Johnson Controls VG1600 Series, VA9905-KGA-2, VA9905 Series, VA9905-KGA-1 Installation Instructions Manual

Page 1

VA9905 Actuator and

VG1600 Series Six-Way Valves

Installation Instructions

14-88360-03206, Rev. -

Page 2

Contents

Compliance Information............................................................................1

About This Document ............................................................................... 1

Accessories ..............................................................................................1

Support Information ..................................................................................1

Parts Included...........................................................................................2

Tools Required..........................................................................................2

Flow Disk Set............................................................................................3

Installing the Six-Way Valve to a System .................................................4

Clearance Required to Install an Actuator ................................................4

Attaching the Actuator to the Six-way Valve ............................................. 5

Setting the DIP Switches ..........................................................................6

Wiring the Actuator ................................................................................... 6

Manual Override and Flow Direction ........................................................7

VA9905 Technical Specications .............................................................. 8

VG1600 Valve Series Technical Specications ........................................9

Compliance Information

IMPORTANT: Use this VA9905 Actuator only to control equipment under normal operating conditions.

Where failure or malfunction of the VA9905 Actuator could lead to personal injury or property damage to the controlled equipment or other property, additional precautions must be designed into the control system. Incorporate

and maintain other devices, such as supervisory or alarm systems or safety or limit controls, intended to warn of or

protect against failure or malfunction of the device.

IMPORTANT : Utiliser ce [nom complet de l’appareil] uniquement en tant que dispositif de contrôle de

fonctionnement. Lorsqu’une défaillance ou un dysfonctionnement du [nom abrégé de l’appareil] risque de

provoquer des blessures ou d’endommager l’équipement contrôlé ou un autre équipement, la conception du

système de contrôle doit intégrer des dispositifs de protection supplémentaires. Veiller dans ce cas à intégrer de

façon permanente d’autres dispositifs, tels que des systèmes de supervision ou d’alarme, ou des dispositifs de

sécurité ou de limitation, ayant une fonction d’avertissement ou de protection en cas de défaillance ou de

dysfonctionnement du [nom abrégé de l’appareil].

About This Document

This guide describes how to install and congure the VA9905 Actuator and Six-Way Valve. The procedures in this

guide must be completed sequentially, as they are listed.

Accessories (order separately)

Code Number Name Description

VG1600-01 Wall Mounting Bracket Kit Provides a mounting bracket for the VA9905 Actuator.

VG1600-02 Flow Disk Kit Provides replacement ow disks.

VG1600-03 Insulation Shell Kit Provides valve insulation.

VG1600-04 Sweat Union Fitting Kit Provides sweat union ttings.

M9300-100 Conduit Adapter Kit (5 per kit) Provides a conduit adapter that protects the input cable.

Support Information

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

Johnson Controls Johnson Controls Johnson Controls

Westendhof 3 507 E Michigan Street C/O Controls Product Management

45143 Essen Milwaukee WI 53202 No. 22 Block D, New District

Germany USA Wuxi Jiangsu Province 214142

China

1

14-88360-03206, Rev. A

Page 3

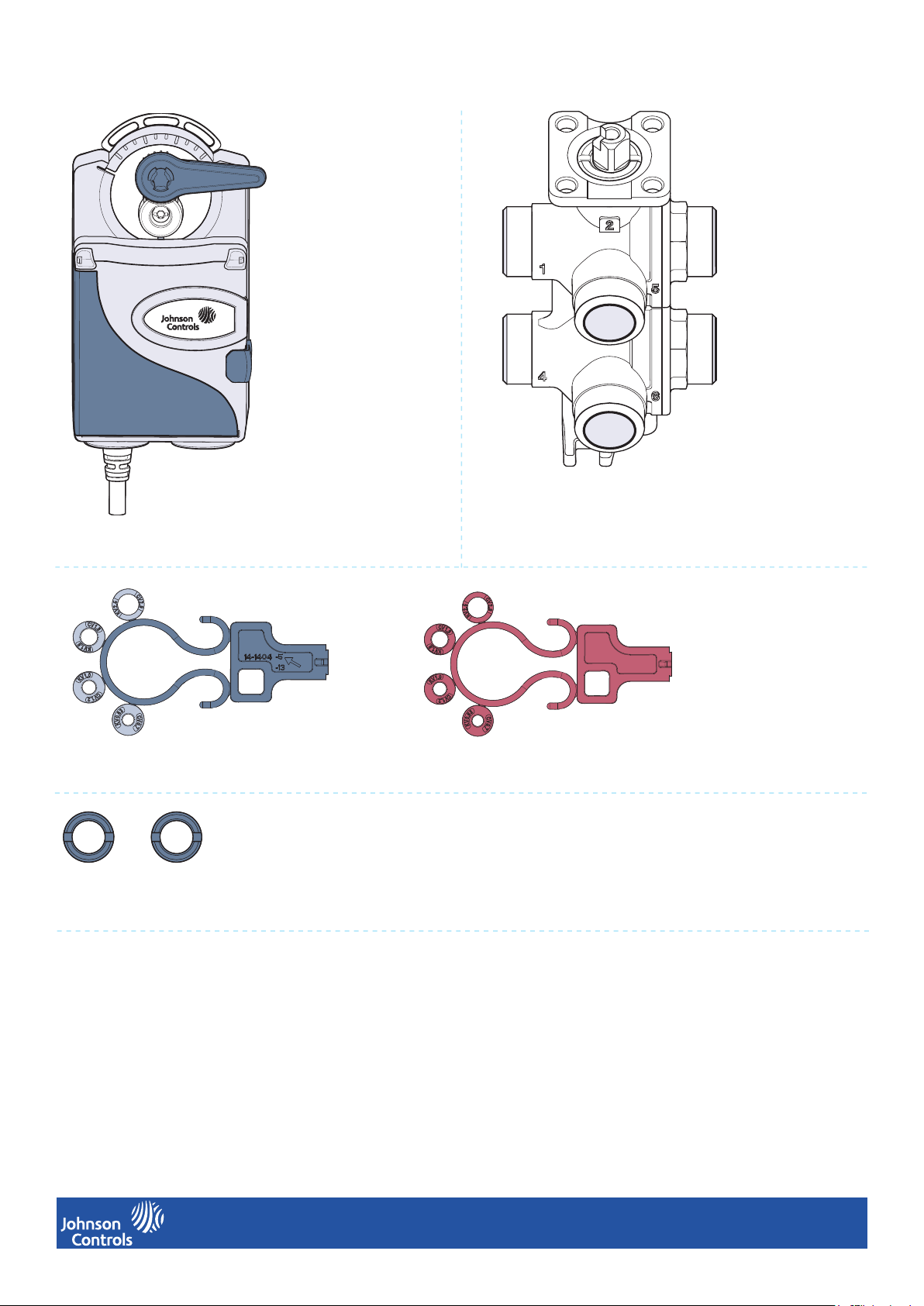

Parts Included

VA9905 Actuator

Two Flow Disk Sets

Two Ring Nuts

VG1600 Series Valve

Tools Required

• 8mm (5/16 in) slotted screwdriver

or a TORX® T-20 driver

2

14-88360-03206, Rev. A

Page 4

Flow Disk Set

Disassembly

1

Disk Storage

1

2

2

3

3

4

Installation

Note: Use blue restriction disks with cold water and red disks with hot water only.

Flow restriction disks have markings that indicate the rate of restriction they provide.

Using the supplied restriction disks, you can set the following ow rates in ports 4 and 6:

Disk Opening Smallest Small Medium Largest No disk

CV 0.7 1.2 1.9 2.9 3.9

Kv 0.63 1.0 1.6 2.5 3.3

1

2

3

3

14-88360-03206, Rev. A

Page 5

Installing the Six-way Valve to a System

The diagram below illustrates the input and output ows for the 6-way valve. Use this diagram as a guide on how to

install the 6-way valve to your system.

Note: Valve port 2 must only be used as coil supply. Valve port 3 must only be used as coil return.

Valve port Description Analog Input Control

1

5

1 Source 1 supply Controlled by the gray wire

2 Coil supply

3 Coil return

4 Source 1 return Controlled by the gray wire

4

2

6

5 Source 2 supply Controlled by the orange wire

6 Source 2 return Controlled by the orange wire

Note: Source 1 and 2 can be used for hot or cold water.

3

Clearance Required to Install an Actuator

The diagrams below illustrate the clearance required to install an actuator to the VG1600 Valve Series.

89 mm

(3 - 1/2 in.)

100 mm (3 -15/16 in.)

75 mm

(2 - 15/16 in.)

150 mm (5 - 29/32 in.)66 mm (2 - 19/32 in.)

114 mm

(4 - 31/64 in.)

4

14-88360-03206, Rev. A

Page 6

Attaching the Actuator to the Six-Way Valve

Note: The VA9905 Actuator ts VG1600 series valves only.

1

Use the valve key to adjust the valve stem

to a 90° angle, away from the curved section.

2

Press the manual override button on the actuator.

4

Ensure the valve stem is aligned as shown.

3

Move the actuator lever to the extreme right position.

5

Align the top of the 6-way valve to the plate

at the back of the actuator.

Use a slotted screwdriver or a TORX® T-20 driver to

tighten the actuator screw to the 6-way valve. Tighten

to a torque of 0.9 to 1.4 Nm (8 to 12 lb-in).

5

14-88360-03206, Rev. A

Page 7

Setting the DIP Switches

!

!

1

AC 24 V

DC 0

(2)

.10V

GRY

BLK

RED

ORN

1

4

2

3

Remove the dip switch cover by placing your

nger behind it and pulling it toward yourself.

2

7

8

6

45

3

1

2

OFF

ON

45

6

3

AC 24 V

BLK

1

7

8

1

45

7

3

2

6

8

DC 0

(2)

.10V

GRY

RED

ORN

4

2

3

You now have access to the actuator dip switches.

1

2

OFF

ON

If the controller output signal range is:

• 2 to 10 V: Push dip switch 1 to the ON position.

-or-

• 0 to 10 V: Push dip switch 1 to the OFF position.

Wiring the Actuator

Risk of electric shock.

Disconnect the power supply before making electrical connections to avoid electric shock.

Risque de décharge électrique.

Débrancher l’alimentation avant de réaliser tout raccordement électrique an d’éviter tout risque de décharge électrique.

Wire the VA9905 Actuator as described in the table below:

CAUTION

ATTENTION

Wire Color Input

Black Com 24 V AC\DC

Red ~(+)

Gray (Source 1 control) Y1 DC 0(2)...10 V

Orange (Source 2 control) Y2

6

14-88360-03206, Rev. A

Page 8

Manual Override and Flow Direction

x

xx

x

xx

x

The manual override lever is used to indicate which ports are in use.

In the absence of power to the actuator, manually set the pointer to the desired position to regulate the ow of the

valve.

Note: The setup procedure described in the Attaching the Actuator to a Six-way Valve section sets ports 1 and 4 to full

ow.

Note: The ball valve and actuator pointer rotate in opposite directions.

The following illustrations indicate lever position and ow:

Full Flow on ports 5 and 6 No Flow Full Flow on Ports 1 and 4

When no actuator is installed, use the following positions of the stem to set the ow of the valve:

Note: The cuts on the valve stem indicate the ports inside the valve.

Full Flow on Ports 5 and 6 No Flow Full Flow on Ports 1 and 4

7

14-88360-03206, Rev. A

Page 9

VA9905 Actuator Technical Specications

Product description VA9905-KGA-1: Proportional mode, VA9905-KGA-2: Proportional mode

Power requirements AC 24 V ±20% at 50/60 Hz, Class 2 (North America) or SELV (Europe), 5.2 VA Running;

DC 24 V ±10% Class 2 (North America) or SELV (Europe), 1.1 W Running.

Transformer sizing

requirements

Input signal/adjustments 0 (2) to 10 VDC or 0 (4) to 20 mA with eld furnished 500 ohm 1/4 W resistor

Control impedance 100k ohm

Rotation rate 1.5 ° per second

Cycles 60,000 full stroke cycles; 2,500,000 repositions

Audible noise <35 dBA at 1 m (39-13/32 in.)

Electrical connections -1 halogen-free

Conduit connections 13 mm NPSM (1/2 in.) threaded conduit connectors with M9300-100 conduit

Ambient conditions Operating: 0 to 60°C (32 to 140°F), 90% RH, noncondensing

Enclosure IP54/NEMA 5

Dimensions VA9905 Actuator: Width: 89 mm (3-1/2 in.), Height: 74 mm (2-15/16 in.), Length: 170

Shipping weight Valves:

≥6 VA

-2 plenum-rated

1.2 m (48 in.) halogen free cable with

0.82 mm² (18 AWG) conductors and

6 mm (0.25 in.) ferrule ends

Storage: -40 to 85°C (-40 to 185°F), 95% RH, noncondensing

mm (5-11/16 in.)

• VG1611AF: 0.7 Kg (1.55 lbs)

• VG1641AF: 0.8 Kg (1.85 lbs)

• VG1671AF: 1 Kg (2.20 lbs)

3.05 m (120 in.) UL 444 type CMP plenum

rated cable with 0.75 mm² (19 AWG cable)

conductors and 6 mm (0.25 in.) ferrule ends

Actuator

• VA9905: 0.8 Kg (1.75 lbs)

Compliance United States: UL Listed, CCN XAPX, File E27734; to UL 60730-1: Automatic Electrical

Controls for Household and Similar Use, Part 1; and UL 60730-2-14: Part 2, Particular

Requirements for Electric Actuators. Plenum Rated (UL 2043). Suitable for use in Other

Environmental Air Space (Plenum) in accordance with section 300.22 (c) of the National

Electrical Code.

Canada: UL Listed, CCN XAPX7, File E27734; to CAN/CSA E60730-1:02: Automatic

Electrical Controls for Household and Similar Use, Part 1; and CAN/CSA-E60730-2-14,

Particular Requirements for Electric Actuators.

Europe:

CE Mark—Johnson Controls declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive.

IEC 60730-1: Automatic Electrical Controls for Household and Similar Use, Part 1:

General Requirements and IEC 60730-2-14, Automatic Electrical Controls for Household

and Similar Use; Part 2—Particular Requirements for Electric Actuators

Australia and New Zealand: RCM—Australia/NZ Emissions Compliant

The performance specications are nominal and conform to acceptable industry standard. For application at conditions beyond

these specications, consult the local Johnson Controls ofce. Johnson Controls shall not be liable for damages resulting from

misapplication or misuse of its products.

8

14-88360-03206, Rev. A

Page 10

VG1600 Valve Series Technical Specications

Total operation angle 270°

Sequence 1 0...>90°

Dead band >90…<180°

Sequence 2 >180…270°

Characteristic curve Linear

ID 10,5 mm

Fluid type Water, glycol solutions (max 50%) for HVAC applications

Fluid temperature 5 to 95 °C (41 to 203 °F)

Nominal pressure PN16 (232 psi)

Close off pressure 350 kPa (50 psi)

Max. differential pressure 240 kPa (35 psi)

Range ability 100:1

Max. Cv (Kv) 3.3 (3.8) - ½’’ pipe size

Connections • Valve Body with Male BSPP Thread (external)

• Valve Body with Female NPT Thread (internal

• Sweat Union Fitting kit

Flow coefcient Flow control disk

Leakage rate A, 100,000 cycles in iron-oxide contaminated water and air-bubble-tight (EN 12266-1)

Water quality Iron-oxide contaminated water (900ppm)

Maintenance Maintenance Free

Warranty Minimum 5 years to our customer

The performance specications are nominal and conform to acceptable industry standard. For application at conditions beyond

these specications, consult the local Johnson Controls ofce. Johnson Controls shall not be liable for damages resulting from

misapplication or misuse of its products.

9

14-88360-03206, Rev. A

Loading...

Loading...