Page 1

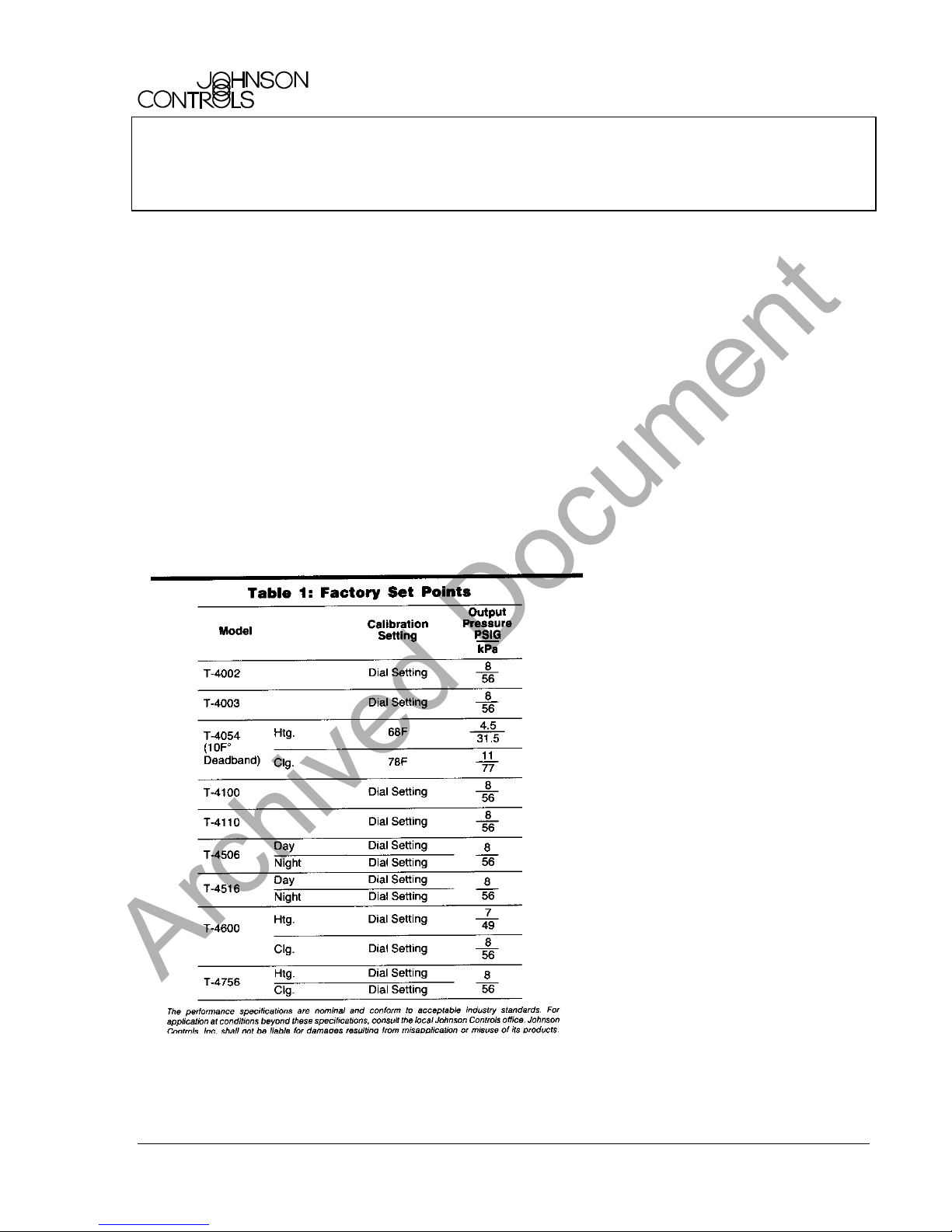

Pneumatic Control Manual 717.1

Archived Document

Room Devices Section

T-4000 Series Room Thermostat

Adjusting Instructions*

Technical Bulletin T-4000

Issue Date 0984

The T-4000 Series Pneumatic

Room Thermostats are factory

calibrated to the values specified

in Table 1. If these settings are

suitable to the application, no

adjustments need to be made. If

different settings are required,

turn the set point dial to the

desired value.

If the room temperature is out of

control, determine the cause of

the problem. Possible causes

not involving the thermostat are

listed below.

1. Check for proper operation

of the controlled device.

*

This bulletin provides adequate instructions for making basic adjustments to

T-4000 series room thermostats. For more detailed information, contact the local

branch office.

2. Check to see if the controlled

medium (water, for example)

is hot or cold enough to

maintain the desired

temperature.

3. Check for unusual or

extreme loads in the space

which may overcome the

efforts of the thermostat to

maintain control.

If it is determined that the

thermostat is out of adjustment,

follow the appropriate instructions

to recalibrate the instrument.

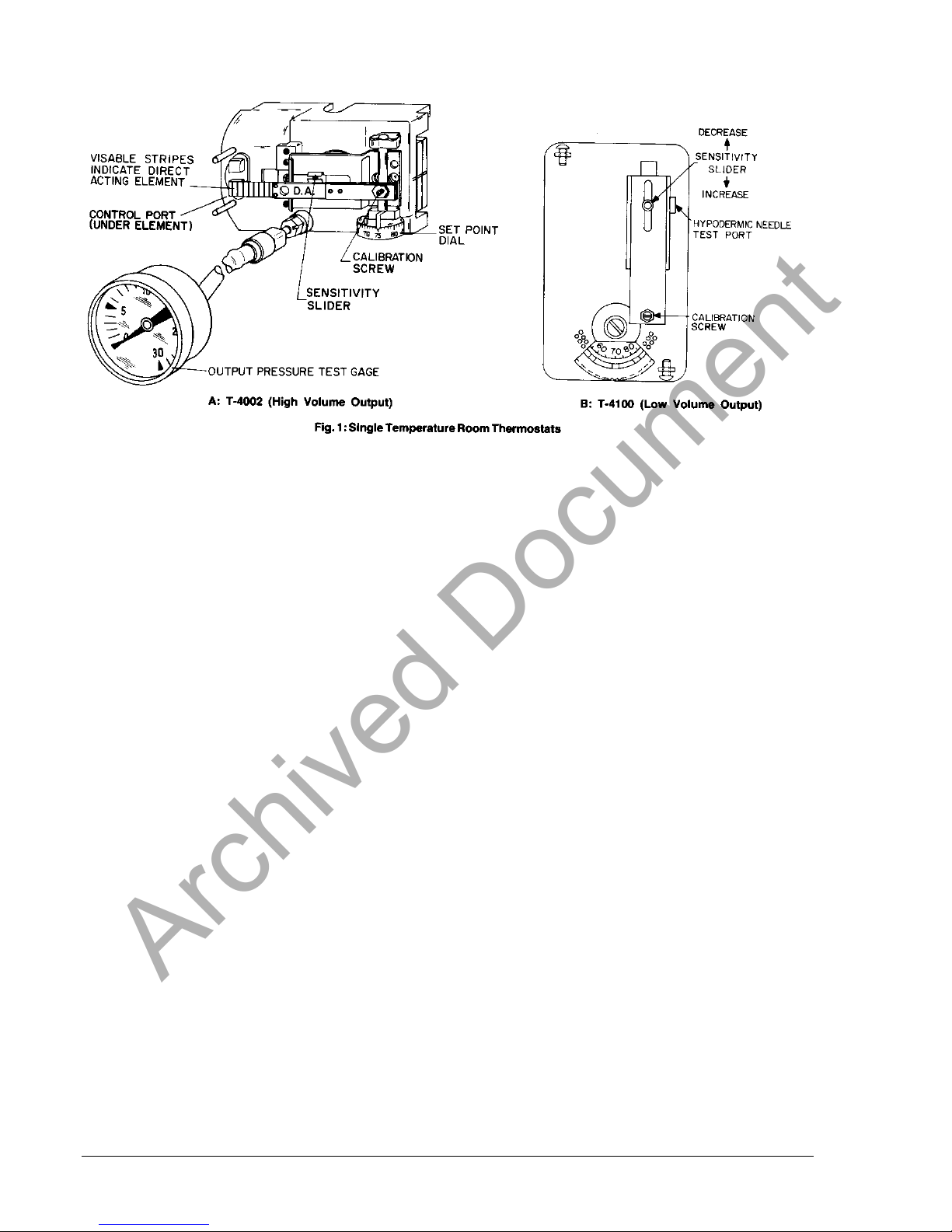

Sensitivity Adjustment

(See Fig. 1)

All T-4000 series thermostats

have an integral output pressure

test port. The newer high volume

output thermostats have a plug-in

test port fitting which accepts a

hypodermic needle test probe

and gage (X-200-140 and G2010-11). On older models, the

test port cap screw must be

removed to accept a screw-in

test gage (X-200-19). For these

units, a test port fitting (T-4000-

615) can be ordered. All low

volume output thermostats have

hypodermic needle test points.

For units that require a screw-in

gage, remember to replace the

test port cap screw after

adjustment.

The sensitivity of the T-4000

series instruments is factory set

at 2.5 PSI/F° (32 kPa/C°). It is

adjustable from 1 to 3 PSI/F

(13 to 38 kPa/C°) for low volume

output thermostats and from .

75 to 4 PSI/F° (10 to 51 kPa/C°)

for high volume output

thermostats. (Sensitivity of the T4003 is fixed at 2.5 PSI/F°).

1. Furnish the appropriate

supply pressure to the

instrument.

2. Insert the appropriate gage.

3. Note the output pressure.

Note:

The output pressure

for T-4054 thermostats must

be within one of the two

control ranges (not within the

deadband range).

4. For high volume output

thermostats, move the

sensitivity slider toward the

control port to increase or

away from the control port to

decrease the sensitivity. For

low volume output

thermostats, move the

sensitivity slider down to

°

© 1984 Johnson Controls, Inc.

Code No. LIT-7171089X

1

Page 2

increase or up to decrease

Archived Document

the sensitivity.

5. Check the output pressure.

If it is different from the value

found in step 3, turn the

sensitivity slider adjusting

screw until the output

pressure equals that value.

For low volume output

(plastic body) instruments,

use the output adjusting

screw to adjust the output

pressure.

6. Check the sensitivity.

Change the control setting

on the dial by at least 5F°

and note the new output

pressure. The change in

output pressure divided by

the change in dial setting is

the actual sensitivity.

7. Repeat steps 4 through 6

until the desired sensitivity is

obtained.

T-4003 Range of Remote

Readjustment

The range of remote

readjustment is adjustable from

.15 to 2.5 F°/PSI (.012 to

.2C°/kPa) and is factory set at

0.5 F°/PSI (.04 C°/kPa). To

determine if the range of remote

readjustment needs to be

adjusted, proceed as follows:

1. Insert the test gage into the

test port fitting and note the

output pressure.

2. Set the master pressure to

4 psig (28 kPa).

3. Turn the set point dial to 80F

and turn the calibration

screw to obtain a 3 psig

(21 kPa) output pressure.

4. Set the master pressure to

14 psig (98 kPa).

5. Turn the set point dial until

the output pressure returns

to 3 psig.

6. The change in dial setting

divided by the 10 psig

(70 kPa) change in master

pressure (14 psig - 4 psig =

10 psig) is the actual range

of readjustment. If this is not

the desired range, move the

range of readjustment slider

(sensitivity slider in Fig. 1a)

toward the control port to

decrease or away from the

control port to increase the

range of readjustment.

Readjust the slider screw to

the pressure noted in step 1

above. Repeat steps 2

through 6 until the desired

range is obtained.

Set Point Adjustment

Before calibrating the instrument,

check to see if the output

pressure is already at an

appropriate value according to

the ambient temperature. For

example, if the actual room

temperature is below the set

point and the output signal is

calling for more heat, the

thermostat is doing its job and

does not require adjustment.

T-4002 and T-4100 (See Fig. 1)

1. Insert the test gage.

2. Furnish supply air to the

instrument (restricted supply

for T-4100).

3. Note the ambient

temperature in the space.

4. Turn the set point dial to that

temperature.

5. Turn the calibration screw

until the output pressure is at

the mid spring range of the

controlled device.

6. Turn the set point dial to the

desired set point.

T-4003 Set Point Adjustment

Insert the gage and set the

master pressure to one half of

the supply pressure. Follow

steps 3 through 6 under T-4002

Set Point Adjustment.

2 T-4000 Technical Bulletin

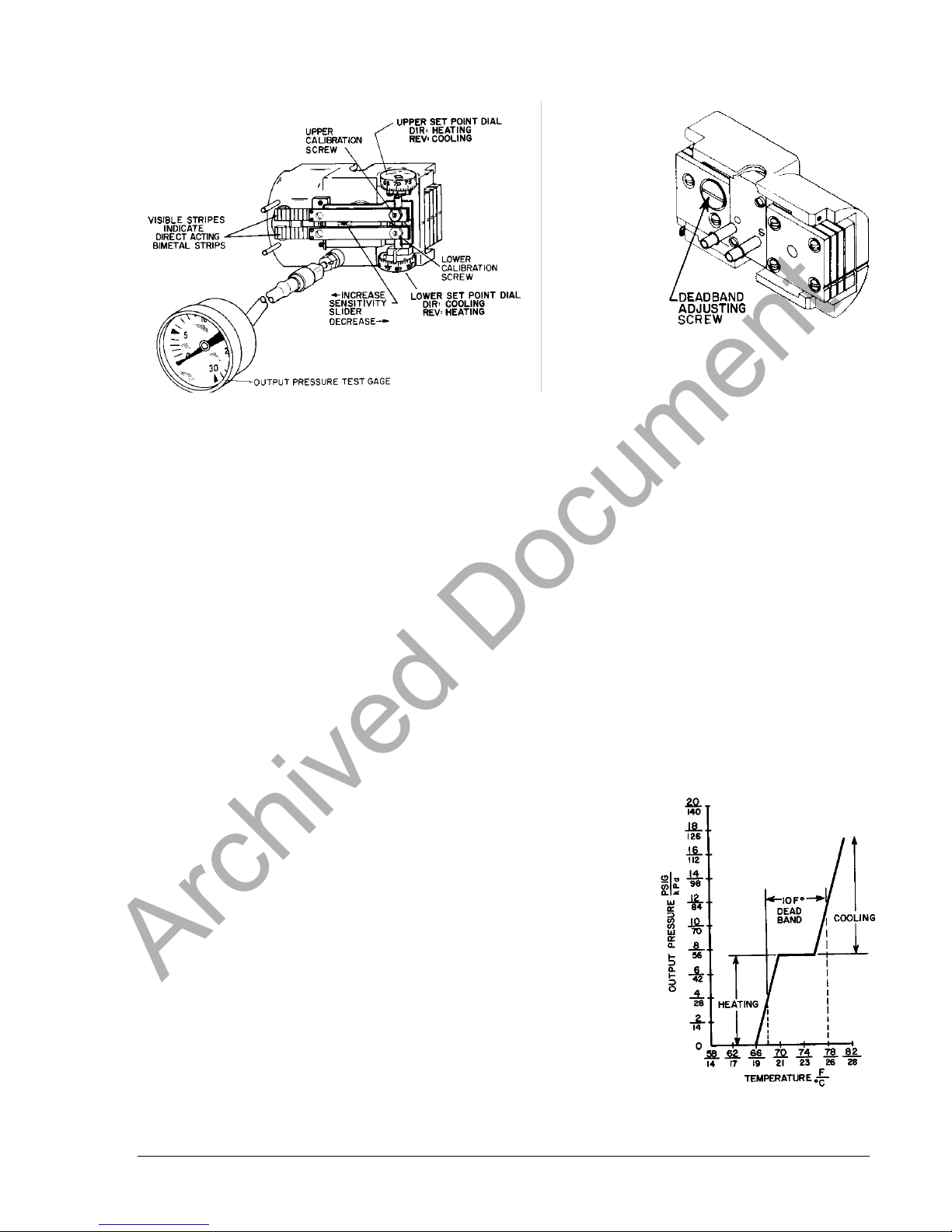

Page 3

Fig. 2: T-4054 Adjustments

Archived Document

Fig. 3: Back View of T-4054

T-4054 Deadband and Set

Point Adjustment

(See Fig. 2)

The T-4054 can easily be

adjusted to suit the application by

changing the settings on the

heating and cooling dials. If the

thermostat has been tampered

with or is out of adjustment,

proceed with the following

instructions to recalibrate the

instrument.

Note: On deadband applications

which have overlapping spring

ranges, it is suggested that a

C-9200 or other sequencing

device be used to bias the

cooling valve spring range to

compensate for spring range

shift.

Deadband Setting

If it is necessary to check or reset

the deadband setting, proceed as

follows:

Turn the lower set point dial to 85F

on direct acting models or 55F on

reverse acting models. Turn the

upper set point dial to 55F on direct

acting models or 85F on reverse

acting models. Insert a hypodermic

needle test probe into the test

connection. The reading on the test

gage is the actual deadband

pressure.

If it is necessary to adjust this

pressure to meet application

requirements, proceed as follows:

1. Remove the T-4054 from the

mounting bracket and pull it

away from the wall so the

deadband adjusting screw

on the back of the instrument

is exposed (see Fig. 3).

2. Turn the screw clockwise to

increase or counterclockwise to decrease the

deadband pressure until the

gage reads the desired

pressure. Approximately

one half turn will produce a

1 PSI (7 kPa) change in

deadband pressure.

3. Return the set point dials to

the original settings.

Set Point Calibration

(See Fig. 2)

1. Set the lower set point dial to

85F for direct or 55F for

reverse acting models.

2. Note the ambient

temperature at the element.

3. Set the upper dial to this

temperature (direct acting

model: heating, reverse

acting model: cooling).

4. Turn the upper calibration

screw until the control

pressure is in the middle of

the spring range of the

controlled device (heating).

5. Set the lower dial to the

temperature noted in step 2

(direct acting model:

cooling, reverse model:

heating).

6. Turn the lower calibration

screw until the control

pressure is in the middle of

the spring range of the

controlled device (cooling).

7. Turn the upper dial to the

desired set point.

T-4054 Operational Graph

T-4000 Technical Bulletin 3

Page 4

8. Turn the lower dial to the

Archived Document

desired set point.

9. The difference in the dial

settings is now the

deadband. Remove the

test gage.

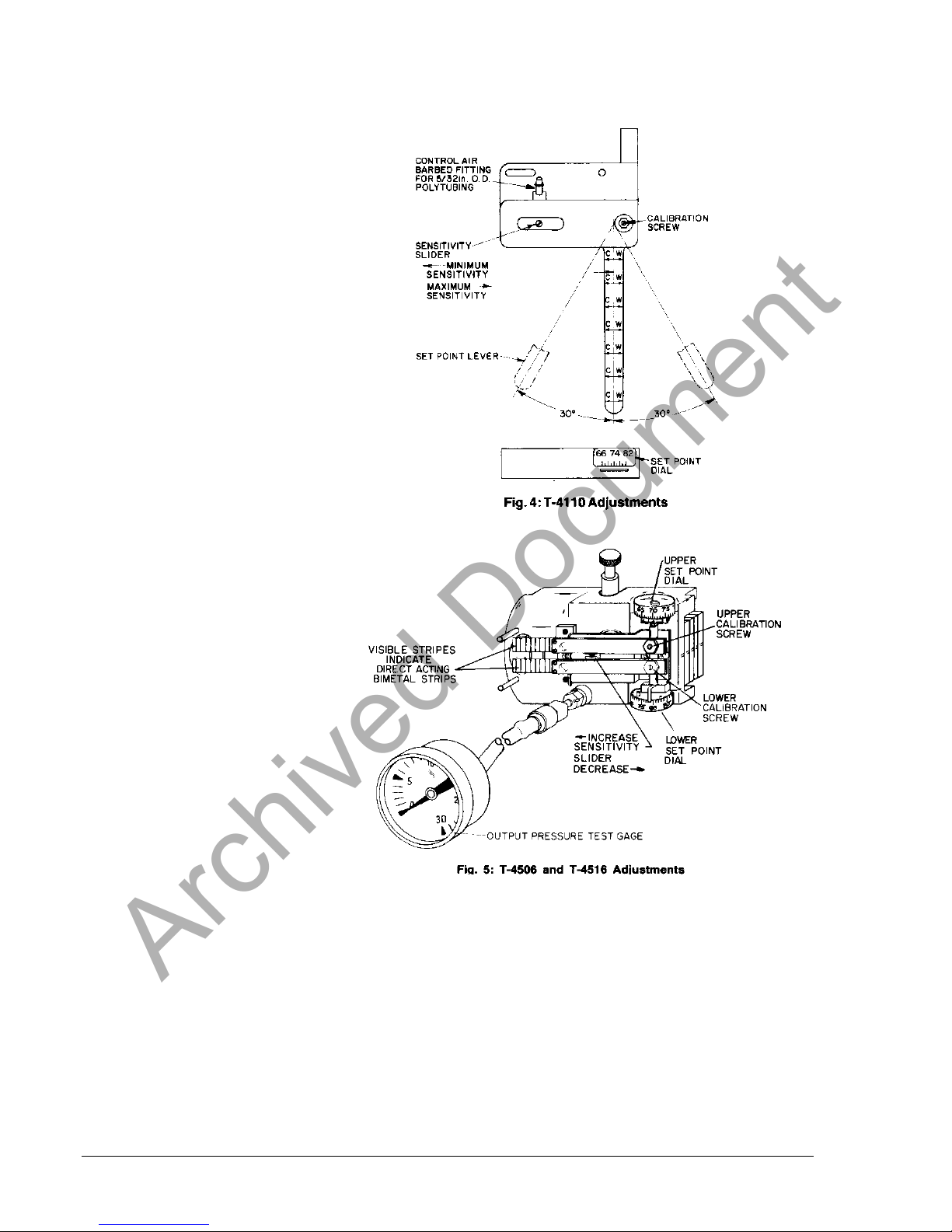

T-4110 Set Point

Adjustment (See Fig. 4)

1. Tee the test gage into the

output line.

2. Furnish restricted supply air

to the instrument.

3. Note the ambient

temperature in the space.

4. Move the set point lever to

that temperature.

5. Turn the calibration screw

until the output pressure is at

the mid spring range of the

controlled device.

6. Move the set point lever to

the desired set point.

T-4506 and T-4516

Set Point Adjustment

Usually the day set point is made

on the lower element with a

15 psig (105 kPa) supply

pressure and the night set point

is made on the upper element

with a 20 psig (140 kPa) supply

pressure. If your application is

different, use the proper element

and supply pressure for the

particular application. The

T-4506 is furnished with DAY and

NIGHT labels which can be

applied to the appropriate

element.

Day Set Point Adjustment

(See Fig. 5)

1. Insert the test gage.

2. Furnish 15 psig supply

pressure for day control

(lower dial).

3. Note the ambient

temperature in the space.

4. Turn the lower set point dial

to that temperature.

5. Turn the lower calibration

screw until the output

pressure is at the mid spring

range of the controlled

device.

4 T-4000 Technical Bulletin

6. Turn the lower set point dial

to the desired day set point.

Night Set Point Adjustment

1. Furnish 20 psig supply

pressure for night control

(upper dial).

2. Note the ambient

temperature in the space.

3. Turn the upper set point dial

to that temperature.

4. Turn the upper calibration

screw until the output

pressure is at the mid spring

range of the controlled

device.

5. Turn the upper set point

dial to the desired night set

point.

6. Restore the supply pressure

to the desired cycle.

Page 5

T-4600 Set Point

Archived Document

Adjustment

The T-4600 is furnished with

HEATING and COOLING labels.

Apply each label to the

appropriate element to avoid

error in calibration or hook up.

Heating Set Point Adjustment

(See Fig. 6)

1. Insert the test gage.

2. Furnish restricted supply air

to the instrument.

3. Note the ambient

temperature in the space.

4. Turn the heating set point

dial to that temperature

(match it with the arrow).

T-4756 Set Point

Adjustment

Usually the heating set point is

made on the lower element with

a 15 psig (105 kPa) supply

pressure and the cooling set

point is made on the upper

element with a 20 psig (140 kPa)

supply pressure. If your

application is different, use the

proper element and supply

pressure for the particular

application. The T-4756 is

furnished with HEATING and

COOLING labels which can be

applied to the appropriate

element.

Heating Set Point Adjustment

(See Fig. 7)

1. Insert the test gage.

2. Furnish 15 psig supply

pressure for heating control

(lower dial).

3. Note the ambient

temperature in the space.

4. Turn the lower set point dial

to that temperature.

5. Turn the lower calibration

screw on the heating

element until the output

pressure is at the mid spring

range of the controlled

device.

6. Turn the lower set point dial

to the desired heating set

point.

5. Turn the calibration screw on

that element until the output

pressure to the heating

apparatus is at the mid

spring range of the

controlled device.

6. Turn the heating set point

dial to the desired set point.

Cooling Set Point Adjustment

Repeat the procedure for heating

adjustment on the other element.

Remember to use the other test

port and the proper value in step

5 for the mid spring range of the

controlled device.

Fig. 7: T-4756 Adjustments

Cooling Set Point Adjustment

1. Insert the test gage.

2. Furnish 20 psig supply

pressure for cooling control

(upper dial).

3. Note the ambient

temperature in the space.

4. Turn the upper set point dial

to that temperature.

5. Turn the upper calibration

screw on the cooling

element until the pressure is

at the mid spring range of

the controlled spring range

of the controlled device.

6. Turn the upper set point dial

to the desired temperature.

7. Restore the supply pressure

for the desired cycle.

T-4000 Technical Bulletin 5

Page 6

Switchover Point

Archived Document

Adjustment for T-4506,

T-4516, and T-4756

The above thermostats are

factory set to switch from one

element to the other at 17 psig

for a typical 15-20 psig supply

system. If a different supply

system is to be used, proceed

with the following instructions to

reset the switchover point to a

value between the two supply

pressures. The switch point is

adjustable from 15 to 20 psig

(105 to 140 kPa).

1. Remove the controller from

the mounting bracket.

2. Connect a variable pressure

source to the supply

connection and attach a

gage to the output

connection.

3. Set the supply pressure to

15 psig and rotate the

lower dial to produce

approximately 5 psig

(35 kPa) on the output gage.

4. Increase the supply pressure

to 20 psig and rotate the

upper dial to produce

approximately 15 psig on the

output gage.

5. Set the supply pressure to

the desired switchover point.

6. Slowly turn the switchover

adjusting screw (see Fig. 8)

clockwise to increase or

counterclockwise to

decrease the switch point

until the output changes.

Note: Do not turn the

switchover adjusting

screw more that 3-1/2

complete revolutions in

either direction.

7. Recheck the switchover

point by increasing and

decreasing the supply

pressure over the switch

point to see that switchover

occurs at the desired value.

8. Remove the gage and tubing

and replace the instrument

on the mounting bracket.

6 T-4000 Technical Bulletin

Page 7

Notes

Archived Document

T-4000 Technical Bulletin 7

Page 8

Notes

Archived Document

Controls Group

507 E. Michigan Street

P.O. Box 423

Milwaukee, WI 53202 Printed in U.S.A.

8 T-4000 Technical Bulletin

Loading...

Loading...