Page 1

14-1104-0, Rev.

A

T-3100, T-3200, and T-3300 Series Controllers

The T-3100 and T-3300 Series proportional action

pneum

temperature in accordance with the return air

temperature in terminal air conditioning units. The

T-3200 Series of pneumatic thermostats are designed

to control pneumatic actuators in single temperature,

dual pressure applications.

The T-3111 and T-3311 Series controllers are

combination pneumatic thermostats and valve

actuators. The T-3111 provides proportional control of

a steam or water valve on a single temperature

application, while the T-3311 provides control in

dual temperature, dual pressure applications.

atic thermostats are designed to maintain

Product/T

echnical Bulletin

Issue Date March 2016

WARM

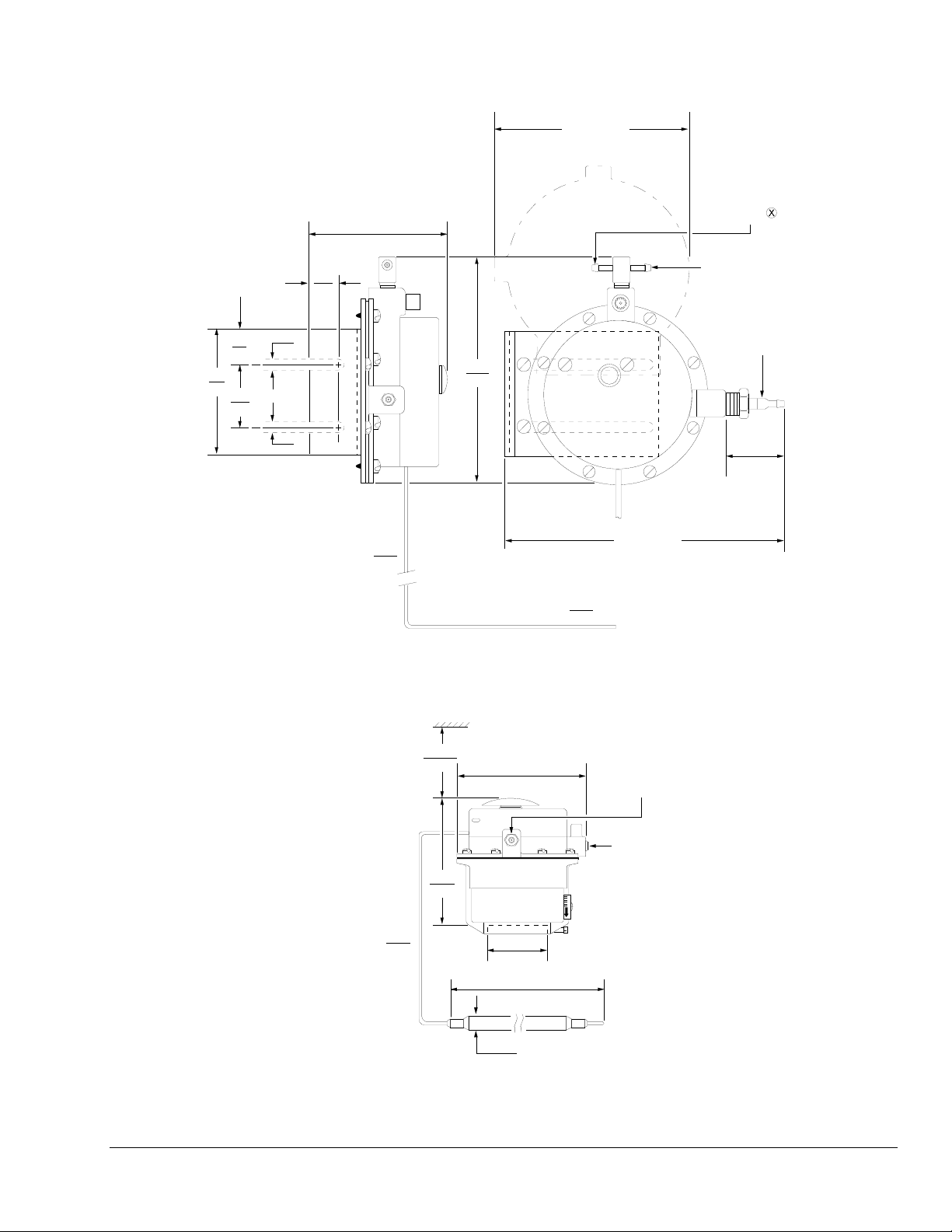

Figure 1: T-3100 Remote Mounted Thermostat and

T-3311 Valv

e Top Thermostat

Models are Available in

Direct or Reverse Acting

Models Available with an

Valve Top Models

2016 Johnson Controls, Inc.

©

Part No. 14-1104-0, Rev. A

Code No. LIT-7171156

Features and Benefits

Direct-reverse Acting or

Reverse-direct Acting

Models Av

ailable wi

Filled Temperature

Measuring Elements

External or Concealed

Setpoint Adjusting Screw

Compatible with

VG7000 Series Valves

th Liquid

Allows seasonal change over from cooling to

heating or heating to cooling automatically

Suits heating or cooling applications

Field adjust

able or concealed to maintain system

design as commissioned

The T-3111 and T-3311 are direct replacements

for the T-3110 and T-3310 Series Valve Top

Actuators

1

Page 2

rdering Information

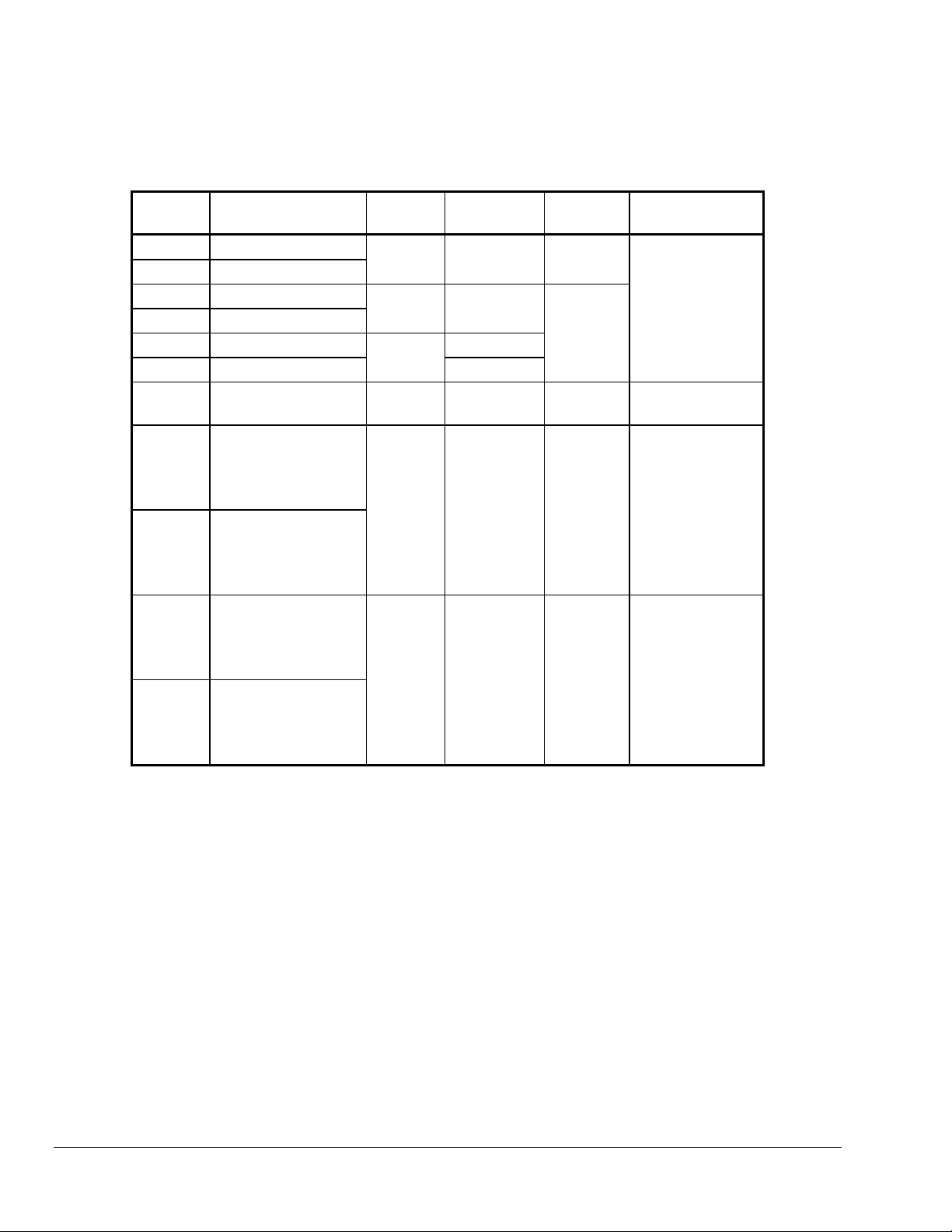

O

Table 1: Ordering Information

Code

Number

T-3100-2

T-3100-3

T-3111-1

T-3111-2

T-3111-3

T-3111-6

T-3200-1

T-3300-1

T-3300-2

T-3311-1

T-3311-2

Direct Acting

Reverse Acting

Direct Acting

Reverse Acting

Direct Acting

Direct Acting Concealed

DIR at 15 and 20 psig

(103/138 kPa)

DIR at 15 psig

(103 kPa)

REV at 20 psig

(138 kPa)

DIR at 20 psig

(138 kPa)

REV at 15 psig

(103 kPa)

DIR at 15 psig

(103 kPa)

REV at 20 psig

(138 kPa)

DIR at 20 psig

(138 kPa)

REV at 15 psig

(103 kPa)

Action

(Proportional)

Element

Bulb External Remote Single Temperature

Bulb External

Averaging External Valve Top Single Pressure

Averaging Concealed Remote

Bulb External Remote

Bulb External Valve Top Dual Temperature

Setpoint

Adjustment

Mounting Application

Single Temperature

Dual Pressure

Dual Temperature

Dual Pressure

Dual Pressure

2 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Page 3

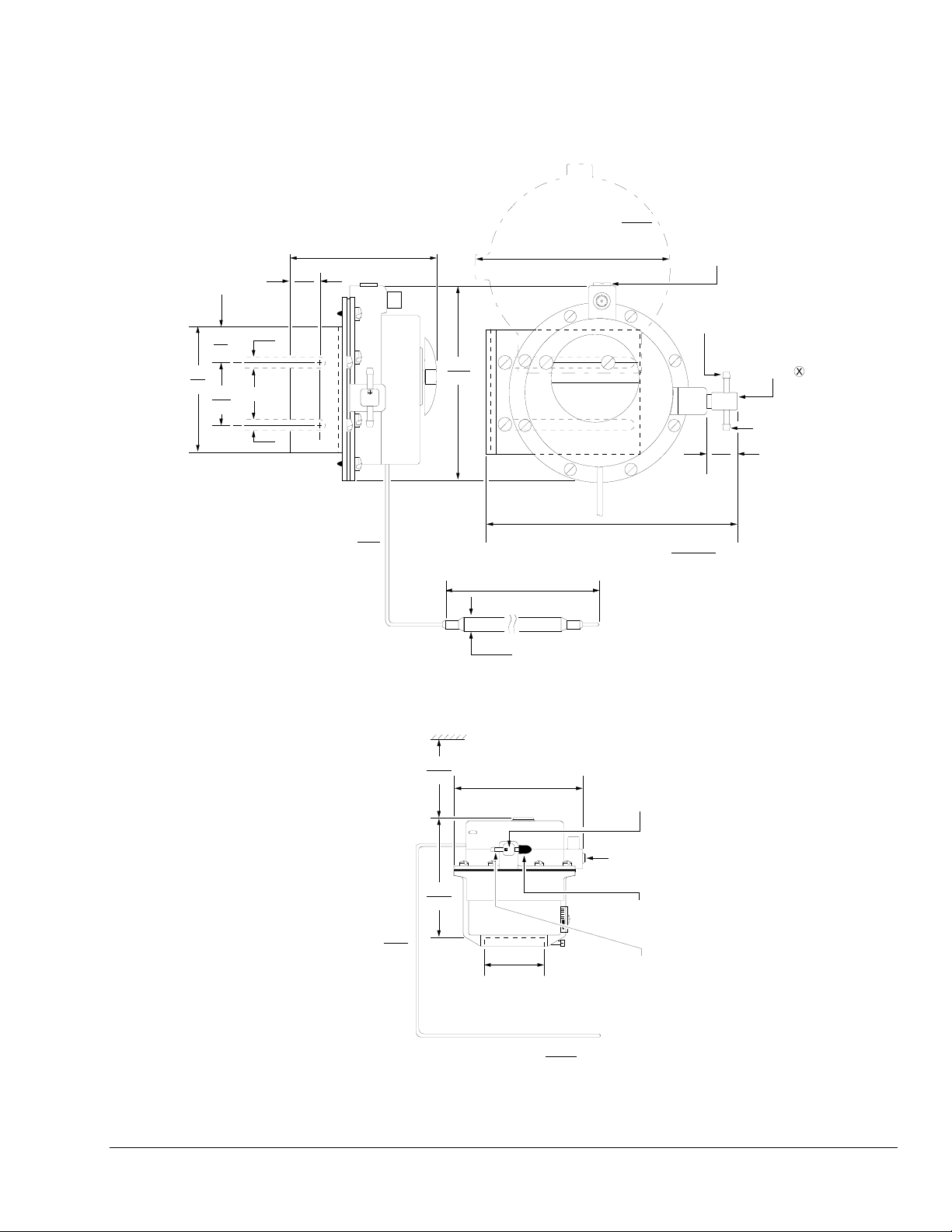

imensions

D

76

3

3/4

19

1-1/2

38

5/8

16

1/4

6

1/4

6

Capillary Length

3-3/8

86

42

1067

4-3/4

121

Extends to maximum

4-3/4

121

Extends to maximum

6-9/16

167

5/16

Diameter

8

5-1/8

130

5-11/16

144

Subordinate

Connection 1/8 inch

NPT, Internal Thread

Supply Air to

Restrictor

Branch

Restrictor

Branch

Marked

Control Air

3/4

19

8-11/16

220

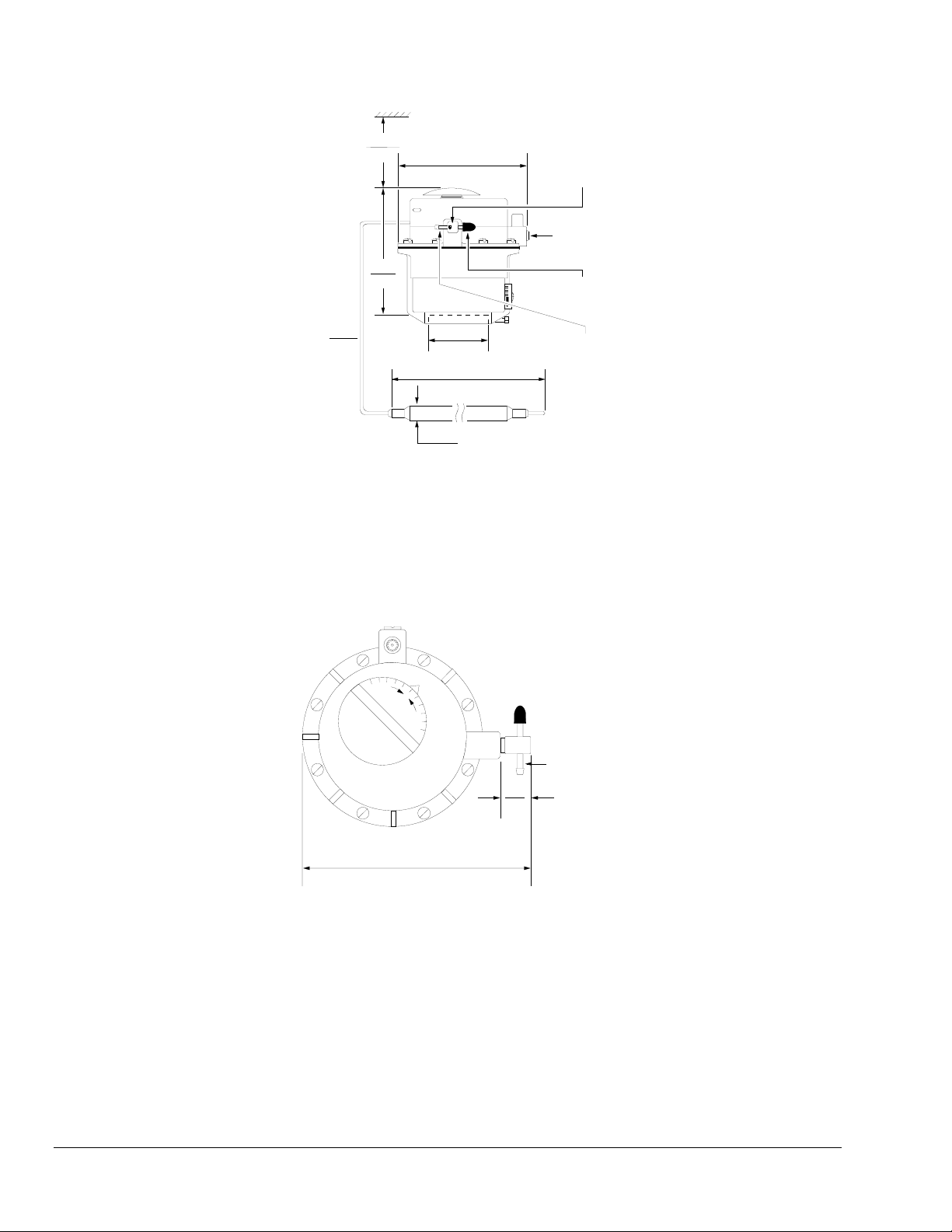

Figure 2: Dimensions and Mounting Details for T-3100, in./mm

3-1/16

Capillary Length

78

4-7/16

113

18

457

Averaging Element Length

4-3/4

120

2-1/4

57

Barbed

Restrictor Tee

Subordinate

Connection

1/8 inch NPT,

Internal Thread

Sealing Cap

(Open Branch)

Supply Air Connection

(Restrictor Branch)

96

2438

Figure 3: Concealed Adjustment for T-3111, in./mm

T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin 3

Page 4

3-3/16

80

4-9/16

116

4-3/4

121

Barbed

Restrictor Tee

Subordinate

Connection

1/8 inch NPT,

Internal Thread

Sealing Cap

(Open Branch)

Capillary Length

42

1067

2-1/4

57

Supply Air Connection

(Restrictor Branch)

6-9/16

167

5/16

Diameter

8

Figure 4: Exposed Adjustment for T-3111, in./mm

O

L

O

C

W

A

R

M

Supply

Air

3/4

19

5-3/16

132

Figure 5: Mounting Details for T-3111, in./mm

4 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Page 5

5/8

16

3-1/8

79

4-3/4

121

to maximum

5-1/8

130

Barbed Restrictor

Tee Suppl y

(Restrictor Branch)

Marked

Output

(Open Branch)

76

3

3/4

19

1-1/2

38

1/4

6

5-1/2

140

1/4

6

8-13/16

224

Capillary Length

18

457

Averagi n g E l em ent Length

5-13/16

148

96

2438

to maximum

Figure 6: Dimensions and Mounting Details for T-3200, in./mm

3-1/16

78

4-3/4

121

Supply Air

Straight Connector

for 1/4 inch O.D.

Poly ethylene T ub ing

Switching Air

Connection

13/16

21

4-9/16

116

Capillary Length

42

1067

2-1/4

5/16

8

57

6-9/16

167

Diameter

Figure 7: Exposed Dimensions for T-3311, in./mm

T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin 5

Subordinate

Connection

1/8 inc h N P T ,

Internal Thread

Page 6

76

3

3/4

19

1-1/2

38

5/8

16

1/4

6

1/4

6

Capillary Length

3-3/8

86

42

1067

5-9/16

141

4-3/4

121

to maximum

5-13/16

148

to maximum

5-1/8

130

Output

Air Connection

Supply Air

Connection

13/16

21

8-13/16

224

6-9/16

167

5/16

Diameter Bulb

8

Figure 8: Dimensions and Mounting Details for T-3300, in./mm

L

O

O

C

H

E

A

T

3/16

21

5-5/16

135

Figure 9: Mounting Details for T-3311, in./mm

6 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Page 7

nstallation Procedures

I

Tubing Installation

The T-3100, T-3200, and T-3300 Series Thermostats

are supplied with barbed fittings for the supply and the

output air connections. It is recommended that Type

“FR” polyethylene tubing be used on the barbed

fittings.

Note: Cut tubing off square for a good fit on the

barbed fitting.

If “HP” or copper tubing is used, the barbed fitting

must be removed and replaced with a compression

fitting and an in-line restrictor when necessary.

Note: Figure 10 illustrates a copper tubing

installation; “HP” tubing installation is the

same except the brass ferrule is replaced with

a thermoplastic ferrule, which is supplied with

the R-3710-1007 restrictor.

.007 inch In-Line

Restrictor with O-Ring

1/8 inch NPT, Internal Thread

Brass Ferrule

(Field F ur ni shed)

Air

Flow

1/4 inc h O.D.

Soft Copper Tubing

Compre ssion

Nut

Supply Air Connecti on

Standard Compression

Fitting (Field Furnished)

Figure 10: Copper Tubing Installation

(Use R-3710-1007 In-Line Restrictor)

Route the capillary so it is not in contact with

extremely high or low temperature sources such as

steam lines, water pipes, or coils. Be sure to route the

element and capillary so that routine maintenance can

be performed on the terminal unit without disturbing

the element.

Bulb Element

In most cases, a bulb element will be installed in the

return air chamber of the terminal air unit in the

following manner:

1. Install the element behind the protective screen or

grille and in a location where normal maintenance

may be performed on the unit without interference.

2. Be sure the bulb will sense only the return air and

will not be influenced by other temperatures.

3. Secure the bulb using holder, T-275-100 (ordered

separately) which can be hung or fastened in

place and bent to the desired position.

Holder

Bulb

5/16

Diameter Hole

8

Sensing Elements

Both the bulb and the averaging sensing element must

be carefully located so the elements measure only the

intended air temperature. The majority of terminal air

condition units are very compact and little clearance

exists between coils. Also, the air flows are of widely

varying temperature. Before selecting an element

location, study the unit interior and make certain that

the sensing element will not be affected by

undesirable temperatures or mechanical damage.

Avoid extremely sharp bends in the capillary which

could obstruct the liquid flow.

T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin 7

8

203

Figure 11: Bulb Element Holder Dimensions,

in./mm (T-275-100, ordered separately)

Page 8

Averaging Element

In most cases, an averaging element will be installed

in the air chamber of the terminal air unit in the

following manner:

1. Install the element in a serpentine fashion across

the top of the unit coil.

2. Secure the element along the entire length by

using holders, T-275-101 (ordered separately), so

that no part of the element touches the coil. The

holder is very flexible and can be bent to any

desired position.

3. On face and bypass units, the element must be

placed in the space where a mixing of coil

discharge air (face) and coil bypass air takes

place. Install the element as close as possible to

the bottom side of the discharge air grille. The

element should be secured by using holders

(T-275-101, ordered separately) fastened to the

unit casing.

For ASHRAE Cycle III applications, the element

must be installed in the mixed air (outside and

return) rather than in the discharge air. Install the

element so it will receive the best possible

sampling of the mixture temperature using holders

(T-275-101, ordered separately) fastened to the

unit casing.

Bend prongs around

bulb or capillary.

alibration Procedures

C

All Johnson Controls instruments are carefully tested

and calibrated at the factory before shipment. If field

calibration is required, it should not be started until all

installation procedures are complete. If, during

calibration, the temperature at the measuring element

fluctuates, place the element in a stable, wellcontrolled temperature area such as a bucket of water,

preferably 75F (24C) for controllers and

56F (13C) for low limit controllers.

Be sure the supply air to the instrument is clean and

free of moisture. The adjusting dial is graduated in

1F increments and can be removed with a flexible

hex head screwdriver (JC 5309, ordered separately).

It is recommended that the middle graduation be used

to represent the desired temperature setpoint.

The adjusting screw for externally adjusted,

Direct Acting (DIR) models is located inside the dial

post and is accessible by removing the dial (refer to

Figure 13, Detail A). For DIR models with concealed

adjustment, it is necessary to remove the small metal

button in the cover (refer to Figure 13, Detail B). A

calibration tool (T-4002-5009, ordered separately)

should be used to adjust the setpoint on these models.

It is necessary to remove the dial and cover for models

with either Reverse Acting (REV) or low limit

adjustments. Use a calibration tool (T-4002-5009,

ordered separately) for Reverse Acting adjustment of

the T-3100 and T-3300 Series Thermostats (refer to

Figure 13, Detail C).

Be sure each T-3100 and T-3111 Thermostat has a

0.007 inch in-line restrictor installed in the supply air

connection. The T-3200 instruments should have a

0.007 inch in-line restrictor in the air line between the

instrument and the room thermostat.

3/16

5

25

2-1/4

57

1

Twist here

if required.

Slip pron gs

over coil fin.

Coil Fin

Figure 12: Averaging Element Holder Dimensions,

in./mm (T-275-101, ordered separately)

8 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Page 9

Switch Stack

Not Furnished on

T-3100 Series

Temperature Set P oi n t

Adjusting Dial

Flexible Driver

JC 5309 (Ordered Separately)

Low Limit Setpoint

Adjustment on Two

Element Controllers

Direct Acting

Set Point Adjustment

(Detai l A )

(Out put Test Port)

Test Co nn ec tion

For Concealed

or Remote

Adjustment Models

For External

Adjustment Models

Reverse Acting

Set Point Adjustment

(Detai l C)

Figure 13: Setpoint Adjusting Features

Recalibration Tool

JC 5360 (o rd er ed s e par ately)

Direct Acting

Set Point Adjustment

(Detail B)

T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin 9

Page 10

Temperature Setpoint Adjustment

For T-3100 and T-3200 Series follow

Steps 1 through 7.

1. Supply the instrument with the proper supply air

pressure.

2. Insert the test gauge (JC 5310, ordered

separately) and the probe assembly (JC 5361,

ordered separately) into the output test port.

Note: For Reverse Acting thermostats it will be

necessary to remove the cover in order to turn

the setpoint adjustment screw.

3. Turn the setpoint adjustment screw until the

pressure reading is approximately in the middle of

the operating range of the actuator. For example,

a 5 to 10 psig operating range would require an

output pressure reading of 7.5 psig.

4. Remove the test gauge and probe assembly.

5. Determine the temperature at the measuring

element.

6. Place the dial on the dial post (do not tighten) and

position it to the temperature at the element.

Remember that each dial increment represents

one Fahrenheit degree. For models with

concealed adjustment, use recalibration tool

JC 5360 (ordered separately).

7. Tighten the dial and turn it to the desired setpoint.

Example: If the desired temperature setpoint is

75F and the temperature at the

element is 71F, then place the dial on

the dial post (do not tighten) and

position it to 71F or four graduations

(75F-71F = 4F) clockwise from the

middle graduation (75F), the desired

setpoint.

For T-3300 Series proceed as follows:

1. Supply the instrument with the appropriate air

pressure for the Direct Acting (DIR) operation.

2. Insert the test gauge (JC 5310, ordered

separately) and the probe assembly (JC 5361,

ordered separately) into the test port

(as illustrated in Figure 14).

3. Remove the knob and cover.

4. Turn the DIR screw until the output pressure is in

the middle of the actuator operating range.

5. Change the supply air pressure to that required for

the Reverse Acting (REV) operation.

6. Turn the REV adjusting screw until the output

pressure is in the middle of the actuator operating

range.

7. Remove the test gauge and probe assembly.

8. Determine the temperature at the element.

9. Attach the cover.

10. Place the dial on the dial post (do not tighten) and

position it to the temperature at the element.

11. Tighten the dial and turn to the desired setpoint.

Note: If the setpoints of several instruments are to

be adjusted before switching the supply

pressure, be sure that the temperature at the

element will not change during both stages of

adjustment.

Note: For T-3200 Series the low limit setpoint is

56F. Use calibration tool T-4002-5009

(ordered separately). Each graduation is

9F (5C).

10 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Page 11

Test P r ob e A s sembly

(JC 5361 , or de red s ep ar ately)

(JC 5310, ordered separately)

Test Gauge

Output Pressure

Test Port

1/8 inc h

NPT, Internal

Thread

15

10

20

5

25

30

0

Figure 14: Test Gauge

Temperature at Element

71°F ( 22°C)

e

s

i

w

k

c

o

l

C

H

E

L

O

O

C

A

T

75°F (24° C) Desired

Temperature Setting

Mid-point of Dial

75°F (24°C)

Pointer

H

E

L

O

O

C

A

T

Figure 15: Temperature Setpoint Dial

T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin 11

Page 12

Restricted Adjustment

The dial pointer on externally adjusted models has

tabs which are factory set to restrict the dial

adjustment to a span of 15F (7.5F on either side of

the pointer). The restriction can be changed to the

spans indicated in Table 2 by bending up the

appropriate tabs and flattening the factory set tabs.

Table 2: Span Adjustment

Span Tab

F C F C

20 11.1 + 10 + 5.6

15 8.3 + 7.5 + 4.2

10 5.6 + 5 + 2.8

5 2.8 + 2.5 + 10

10°F

7.5°F

5°F

2.5°F

10°F

7.5°F

5°F

2.5°F

Figure 16: Restricted Adjustment

aintenance and

M

Troubleshooting Procedures

These instruments are designed so that a minimum of

routine maintenance is required. The following

procedures should be used to ensure proper operation

and to locate malfunctioning components:

1. Check all air lines, connections

for air leaks. Make sure that the in-line restrictors

are not defective.

2. Check the operation of the thermostat to be sure it

is passing the correct control signal and that it is

functioning properly. Make sure it has the proper

supply air pressure and that air is exhausting from

the control port. The port must exhaust

continuously to ensure proper operation of the

thermostat.

3. Check that the temperature measuring element

has not been damaged or moved from its intended

sensing position.

4. Check that the valve packing nut is tight enough to

prevent leaks, but not so tight that the packing

becomes distorted and binds the stem; usually

finger tight is sufficient. If the valve is leaking

around the centerpiece, tighten it with the

appropriate wrench.

5. Verify that the valve seats completely when the

actuator is fully stroked. If there is fluid flow after

the plug is seated, the seat, plug, or disc may be

worn or scored and should be repaired or

replaced.

, and diaphragms

6. If there are subordinate actuators, make sure the

actuators are operating in the proper sequence

and adjusted correctly.

12 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Page 13

ccessories

A

Table 3: Accessories (Order Separately)

Description Code Number

Hex Head Flexible Screwdriver JC 5309

Control Line Test Gauge and

Adaptor

Recalibration Tool JC 5360

Test Probe Assembly JC 5361

Averaging Element Holder for

3 inch (76 mm) Coil

(See Figure 17.)

Restrictor Tee (.007 inch) R-3710-1007

“B” Bulb Holder T-275-100

Averaging Element Holding Clip T-275-101

Supply Inlet Filter

(Order in multiples of 100.)

Calibration Tool T-4002-5009

Averaging Element Holder for

Radius Bends (minimum 3-1/2 in.

(See Figure 18.)

Diaphragm for Exposed Actuator

V-3000-1 only

JC 5310

Order QEO-1 from

Temperature Control

Specialties

2800 Laura Lane

Middleton, WI 53562

(608) 836-9034

T-3100-605

TE-6001-8

V-3000-600

Figure 17: QEO-1, Averaging

Element Holder

Figure 18: TE-6001-8,

Averaging Element Holder

T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin 13

Page 14

epair Procedures

R

Actuators

To replace the diaphragm, follow Steps 1 through 7

below.

1. Remove the eight screws holding the thermostat

to the integral actuator.

2. Lift the thermostat exposing the diaphragm and

remove the piston.

3. Turn the new diaphragm inside out and place it

over the piston. Smooth out all of the wrinkles and

release any air trapped between the head of the

piston and the diaphragm, then pull the flange up.

The diaphragm will assume its shape, as

illustrated in Figure 19.

4. On piston top valve actuators, place the piston

straight within the new diaphragm and insert into

the bell housing.

5. Replace the thermostat.

Thermostat

Diaphragm

V-3000-600

Piston

Spider

Figure 19: Diaphragm Installation for

T-3111 and T-3311 Series

6. Replace all the screws and tighten equally.

7. Place the instrument in operation and check its

action.

14 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Page 15

pecifications

S

Product T-3100, T-3200, and T-3300 Series Controllers

Models See Table 1.

Proportional Action See Table 1.

Maximum Supply Pressure

Ambient Temperature Limits

Supply

Air Connections

S

ubordinate

Ty

Element

Range

Span 20F (11C) Maximum

Dial Range

Marking “Cool-Warm,” Graduated in one degree “F” Increments

Sensitivity

Remote Bulb

veraging Bulb T-3111

A

Factory Setpoint T-3200 56F (13C)

Continued on next page. . .

* The maximum length of 5/32 inch tubing is 15 feet. It is recommended that 1/4 inch tubing is used at all times to ensure

proper switchover.

25 psig (172 kPa)

-20 to +150F (-29 to 66C)

T-3100

T-3111

T-3200

T-3311

-3300

T

All Models

T

-3111

T-3111 and

pe

T-3200

T-3100

T-3300

T-3311

T-3100

T-3200

T-3300

T-3311

T

-3111

All Models

Except

T-3200

T-3100

T-3111

T-3300

T-3311

T-3200

T-3100 75F (24C)

T-3300 75F (24C)

Barbed Restrictor Tee for 1/4 inch O.D. Polyethylene Tubing

Straight Connector for 1/4 inch O.D. Polyethylene Tubing;

1/8 inch NPT Barbed Fitting for 5/32 or 1/4 inch O.D.

Polytubing*

1/8 inch NPT, Internal Thread

Bulb with 42 inch (1067 mm) Capillary

8 ft (2438 mm) Averaging with 18 inch (457 mm) Capillary

Bulb with 42 inch (1067 mm) Capillary

60 to 150F (16 to 66C)

Bulb, 60 to 150F (16 to 66C)

Averaging, 30 to 175F (-1 to 80C)

Factory Set at + 7.5F (+ 4C)

2.5 psi/F (31 kPa/C)

0.5 psi/F (31 kPa/C)

T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin 15

Page 16

pecifications (Cont.)

S

Body

Cover

Material

Accessories (Order Separately) See Table 3.

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications,

consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.

Yoke

Diaphragm

Finish Green Lacquer

All Models

All Models

T-3111 and

T-3311

T-3111 and

T-3311

Die Cast Aluminum

Die Cast Zinc

Die Cast Aluminum

Molded Synthetic Rubber

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT

MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

Controls Group

507 E. Michigan Street

P.O. Box 423

Milwaukee, WI 53201 Printed in U.S.A.

16 T-3100, T-3200, and T-3300 Series Controllers Product/Technical Bulletin

Loading...

Loading...