Page 1

Two-Way , Industrial-Grade, Manually Operated,

Standard-Pressure, Standard-Temperature

Butterfly Valve Assemblies

Butterfly Valves and Actuators

Code No. LIT-1900148

Two-Way, Industrial-Grade, Manually Operated, Standard-Pressure,

Standard-Temperature Butterfly Valve Assemblies

Description

VF Series Two-Way, Industrial-Grade, Manually Operated,

Standard-Pressure, Standard-Temperature Butterfly Valves are

specifically designed for a wide range of HVAC applications, including

two-position and modulating control of hot, chilled, or condenser water,

and 50/50 glycol solutions. All valves are factory tested for bubble-tight

shutoff at 100% of the fully rated pressure. These valves are

bidirectional, allowing positive shutoff with the flow in either direction.

Refer to the VF Series Standard-Pressure, Standard-Temperature

Butterfly Valves Product Bulletin (LIT-977205P) for important product

application information.

Features

• low seating/unseating torques

• bubble-tight shutoff

• broad range of pre-assembled actuators

• compatible with all types of American National Standards Institute

(ANSI) 125/150 slip-on and weld-neck flanges

• high-integrity components

• manually operated

Repair Information

If the VF Series Butterfly Valve Assembly fails to operate within its

specifications, refer to the VF Series Standard-Pressure,

Standard-Temperature Butterfly Valves Product Bulletin

(LIT-977205P) for a list of repair parts available.

Actuators

Actuators

Actuators

Actuators

Pneumatic Damper

Pneumatic Damper

Buttery Valves and

Buttery Valves and

Selection Chart

Valve Code

Number

Two-Way, Manually Opera ted — 150 or 175 psig Closeoff Pressure; 75 psig Dead-End Service

VFM-020HB 2 144 175 VFM-020HB-000M VFM-020HB-000G

VFM-025HB 2-1/2 282 175 VFM-025HB-000M VFM-025HB-000G

VFM-030HB 3 461 175 VFM-030HB-000M VFM-030HB-000G

VFM-040HB 4 841 175 VFM-040HB-000M VFM-040HB-000G

VFM-050HB 5 1,376 175 VFM-050HB-000M VFM-050HB-000G

VFM-060HB 6 1,850 175 VFM-060HB-000M VFM-060HB-000G

VFM-080HB 8 3,316 175 VFM-080HB-000G

VFM-100HB 10 5,430 175 VFM-100HB-000G

VFM-120HB 12 8,077 175 VFM-120HB-000G

VFM-140HC 14 10,538 150 VFM-140HC-000G

VFM-160HC 16 13,966 150 VFM-160HC-000G

VFM-180HC 18 17,214 150 VFM-180HC-000G

VFM-200HC 20 22,339 150 VFM-200HC-000G

Actuator Ten-Position Manual Handle Gear-Operated Manual Hand

Size, in. Cv at 90° Closeoff Pressure,

psig

Wheel

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

V–271

Page 2

Two-Way, Industrial-Grade, Manually Operated, Standard-Pressure,

Standard-Temperature Butterfly Valve Assemblies (Continued)

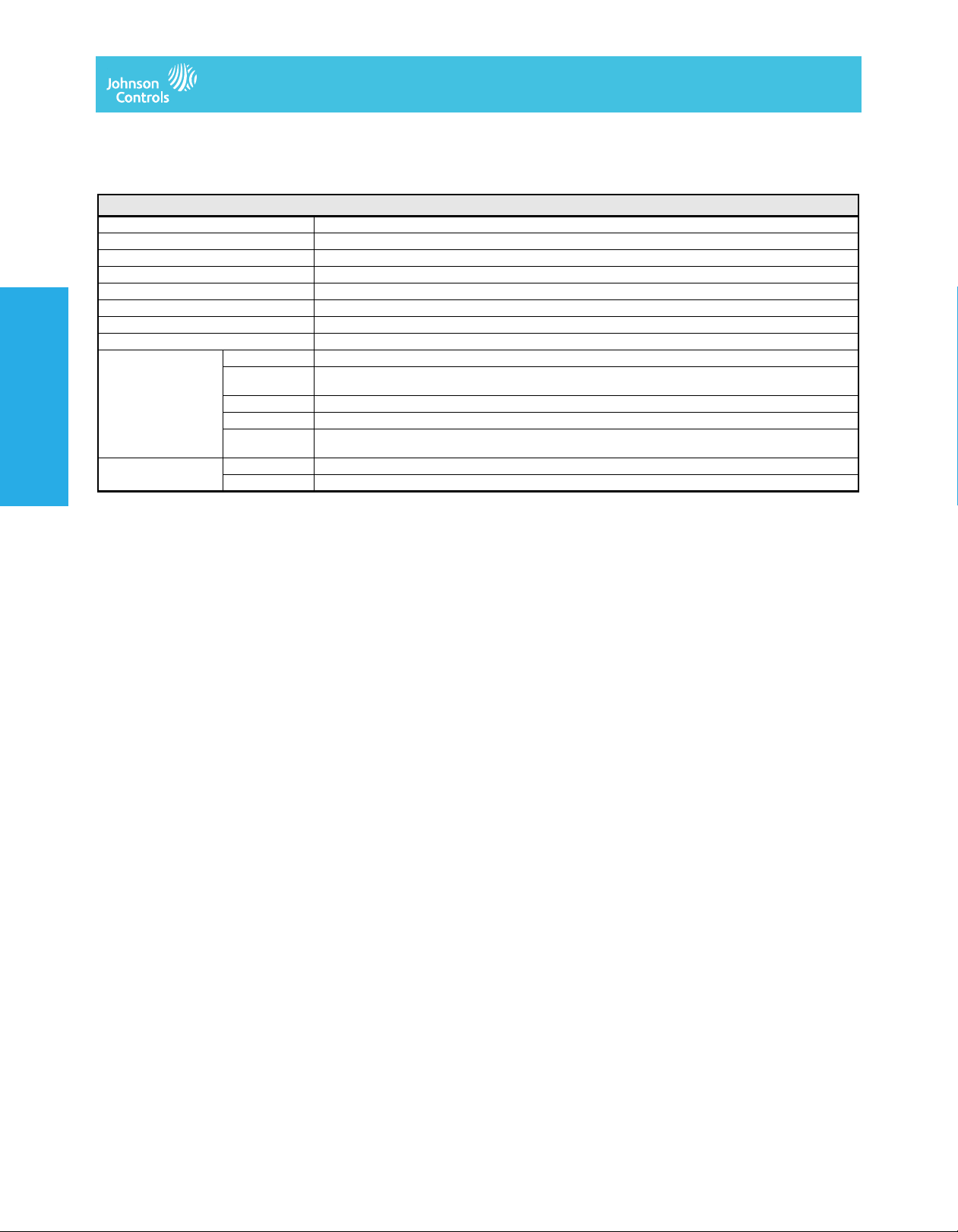

Technical Specifications

Two-Way, Industrial-Grade, Manually Operated, Standard-Pressure, Standard-Temperature Butterfly Valve Assemblies

Service Hot, Chilled, or Condenser Water, and 50/50 Glycol Solutions (Not Designed for Use in Steam Applications)

Body Styles and Sizes Two-Way, 2 through 20 in., Fully Lugged

Fluid Temperature Limits -40°F to 250°F (-40°C to 121°C)

Body Pressure Rating 175 psig

Maximum Fluid Velocity 30 ft/second (9 m/second)

Rangeability Refer to the VF Series Standard-Pressure, Standard-Temperature Butterfly Valves Product Bulletin (LIT-977205P).

Leakage Bubble Tight

Flow Characteristics Modified Equal Percentage

Materials Body Cast Iron, ASTM A126 Class B

Actuators

Actuators

Pneumatic Damper

Buttery Valves and

Ambient Temperature

Limits

1. Refer to the VF Series Standard-Pressure, Standard-Temperature Butterfly Valves Product Bulletin (LIT-977205P) for actuator specifications.

Butterfly Valves and Actuators

Tee (Three-Way

Valves Only)

Disc Ductile Iron, Nylon 11 Coat ed, ASTM A536 Gr 65-45-12

Seat Ethylene Propylene Diene Monomer (EPDM)

Stem 416 Stainless Steel (2 through 12 in.)

Storage -20 to 150°F (-29 to 66°C), Preferably 40 to 85°F (4 to 29°C)

Operating -40 to 200°F (-40 to 95°C)

Cast Iron

304 Stainless Steel (14 through 20 in.)

1

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

V–272

Loading...

Loading...