-360B

VFN-025VE-340B

3

185

123

VFC-030VE-360C

VFN-030VE-340C

VFC-030VE-360B

VFN-030VE-340B

4

375

250

VFC-040VE-430C

VFN-040VE-440C

VFC-040VE-430B

VFN-040VE-440B

5

790

360

VFC-050VE-462C

VFN-050VE-530C

VFC-050VE-462B

VFN-050VE-530B

6

1,350

510

VFC-060VE-550C

VFN-060VE-530C

VFC-060VE-550B

VFN-060VE-530B

8

2,800

1,060

VFC-080VE-650C

VFN-080VE-630C

VFC-080VE-650B

VFN-080VE-630B

10

4,300

1,630

VFC-100VE-750C

VFN-100VE-730C

VFC-100VE-750B

VFN-100VE-730B

12

6,650

2,530

VFC-120VE-830C

VFN-120VE-820C

VFC-120VE-830B

VFN-120VE-820B

14

7,650

2, 900

VFC-140VE-850C

VFN-140VE-830C

VFC-140VE-850B

VFN-140VE-830B

1.

2.

3.

4.

psig (1034.2 kPa) for On/Off service, and 50 psig (344.8 kPa) for proportional service.

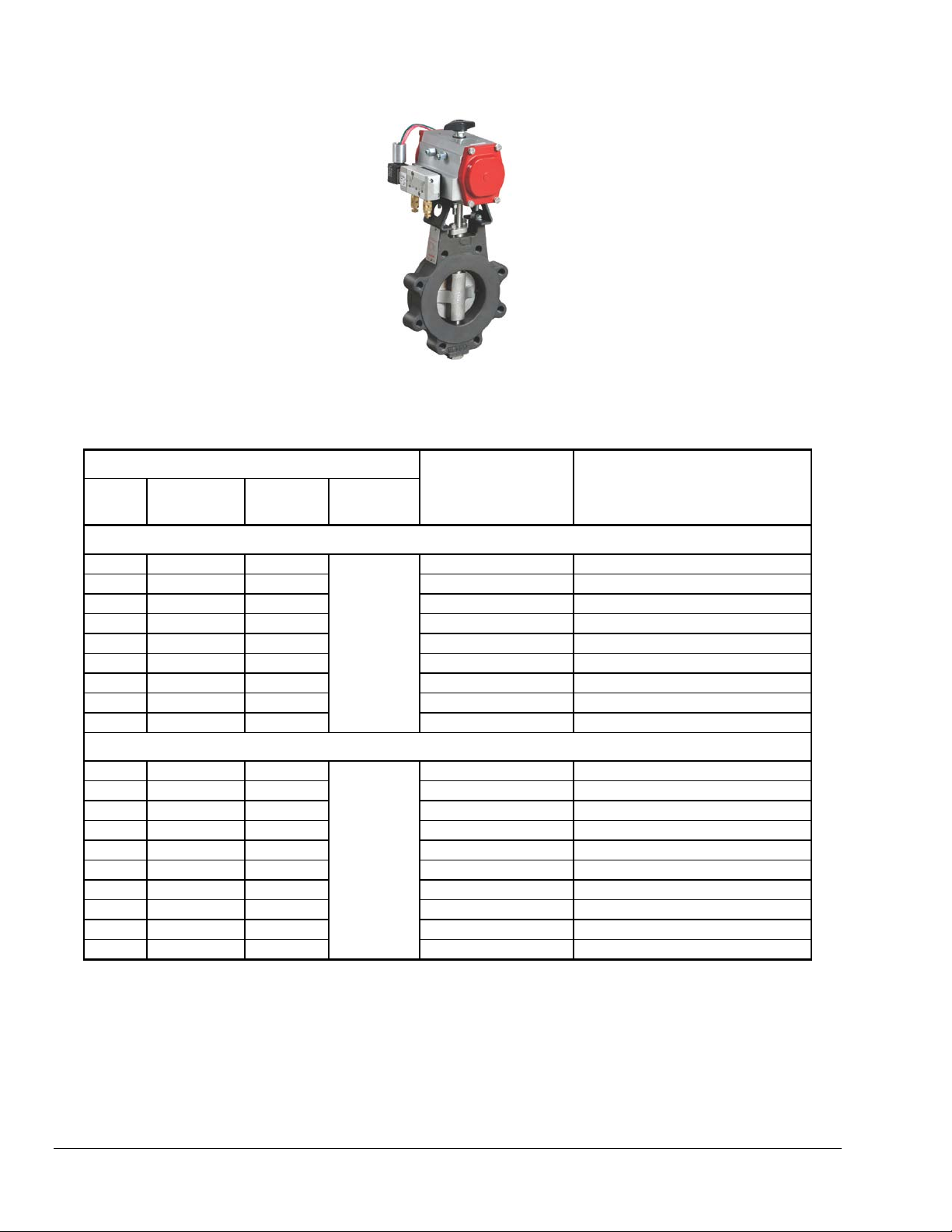

Figure 3: Two-Way Valve with Industrial-Grade,

Spring Return, V-919x Series High Pressure Pneumatic Actuator

Table 4: Two-Way Valves with Indust rial-Grade, Spring Return, V-919x Series High Pressure Pneumatic

Actuators

Actuator On/Off

1

Proportional

(with Positioner)

Size,

in.

Cv at 90

Degrees

Cv at 60

Degrees

Closeoff

Pressure

Spring Closed Spring Open Spring Closed Spring Open

2

Two-Way, Normally Closed – ANSI Class 300 Flanges3

550 psig

Two-Way, Normally Closed – ANSI Class 150 Flanges4

240 psig

On/Off assemblies come with 120 VAC solenoid valve and speed controls. If a 24 VAC solenoid is desired, change

the C at the end of the code number to an E.

Close-off pressures are dimensioned for a valve seat retainer that is oriented upstream.

Maximum closeoff pressure for ANSI Class 300 valves is 740 psig (5102.1 kPa) for fluid temperatures below 100°F

(37.8°C), and 550 psig (3,790 kPa) for fluid temperatur es at 250° F (121.1°C). Maximum steam pressure is 150 psig

(1034.2 kPa) for On/Off service, and 50 psig (344.8 kPa) for proportional service.

Maximum closeoff pressure for ANSI Class 150 valves is 285 psig (1965 kPa) for fluid temperatures below 100°F

(37.8°C), and 240 psig (1654.8 kPa) for fluid temperatures at 250°F (121.1°C). Maximum steam pressure is 150

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 5

Page 6

2-1/2

160

78

VFC-025ZE-030C

VFC-025ZE-030B

3

185

123

VFC-030ZE-030C

VFC-030ZE-030B

4

375

250

VFC-040ZE-040C

VFC-040ZE-040B

5

790

360

VFC-050ZE-042C

VFC-050ZE-042B

6

1,000

530

VFC-060ZE-050C

VFC-060ZE-050B

8

2,000

950

VFC-080ZE-060C

VFC-080ZE-060B

10

2,650

1,025

VFC-100ZE-070C

VFC-100ZE-070B

12

4,000

1,690

VFC-120ZE-070C

VFC-120ZE-070B

14

4,100

1,770

VFC-140ZE-080C

VFC-140ZE-080B

2-1/2

160

78

VFC-025VE-030C

VFC-025VE-030B

3

185

123

VFC-030VE-030C

VFC-030VE-030B

4

375

250

VFC-040VE-030C

VFC-040VE-030B

5

790

360

VFC-050VE-042C

VFC-050VE-042B

6

1,350

510

VFC-060VE-042C

VFC-060VE-042B

8

2,800

1,060

VFC-080VE-050C

VFC-080VE-050B

10

4,300

1,630

VFC-100VE-060C

VFC-100VE-060B

12

6,650

2,530

VFC-120VE-070C

VFC-120VE-070B

14

7,650

2,900

VFC-140VE-070C

VFC-140VE-070B

16

9,800

3,170

VFC-160VE-080C

VFC-160VE-080B

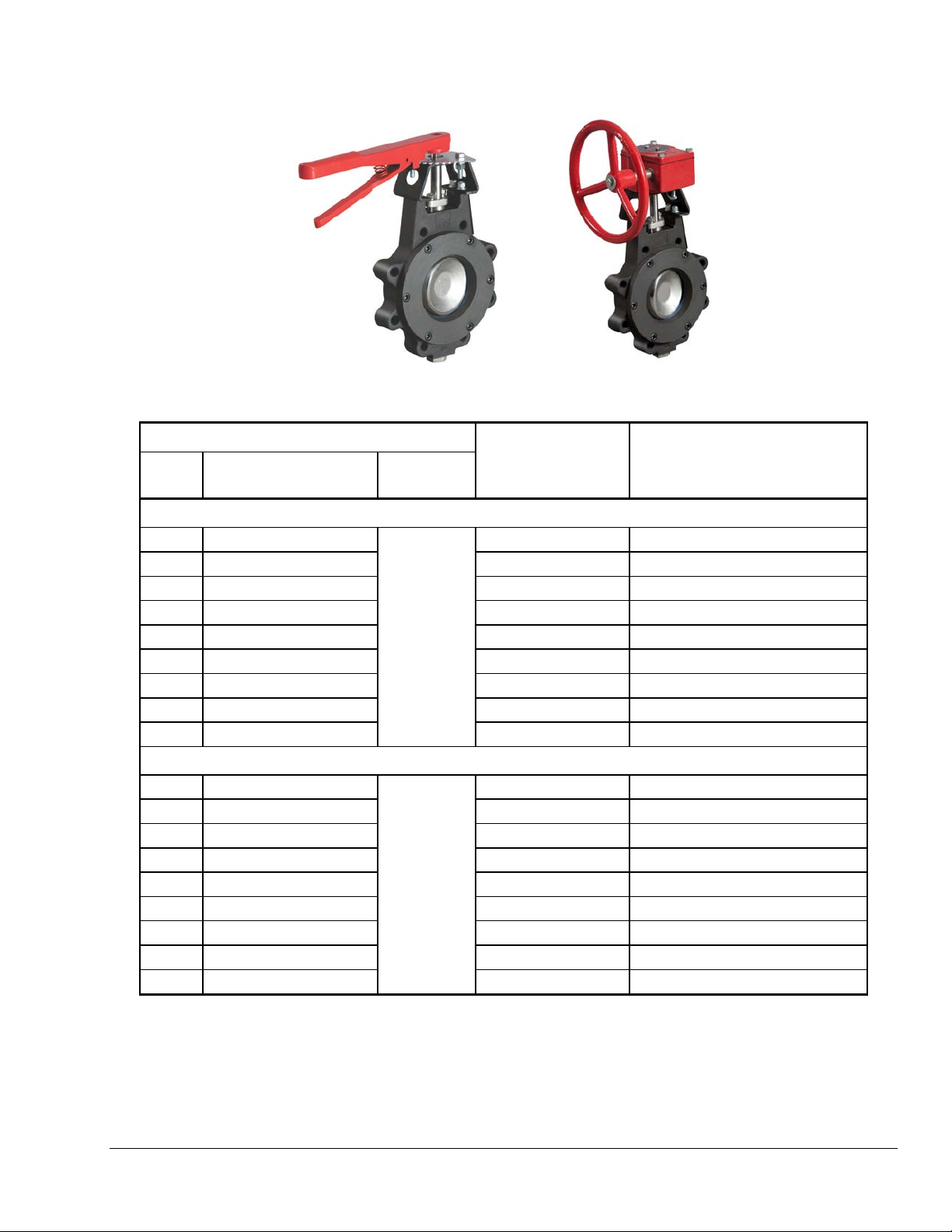

Figure 4: Two-Way Valve with Industrial-Grade, Non-Spring Return, V-909x Series High Pressure

Pneumatic Actuator

Table 5: Two-Way Valves with Indust rial-Grade, Non-Spring Return,V-909x Series High Pressure

Pneumatic Actuators

Actuator

Size,

in.

Cv at 90

Degrees

Cv at 60

Degrees

Closeoff

Pressure

1

2

On/Off

Proportional

(with Positioner)

Two-Way, Normally Closed – ANSI Class 300 Flanges3

550 psig

Two-Way, Normally Closed – ANSI Class 150 Flanges4

240 psig

1. On/Off assemblies come with 120 VAC solenoid valve and speed controls. If a 24 VAC solenoid is desired,

change the C at the end of the code number to an E.

2. Close-off pressures are dimensioned for a valve seat retainer that is oriented upstream.

3. Maximum closeoff pressure for ANSI Class 300 valves is 740 psig (5102.1 kPa) for fluid temperatures below 100°F

(37.8°C), and 550 psig (3,790 kPa) for fluid temperatur es at 250° F (121.1°C). Maximum steam pressure is 150 psig

(1034.2 kPa) for On/Off service, and 50 psig (344.8 kPa) for proportional service.

4. Maximum closeoff pressure for ANSI Class 150 valves is 285 psig (1965 kPa) for fluid temperatures below 100°F

(37.8°C), and 240 psig (1654.8 kPa) for fluid temperatures at 250°F (121.1°C). Maximum steam pressure is 150 psig

(1034.2 kPa) for On/Off service, and 50 psig (344.8 kPa) for proportional service.

6 VF Series High-Pressure, High-Tem perat ure Butt er f l y Valves Product Bulle tin

Page 7

Figure 5: Two-Way Valve with Manual Operator

2-1/2

4

375

VFM-040ZE-000M

VFM-040ZE-000G

5

8

10

14

2-1/2

5

8

2,800

---

VFM-080VE-000G

10

14

Table 6: Two-Way Valves with Manual Operato rs

Actuator

Size,

in.

Cv at 90 Degrees

Closeoff

Pressure

1

Two-Way, Manually Operated – ANSI Class 300 Flanges2

Ten-Position

Manual Handle

Manual Hand Wheel

Gear-Operated

160

3 185 VFM-030ZE-000M VFM-030ZE-000G

790

6 1,000 VFM-060ZE-000M VFM-060ZE-000G

2,000 --- VFM-080ZE-000G

2,650 --- VFM-100ZE-000G

12 4,000 --- VFM-120ZE-000G

4,100 --- VFM-140ZE-000G

550 psig

VFM-025ZE-000M VFM-025ZE-000G

VFM-050ZE-000M VFM-050ZE-000G

Two-Way, Manually Operated – ANSI Class 150 Flanges3

160

3 185

4 375 VFM-040VE-000M VFM-040VE-000G

790 VFM-050VE-000M VFM-050VE-000G

6 1,350 VFM-060VE-000M VFM-060VE-000G

4,300

12 6,650 --- VFM-120VE-000G

7,650 --- VFM-140VE-000G

1. Close-off pressures are dimensioned for a valve seat retainer that is oriented upstream.

2. Maximum closeoff pressure for ANSI Class 300 valves is 740 psig (5102.1 kPa) for fluid temperatures below 100°F

(37.8°C), and 550 psig (3,790 kPa) for fluid temperatur es at 250° F (121.1°C). Maximum steam pressure is 150 psig

(1034.2 kPa) for On/Off servi c e, and 50 psig (344. 8 kPa) for proportional service.

3. Maximum closeoff pressure for ANSI Class 150 valves is 285 psig (1965 kPa) for fluid temperatures below 100°F

(37.8°C), and 240 psig (1654.8 kPa) for fluid temperatures at 250°F (121.1°C). Maximum steam pressure is 150 psig

(1034.2 kPa) for On/Off service, and 50 psig (344.8 kPa) for proportional service.

240 psig

VFM-025VE-000M VFM-025VE-000G

VFM-030VE-000M VFM-030VE-000G

--- VFM-100VE-000G

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 7

Page 8

Application Overview

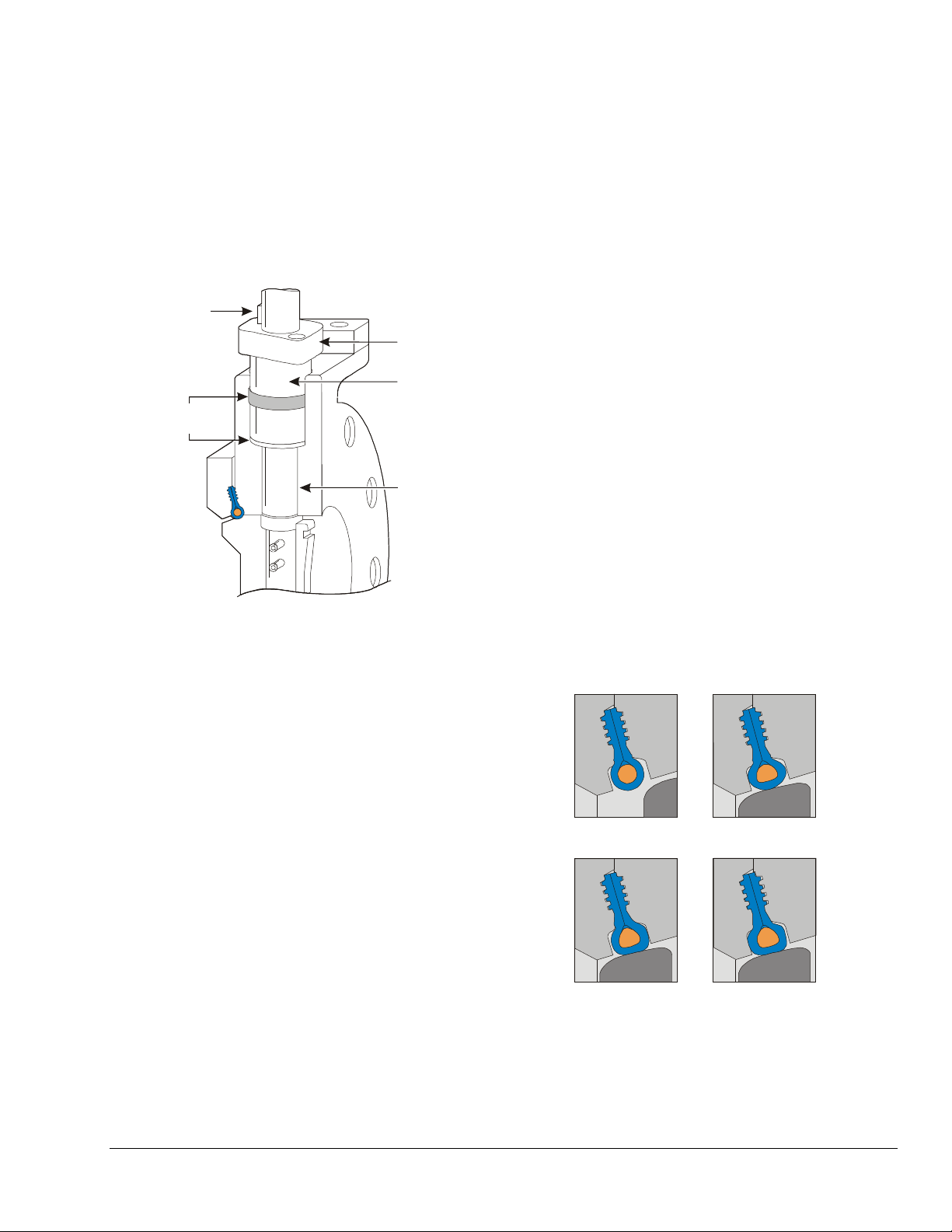

Stem

Extended

Neck

Valve

Body

Disc

Taper Pin s

Internal Travel Stop

VF Series High-Press ur e, High-Temperature Butterfly

Valves provide the highest quality and best value

available in the HVAC control industry. These valves

are recognized as a proven leader, with more than

25 years of successful service in process industries

worldwide. Their unique, patented design has received

Chemical Processing’s Valor Award for Best Product.

The simple, innovative design of these valves provides

rugged reliability and extremely easy maintenance in

the field. Independent and internal tests have proven

their superior service life capability, with bubble-tight

shutoff through over 100,000 cycles.

VF Series High-Pr ess ur e, High-Temperature Butterfly

Valves can be automated inexpensively with

pneumatic and electric actuators.

When compared to gate, globe, ball, and plug valves,

VF Series High-Press ur e, High-Temperature Butterfly

Valves are significantly smaller and lighter in weight;

therefore, installation time and maintenance costs are

greatly reduced.

All VF Series High-Pressure, High-Temperature

Butterfly Valves are available with a factory-assembled

and calibrated actuator, sized with a 25% safety factor

to provide years of trouble-free operation. The wide

variety of actuator choices include high-pressure

pneumatic rack and pinion-style actuators (both spring

return and non-spring return), and high-torque rotary

electric actuators which are fully compatible with

®

Metasys

controllers. The valve and actuator can be

provided in Normally Open (N.O.) or Normally

Closed (N.C.) combinations for pneumatic two-way

operation.

Stem

The one-piece stem is constructed of high strength

17-4 PH stainless steel. The output shaft of the stem is

extended to provide a direct connection of the actuator

to the valve.

Disc

The disc is constructed of 316 stainless steel, and is

engineered to maximize flow. The double offset design

of the stem reduces seat wear to significantly extend

cycle life. Bidirectional bubble-tight shutoff is assured

throughout the full pressure range.

Taper Pins

The taper pins are precision fit into drilled,

taper-reamed holes, providing a positive connection

and maximum strength between the valve disc and

stem.

Internal Travel Stop

An internal travel stop is designed to prevent

overtravel of the disc, minimizing possible seat

damage.

Valve Body

The ANSI Class 150 lug-style valve body is carbon

steel, and meets the pressure and temperature

requirements for ANSI B16.5, Class 150 pipe flanges.

The ANSI Class 300 lug-style valve body is carbon

steel, and meets the pressure and temperature

requirements for ANSI B16.5, Class 300 pipe flanges.

Figure 6: VF Series High-Pressure,

High-Temperature Butterfly Valve

Extended Neck

The extended neck allows for 2 in. (51 mm) of pipeline

insulation, as well as easy access for stem packing

adjustments and actuator mounting.

8 VF Series High-Pressure, High-Tem perat ure Butt er f l y Valves Product Bulle tin

Page 9

Gland

Retainer

Gland

Ring

Stem Bearings

Stem

Seal

Studs,

Hex-Head

Nuts, and

Lock

Washers

Seat non-compressed

as disc approaches.

Disc in c losed p os ition;

with no line pressure.

Disc in c losed p os ition;

line pressure applie d

from the left.

Disc in c losed p os ition;

line pressure applie d

from the right.

Adjustable Stem Packing

The stem packing system features easy access to

adjusting hex-head nuts wit hout re qu irin g removal of

the actuator. The stem consists of a gland ring, a

gland retainer, studs, hex-head nuts, and lock

washers. A slight 1/4 turn of the hex-head nuts is

usually all that is required should field adjustment ever

be needed. Both hex-head nuts must be evenly

adjusted, and not over tightened.

Figure 7: Adjustable Stem Packing System

Stem Seal

A positive seal is formed around the stem by the

constant compression and excellent corrosion

resistance of the stem seal. PTFE packing rings seal

the stem, and a carbon fiber anti-extrusion ring retains

the packing.

Seat Design

The unique, live-loaded seat consists of a resilient

silicone O-ring energizer that is fully encased by the

reinforced polytetrafluoroethylene (RPTFE) seat. The

seat is locked into the valve body recess by a

full-faced seat retainer plate. This simple, reliable, and

proven combination provides many exclusive

advantages including:

• The O-ring energizer is completely isolated from

all contact with the line media by the RPTFE seat.

• Serrations in the seat retainer plate and body

recess secure the seat in place. The full-faced

retainer plate is bolted to the body, locking the

seat in the correct position. The seat is secured

even without the mating flange.

• The closely confined and well supported seat is

energized by the disc and line pressure. The

higher the pressure, the tighter the seal. In low

pressure applications, the energized seat offers

superior sealing and longer service life than many

other designs.

• Line media is sealed bubble-tight in both

directions.

• The live-loaded seat is self adjusting for wear and

temperature fluctuations.

• Seat replacement is extremely easy – just remove

the seat retainer plate, rotate the disc into the

closed position, and place a new seat in the

machined recess of the body. Performing this

procedure does not disturb the disc or stem.

All ANSI Class 150 and 2-1/2 through 12 in.

ANSI Class 300 valves feature one set of stem seal

packing rings and a stem locating plug with an O-ring

seal in the body base. The 14 in. ANSI Class 300

valves feature upper and base twin stem seals that

balance axial forces on the stem and disc under all

operating conditions.

Stem Bearings

Top and bottom bearings, consisting of a

316 stainless steel shell with a TFE/glass fabric liner

bearing surface, securely support the stem. The stem

bearings provide excellent resistance to corrosion and

distortion from high temperatures and mechanical

loading forces.

Figure 8: Exclusive High Performance Seat

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 9

Page 10

Double Offset Stem and Disc Design

Disc in the

Open Position

Disc in the

Closed Position

Stem

Seat

Body

Temperature °C

Pr essur e psig

Press ure Bar

Tem perat ure °F

350

0

100

200

250

300

250

200

150

100

50

20

15

10

5

-20

0 100

200

300 400 500

Temperature °C

Pressure psig

Press ure B ar

Tem perat ure °F

800

0 100 200 250

700

600

500

400

300

200

100

50

40

30

20

10

-20

0

100 200 300 400 500

The double offset design of VF Series High-Pressure,

High-Temperature Butterfly Valves ensures reduced

seat wear and bidirectional bubble-tight shutoff

throughout the full pressure range.

At the point of initial disc opening, the offset disc

produces a cam-like action that rotates the disc away

from the seat with minimum drag. This

cam-like action reduces seat wear and eliminates seat

deformation when the disc is in the open position.

When the disc rotates beyond the point of initial

opening, the disc does not make contact with the seat.

This superior design extends the seat service life and

reduces the valve operating torque. As the valve

closes, the cam-like action converts the rotary motion

to effectively push the disc onto the seat. The wip ing

action of the disc against the seat prevents

undesirable material buildup from suspended solids.

The taper pins carry essentially equal loads while

anchoring the disc to the stem. This arrangement

permits accurate disc closure for consistent sealing

and positive shutoff.

For more than 25 years, the reliability of these butterfly

valves has been conclusively proven, both in lab tests

as well as thousands of field applications. In one test

of over 100,000 cycles at 720 psig (4,961 kPa) of

pressure, the seat remained in excellent condition and

continued to provide a bidirection al bub bl e-tight seal.

In another test of more than 878,000 cycles at 2 psig

(14 kPa) of pressure, the ANSI Class 150 valve

continued to seal bubble-tight in both directions.

Figure 10: ANSI Class 150

VF Series High-Pressure, High-Temperature

Butterfly Valves

Pressure/Temperature Ratings

Figure 9: Double Offset Stem and Disc

Figure 11: ANSI Class 300

VF Series High-Pressu r e, Hig h-Temperature

Butterfly Valves

Pressure/Temperature Ratings

10 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 11

2-1/2

3

5

6

10

16

Table 7: Rangeability Values for 90° Rotation1

Valve Size,

in.

4 30:1 30:1

8 43:1 43:1

12 43:1 43:1

14 43:1 43:1

1. For steam throttling service applications, refer to the VF Series High-Pressure, High-Temperature Butterfly Valves

for Steam Service Application Note (LIT-977321).

ANSI Class 150 Valves ANSI Class 300 Valves

30:1 30:1

30:1 30:1

39:1 39:1

39:1 39:1

43:1 43:1

43:1 ---

90° Disc Rotation

Valve Actuators

All VF Series High-Pressure, High-Temperature

Butterfly Valves are available with a wide range of

factory-installed pneumatic and electric actuators.

Table 8 and Table 9 list the actuator choices available

for each ANSI Class valve type. All valve and actuator

combinations have been sized with torque safety

factors to provide adequate actuator torque for years

of trouble-free operation.

Optional Actuator Accessories

All V-909x and V-919x Series High Pressure

Pneumatic Rack and Pinion Actuators are furnished

with factory installed 120 VAC solenoid valves for

two-position operation. When these actuators are used

for proportional service, the solenoid valve is replaced

with a high pressure positioner. In two-position

applications, factory-installed speed controls are

available as a selec tab le o ptio n.

For more details on additional actuator accessories,

refer to the appropriate actuator product bulletin.

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 11

Page 12

2-1/2

3

5

6

10

16

2-1/2

4

8

14

Table 8: Representative Maximum Shipping Weights for VF Series High-Pressure,

High-Temperature ANSI Class 150 Butterfly Valve a n d Actu ato r Assembli es

Valve Size,

in.

4 V-9194-13 (430) 56 (25.4)

8 V-9196-15 (650) 165 (74.9)

12 V-9198-13 (830) 389 (177.6)

14 V-9198-15 (850) 482 (218.8)

1. The above shipping weights are approximate, and are based on the heaviest valve, actuator, and accessory

combination available for each assembly size.

Representative Actuator

(Actuator Sub-Code)

V-9193-16 (360) 41 (18.6)

V-9193-16 (360) 45 (20.4)

V-9195-13 (530) 80 (36.3)

V-9195-15 (550) 90 (40.9)

V-9197-15 (750) 250 (113.5)

V-9098-1 (080) 571 (259.2)

1

Shipping Weight,

lb (kg)

Table 9: Representative Maximum Shipping Weights for VF Series High-Pressure,

High-Temperature ANSI Class 300 Butt erfl y Valve and Actuator Assemblies

Valve Size,

in.

Representative Actuator

(Actuator Sub-Code)

1

Shipping Weight,

lb (kg)

VA-9072-01 (702) 42 (19.3)

3 VA-9072-01 (702) 52 (23.9)

VA-9075-01 (705) 75 (34.1)

5 V-9196-15 (650) 135 (61.3)

6 V-9196-16 (660) 155 (70.4)

V-9197-15 (750) 240 (109.0)

10 V-9198-14 (840) 386 (175.2)

12 V-9198-15 (850) 474 (215.2)

V-9098-1 (080) 621 (281.9)

1. The above shipping weights are approximate, and are based on the heaviest valve, actuator, and accessory

combination available for each assembly size.

12 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 13

Optional Actuator Accessories

A

C

D

B

For manually operated actuator and valve assemblies,

a ten-position manual handle or gear-operated manual

hand wheel is available. See Table 10 and Table 11

for more details.

Figure 12: Dimensions for Ten-Position Manual H andles

(See Table 10.)

Table 10: Dimensions for Ten-Position Manual Handles, in. (mm)

Valve Size,

ANSI

Class 150

Valves

in.

ANSI

Class 300

Valves

Ten-Position

Manual Handle

Kit

1

A B C D

2-1/2

through 4

5 and 6 5 VF-999-402

1. Kit includes a manual handle, notch plate, bracket, and mounting hardware.

2-1/2

through 4

VF-999-401

10.62

(270)

10.62

(270)

1.12

(28)

1.12

(28)

1.38

(35)

1.38

(35)

1.0

(25)

1.0

(25)

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 13

Page 14

A

B

C

D

E

Figure 13: Dimensions for Gear-Operated Manual Hand Wheels

(See Table 11.)

Table 11: Dimensions for Gear-Operated Manual Hand Wheels, in. (mm)

Valve Size,

ANSI

Class 150

Valves

in.

ANSI

Class 300

Valves

Gear-Operated

Manual

Hand Wheel Kit

A B C D E

1

2-1/2

through 4

5 and 6 5 VF-999-502

8 6 VF-999-503

10 8 VF-999-504

12 --- VF-999-505

14 and 16 --- VF-999-506

--- 10 VF-999-507

--- 12 VF-999-508

--- 14 VF-999-509

1. Kit includes a manual hand wheel, bracket, adaptor (if required), and mounting hardware.

2-1/2

through 4

VF-999-501

6.89

(175)

6.89

(175)

6.89

(175)

6.89

(175)

6.89

(175)

10.51

(267)

10.51

(267)

10.51

(267)

10.51

(267)

5.91

(150)

5.91

(150)

5.91

(150)

5.91

(150)

5.91

(150)

8.27

(210)

8.27

(210)

8.27

(210)

8.27

(210)

7.50

(191)

7.50

(191)

7.50

(191)

7.69

(195)

7.69

(195)

14.88

(378)

14.81

(376)

14.81

(376)

14.88

(378)

8.0

(203)

8.0

(203)

8.0

(203)

12.0

(305)

12.0

(305)

18.0

(457)

12.0

(305)

12.0

(305)

18.0

(457)

2.50

(64)

2.50

(64)

2.50

(64)

2.50

(64)

2.50

(64)

4.39

(112)

4.39

(112)

4.39

(112)

4.39

(112)

14 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 15

Product Guidelines

Please be sure to read the following information

carefully before installing a VF Series High-Pressure,

High-Temperature Butterfly Valve Assembly:

• The valve is designed to be mounted between

ANSI flanges. When the valve is open, the disc

extends into the pipe on both sides of the valve

(further on the body side than the seat retainer

side). Piping must be large enough to allow the

disc to clear the pipe. In general, Class 150 valves

clear the Schedule 40 pipe, and Class 300 va lves

clear the Schedule 80 pipe adeq uat ely.

If heavier piping is required, chamfering or

recessing of the pipe inner diameter may be

necessary. Contact the local Bray representative

for more information.

• If the handle or actuator has been removed, do not

rotate the disc beyond the fully open or closed

position; doing so could cause damage to the

sealing surfaces. VF Series High-Pressure,

High-Temperature Butterfly Valves are equipped

with stops to prevent overclosure. The valve is

opened by turning counterclockwise and closed by

turning clockwise. The machined flats at the top of

the stem are parallel to the disc. For larger

diameter valves that use a keyway, the disc

follows the orientation of the key.

• For maximum service life, install the valve with the

seat retainer upstream. Positive shutoff is obtained

with the valve in either position; however,

installation with the seat retainer upstream

provides longer service life, especially in erosive

services.

• With the disc in the closed position, carefully

center the valve between the flanges. Tapped

holes match ANSI pipe flanges and assist in

positive alignment.

• The seat is sufficiently compressed by the seat

retainer, and additional force from flange bolting is

not required.

• Gaskets must conform to the requirements of

API Standard 601, Edition 3 for ANSI B16.5 class

flanges. Spiral wound gaskets are acceptable.

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 15

Page 16

K

H

(=)

(=)

C

B

L

D

E

F

A

K

Mounting

J

G

Lug Bolt ing

Figure 14: Two-Way VF Series High-Pressure, High-Temperature

Butterfly Valve Dimensions (See Table 12 and Table 13.)

1

Table 12: ANSI Class 150 Two-Way Valve Dimensions, in.

Valve

Size, in.

2-1/2 4.75 1.88 2.28 3.81 6.38 4.36 0.63 0.43 1.25 2.50 0.77 5.50 4 5/8–11 14

3 5.25 1.88 2.86 4.09 6.63 4.36 0.63 0.43 1.25 2.50 0.77 6.00 4 5/8–11 15

4 6.75 2.03 3.72 4.71 7.50 4.36 0.63 0.43 1.25 2.50 0.75 7.50 8 5/8–11 23

5 7.50 2.23 4.80 5.07 7.50 5.12 0.75 0.51 1.25 4.50 0.94 8.50 8 3/4–10 34

6 8.62 2.23 5.88 5.57 8.00 5.12 0.75 0.51 1.25 4.50 0.94 9.50 8 3/4–10 47

8 10.75 2.40 7.80 6.94 9.50 5.12 0.87 0.63 1.25 4.50 0.94 11.75 8 3/4–10 54

10 13.06 2.75 9.78 8.56 10.75 6.12 1.18 0.87 2.00 4.50 1.07 14.25 12 7/8–9 94

12 15.50 3.08 11.74 10.18 12.25 6.12 1.18 0.87 2.00 4.50 1.13 17.00 12 7/8–9 136

14 17.50 3.73 12.90 11.95 14.50 7.75 1.38 .39x.39 2.00 6.50 1.42 18.75 12 1–8 227

16 19.81 4.11 14.68 12.94 17.75 10.38 1.97 .47x.39 2.50 6.50 1.66 21.25 16 1–8 345

1. 1 in. x 25.4 = 1 mm.

2. 1 lb x 0.454 = 1 kg (net weight for valve only – no actuator).

A B C D E F G H J K L

Lug Bolting Data

BC,

in.

No. of

Holes

Threads

UNC-2B

Net

Valve

Weight,

2

lb

16 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 17

6

12

3

5

2-3/4 (70)

4

3/8 (10)

8-1/2 (216)

8

3/4–10

6

10

4-29/32 (125)

4

9/16 (14)

14-1/4 (362)

12

7/8–9

12

16

Table 13: ANSI Class 300 Two-Way Valve Dimensions, in.

Valve

Size, in.

2-1/2 4.75 1.88 2.28 3.81 6.38 4.36 0.63 0.43 1.25 2.50 0.77 5.88 8 3/4–10 15

3 5.25 1.88 2.28 4.09 6.63 4.36 0.63 0.43 1.25 2.50 0.77 6.63 8 3/4–10 17

4 6.75 2.03 3.72 4.71 7.50 4.36 0.63 0.43 1.25 2.50 0.75 7.88 8 3/4–10 23

5 8.25 2.23 4.80 5.13 8.00 5.12 0.75 0.51 1.25 4.50 0.94 9.25 8 3/4–10 39

8 10.94 2.82 7.56 7.55 10.00 6.12 1.18 0.87 2.00 4.50 1.10 13.00 12 7/8–9 89

10 13.26 3.28 9.44 9.36 11.38 6.12 1.38 .39x.39 2.00 4.50 1.28 15.25 16 1–8 144

14 17.90 4.66 11.38 12.50 18.25 10.38 1.97 .47x.39 2.50 6.50 2.13 20.25 20 1-1/8–8 444

1. 1 in. x 25.4 = 1 mm.

A B C D E F G H J K L

8.88 2.42 5.75 6.25 8.75 5.12 0.87 0.63 1.25 4.50 0.97 10.62 12 3/4–10 54

15.57 3.62 11.31 10.89 13.50 7.75 1.38 .39x.39 2.00 6.50 1.40 17.75 16 1-1/8–8 217

1

Lug Bolting Data

BC,

in.

No. of

Holes

Threads

UNC-2B

2. 1 lb x 0.454 = 1 kg (net weight for valve only – no actuator).

Table 14: Two-Way ANSI Class 150 VF Series High-Pressure, High-Temperature

Butterfly Valve Actuator Mounting and Valve Lug Bolting

1

Dimensions

Actuator Mounting Valve Lug Bolting

Valve

Size,

in.

Bolt

Pattern,

in. (mm)

Number of

Holes

2

Hole

Diameter,

in. (mm)

Bolt Circle,

in. (mm)

Number of

Holes

3

Net

Valve

Weight

2

lb

Bolt Thread

UNC-2B

2-1/2 2-3/4 (70) 4 3/8 (10) 5-1/2 (140) 4 5/8–11

2-3/4 (70) 4 3/8 (10) 6 (152) 4 5/8–11

4 2-3/4 (70) 4 3/8 (10) 7-1/2 (191) 8 5/8–11

2-3/4 (70) 4 3/8 (10) 9-1/2 (241) 8 3/4–10

8 4-29/32 (125) 4 9/16 (14) 11-3/4 (298) 8 3/4–10

4-29/32 (125) 4 9/16 (14) 17 (432) 12 7/8–9

14 6-1/2 (165) 4 13/16 (21) 18-3/4 (476) 12 1–8

6-1/2 (165) 4 13/16 (21) 21-1/4 (540) 16 1–8

1. See Table 12 and Table 13 for bolting requirements.

2. Actuator mounting holes are drilled (not tapped).

3. Lug holes are drilled and tapped, and evenly spaced around the valve.

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 17

Page 18

Actuator Mounting

Valve Lug Bolting

2-1/2

2-3/4 (70)

4

3/8 (10)

5-7/8 (149)

8

3/4–10

3

2-3/4 (70)

4

3/8 (10)

6-5/8 (168)

8

3/4–10

4

2-3/4 (70)

4

3/8 (10)

7-7/8 (200)

8

3/4–10

5

2-3/4 (70)

4

3/8 (10)

9-1/4 (235)

8

3/4–10

6

4-29/32 (125)

4

9/16 (14)

10-5/8 (270)

12

3/4–10

8

4-29/32 (125)

4

9/16 (14)

13 (330)

12

7/8–9

10

4-29/32 (125)

4

9/16 (14)

15-1/4 (387)

16

1–8

12

4-29/32 (125)

4

9/16 (14)

17-3/4 (451)

16

1-1/8–8

14

6-1/2 (165)

4

13/16 (21)

20-1/4 (514)

20

1-1/8–8

5/8 (16)

2 (51)2 4 4

3/4 (19)

2-1/4 (57)2

8

5/8 (16)

2 (51)2 4 4

3/4 (19)

2-1/4 (57)2

8

5/8 (16)

5/8 (16)

1-3/4 (44)

2-1/4 (57)2

8

8

3/4 (19)

3/4 (19)

2 (51)

2-1/2 (64)2

8

8

3/4 (19)

3/4 (19)

1-3/4 (44)

2-1/4 (57)2

8

8

3/4 (19)

3/4 (19)

2-1/2 (64)

3-1/4 (82)2

12

12

3/4 (19)

2-1/4 (57)2

8

3/4 (19)

3 (76)2

12

3/4 (19)

2-1/2 (64)2

8

7/8 (22)

3-1/2 (88)2

12

7/8 (22)

7/8 (22)

2 (51)

3 (76)2

12

12

1 (25)

1 (25)

3-1/2 (88)

3-1/2 (88)2

16

16

7/8 (22)

7/8 (22)

2 (51)

3 (76)2

12

12

1-1/8 (29)

1-1/8 (29)

3-1/2 (88)

4 (102)2

16

16

1-1/8 (29)

3-1/2 (88)2

43

Table 15: Two-Way ANSI Class 300 VF Series High-Pressure, High-Temperature

Butterfly Valve Actuator Mounting and Valve Lug Bolting

1

Dimensions

Valve

Size,

in.

1. See Table 12 and Table 13 for bolting requirements.

2. Actuator mounting holes are drilled only (not tapped).

3. Lug holes are drilled and tapped, and evenly spaced around the valve.

Bolt

Pattern,

in. (mm)

Number of

Holes

2

Hole

Diameter,

in. (mm)

Bolt Circle,

in. (mm)

Number of

Holes

3

Bolt Thread

UNC-2B

Table 16: Flange Screws Required for VF Series High-Pressure, High-Temperature Butterfl y Valves

Regular Hex-Head Screws with National Course Threads

Valve

Size,

in.

2-1/2

Diameter,

in. (mm)

ANSI Class 150 Valves ANSI Class 300 Valves

5/8 (16)

Length1,

in. (mm)

1-1/2 (38)

Number

Required

Diameter,

in. (mm)

3/4 (19)

Length1,

in. (mm)

1-3/4 (44)

Number

Required

8

3

4

5

6

8

10

12

14

16

1. Bolt lengths indicated include allowances for installing 1/16 or 1/8 in. thick gasket. Refer to the flange standards

for bolting material specifications (as listed in ANSI B16.5 and American Society of Mechanical Engineers [ASME]

B16.47).

2. Install from seat retainer side of valve.

3. Install in flange bolt holes closest to the valve stem.

5/8 (16)

3/4 (19)

3/4 (19)

1 (25)

1 (25)

1 (25)

1 (25)

1-1/2 (38)

1-3/4 (44)

2 (51)

2-1/2 (64)

3-1/2 (88)

3 (76)

3-1/2 (88)

3/4 (19)

8

8

2

2

12

12

16

16

3/4 (19)

7/8 (22)

1-1/8 (29)

1-1/8 (29)

1-1/8 (29)

--- --- ---

1-3/4 (44)

2-1/4 (57)

3 (76)

4 (102)

2

4 (102)

3 (76)

8

12

12

16

16

4

3

18 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 19

H

G

F

E

D

C

A

B

FRONT VIEW

SIDE VIEW

3

6

10

2.75 (70)

3.28 (83)

10.75 (273)

11.38 (289)

12

16

Figure 15: Overall Dimensions, in. (mm) for Industrial-Grade V-9000 Series High Pressure

Pneumatic Actuated Two-Way VF Series High-Pressure, High-Temperature Butterfly Valves

(See Table 17 and Table 18.)

Table 17: Overall Dimensions, in. (mm) for Industrial-Grade V-9000 Series

High Pressure Pneumatic Actuated Two-Way VF Series High -Pressure,

High-Temperature Butterfly Valves

1, 2

Dimensions, in. (mm)

Valve

Size,

in.

ANSI Class 150

Valves

2-1/2 1.88 (48) 1.88 (48) 6.38 (162) 6.38 (162)

1.88 (48) 1.88 (48) 6.63 (168) 6.63 (168)

4 2.03 (52) 2.03 (52) 7.50 (191) 7.50 (191)

5 2.23 (57) 2.23 (57) 7.50 (191) 8.01 (203)

8 2.40 (61) 2.82 (72) 9.50 (241) 10.00 (254)

14 3.73 (95) 4.66 (117) 14.50 (368) 18.25 (464)

1. The overall height requirements listed for V-9x92, V-9x93, V-9x94, and V-9x95 actuated VF Series

High-Pressure, High-Temperature Butterfly Valves include 6-1/2 in. (165 mm) for a positioner; overall height

requirements for V-9x96, V-9x97, and V-9x98 actuated assemblies include 7-1/2 in. (191 mm) for a positioner.

2. If a positioner is mounted on a travel switch, add 7 in. (178 mm) to the overall height requirement listed above.

2.23 (57) 2.42 (61) 8.00 (203) 8.75 (222)

3.08 (78) 3.62 (92) 12.25 (311) 13.50 (343)

4.11 (104) --- 17.75 (451) ---

B E

ANSI Class 300

Valves

ANSI Class 150

Valves

ANSI Class 300

Valves

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 19

Page 20

-3x0

-4x2

-042

7.28 (185)

11.90 (302)

5.15 (131)

-5x0

-7x0

-8x0

A

A

B

G F

E

D

C

Table 18: Overall Dimensions, in. (mm) for Industrial-Grade V-9000 Series

High Pressure Pneumatic Actuated Two-Way VF Series High -Pressure,

High-Temperature Butterfly Valves

1, 2

Actuator Sub-Code Dimensions, in (mm)

Spring Return

-4x0 -040 5.78 (147) 8.59 (218) 4.44 (113)

-6x0 -060 9.36 (238) 15.54 (395) 7.17 (182)

1. The overall height requirements listed for V-9x92, V-9x93, V-9x94, and V-9x95 actuated VF Series

High-Pressure, High-Temperature Butterfly Valves include 6-1/2 in. (165 mm) for a positioner; overall height

requirements for V-9x96, V-9x97, and V-9x98 actuated assemblies include 7-1/2 in. (191 mm) for a positioner.

2. If a positioner is mounted on a travel switch, add 7 in. (178 mm) to the overall height requirement listed above.

Non-Spring

Return

-030 5.43 (138) 7.40 (188) 4.07 (103)

-050 8.09 (205) 12.31 (313) 5.58 (142)

-070 11.62 (295) 19.57 (497) 8.97 (228)

-080 13.49 (343) 28.78 (731) 10.79 (274)

F G H

Figure 16: Overall Dimensions, in. (mm) for Industrial-Grade VA-9070 Series Electric Actuated

Two-Way VF Series High-Pressure, High Temperature Butterfly Valves

(See Table 19 and Table 20.)

20 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 21

4

6

2.23 (57)

2.42 (61)

8.00 (203)

8.75 (222)

8

12

14

-722

-723

-725

-726

-728

Table 19: Overall Dimensions, in. (mm) for Industrial-Grade VA-9070 Series Electric Actuated

Two-Way VF Series High-Pressure, High-Temperature Butterfly Valves

Dimensions, in. (mm)

Valve

Size,

in.

ANSI Class 150

Valves

2-1/2 1.88 (48) 1.88 (48) 6.38 (162) 6.38 (162)

3 1.88 (48) 1.88 (48) 6.63 (168) 6.63 (168)

2.03 (52) 2.03 (52) 7.50 (191) 7.50 (191)

5 2.23 (57) 2.23 (57) 7.50 (191) 8.01 (203)

2.40 (61) 2.82 (72) 9.50 (241) 10.00 (254)

10 2.75 (70) 3.28 (83) 10.75 (273) 11.38 (289)

3.08 (78) 3.62 (92) 12.25 (311) 13.50 (343)

3.73 (94.7) 4.66 (118.4) 14.5 (368.3) 18.25 (463.6)

16 4.11 (104.4) 5.35 (135.9) 17.75 (450.9) 21.00 (533.4)

B D

ANSI Class 300

Valves

ANSI Class 150

Valves

ANSI Class 300

Valves

Table 20: Overall Dimensions, in. (mm) for Industrial-Grade VA-9070 Series

Electric Actuated Two-Way VF Series High-Pressure, High-Temperature Butterfly Valves

Actuator Sub-Code Dimensions, in. (mm)

On/Off Proportional E1 F G

-702 6.70 (170) 7.50 (191) 5.60 (142)

-703 8.10 (206) 10.10 (257) 7.80 (198)

-724 -704 8.10 (206) 10.10 (257) 7.80 (198)

-705 8.10 (206) 10.10 (257) 7.80 (198)

-706 8.80 (224) 12.10 (307) 9.50 (241)

-727 -707 8.80 (224) 12.10 (307) 9.50 (241)

-708 8.80 (224) 12.10 (307) 9.50 (241)

-927 -907 12.50 (317.5) 18.80 (477.5) 9.50 (241)

-928 -908 12.50 (317.5) 18.80 (477.5) 9.50 (241)

1. Allow an additional 6 in. (152 mm) for actuator cover removal.

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 21

Page 22

(137)

(117)

(86)

(67)

(43)

(26)

(14) 8 (6.8)

(2.6)

(159)

(152)

(133)

(105)

(75)

(48)

(27)

(12)

(4.1)

(321)

(313)

(270)

(214)

(150)

(99)

(54)

(27)

(8.6)

790

(677)

675

(578)

500

(429)

360

(309)

238

(204)

146

(125)

78

(67)

41

(35)

16

(14)

(1,160)

(917)

(643)

(437)

(283)

(187)

(120)

(69)

(30)

(2,400)

(1,910)

(1,360)

(908)

(587)

(391)

(240)

(141)

(56)

(3,690)

(2,960)

(2,080)

(1,400)

(900)

(600)

(386)

(214)

(86)

6,650

(5,700)

5,330

(4,570)

3,750

(3,210)

2,530

(2,170)

1,630

(1,400)

1,080

(926)

700

(600)

390

(334)

155

(133)

(6,560)

(5,230)

(3,685)

(2,490)

(1,620)

(1,070)

(694)

(386)

(150)

(8,400)

(6,740)

(4,720)

(3,170)

(2,070)

(1,310)

(874)

(497)

(197)

Table 21: AN S I Class 150 Valve Flow Coefficients, Cv (Kv)

Valve

Disc Position (Degrees of Rotation)

Size,

in.

2-1/2

90° 80° 70° 60° 50° 40° 30° 20° 10°

160

136

100

78

50

30

1

16

3

3

4

5

6

8

10

12

14

16

1. Recommended disc rotation is between 30° and 70° open. When selecting a valve for modulating application, use a

valve where the calculated Cv falls between 0 and 60°. When selecting a valve for two-position application, use a

valve where the calculated Cv falls between 0 and 90°.

185

375

1,350

2,800

4,300

7,650

9,800

178

365

1,070

2,230

3,450

6,100

7,860

155

315

750

1,590

2,430

4,300

5,510

123

250

510

1,060

1,630

2,900

3,700

87

175

330

685

1,050

1,890

2,420

56

115

218

456

700

1,250

1,530

32

63

140

280

450

810

1,020

14

31

81

165

250

450

580

4.8

10

35

65

100

175

230

22 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 23

Valve

in.

Disc Position (Degrees of Rotation)1

(137)

(117)

(86)

(67)

(43)

(26)

(14) 8 (6.8)

(2.6)

(159)

(152)

(133)

(105)

(75)

(48)

(27)

(12)

(4.1)

375

(321)

365

(313)

315

(270)

250

(214)

175

(150)

115

(99)

63

(54)

31

(27)

10

(8.6)

790

(677)

675

(578)

500

(429)

360

(309)

238

(204)

146

(125)

78

(67)

41

(35)

16

(14)

(857)

(750)

(608)

(454)

(317)

(206)

(118)

(68)

(22)

2,000

(2,270)

1,720

(1,470)

1,360

(1,170)

950

(814)

630

(540)

405

(347)

240

(206)

121

(104)

47

(40)

(2,270)

(1,930)

(1,490)

(1,028)

(668)

(437)

(253)

(129)

(52)

(3,430)

(2,910)

(2,140)

(1,450)

(943)

(608)

(369)

(189)

(79)

4,100

(3,514)

3,500

(3,000)

2,600

(2,228)

1,770

(1,517)

1,200

(1,028)

830

(711)

490

(420)

240

(206)

100

(86)

Table 22: ANSI Class 300 Valve Flow Coefficients, Cv (kv)

Size,

2-1/2

3

4

5

6

8

10

12

14

1. Recommended disc rotation is between 30° and 70° open. When selecting a valve for modulating application, use a

valve where the calculated Cv falls between 0 and 60°. When selecting a valve for two-position application, use a valve

where the calculated Cv falls between 0 and 90°.

90° 80° 70° 60° 50° 40° 30° 20° 10°

160

185

1,000

2,650

4,000

136

178

875

2,250

3,400

100

155

710

1,740

2,500

78

123

530

1,200

1,690

50

87

370

780

1,100

30

56

240

510

710

16

32

138

295

430

14

79

150

220

4.8

26

61

92

3

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 23

Page 24

∆

∆

1

1

(24.3)

(53.1)

(82.5)

(203.4)

(177.4)

(418.0)

(324.3)

(463)

(94.6)

(790.9)

(1130.0)

(132)

(514.1)

(1,186.3)

(751.3)

(1,340.0)

Table 23: Expected Seating/Unseating Torque Values

U.S.G.P.M. (Liters per Second)

ANSI Class 150 Valves ANSI Class 300 Valves

Valve

Size,

in.

2-1/2

3

4

5

6

8

10

150 to 285 psig (1,034 to 1,964 kPa)

Torque

Upstream

215

230

(26.0)

320

(36.2)

730

840

(95.0)

1570

2870

High-Pressure Valves

P Pressure, psig (kPa)

Torque

Downstream

300

(33.9)

320

(36.2)

460

(52.0)

1,040

(118)

1,200

(136)

2,100

(237)

4,100

Maximum

Flow

400

(25.2)

400

(25.2)

400

(25.2)

500

(31.5)

600

(37.8)

1,000

(63.1)

1,500

2

1

, lb·in (N·m) and Maximum Flow Rates2,

High-Pressure Valves

P Pressure, psig (kPa)

285 to 740 psig (1,965 to 5,102 kPa)

Torque

Upstream

470

490

(55.4)

700

(79.1)

1,800

2,100

(237.3)

3,700

7,000

Torque

Downstream

670

(75.7)

690

(78.0)

1,000

(113.0)

2,550

(288.1)

3,000

(339.0)

5,300

(599.0)

10,000

Maximum

Flow

(34.7)

(34.7)

(36.5)

(39.7)

(55.5)

(66.8)

550

550

580

630

880

1,060

2,100

2

12

14

16

1. Includes a safety factor (valve installed with the seat retainer oriented upstream).

2. Maximum flow rates of water in U.S.G.P.M. (liters per second). The values listed are the maximum flow rates in

U.S.G.P.M. before dynamic torques must be considered to determine which torque is greater (seating/unseating or

dynamic). Water equivalent is used; for other fluids, divide the given flow rates by the square root of SG, where

SG = Specific Gravity. For water, SG = 1.

4550

6,650

10,500

(1186.3)

6,500

(734)

9,500

(1,073)

15,000

(1,695)

2,500

(157)

3,400

(214)

5,200

(328)

10,500

15,400

--- --- ---

15,000

(1694.8)

22,000

(2485.7)

3,400

(214)

3,800

(239)

Note: For fluids with solids or abrasive content, the torque may be increased; consult the local

Johnson Controls office for increased torque values.

24 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 25

2-1/2

3

5

6

10

16

2-1/2

4

5

8

VA

0

VA

0

14

VA

1600

VA

2000

Table 24: Mounting Kits

1

for Field Mounting Industrial-Grade V-9000 Series

High Pressure Pneumatic Actuators to Two-Way ANSI Class 150 VF Series

High-Pressure, High-Temperature Butterfly Valves

Valve

Industrial-Grade V-9000 Series High Pressure Pneumatic Actuator

Size,

in.

4 V-9094-400 V-9094-400 V-9095-400 V-9095-400 --- --- ---

8 --- --- --- V-9095-800 V-9096-800 V-9097-810 ---

12 --- --- --- --- --- V-9097-120 --14 --- --- --- --- --- V-9097-160 V-9098-100

1. Mounting kit contains a bracket, adaptor, and mounting hardware.

V-9x93 V-9x94-1 V-9x94-2 V-9x95 V-9x96 V-9x97 V-9x98

V-9094-400 V-9094-400 V-9095-400 V-9095-400 --- --- --V-9094-400 V-9094-400 V-9095-400 V-9095-400 --- --- ---

--- --- V-9095-610 V-9095-600 V-9096-600 --- ---

--- --- V-9095-610 V-9095-600 V-9096-600 --- ---

--- --- --- --- --- V-9097-120 ---

--- --- --- --- --- --- V-9098-100

1

Table 25: Mounting Kits

for Field Mounting Industrial-Grade VA-907x Series

Electric Actuators to Two-Way ANSI Class 150 VF Series High-Pressure,

High-Temperature Butterfly Valves

Valve

Industrial-Grade VA-907x Series Electric Actuator

Size,

in.

VA-9072 VA-9075 VA-9076 VA-9077 VA-9078 VA-907A VA-907B

VA-9072-400 --- --- --- --- --- ---

3 VA-9072-400 --- --- --- --- --- ---

VA-9072-400 --- --- --- --- ---

--- VA-9075-610

6 --- VA-9075-610

--- VA-9075-800 VA-9078-800 --- --- --- ---

10 --- --12 --- --- --- ---

--- --- --- --- ---

16 --- --- --- --- ---

1. Mounting kit contains a bracket, adaptor, and mounting har d ware.

--- --- --- --- ---

--- --- --- --- ---

-9078-1200 VA-9078-120

--- --- ---

-9078-120

--- ---

-9078-

-9078-

---

---

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 25

Page 26

2-1/2

3

5

6

10

3

5

16

---

---

---

---

---

---

---

Table 26: Mounting Kits

1

for Field Mounting Industrial-Grade V-9000 Series

High Pressure Pneumatic Actuators to Two-Way ANSI Class 300 VF Series

High-Pressure, High-Temperature Butterfly Valves

Valve

Industrial-Grade V-9000 Series High Pressure Pneumatic Actuator

Size,

in.

4 --- --- V-9095-400 V-9095-400 --- --- ---

8 --- --- --- --- V-9096-830 V-9097-120 V-9098-830

12 --- --- --- --- --- V-9097-160 V-9098-100

14 --- --- --- --- --- --- V-9098-1430

1. Mounting kit contains a bracket, adaptor, and mounting hardware.

V-9x93 V-9x94-1 V-9x94-2 V-9x95 V-9x96 V-9x97 V-9x98

V-9094-400 V-9094-400 V-9095-400 --- --- --- --V-9094-400 V-9094-400 V-9095-400 --- --- --- ---

--- --- V-9095-610 V-9095-610 V-9096-610 V-9097-530 ---

--- --- --- V-9095-800 V-9096-800 V-9097-800 ---

--- --- --- --- --- V-9097-160 V-9098-100

1

Table 27: Mounting Kits

for Field Mounting Industrial-Grade VA-907x Series Electric Actuators to

Two-Way ANSI Class 300 VF Series High-Pressure, H igh -Temperature Butterfly Valves

Valve

Industrial-Grade VA-907x Series Electric Actuator

Size,

in.

VA-9072 VA-9075 VA-9076 VA-9077 VA-9078 VA-907A VA-907B

2-1/2 VA-9072-400

VA-9072-400

4 VA-9072-400 VA-9075-400

--- VA-9075-610

6 --- VA-9075-800 VA-9078-800 VA-9075-800

8 --- --- ---

10 --- --- ---

12 --- --- --- --- ---

14 --- --- --- --- --- ---

1. Mounting kit contains a bracket, adaptor, and mounting hardware.

--- --- --- --- --- ---

--- --- --- --- --- ---

--- --- --- --- ---

--- --- --- --- ---

--- --- ---

VA-9078-

1200

VA-9078-

1600

--- --- ---

VA-9078-

1600

--- ---

VA-9078-

1600

---

VA-9078-

2000

26 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 27

C

D

N

M

L

K

G

H

J

F

A

F

R

S

E

B

O

P

Q

E

Figure 17: VF Series High-Pressure, High-Temperature

Butterfly Valve Materials of Construction

(See Table 28.)

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 27

Page 28

C

E

Disc Spacer3 (Two Locations)

316 Stainless Steel, ASTM 276 Type 316

F

H

J

L

Stud4 (Two Locations)

316 Stainless Steel, ASTM A193-B8M

M

O

R

S

Table 28: Materials of Construction

Valve

Part

A Body Carbon Steel, ASTM A216 GR WCB/A516 GR 70

B Disc Stainless Steel, ASTM A 351 GR CF8M

Stem 17-4 PH Stainless Steel, ASTM A564-Type 630

D Taper Pin (Two Locations)

Bearing Assembly (Two Locations) 316 Stainless Steel with TFE and Glass Fiber Liner

G Gland Ring 216 Stainless Steel, ASTM 276 Type 316

Stem Seal One Carbon Fiber Ring and Three TFE Rings

Thrust Washer 316 Stainless Steel, ASTM 276 Type 316

K Gland Retainer Carbon Steel, ASTM A216 GR WCB/A516 GR 70

Lock Washer4 (Two Locations) 18-8 Stainless Steel

N Hex Nut4 (Two Locations) 18-8 Stainless Steel

Seat Assembly RTFE5 with Silicone Rubber O-Ring

P Seat Retainer Carbon Steel, ASTM A516 GR 70

Q Cap Screw (Eight Locations) Alloy Steel

O-Ring Gasket PTFE

Locating Plug6 Carbon Steel, Phosphate Coated

Not

Shown

1. 2-1/2 through 12 in. ANSI Class 150, and ANSI Class 300 valves.

2. 14 and 16 in. ANSI Class 150, and 14 in. ANSI Class 300 valves.

3. Four for 8 in. and larger valves.

4. Four for 14 and 16 in. valves.

5. RTFE is supplied by Johnson Controls as RPTFE (reinforced polytetrafluoroethylene).

6. Not applicable for 2-1/2 through 5 in ANSI Class 150 valves (applicable only for 6 through 12 in.

ANSI Class 300 valves).

Bellville Washer and

Grounding Washer

Description Materials of Construction

17-4 PH Stainless Steel, ASTM A564-Type 6301

316 Stainless Steel

18-8 Stainless Steel

(For 14 and 16 in. ANSI Class 150 Valves and

14 in. ANSI Class 300 Valves)

2

, ASTM 276 Type 316

28 VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin

Page 29

Product

VF Series High-Pressure, High-Temperature Butterfly Valves

Service

Hot Water, Chilled Water, Condenser Water, and Steam2

Models and Ordering Data

See Table 1 through Table 6.

Body Styles and Sizes

Two-Way, 2-1/2 through 16 in., Fully Lugged3

Fluid Temperature Limits

-20 to 500°F (-29 to 260°C)

Fluid Temperature, Dead-En d Service

2-1/2 through 14 in.

550 psig (3,790 kPa) at 250°F (121°C)

Fluid Temperature, Dead-En d Service

Maximum Flow Rate

See Table 23. 6

ANSI Class 150 Valves

See Table 21.

ANSI Class 300 Valves

See Table 22.

ANSI Class 150 Valves

See Table 23. 6

ANSI Class 300 Valves

See Table 23. 6

Materials

See Table 28.

Preferably 40 to 85°F (4 to 29°C)

Accessories

(Order Separately)

Ten-Position Manual Handles (See Table 10.)

Gear-Operated Manual Hand Wheels (See Table 11.)

Weights

ANSI Class 150 Valves

See Table 8.

Building Efficiency

Technical Specifications

Table 29: Technical Specifications1

Maximum Closeoff

Pressure

(See Table 3 through

2-1/2 through 16 in.

ANSI Class 150

Valves (Type V)

Table 6.)

ANSI Class 300

Valves (Type Z)

Flow Coefficients (Cv)

Torque Requirements

Ambient Storage Temperature Limits -20 to 150°F (-29 to 66°C);

240 psig (1,654 kPa) at 250°F (121°C)

Fluid Temperature, Bidirectional

240 psig (1,654 kPa) at 250°F (121°C)

Fluid Temperature, Bidirectional;

550 psig (3,790 kPa) at 250°F (121°C)

3

3, 5

3, 4

3, 4, 5

Representative Maximum

Valve and Actuator

ANSI Class 300 Valves See Table 9.

Assembly Shipping

1. Refer to the appropriate actuator product bulletin for actuator specifications.

2. Type V and Z valves are rated for 150 psig (1,034 kPa) saturated steam at 366°F (186°C) for two-position applic atio ns,

and 50 psig (345 kPa) saturated steam at 297°F (147°C) for modulating applications. Refer to

VF Series High-Pressure, High-Temperature Butterfly Valves for Steam Service Application Note (LIT-977321)

for more information.

3. For 18 in. or larger ANSI Class 150 valves and 16 in. or larger ANSI Class 300 valves, consult the local

Johnson Controls office.

4. The preferred orientation of the seat retainer in dead-end service is against the flange.

5. For pressures between 550 and 740 psig (3,790 and 5,099 kPa), consult the local Johnson Controls office.

6. Published valve torque requirements are based on flow conditions that do not exceed the maximum flow rates found in

Table 23.

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misappl ication or

misuse of its products.

507 E. Michigan Street, Milwaukee, WI 53202

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2014 Johnson Controls, Inc.

VF Series High-Press ur e, High-Temperature Butterfly Valves Product Bulletin 29

Loading...

Loading...