Page 1

T500 Series Programmable Thermostats

T500 Series Thermostats provide an economical

control solution for single-stage, multi-stage, or heat

pump systems. Up to four event setpoints can be

selected, as well as heat, cool, automatic changeover,

and off modes.

Thermostats are available in the following types:

T500HCP-1 (1 heat/1 cool), T500HPP-1 (heat pump,

3 heat/2 cool), T500HPP-2 (heat pump, 1 heat/1 cool),

T500MSP-1 (2 heat/2 cool). Each thermostat is

packaged with the necessary mounting hardware, and

installation is simple and fast for reduced cost.

FANs 216, 1628.3

Product/Technical Bulletin T500

Issue Date 0899

Features and Benefits

!!!! Low-Profile Design

!!!! No Batteries Required

!!!! Lockable Access Cover and

Keypad Lockout

!!!! Full Function Liquid Crystal

Display (LCD)

!!!! Remote Sensor Terminals

!!!! Auxiliary Output

!!!! Fuzzy Logic Control

!!!! Smart Fan Option

Figure 1: T500 Series Programmable Thermostats

Complements any decor

Retains scheduled events and temperatures

upon loss of power

Prevents unauthorized changes

Makes controls easy to read, easy to use

Allows the T500 thermostat to be mounted up

to 300 m (1,000 ft) away from the controlled

space using a SEN-500-1 (sold separately)

Energizes for auxiliary equipment operation

Optimizes control performance

Provides continous fan operation in the

occupied mode and intermittent operation at

night

© 1999 Johnson Controls, Inc.

Part No. 24-8347-35, Rev. E www.johnsoncontrols.com

Code No. LIT-216173

1

Page 2

ntroduction

I

ocation Considerations

L

The T500 thermostats use an adaptive control routine,

based on fuzzy logic, to determine the heating or

cooling load of the controlled space. The routine

calculates load by evaluating recent room conditions

and room reactions to heating and cooling. This load is

used to determine the cycle rate of the equipment,

giving optimal control of the space.

upplies Needed

S

•

drill

•

4.7 mm (3/16 in.) drill bit

•

3 mm (1/8 in.) flat-blade screwdriver

•

hammer

•

marking pencil

•

wire stripper

114. 3

(4-1/2)

Locate T500 thermostat as follows:

•

on a partitioning interior wall, and approximately

1.5 m (5 ft) above the floor in a location of average

temperature

•

away from direct sunlight or radiant heat, outside

walls or behind doors, air discharge grills,

stairwells, or outside doors

•

away from steam or water pipes, warm air stacks,

unheated/uncooled areas, or sources of electrical

interference

!

CAUTION:

nstallation and Wiring

I

Note: When replacing an existing thermostat,

remove and use wire tags to identify terminal

designations.

To install and wire the thermostat:

Shock Hazard.

Disconnect power supply before

wiring connections are made to

prevent electrical shock or

possible damage to the

equipment.

T500MSP-1

T500HPP-1

T500HCP-1

T500HPP-2

Figure 2: T500 Dimensions, mm (in.)

127

(5)

101.6

(4)

Dimn

22.2

(7/8)

1. Lift the thermostat cover and insert a small coin

into the slot located in the bottom center of the

thermostat case and twist 1/4 turn. (See Figure 3.)

Grasp the base from the bottom two corners and

separate from the thermostat.

2. Swing the thermostat out from the bottom, and lift

up and out of the base. Place the rectangular

opening in the base over the equipment control

wires protruding from the wall and, using the base

as a template, mark the location of the two

mounting holes. No leveling is required.

3. Use the supplied anchors and screws for mounting

on drywall or plaster. Drill two 4.7 mm (3/16 in.)

holes at the marked locations, tap nylon anchors

flush to wall surface, and fasten. (See Figure 4.)

4. Connect the wires from the existing system to the

thermostat terminals according to wiring

designations in Table 2, Table 3, Table 4, or

Table 5. Push extra wire back into the wall. Wires

must be flush to the plastic base. Plug hole with a

fireproof material to prevent drafts from affecting

ambient temperature readings.

2

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 3

!

CAUTION:

Equipment Damage Hazard.

Before applying power, make all

wiring connections and check

the connections. Short-circuited

or improperly connected wires

may result in permanent

damage to the unit.

Figure 4: Mounting the Base

Figure 3: Separating the T500 from the Base

T500 Series Programmable Thermostats Product/Technical Bulletin

3

Page 4

nstalling the Thermostat Cover Lock

I

If desired, insert the plastic lock piece into the bottom

of the mounted base. The ends of the lock piece

should fit snugly under the lock pins extending from the

bottom of the mounted base. The tab in the middle of

the lock piece should extend downward from the

mounted base. (See Figure 5.)

To release the locking mechanism, press the lock

piece up and into the base while gently prying open the

thermostat at the same time. Use caution to avoid

cracking the thermostat base or cover.

eattaching the Thermostat and Cover

R

to the Installed Base

1. Position the thermostat inside the cover, and

attach on the hinged tabs located at the top of the

base.

2. Swing the thermostat and cover down, and press

on the bottom center edge until they snap in place.

(See Figure 6.)

Plastic Lock Pin

Snap

plastic lock

into place.

Figure 5: Installing the Thermostat Lock

Thermostat

Base

Hinged

Ta b s

Figure 6: Installing the T500 Thermostat

4

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 5

IP Switch Selections

D

!

CAUTION:

Equipment Damage Hazard.

Before selecting a minimum

on/off time, ensure the

equipment can tolerate the

following maximum hourly

cycle rates: 7.5 cycles per hour

when using 4-minute on/off, or

15 cycles per hour when using

2-minute on/off.

Table 1: DIP Switch Selections

DIP Switch Switch

Selection

1

2

(Smart Fan)

3

4

5

Continued on next page . . .

On Allows 2-event (day, night) programming.

Off Allows 4-event (morning, day, evening, night) programming.

On During the

Off Allows the fan to cycle with equipment or run continuously if the

On Allows 2-minute minimum on/off time for heating and cooling equipment.

Off Allows 4-minute minimum on/off time for heating and cooling equipment.

On Locks the keyboard, disabling buttons to prevent tampering. (Only the

Off Unlocks the keyboard.

On

Off

Description

equipment or runs continuously if the

Fan

after programming the thermostat. Smart Fan remembers that the fan should run

continuously during these events after that.

During the

Pressing the

continuously for that night only.

At the end of the

cycling or continuous fan) for the

pressed, regardless of the event. Changing between events does not affect the fan.

∨∨∨∨ and ∧∧∧∧ buttons will function. See

Programming Changes While the Keyboard is Locked,

[Keyboard Locked]

T500HCP-1, T500HPP-2, T500MSP-1 only:

switch.

T500HPP-1 only:

the auxiliary heat is on. The compressor will remain off for 2 minutes after the

auxiliary heat is turned off to ensure that the heat pump coil has cooled.

T500HCP-1, T500HPP-2, T500MSP-1 only:

call for heat.

T500HPP-1 only:

heat to be on simultaneously.

morning, day, and evening

button need only be pressed once during the morning, day, or evening event

night

event, the fan automatically cycles with the equipment by default.

Fan

button during the night event overrides and causes the fan to run

night

event, Smart Fan remembers the fan selection (automatic

in this bulletin.)

Compressor/Auxiliary Interlocked: Turns off the compressor when

Compressor/Auxiliary Normal: Allows the compressor and auxiliary

events, the fan automatically cycles with the

Fan

button is pressed. To run continuously, the

morning, day, and evening

Programming the Thermostat, Making

Allows the fan to delay with the plenum

Allows fan to operate immediately with a

events and reverts back.

Fan

button is

Outdoor

Temporary [1 Hour]

and

and

T500 Series Programmable Thermostats Product/Technical Bulletin

5

Page 6

DIP Switch

(Cont.)

Switch

Selection

Description

6

On

Off

7

LED 1 icon

T500HPP-1, T500MSP-1 only:

T500HPP-1, T500MSP-1 only:

T500HPP-1, T500MSP-1 only:

off/on

(See Table 5.)

8

LED 2 icon

T500HPP-1, T500MSP-1 only:

off/on

(See Table 5.)

4 Events Per Day

Smart Fan Disabled

Heat/Cool: 4 Min ute

(Minimum On)

Keyboard Unlocked

Fan Immediate

with Heat Call

1

2

3

4

5

O

N

2 Events Per Day

Smart Fan Enabled

Heat/Cool: 2 Minute

(Min imum On)

Keyboard Locked

Fan On with

Plenum Switch

Figure 7: T500HCP-1 Factory-Set DIP Switch

Settings (All Off)

Allows multi-stage heating or cooling.

Allows single-stage heating or cooling.

Optional selection: LCD icon comes on with LED 1.

Optional selection: LCD icon comes on with LED 2.

Table 2: T500HCP-1 Output Terminal

Designations

Terminal Function

W1

Y1

G

R

24V

24V(c)

RS2

RS1

RS+V

Energizes on call for heating

Energizes on call for cooling

Energizes fan on call for heating or

cooling or by pressing

Fan

button

Independent switching voltage

24 VAC from equipment transformer

24 VAC (common) from equipment

transformer

Connections for outdoor air

temperature or indoor remote

sensors; refer to instructions included

with sensors.

W1

Y1

24V

24V(c)

RS2

RS1

RS+V

Heating

Cooling

Fan

Common

Figure 8: T500HCP-1 Wiring Terminals

6

T500 Series Programmable Thermostats Product/Technical Bulletin

G

R

Hcp-1wire

Page 7

4 Events Per Day

Smart Fan Disabled

Heat/Cool: 4 Minute

(Minimum On)

Keyboard Unlocked

Compressor/Auxiliary

Normal

Single Stage

LED 1 Icon Off

LED 2 Icon Off

1

2

3

4

5

6

7

8

ON

Figure 9: T500HPP-1 DIP Factory-Set

DIP Switch Settings

1st Stage Compressor

24VAC

Figure 10: T500HPP-1 Wiring Terminals

2 Events Per Day

Smart Fan Enabled

Heat/Cool: 2 Minute

(Minimum On)

Keyboard Locked

Compressor/Auxiliary

Interlocked

Multi-stage

LED 1 Icon

(Filter)

LED 2 Icon

(Wrench/Fault)

W2

Table 3: T500HPP-1 Output Terminal

Designations

Terminal Function

W2

Y2

W1

Y1

G

R

24V

24V(c)

O

B

LED 1

LED 2

RS2

RS1

RS+V

NO

COM

NC

Energizes auxiliary heat as

second-stage heating in emergency

heat mode

Energizes compressor No. 2 on call

for second-stage heating or cooling

Energizes auxiliary heat as

last-stage heating or first-stage in

emergency heat

Energizes compressor No. 1 on call

for heating or cooling

Energizes fan on call for heating or

cooling or by pressing

Fan

button

Independent switching voltage

24 VAC from equipment transformer

24 VAC (common) from equipment

transformer

Energizes reversing valve in the

cooling mode

Energizes reversing valve in the

heating mode

Input connection that energizes

LED 1 or LED 2 from remote status

device (See Figure 9 and Table 6.)

Connections for outdoor air

temperature or indoor remote

sensors; refer to instructions

included with sensors.

The relay coil is de-energized in the

night event. In all other events, the

relay coil is energized. (See

Figure 16.)

T500 Series Programmable Thermostats Product/Technical Bulletin

7

Page 8

4 Events Per Day

Smart Fan Disabled

Heat/Cool: 4 Minute

(Minimum On)

Keyboard Unlocked

Fan Immediate

with Heat Call

1

2

3

4

5

ON

2 Events Per Day

Smart Fan Enabled

Heat/Cool: 2 Minute

(Minimum On)

Keyboard Locked

Fan On with

Plenum Switch

Table 4: T500HPP-2 Output Terminal

Designations

Terminal Function

Single-Stage

Heat Pump

Thermostat

Conventional

Single-Stage

Heat/Cool

Thermostat

Figure 11: T500HPP-2 Factory-Set DIP Switch

Settings (All Off)

RS2

RS1

RS+V

Compressor

Fan

24VAC

Common

W1

B

Hpp-2wire

Figure 12: T500HPP-2 Wiring Terminals

Note:

W1*

Jumpered to Y1

(See Note.)

Energizes on call

for heating

(See Note.)

Y1

Energizes

compressor

contactor

Energizes on call

for cooling

(See Note.)

(See Note.)

G

R

Energizes fan on call for heating or

cooling or by pressing

Fan

button

Independent switching voltage

(See Note.)

24V

24V(c)

24 VAC from equipment transformer

24 VAC (common) from equipment

transformer

RS2

RS1

RS+V

O

Connections for outdoor air temperature

or indoor remote sensors; refer to

instructions included with sensors

Energizes

Not used

reversing valve in

the cooling mode

B

Energizes

Not used

reversing valve in

the heating mode

Single-Stage Heat Pump:

Leave the factory-installed jumper connected

between W1 and Y1 and wire O or B as shown in

Figure 12.

Conventional Single-Stage Heat/Cool:

Remove the factory-installed jumper between W1

and Y1 and wire as shown in Figure 12. Note that

the O and B terminals are not used in this

application.

8

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 9

4 Events Per Day

Smart Fan Disabled

Heat/Cool: 4 Minute

(Minimum On)

Keyboard Unlocked

Fan Immediate

with Heat Call

Single Stage

LED 1 Icon Off

LED 2 Icon Off

1

2

3

4

5

6

7

8

ON

2 Events Per Day

Smart Fan Enabled

Heat/Cool: 2 Minute

(Minimum On)

Keyboard Locked

Fan On with

Plenum Switch

Multi-stage

LED 1 Icon

(Filter)

LED 2 Icon

(Wrench/Fault)

Figure 13: T500MSP-1 Factory Set

DIP Switch Settings

2nd Stage Heating

2nd Stage Cooling

1st Stage Heating

1st Stage Cooling

NO

COM

NC

Fan

24VAC

Common

W2

Figure 14: T500MSP-1 Wiring Terminals

Table 5: T500MSP-1 Output Terminal

Designations

Terminal Function

R

W2

Y2

W1

Y1

G

R

24V

24V(c)

O

B

LED 1

LED 2

RS2

RS1

RS+V

NO

COM

NC

Energizes on a call for

second-stage heat

Energizes on a call for

second-stage cooling

Energizes on a call for first-stage

heat

Energizes on a call for first stage

cooling

Energizes fan on call for heating or

cooling or by pressing the

Fan

button

Independent switching voltage

24 VAC from equipment

transformer

24 VAC (common) from equipment

transformer

Energizes in the cooling mode

Energizes in the heating mode

Input connection that energizes

LED 1 or LED 2 from remote status

device (See Figure 13 and

Table 6.)

Connections for outdoor air

temperature or indoor remote

sensors; refer to instructions

included with sensors

The relay coil is de-energized in the

night event. In all other events, the

relay coil is energized. (See

Figure 18.)

T500 Series Programmable Thermostats Product/Technical Bulletin

9

Page 10

iring Diagrams

W

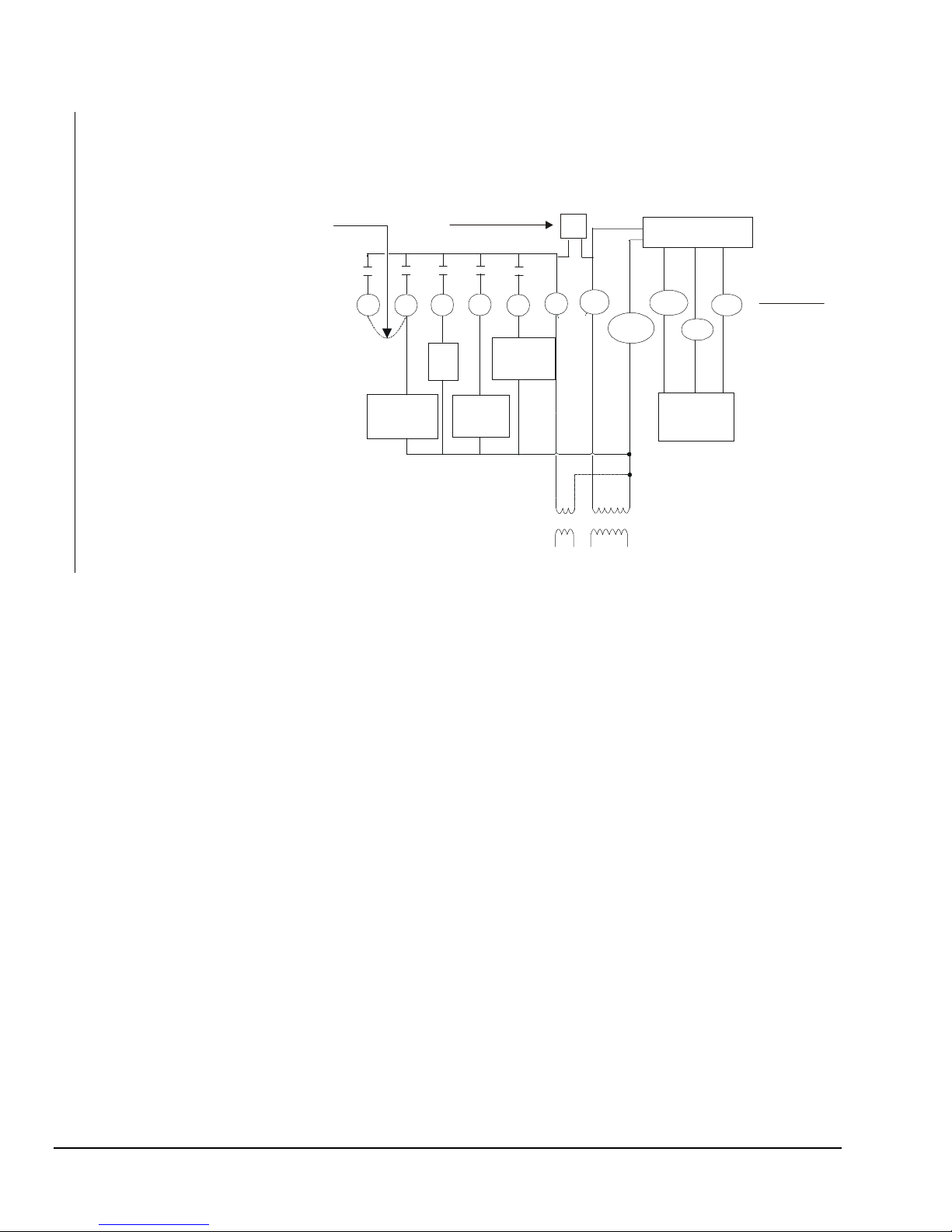

If the transformer (T2) is to power all of the loads,

R and 24 must be connected by inserting jumper J 1

located above the relays. If a separate 24V

transformer (T1) is to be used, remove J 1 to

disconnect R and 24V(c).

P

P

J1P

Electronics

W1

1st Stage

Heat

Compressor

24V

Y1 G

Fan

1st Stage

Optional

R

T1

T2

24V(c)

RS+V

Figure 15: T500HCP-1 Wiring Schematic

RS1

Remote

Sensor

(if used)

RS2

Thermostat

Equipment

Hcp-1diag

10

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 11

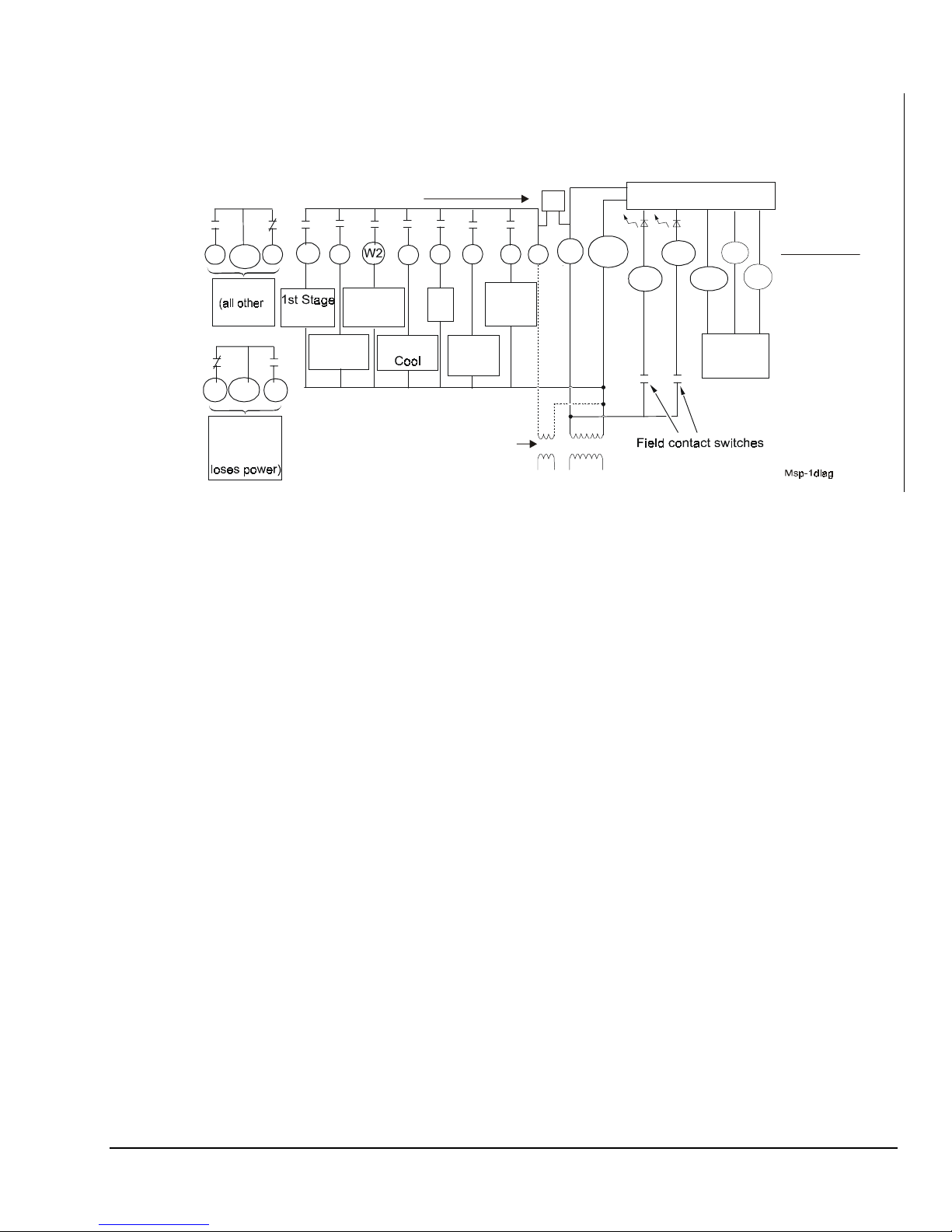

If the transformer (T2) is to power all of the loads

R and 24V must be connected by inserting jumper

1, located above the relays. If a separate 24V

JP

transformer (T1) is to be used, remove the jumper

to disconnect R and 24V.

JP1

JP1

Electronics

COM

NO NC

OCC

(all other

events)

COM

NO

UNOCC

(night event

if

thermostat

loses power)

1st Stage

NC

W1

Heat

1st Stage

Compressor

Y1 Y2W2G

2nd Stage

Heat

2nd Stage

Compressor

Fan

Figure 16: T500HPP-1 Wiring Schematic

O

Reverse

Val ve

Cooling

Optional

B

Reverse

Val ve

Heating

24V(c)

24V

R

T1

T2

LED1

LED2

Field contact switches

RS+V

RS1

Remote

sensor

(if used)

RS2

Thermostat

Equipment

Hpp-1diag

T500 Series Programmable Thermostats Product/Technical Bulletin

11

Page 12

Single-Stage Heat Pump:

Leave the factory-installed jumper

connected between W1 and Y1 and

wire O or B as shown.

Conventional Single-Stage Heat/Cool:

Remove the factory-installed jumper

between W1 and Y1 and wire as shown

in Figure 12. Note that the O and B terminals

are not used in this application.

If the transformer (T2) is to power all of the

loads, R and 24V must be connected by

inserting jumper JP1, located above the

relays. If a separate 24V transformer (T1)

is to be used, remove the jumper JP1 to

disconnect R and 24V(c).

W1

Y1

G

Fan

O B

Reverse

Val ve

Heating

JP1

24V

R

24V(c)

Electronics

RS+V

RS1

RS2

Thermostat

Equipment

Reverse

Compressor

Val ve

Cooling

T1 T2

Figure 17: T500HPP-2 Wiring Schematic

Remote

sensor

(if used)

Hpp2-diag

12

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 13

If the transformer (T2) is to power all of the loads,

R and 24V must be connected by inserting jumper

J 1 located above the relays. If a separate 24V

P

transformer (T1) is to be used, remove the jumper

1 to disconnect R and 24V(c).

JP

JP1

Electronics

NO NC

COM

OCC

events)

COM

UNOCC

or

if

NC

NO

(night event

thermostat

W1

Heat

1st Stage

Y1

2nd Stage

Cool

24V(c)

24V

R

T2

T1

Heat

2nd Stage

Y2

G

Fan

Reverse

Val ve

Cooling

OB

Reverse

Val ve

Heating

optional

Figure 18: T500MSP-1 Wiring Schematic

LED2

LED1

RS+V

Remote

(if used)

RS1

Sensor

Thermostat

Equipment

RS2

T500 Series Programmable Thermostats Product/Technical Bulletin

13

Page 14

ommissioning

C

The thermostat normally displays room temperature

and mode of operation (whether cooling

or heating

is currently on).

Table 6: LED Indicators (T500MSP-1, T500HPP-1 only)

LED Position Function

Left

Center

Right

hermostat Operation Overview

T

Used to set current day and time.

Used to select event start times.

Used for constant hold.

An external switch on the LED 1 Display enables the filter symbol; see Table 1

(T500HPP-1 only) Indicates when highest stage heat is activated; internally controlled

An external switch on the LED 1 Display enables the wrench symbol; see Table 1

Used to select setpoints.

setpoint

Clock

Set Temp

Program

66

Mo

12:51

LEDs (T500MSP-1, T500HPP-1 only) indicate

system activity or problems. See Table 6.

Outdoor

Mode

AM

Fan

ResumeHold

Used to display outdoor temperature

(optional).

Used to select mode of operation.

Used to run fan continuously.

Used to resume normal operati on.

14

T500 Series Programmable Thermostats Product/Technical Bulletin

Piface1

Figure 19: T500 Pushbuttons

Page 15

Mode

Repeated pressing of the

selection from four modes of operation (five for the

T500HPP-1/Heat Pump model):

•

When the

displayed, the thermostat is in the cooling mode.

When the thermostat is calling for cooling, the

snowflake will flash.

•

When the

displayed, the thermostat is in the heating mode.

When the thermostat is calling for heating, the

flame will flash.

•

When the

are displayed, the thermostat will control using the

emergency heat with the compressor locked out.

(T500HPP-1/Heat Pump only.)

•

When the

and word

automatically change over between heating and

cooling.

Note: The thermostat never allows less than a 1°C

•

When

operate.

Note: Use caution when using the

Snowflake

Flame

Flame

Snowflake

AUTO

(2°F) difference between the heating and

cooling setpoints.

OFF

is displayed, the equipment will not

extremely cold weather.

Mode

button allows

and the word

and the word

and

E Ht

(emergency heat)

and the

are displayed, the thermostat will

COOL

HEAT

are

Flame

OFF

mode in

are

symbols

T500 does not bring on the next stage of cooling or

heating if it knows that the system can change the

temperature by 6 degrees in 1 hour, or 1 degree in

10 minutes. To verify thermostat operation, force the

next stage on by changing the setpoint more than

2 degrees.

an

F

If continuous fan is not selected, the fan will operate

automatically and the fan symbol will be off. To select

continuous fan operation, press the Fan button. The

fan symbol

Smart Fan DIP switch in Table 1.

Clock

will be displayed. (See Figure 20.) See

Outdoor

66

Set Temp

Program

Hold

Mo

4:22

AM

Mode

Fan

Resume

Press to

select

continuous

fan

op erat ion .

Celsius/Fahrenheit

∨∨∨∨

Press the

between Celsius and Fahrenheit display.

uzzy Logic Control

F

Over time, the T500 learns how long it takes the

system to meet the load. If the system can change the

room temperature quickly, the T500 allows the

thermostat to drift further from setpoint before starting

the equipment. If the system takes a longer period of

time to change the room temperature, it will not allow

the temperature to drift as far from setpoint. The T500

also takes into account the minimum On/Off times.

The 2-minute On/Off time allows the equipment to

cycle more frequently at smaller differentials than the

4-minute On/Off time. For multi-stage applications, the

∧∧∧∧

and

buttons simultaneously to alternate

T500 Series Programmable Thermostats Product/Technical Bulletin

Figure 20: Selecting Continuous Fan Operation

Outdoor Button

When an outdoor temperature sensor (order

separately) is connected to the T500 thermostat, you

can display the current outdoor temperature by

pressing the

not connected, the thermostat will display “— —”.

See the

Outdoor

Ordering Information

button. If the sensor option is

section.

15

Page 16

rogramming Overview

P

Thermostat programming is a 3-part process: setting

current time, choosing event setpoints, and setting

event times. Throughout the programming procedure,

the following terms will be used:

Event

= morning, day, evening, night

Event time

Event setpoint

= the time the event starts

= the temperature setpoint of the

event; each event can have only one setpoint for

heating or cooling.

Table 7: Sample 4-Event Program Settings

Event Morning Day Evening Night

Event

Setpoint

Monday

Tuesday

Heat

68°F

Cool

80°F

Heat

72°F

(Time) (Time) (Time) (Time)

6 a.m. 8 a.m. 5 p.m. 11 p.m.

6 a.m. 8 a.m. 5 p.m. 11 p.m.

Program flexibility is achieved by varying the program

start times. When consecutive events are programmed

with the same event time, the thermostat will control

the temperature according to the setpoint of the latest

event.

Table 7 is an example of event times and setpoints for

a given week using a 4-event program. See the

owner’s manual for a blank table.

Note: A 2-event program will only include day

and night events.

Cool

76°F

Heat

66°F

Cool

78°F

Heat

60°F

Cool

85°F

Wednesday

Thursday

Friday

Saturday

Sunday

* Thermostat controls to the day setpoint until noon.

** Thermostat controls to the night setpoint until 6 a.m. Monday morning.

6 a.m. 8 a.m. 5 p.m. 11 p.m.

6 a.m. 8 a.m. 5 p.m. 11 p.m.

6 a.m. 8 a.m. 5 p.m. 11 p.m.

6 a.m.* 6 a.m. 12 p.m. 12 p.m.

12 p.m. 12 p.m. 12 p.m. 12 p.m.**

16

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 17

rogramming the Thermostat

P

Setting the Current Day and Time

To set the current day and time:

1. Press and release the

Clock

button.

The display will flash a day of the week.

2. Press the

∨∨∨∨ or ∧∧∧∧

buttons until the current day

shows.

3. Press

4. Press the

Clock

again. The display will flash the hour.

∨∨∨∨ or ∧∧∧∧

buttons until the current hour

shows. Be sure AM or PM corresponds to the

proper time.

5. Press

Clock

again. The display will flash minutes

(:00). (See Figure 21.)

6. Press the

∨∨∨∨ or ∧∧∧∧

buttons until the current minutes

show.

7. Press

Clock

to complete the procedure or wait

15 seconds to return to normal display.

Setting the Event Setpoints

Setpoints are programmed for both heating and

cooling

four (morning, day, evening, and night) events per day.

(See Table 1.) To program a setpoint:

modes, and either two (day and night) or

6. Select the desired mode of operation: heat, cool,

auto.

7. When programming is complete, press the

Resume

!

button to return to the normal display.

CAUTION:

Equipment Damage Hazard.

Operating a cooling system

without proper limit controls in

very low outdoor air

temperatures can permanently

damage the cooling equipment.

Press to

set days,

hours, and

minutes.

Clock

Set Temp

Program

Mo

66

AM

Outdoor

Mode

Fan

:0 0

Hold

Resume

1. Press the

2. Press the

cool

), event (morning, day, evening, or night)

Mode

button until heat

Set Temp

button. The mode (heat

is displayed.

symbols, and the present setpoint will be

displayed.

3. Press the

∨∨∨∨ or ∧∧∧∧

buttons to adjust setpoints for the

displayed event and mode.

the

Set Temp

∨∨∨∨ or ∧∧∧∧

to move to the next event. Press

buttons to adjust the setpoint. Repeat

4. Press

this step until all event setpoints are programmed.

5. Press

Mode

until cooling

is displayed, and

repeat Steps 2 through 4.

or

Figure 21: Setting the Current Day and Time

Push Button Auto Repeat

Holding the

through the programming menu in sequence to the

desired option.

Program

button down will advance you

T500 Series Programmable Thermostats Product/Technical Bulletin

17

Page 18

Setting the Event Times

To program event times:

1. Press and release the

Program

button. The

morning event symbol and the current day

appear.

2. Press the

∨∨∨∨ or ∧∧∧∧

buttons to select the first single

day or the first day of a block of days to be

programmed.

3. Press and release

Program

. Press the

∨∨∨∨ or ∧∧∧∧

buttons to set the start time hour for the first event.

4. Press and release

Program

. Press the

∨∨∨∨ or ∧∧∧∧

buttons to set the minutes in 10-minute intervals

(i.e., 8:10, 8:20, etc.).

5. Press

Program

to advance to the next event.

6. Repeat Steps 3 through 5 for all remaining events.

After programming the last event, press

Copy

will be displayed.

Program

7. If you do not want to copy the program, press

Program

program, press the

individual days to copy the program to. The

and proceed to Step 9. To copy the

∨∨∨∨ or ∧∧∧∧

buttons to select

Copy

function will only allow program times to be copied

to sequential days (i.e., Tuesday, Wednesday,

Thursday).

8. Press

Program

to copy program settings to the

selected days of the week.

9. Repeat the procedures for

Setting the Event Times

for any remaining unprogrammed days of the

week.

10. When finished, verify that all events are

programmed correctly by repeatedly pressing the

Program

Program

button. When

to skip to the next day.

11. When programming is complete, press

Copy

appears, press

Resume

to

return to normal display.

Clock

Outdoor

66

Set Temp

Press to

Program

set hours,

minutes,

and

events .

Mo

5:00

AM

Figure 22: Setting the Event Times

.

Scheduling 1-, 2-, 3- and 4-Event Days in

the Same Week

If the DIP switch is set for 4-event days, a 2-event day

can be programmed by setting the same event time for

consecutive events. See the example shown in

Table 7.

Making Programming Changes While the

Keyboard is Locked

To make programming changes while the DIP switch is

set to lock the keyboard:

1. Open the thermostat and switch the DIP switch to

unlock the keyboard. (See

Selections.

) Close the thermostat.

2. Make necessary program changes.

3. Open the thermostat and switch the DIP switch to

lock the keyboard again. Close the thermostat.

Table 1: DIP Switch

Mode

Fan

ResumeHold

Note: See Table 7 for an example of programming

for a given week.

18

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 19

O

verride

Constant Hold

To maintain a constant temperature setting:

1. Press the

Mode

button until the desired mode is

displayed (heating, cooling, auto).

∨∨∨∨

2. Press the

∧∧∧∧

or

buttons to set the desired

setpoint(s).

Note: If the Auto mode is used, press

and press the

cooling setpoint. Press

∨∨∨∨ or ∧∧∧∧

buttons to select a heating setpoint.

Mode

Press

∨∨∨∨ or ∧∧∧∧

buttons to select a

Mode

again to set the mode back to

Mode

again, and the

Auto.

3. Press the

Hold

button. Setpoint(s) will be

maintained continuously.

4. Pressing and releasing the

cancel the

Hold

and return to programmed

Resume

button will

setpoints.

Clock

Outdoor

66

Set Temp

Mode

twice,

Temporary (3 Hour) (Keyboard

Unlocked)

To implement a temporary change from the current

event setpoint for a 3-hour period:

1. Press the

∨∨∨∨ or ∧∧∧∧

buttons to change the scheduled

setpoint ± 3°C or ± 6°F. The current mode of

operation will appear on the display and an

hourglass symbol

will appear. The temporary

setpoint will be maintained for 3 hours.

Note: If the Auto mode is used, press

press the

setpoint. Press

∨∨∨∨ or ∧∧∧∧

buttons to select a heating

Mode

again, and the

Mode

, and

∨∨∨∨

or

∧∧∧∧

buttons to select a cooling setpoint.

2. Pressing and releasing the

Resume

button will

cancel the override and return to the programmed

setpoint at any time during the 3 hours.

Note: If the setpoint is altered while in the night

mode, the thermostat will change to the day

mode setting.

Temporary (1 Hour) (Keyboard Locked)

To implement a temporary change from the current

event setpoint for a 1-hour period:

Program

Mo

AM

Fan

HOLD

ResumeHold

Press for

constant

hold.

Figure 23: Constant Override (Hold)

Progressive Recovery

During the night mode the thermostat is designed to

anticipate a programmed setpoint change. With

Progressive Recovery, the desired temperature will be

attained at the programmed time instead of beginning

the temperature cycle change. Recovery option is

selected by pressing the

simultaneously.

Program

and

Fan

buttons

1. Press the

∨∨∨∨ or ∧∧∧∧

buttons to change the scheduled

setpoint. The current mode of operation will appear

on the display and an hourglass symbol

appear. The temporary setpoint will be maintained

for 1 hour.

Note: If the Auto mode is used, press

press the

setpoint. Press

∨∨∨∨ or ∧∧∧∧

buttons to select a heating

Mode

again, and the

Mode

buttons to select a cooling setpoint.

2. Pressing and releasing the

Resume

button will

cancel the override and return to the programmed

setpoint at any time during the 1 hour.

will

, and

∨∨∨∨ or ∧∧∧∧

T500 Series Programmable Thermostats Product/Technical Bulletin

19

Page 20

etting Electronic Outdoor High and

S

Low Temperature Balance Points

(T500HPP-1 only)

The optional outdoor temperature sensor (order

separately) can be installed to allow the selection of

outdoor balance points that will lock out auxiliary heat

or cooling, depending on the outdoor temperature.

The factory-set HibP (auxiliary heat) and LobP

(compressors) setpoints are 48°C (118.4°F), and

-48°C (-54.4°F) respectively. The HibP and/or LobP will

be shown on lower LCD.

The HibP is the temperature above which the auxiliary

heat is locked out. The LobP is the temperature below

which the compressors are locked out.

12:00 AM will flash and the thermostat will control to

the night event setpoint until the clock is reset.

Note: If the power fails when the thermostat is in the

continuous HOLD mode, the thermostat will

continue controlling to the HOLD temperature

when power is restored. When the user

presses the

flash 12:00 AM and will remain in the night

event setpoint until the clock is reset.

erification

V

To verify proper functioning of the thermostat:

1. Press the

mode. (See Figure 24.)

Resume

Mode

button to select the heat or cool

button, the clock will

To set the balance points:

1. Press and hold the

Mode

the

2. Raise or lower the HibP (high balance point) by

pressing the

3. Set the LobP (low balance point) by pressing and

holding the

the display.

4. Raise or lower the LobP by pressing the

buttons to set the auxiliary heat setpoint.

5. Press

ptions

O

button.

Outdoor button. LobP

Resume

Outdoor

HibP

∨∨∨∨ or ∧∧∧∧

buttons.

to return to the normal display.

button while pressing

will appear on the display.

will appear on

∨∨∨∨ or ∧∧∧∧

Remote Sensor

The indoor remote sensor allows the T500 to be

mounted away from the controlled space, and allows

use of multiple sensors for temperature averaging.

Order separately. See

Table 10: Optional Accessories.

Clock

∨∨∨∨ or ∧∧∧∧

buttons to raise the setpoint

section.

Outdoor

2. Press the

above or below the current ambient temperature.

The thermostat should call for either heating or

cooling.

If the equipment does not come on, proceed to the

Troubleshooting

66

Set Temp

Program

Mo

AM

Mode

Fan

Press to

select mode

(heat or cool) .

5:00

ResumeHold

Figure 24: Verifying Proper Operation

Outdoor Sensor

Order separately. See

ower Failures

P

If power fails, AC will be displayed for 2 hours. After

2 hours, the display will go blank.

If power is restored in the first 2 hours, the internal

clock will be current and the thermostat will resume

normal operation. If power is restored after 2 hours,

20

T500 Series Programmable Thermostats Product/Technical Bulletin

Table 10: Optional Accessories.

Sensor Calibration (Fan/10 Seconds)

The internal and remote sensors can be calibrated to

eliminate wire resistance errors or to match another

reference.

1. Press and hold the

2. Adjust the temperature with the

The temperature is shown on the lower display to

the hundredths place. For example, 72°F on the

large display is shown as 72 13.

Fan

button for 10 seconds.

∨∨∨∨ or ∧∧∧∧

buttons.

Page 21

roubleshooting

T

Table 8: Troubleshooting

Symptom Possible Cause Corrective Action

No display/faint display ...

Keyboard inoperative ...

Thermostat will not call for

heat ...

Thermostat will not call for

cooling ...

Fan does not turn on ...

AC appears on the LCD ...

LCD shows missing or

extra segments ...

Supply voltage incorrect Use a voltmeter to check the voltage between the 24V and

24V(c) terminals. Voltage should be between 20-30 VAC.

If voltage is less than 20 VAC, disconnect the thermostat

and check the voltage between 24V and the other system

wires; see possible causes below. If voltage is greater than

30 VAC, troubleshoot the power source and replace the

thermostat.

System transformer weak or

overloaded

Thermostat damaged

because system voltage

was greater than 30 VAC

Keyboard locked Switch the keyboard DIP switch to the unlocked position.

Compressor delay still in

progress

Thermostat setpoint is

satisfied

Compressor delay still in

progress

Thermostat setpoint is

satisfied

Fan failure Place a jumper between terminals R and G. Fan should

20-30 VAC is absent from

24V and 24V(c)

LCD failure Replace the unit.

Check and/or replace with a suitable 24V transformer.

Replace with new thermostat and ensure new thermostat is

isolated from the system using suitable relays and a

transformer of the proper rating.

Wait - equipment short cycle protection in progress.

Raise the heating setpoint using the

Wait - equipment short cycle protection in progress.

Lower the cooling setpoint using the

come on. If it does not, troubleshoot the fan system. If fan

does come on, replace the thermostat.

Using a voltmeter, measure voltage between the 24V and

24V(c) terminals. If the reading is less than 20 VAC, check

system transformer. If the voltage is between 20-30 VAC,

replace the thermostat.

button.

∧∧∧∧

button.

∨∨∨∨

T500 Series Programmable Thermostats Product/Technical Bulletin

21

Page 22

rdering information

O

Table 9: Ordering Information

Item Product Code Number

Programmable Thermostat, Single-stage, 1 Heat, 1 Cool

Programmable Thermostat, Multi-stage, 2 Heat, 2 Cool

Programmable Thermostat, Heat Pump, 3 Heat, 2 Cool

Programmable Thermostat, Heat Pump, 1 Heat, 1 Cool

ccessories

A

T500HCP-1

T500MSP-1

T500HPP-1

T500HPP-2

Table 10: Optional Accessories (includes mounting hardware)

Item Product Code Number

Remote Indoor Temperature Sensor

Outdoor Air Temperature Communication Module with Outdoor Air Sensor

Outdoor Air Temperature Communication Module with Duct Mount Sensor

Conversion Module

Thermostat Wall Plate

eplacement and Repair Parts

R

SEN-500-1

SEN-500-2

SEN-500-3

ACC-500-1

ACC-500-2

The SEN-500 series of products allows for easy

replacement of the sensor. For a replacement sensor,

contact the nearest Johnson Controls branch office or

wholesale distributor and order using the information

Table 10: Optional Accessories, Table 11:

from

Replacement Parts,

Table 12: Repair Parts

and

.

Table 11: Replacement Parts

Item Product Code Number

Replacement Outdoor Air Temperature Communication Module

Replacement Outdoor Air Temperature Sensor (including mounting hardware)

Replacement Duct Mount Temperature Sensor (including mounting hardware)

SEN-500-603

SEN-500-604

SEN-500-605

Table 12: Repair Parts

Item Product Code Number

3 in. Sensor Probe (use with outdoor air sensor)

8 in. Sensor Probe (use with duct mount sensor)

SEN-500-601

SEN-500-602

22

T500 Series Programmable Thermostats Product/Technical Bulletin

Page 23

pecifications

S

Product

Power Requirements

Relay Contact Rating

Recommended Wire Size

Occupied/Unoccupied

Relay Contacts

(T500HPP-1 and

T500MSP-1 only)

Thermostat Measurement

Range

Outdoor Air Temperature

Indication Range

Control Range

Display Resolution

Minimum Deadband

F Conversion

°°°°C/°°°°

Ambient Operating

Conditions

Continued on next page . . .

T500HCP-1, T500MSP-1, T500HPP-1, T500HPP-2

20-30 VAC, 50/60 Hz, 24 VAC nominal

Maximum Inductive: 1 ampere with surges to 3 amperes, 24 VAC Class 2

Maximum Resistive: 1 ampere, 24 VDC (2000 VA Maximum for all outputs)

Minimum: 10 uA for 24 VAC circuit; 10 mA for 24 VDC circuit

18 gauge

Single-Pole/Double-Throw; The normally open contact is closed in the night event or if the

thermostat loses power. The normally closed contact is closed in all other events.

0 to 48°C (28 to 124°F)

-48 to 48°C (-50 to 124°F)

Heating: 5 to 30°C in 1° steps; 38 to 88°F in 1° steps

Cooling: 16 to 40

1C or 1F

(Between heating and cooling) 1°C

20°C = 68°F, each Celsius degree above or below 20°C = 2°F

0 to 55°C (32 to 131°F); 5 to 90% RH non-condensing

C in 1° steps; 60 to 108°F in 1° steps

°

2°F

or

T500 Series Programmable Thermostats Product/Technical Bulletin

23

Page 24

pecifications (Cont.)

S

Ambient Storage

Temperatures

Dimensions (H x W x D)

Shipping Weight

FCC Compliance

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication

or misuse of its products.

This device complies with Class A Part 15 of the FCC rules. It was also verified to Class B. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired operation.

This Class A digital apparatus meets all of the requirements of the Canadian Interference-Causing Equipment Regulations. Cet appareil

numerique de la Classe A respecte toutes les exigences du Reglement sur le materiel brouilleur du Canada.

-34 to 55°C (-30 to 131°F)

114.3 x 101.6 x 22.2 mm (4 1/2 x 4 x 7/8 in.) (T500HCP-1, T500HPP-2)

114.3 x 127 x 22.2 mm (4 1/2 x 5 x 7/8 in.) (T500HPP-1, T500MSP-1)

0.171 kg (0.37 lb) (T500HCP-1, T500HPP-2)

0.204 kg (0.45 lb) (T500HPP-1, T500MSP-1)

This equipment has been tested and found to comply with the limits for a Class A digital

device and verified to Class B pursuant to Part 15 of FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when this equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own expense.

Controls Group

507 E. Michigan Street

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201 www.johnsoncontrols.com

24

T500 Series Programmable Thermostats Product/Technical Bulletin

Loading...

Loading...