Johnson Controls System 450 Series, System C450CQN-1, System C450CPN-1 Installation Instructions Manual

Page 1

Figure 1: System 450 Module Dimensions, mm (in.)

127

(5)

4

Screw

Slots

11

(7/16)

(2-3/8)

75

(2-15/16)

1/2 in. No minal

Trad e Size

Conduit Hole

22

(7/8)

40

(1-9/16)

DIN Rail

Clips

FIG:sys450_dims

System 450™ Series Control Modules with Analog Outputs

Installation Instructions

C450CPN-1

C450CQN-1

Part No. 24-7664-2780, Rev. A

Issued December 10, 2009

Application

IMPORTANT: Use this System 450 Series Control

Module with Analog Output only as an operating

control. Where failure or malfunction of the System

450 control module could lead to personal injury or

property damage to the controlled equipment or

other property, additional precautions must be

designed into the control system. Incorporate and

maintain other devices, such as supervisory or

alarm systems or safety or limit controls, intended to

warn of or protect against failure or malfunction of

the System 450 control module.

System 450 is a family of modular, digital electronic

controls that is easily assembled and set up to provide

reliable temperature, pressure, and humidity control for

a wide variety of Heating, Air Conditioning, Ventilation,

and Refrigeration (HVACR), and commercial/industrial

process applications.

The System 450 Series allows you to configure custom

application-specific control systems with up to three

input sensors and ten (relay and/or analog) outputs,

including control systems that can monitor and control

temperature, pressure, and humidity applications

simultaneously.

You can easily install and quickly configure a

stand-alone System 450 control module and sensor in

the field as a replacement control for almost any

temperature, pressure, and humidity control.

C450CxN-1 models are analog output control modules

with Liquid Crystal Display (LCD) and four-button touch

pad User Interface (UI) that allows you to set up a

System 450 control system. C450CPN-1 models

provide one self-selecting analog output, C450CQN-1

models provide two self-selecting analog outputs.

Refer to the System 450 Series Technical Bulletin

(LIT-12011459) for more detailed information on

designing, installing, setting up, and troubleshooting

System 450 Series control systems. The System 450

technical bulletin can be accessed and downloaded on

the Johnson Controls® Online Product Litera tu re Web

site at the following Web address:

http://cgproducts.johnsoncontrols.com/default.aspx

13

(1/2)

(3/16)

(Four)

61

61

(2-3/8)

Mounting

Location Considerations

Observe the following System 450 location guidelines:

• Ensure that the mounting surface can support the

module assembly, mounting hardware, and any

(user-supplied) panel or enclosure.

• Mount the modules in upright and plugged together

in a horizontal row where possible. DIN rail

mounting is highly recommended.

• Mount modules on flat even surfaces.

• Allow sufficient space for wires and connections.

• Mount the modules in locations free of corrosive

vapors and observe the ambient operating

conditions in the Technical Specifications

• Do not mount the modules on surfaces that are

prone to vibration or in locations where radio

frequency or electromagnetic emissions may

cause interference.

• Do not install the modules in airtight enclosures.

• Do not install heat-generating devices in an

enclosure with the modules that may cause the

temperature to exceed the ambient operating limit.

.

System 450™ Series Control Modules with Analog Outputs Installation Instructions 1

Page 2

Mounting System 450 Modules

!

Figure 2: C450CxN-1 Wiring Terminals

with Analog

Outputs

(C450CQN-1)

A

A

AO2

COM

AO1

Analog

Controlled

Device

Analog

Device

+

__

+

Low-Voltage

Analog Output Terminals

C

5V

24V

C

Sn1

C

Common terminals (C)

are internally

connected.

Mount System 450 modules on 35 mm DIN rail

(recommended) or directly to an even wall surface. To

mount the modules on DIN rail:

1. Provide a section of 35 mm DIN rail that is longer

than the module assembly width, and mount the

DIN rail horizontally in a suitable location using

appropriate mounting hardware/fasteners.

2. Clip the control module on the rail, position the

upper DIN rail clips on the top rail, and gently snap

the lower clips on to the rail.

3. Clip the remaining modules to the right of the

control module on to the DIN rail and plug together.

To direct mount modules to wall surfaces:

1. Plug the modules together, remove the module

covers, place the assembly against wall surface

horizontally in a suitable location, and mark the

mount hole locations on the surface.

IMPORTANT: Do not exceed the System 450

module electrical ratings. Exceeding module

electrical ratings can result in permanent da mage to

the modules and void any warranty.

IMPORTANT: Do not connect 24 VAC supply

power to the System 450 modules before finishing

wiring and checking all wiring connections. Short

circuits or improperly connected wires can result in

damage to the modules and void any warranty.

IMPORTANT: Run all low-voltage wiring and

cables separate from all high-voltage wiring.

Shielded cable is strongly recommended for input

and output cables that are exposed to high

electromagnetic or radio frequency noise.

2. Install appropriate screw fasteners, leaving screw

heads approximately one to two turns away from

flush to the surface.

Sn2

Sn3

FIG:sys450_anlg_c ntrl_wi r

3. Place the assembly over screw heads and on the

mounting slots, and carefully tighten mount screws.

Note: If you mount the modules on an uneven

surface, do not damage the housings when

tightening mounting screws. Use shims/washers to

mount module assembly evenly on the surface.

COM

O2

O1

Refer to the control sensor installation instructions for

information on locating and mounting control sensors.

Wiring

See Figure 2 and Table 1 for electrical termination

Controlled

System 450

Control Module

locations and wiring information. See Technical

Specifications on page 11 for electrical ratings.

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnect or isolation

may be required to completely

de-energize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

IMPORTANT: Use copper conductors only. Make

all wiring in accordance with local, national, and

regional regulations.

System 450™ Series Control Modules with Analog Outputs Installation Instructions2

Page 3

Figure 3: Example System 450 Heat/Cool System with Condenser Fan Speed Control

Analog Output

Signal

Active/Passive Sensor DIP Switches

DIP Switch 1 is Off; switch 2 is ON.

COM

AO2

AO1

FIG:sys450_app_anlg_exmpl

L1

L1 L2

L2

Table 1: System 450 Analog Output Control Module Terminal Wiring Information

Label Terminal Function Wire Sizes

24V Accepts 24 V AC supply power, when a C450YNN power module is not connected,

and provides power terminal for 24 VAC (humidity) sensors.

5V Provides 5 VDC power for active sensors.

S1, S2, S3 Accepts passive or active (0-5 VDC) input signals from control sensors.

C

(Three

Terminals)

Provide low-voltage Common connections for 24 VAC power and passive or active

sensors connected to the 5V, Sn1, Sn2, and Sn3 terminals.

Note: The three C terminals are connected internally and can be connected to

ground in the field.

AO1,

AO2

Provides a self-detecting analog output signal in conjunction with the COM

terminal; either 0–10 VDC or 4–20 mA.

COM Provides a self-detecting analog output signal in conjunction with the AO1 or AO2

terminal; either 0–10 VDC or 4–20 mA.

2

0.8 mm

28 AWG to 16 AWG

0.08 mm

28 AWG to 16 AWG

to 1.5 mm

2

to 1.5 mm

2

2

System 450™ Series Control Modules with Analog Outputs Installation Instructions 3

Page 4

4

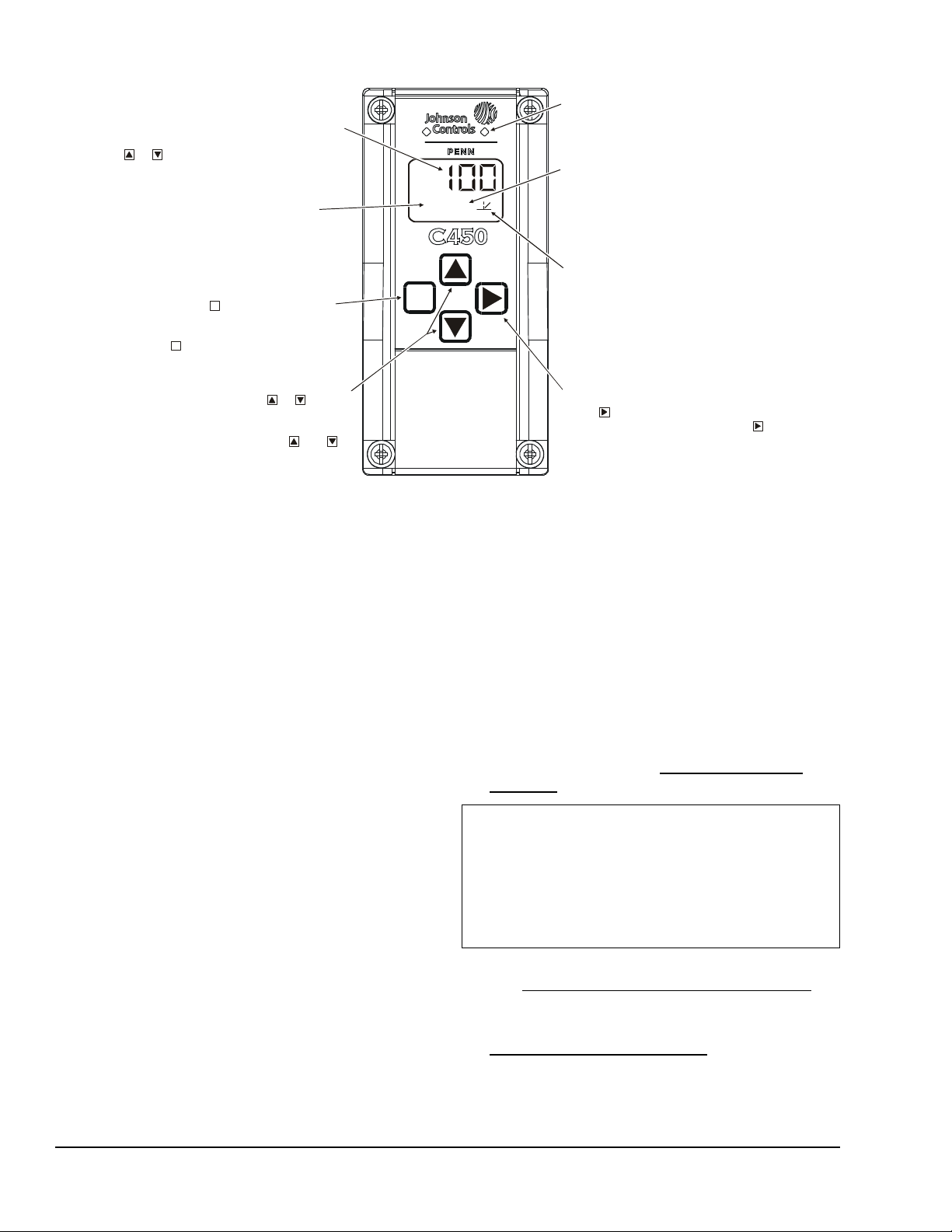

Displays a

Setup Value shown on the screen. Output

Numbers are automatically determined by

in the module assembly. ( = Output 4.)

Control Ramp Icon:

Displays whether an

Analog Output increases or decreases as

the sensor input increases, an d w hether the

output signal strength is at min imum or

maximum when the sensed property is at

Setpoint. The Control Ramp icon displayed

is determined by the Output's SP , EP, OSP,

and OEP setup values.

MENU Button:

Press to move through the

sensor and output setup-start-screens.

When moving through the status or setup

screens, press to return to the status start

screen or setup start screen.

M

M

Status or Setup Identifier:

or

OSP

Displays the

unit of me asurement, output, sensor number,

setup parameter for the displa yed Status or

Setup Value. (Setup Identifier repres ents

% Output Si gnal Strength at Setpoint.)

UP and DOWN Buttons:

Press or to select

a differ ent value for any flashing value in the

Setup Value field. In the Main/Default (Sensor

Status) sc r een, press and hold bot h and

for 5 seconds to access the Setup Start screens.

Status or Setup Value:

or

100

Displays th e current

input stat us, output status setup parameter

value for t he displayed input sensor or output.

select a different Parameter

Value when the value is fl ashing. ( = 100%.)

Press or to

M

osp

4

Light-Emitting Diode (LED):

Green LEDs

associat ed Relay Out put is On or Off.

the (flashing) Setup Value and go to the

next setu p screen.

Figure 4: System 450 Control Module Output Analog LEDs, LCD, Four-Button Touch Pad User Interface

on Relay Control Module and R el ay

Expansion Modules (only) indicates if the

Output (or Sens or ) N um be r:

numerical value tha t identifies the Output

(or Sensor ) associated with the S tatus or

the outputs' physical positions (left to right)

FIG:sys450cntrl_m odul

NEXT Button:

press to scroll through the system status

screens. In a setup screen , press to save

In the Main /D efault screens,

Setup and Adjustments

System 450 Components

A System 450 control system consists of one control

module, one to three control sensors, and one to ten

outputs that provide analog control and/or On/Off

control. Figure 3 shows an example System 450

module assembly with two sensors and three outputs

(two analog outputs and one relay output).

Setting up a Module Assembly

To set up a System 450 module assembly:

1. Determine the controlled conditions, sensor types,

and value ranges required for your application, and

select the appropriate System 450 sensor types.

2. Determine the number and type (relay or analog) of

outputs required to control your application, and

select the appropriate System 450 control module

and expansion modules.

3. Assemble the control and expansion modules,

starting with the control module on the left .

Note: If you use a C450YNN-1 power module, it

must be plugged into the control module. Plug

remaining expansion modules to the right of the

power module.

4. Apply power to the module assembly.

Y ou ca n now set up the module assembly in the control

module UI.

Setting up a Control System in User Interface

System 450 control modules have a back-lit LCD and a

four-button touch pad User Interface (UI) that enable

you to set up all of the inputs (sensors) and outputs in

the module assembly (Figure 4).

Figure 7 provides an example System 450 setup

overview that corresponds to the control system

example shown in Figure 3 and the following setup

examples and procedures.

To set up a control system in the System 450 UI:

1. Build your control system module assembly and

connect it to power. See Setting up a Module

Assembly on page 4.

IMPORTANT: Each time a module assembly is

powered ON, the control module polls all of the

modules to identify output type (relay or analog) and

assigns a sequential output number (1 to 9 [0= 10])

to each output starting with the control module

output on the left. The output numbers identify each

output’s setup screens in the UI. (See Figure 4.)

2. Access the System 450 setup screens in the UI.

See Accessing the System 450 Setup Screens

page 5.

3. Set up the control system inputs in the UI. See

Setting up System 450 Sensors

on

on page 5.

System 450™ Series Control Modules with Analog Outputs Installation Instructions4

Page 5

4. Set up the control system outputs in the UI. See

1

74

2

F

OUT

1

On

64

OUT

3

Setting up System 450 Outputs

IMPORTANT: Do not change the module positions

after a System 450 control system is set up in the

System 450 UI. System 450 control logic is set up in

the UI according to the input Sensor T ypes, the output

types, and the output numbers. Changing modules or

module positions in a module assembly that is

already set up in the UI, can change the output

numbers, output types, and/or the setup values of the

assembly outputs, which will require setting up the

outputs again.

Use the worksheet provided on page 14 to plan and

record the settings for your System 450 control system.

Table 2: System 450 Main Screens and Status Screens Informatio n and Procedures

LCD Screen Name, Description/Function, User Action, and Example

Main (Input Status) Screen: During normal operation, the Main screen automatically scrolls through the

232

PSI

current status at each input sensor in your control system and displays the sensor number, the unit of

measurement, and the sensed condition value. See Figure 7.

Note: Main screens are view-only, selections are not made in Main screens.

Press NEXT repeatedly to scroll through and view the System Status screens for all inputs and

outputs in your control system.

Press and hold both UP and DOWN for 5 seconds to access your control system’s setup screens.

Note: In any system setup screen, you can return to the Main Screens by pressing both UP and DOWN

simultaneously. Also, the UI retu rns to the Main screen after 2 minutes of inactivity in any screen.

Examples show Sensor 1 sensing 232 psi and Sensor 2 sensing 74°F.

System Status Screens: The System Status screens display current status of all inputs and outputs in

your control system. Relay output status screens display output number and relay status (On/Off). Analog

output status screens display output number, signal strength, and control ramp icon. See Figure 7.

Note: System Status screens are view-only, selections are not made in Status screens.

Press NEXT repeatedly to scroll and view the System Status screens for the inputs and outputs in

your control system.

Examples show Output 1 relay is On and Output 3 signal strength is 64% of the total signal strength. The

control ramp icon in the bottom screen example indicates that the Analog Output is set up with SP<EP and

OSP<OEP. (See Setting up an Analog Output (OUTA

on page 7.

Viewing the Main and System Status Screens

After your control system is installed, wired, and setup,

the Main (Input Status) screen appears when you

connect power to your system. During normal

operation, the Main screen displays the current status

of each input (sensor) in your control system. See

Table 2 for more information on the Main screens.

The System Status screens can display an output

status screen for each output in your control system

along with the Input Status screens; in the Main (Input

Status) screen, press NEXT repeatedly to scroll

through and view all of the Output Status screens in

your control system. See Table 2 for more information

on the System Status screens.

#) for information about control ramp icons.)

Accessing the System 450 Setup Screens

You can access the setup screens from the Main

screen. To access the System 450 setup screens:

1. Apply power to your module assembly. After a

startup check, the Main screen appears on the

LCD.

2. In the Main screen, press and hold UP and DOWN

simultaneously for 5 seconds to access the setup

screens and to go to the Sensor Setup Start

screen.

Note: The Sensor Setup Start screen is the first

screen displayed when you access the System 450

setup screens. From the Sensor Setup Start

screen, you can navigate to all of the remaining

setup screens for your control system.

System 450™ Series Control Modules with Analog Outputs Installation Instructions 5

3. Press MENU repeatedly to scroll through the setup

start screens. See Figure 7.

Note: The setup start screens are view-only;

selections cannot be made in setup start screens.

Press NEXT in a Setup Start screen to go to the

sensor or output setup screens.

Setting up System 450 Sensors

You must set up the input sensors for your control

system before you can set up any of outputs. T o set up

the input sensors you must access the setup screens.

See Accessing the System 450 Setup Screens

The Sensor Setup Start screen is the first screen

displayed when you access the system setup screens

in the System 450 UI.

.

Page 6

Table 3 provides information about System 450

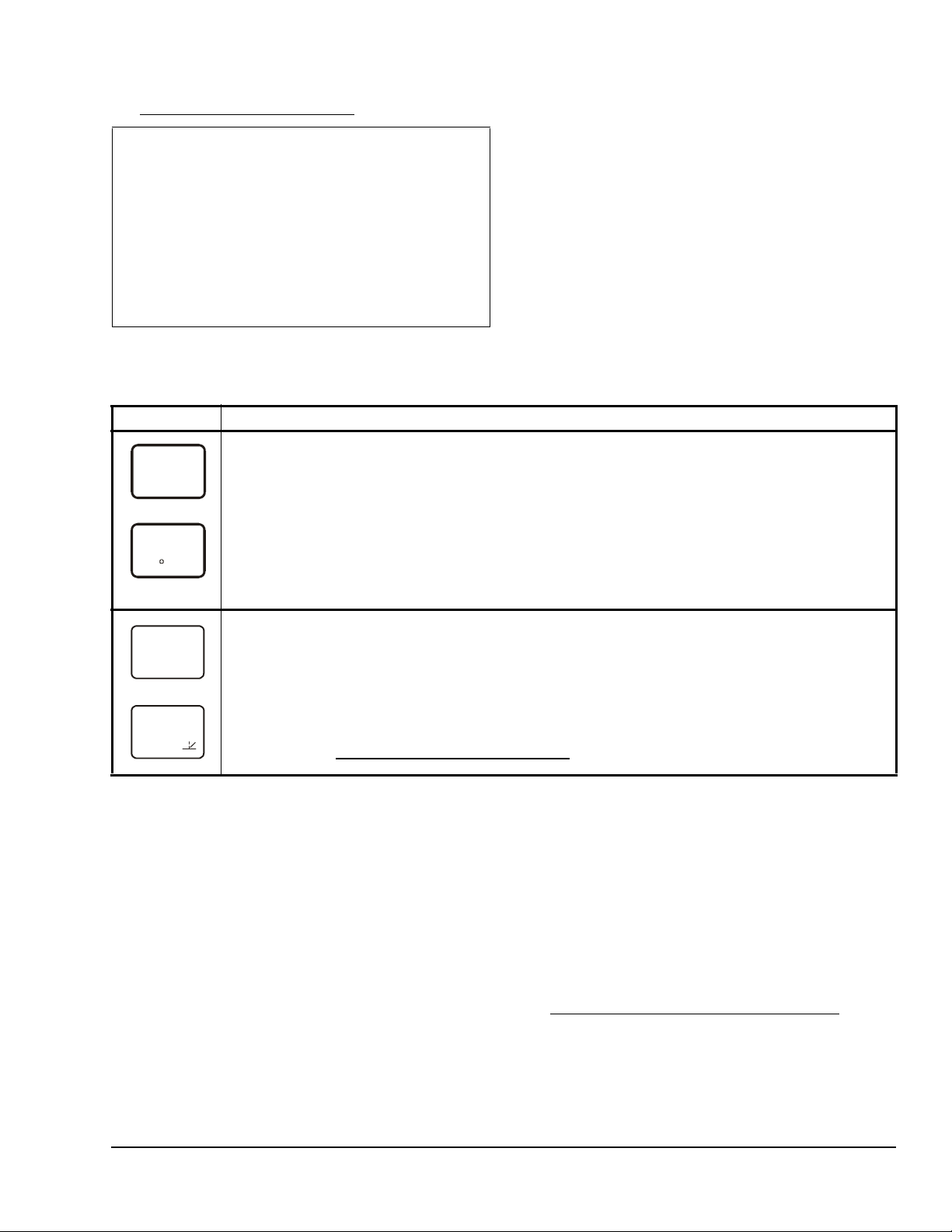

Figure 5: Active/Passive Sensor DIP Switch

Block (Set up for Example in Figure 3)

21

ON

(No sens or connected to S3 in Figur e 3.)

S1

S2

S3

SENS

-- -

sensors, Sensor Ty pes, parameter values, and

specified sensor/transducer product code numbers.

Table 4 provides information, procedures, and

examples regarding Sensor Setup screens and setting

up sensors. Figure 7 provides a System 450 UI and

Temperature sensors are passive (2-wire) sensors and

corresponding switches must be set to ON. Humidity

and pressure transducers are active (3-wire) sensors

and corresponding switches must be set to Off. See

Figure 5 for the switch settings for the System 450

example shown in Figure 3.

setup overview example.

Setting Active/Passive Sensor DIP Switches

Before putting your control system into operation, you

must set up each sensor in the system as either

passive or active by positioning the associated switch

3

sys450_dip

Switch 1 sets Sensor (Set to Active/Off)

Switch 2 sets Sensor (Set to Passive/On)

Switch 3 sets Sensor (Set to Active/Off)

(On or Off) on the DIP switch block located below the

sensor terminal block. See Figure 3.

Table 3: System 450 Sensor Types, Setup Values, and Sensor/Transducer Product Codes

Sensor

Type

Unit of Measurement

Value

(Condition/Units)

Effective

Sensing

Range

Range of

Usable

Values

Resolution

Increment

Value

Minimum

Differential

or

Sensor Product

Type Number

1

Proportional

Band

°F °F (Temperature/degrees) -46 to 255 -40 to 250 1 1 A99B-xxx

°C °C (Temperature/degrees) -43 to 124 -40 to 121 0.5 0.5 A99B-xxx

rH % (Humidity/%RH) 1 to 100 10 to 95 1 2 HE67Sx-x

P 05 INWC (Pressure/in. W.C.) 0 to 0.5 0.025 to 0.5 0.005 0.025 DPT-2650-0R5D-AB

P 8 bAR (Pressure/bar) -1 to 8 -1 to 8 0.05 0.1 P499Rxx-401C

P 10 INWC (Pressure/in. W.C.) 0 to 10 0.5 to 10 0.05 0.2 DPT-2650-010D-AB

P 15 bAR (Pressure/bar) -1 to 15 -1 to 15 0.1 0.2 P499Rxx-402C

P 30 bAR (Pressure/bar) 0 to 30 0 to 30 0.1 0.4 P499Rxx-404C

P 50 bAR (Pressure/bar) 0 to 50 0 to 50 0.2 0.4 P499Rxx-405C

P100 PSI (Pressure/psi) 0 to 100 0 to 100 0.5 1 P499Rxx-101C

P200 PSI (Pressure/psi) 0 to 200 0 to 200 1 1 P499Rxx-102C

P500 PSI (Pressure/psi) 0 to 500 90 to 500 1 5 P499Rxx-105C

P750 PSI (Pressure/psi) 0 to 750 150 to 750 2 6 P499Rxx-107C

1. Refer to the System 450 Series Modular Controls Product Bulletin (LIT-12011458), Catalog Page (LIT-1900549), or

Technical Bulletin (LIT-12011459) for complete ordering information for System 450 compatible sensors and transducers.

Table 4: System 450 Sensor Setup Information and Procedures

LCD Screen Name, Description/Function, User Action, and Example

Sensor Setup Start Screen: The Sensor Setup Start screen is the first screen displayed when you

access the System 450 setup screens. From the Sensor Setup Start screen you can navigate to the

Output Setup Start screens or the Sensor Setup screens. See Figure 7.

Note: You must setup the input sensors before you can setup the control system outputs. The Sensor

Setup Start screen is view-only, selections are not made in setup start screens.

Press MENU (repeatedly) to scroll through the Output Setup Start screens. (See Setting up a

Relay Output (OUTR#) and Setting up an Analog Output (OUTA#) for information and procedures on

setting up outputs.)

1. Press NEXT to go to the first Sensor Type Selection screen (Sn-1) and begin setting up the

sensors in your control system.

Example shows the Sensors Setup Start screen with four flashing dashes.

System 450™ Series Control Modules with Analog Outputs Installation Instructions6

Page 7

Table 4: System 450 Sensor Setup Information and Procedures (Continued)

P500

Sn-1

°F

Sn-2

--

Sn-3

-3

OFFS

SENS

-- -

LCD Screen Name, Description/Function, User Action, and Example

Sensor Type Selection Screens: The Sensor Type you select for an input sensor automatically

determines the setup parameters and values for each output that is set up to reference that sensor. See

Table 3 for information about System 45 0 sensors/transducers, Sensor Types, condition type, units of

measurement, minimum differential or proportional band, setup values, value ranges, and product code

numbers.

Note: For an output to operate properly, the selected Sensor Type must match the sensor/transducer

model wired to the control module, and the sensor/transducer must be wired to the proper control module

input terminals.

2. In the Sn-1 Sensor Type Selection screen, press UP or DOWN to select the desired Sensor

Type. Press NEXT to save your selection and go to the Sn-2 Sensor Type Selection screen.

3. In the Sn-2 Sensor Type Selection screen, press UP or DOWN to select the desired Sensor

Type. Press NEXT to save your selection and go to the Sn-3 Sensor Type Selection screen.

Note: If your control system does not use three input sensors, simply press NEXT while the two dashes

are flashing in a Sensor Type Selection screen to save no Sensor Type and go to the next setup screen.

4. In the Sn-3 Sensor Type Selection screen, press UP or DOWN to select the desired Sensor

Type. Press NEXT to save your selection and either:

• go to the Temperature Offset Setup screen for the first temperature sensor in your system.

• return to the Sensor Setup-Start Screen, if your control system has no temperature sensors.

Examples show Sensor 1 with the P500 Sensor Type selected; Sensor 2, with the °F Sensor Type

selected; and Sensor 3, with the no Sensor Type selected.

T emperature Offset Selection Screens: Select a temperature offset for the temperature inputs (only) in

your control system.

2

Sensor Type °F enables an offset of +/- 5°F in 1 degree increments.

Sensor Type °C enables an offset of +/- 2.5°C in 0.5 degree increments.

Note: The temperature offset changes the displayed temperature value by the selected offset value.

5. Press UP or DOWN to select the desired temperature offset value. Press NEXT:

• to go to the next Temperature Offset Selection screen and repeat this step (if required).

• to return to the Sensors Setup-Start Screen.

Example shows -3 (flashing) is the selected temperature offset value for Sensor 2, thus a sensed

temperature of 75°F at Sensor 2 is displayed as 72°F.

Sensors Setup Start Screen: The Sensor Setup screens return to the Sensor Setup Start screen.

After the sensors are set up for your control system, you can:

• Press MENU to scroll through the Output Setup Start screens and begin setting up your

system outputs. (See Setting up a Relay Output (OUTR

for more information and procedures.)

• Press UP and DOWN simultaneously and hold for 5 seconds to return to the Main screens.

Example shows Input Sensors Setup-Start screen with four flashing dashes.

#) and Setting up an Analog Output (OUTA#)

Setting up System 450 Outputs

After you build and connect power to your control

system module assembly, the output numbers and

output types for your control system are auto m at ica lly

assigned in the UI.

Note: You must set up the input sensors for your

control system before you can set up the outputs.

To set up System 450 outputs in the UI:

1. Access the System 450 setup screens, the Sensor

Setup Start screen (SENS) appears. (See

Accessing the System 450 Setup Screens

System 450™ Series Control Modules with Analog Outputs Installation Instructions 7

.)

2. In the Sensor Setup Start screen (SENS), press

MENU repeatedly to scroll through and select the

desired Output Setup Start screen. The Output

Setup Start screen indicates the output number

and the output type for the selected output.

For Relay Outputs, see Setting up a Relay Output

(OUTR#) and Table 5 for setup information and

procedures.

For Analog Outputs, see Setting up an Analog Output

(OUTA#) and Table 7 for setup information and

procedures.

Page 8

Setting up a Relay Output (OUTR#)

OUTR

1

-- -

SENS

SENS

N

1

78

1

T

1

0

T

1

120

1

OFF

Relay outputs provide On/Off contro l for the equipment

in your application based on input from the sensor the

output is set up to reference. See Table 5 for relay

output setup information and procedures.

Table 5: System 450 Relay Output Setup Screen Information, and User Actions

LCD Screen Name, Description/Function, User Action, and Example

Relay Output Setup Star t Scr e en : Output number and the output type (relay or analog) are

automatically assigned when you connect power to your control system’s module assembly.

Note: You must set up the system’s sensors before you can set up the outputs.

1. Press NEXT to go to this output’s Sensor Selection screen.

Example shows the Relay Output Setup-Start screen for Output 1.

Sensor Selection Screen: The sensor you select here determines this output’s setup parameters and

--

Sn-2

O

OFF

ON

OFF

SNF

values, including condition type, unit of measurement, minimum differential, default setup values, and

setup value ranges for several of the remaining output setup screens. If a sensor is not selected here, this

output’s remaining setup screens do not appear. If a sensor is already selected for this output, the Sensor

Selection screen does not appear here, instead the Relay ON Selection screen appears.

Note: Y ou must select a sensor in this Sensor Selection screen and the selected sensor must be already

set up in the System 450 UI. (See Setting up System 450 Sensors

2. Press UP or DOWN to select the Sensor (Sn-1, Sn-2, or Sn-3) that this output references. Press

NEXT to save your sensor selection and go to the Relay ON Selection Screen.

Example shows input Sensor 2 selected for Output 1.

Relay ON Selection Screen: Select the value at which the relay turns On. Relay ON is defined as relay

LED On/Lit, relay contacts NO to C are closed, and NC to C contacts are open.

Note: The value ranges and minimum differential are determined by the Sensor Type selected for the

sensor that this output references and are enforced in the Relay ON and Relay OFF Selection screens.

3. Press UP or DOWN to select the value at which the output relay turns On. Press NEXT to save

your selection and go to Relay OFF Selection Screen.

Example shows an ON value of 78 (°F) selected for Relay Output 1.

Relay OFF Selection Screen: Select the value at which the relay turns Off. Relay OFF is defined as

relay LED Off, relay contacts NC to C are closed, and NO to C contacts are open.

Note: The value ranges and minimum differential are determined by the Sensor Type selected for the

sensor that this output references and are enforced in the Relay ON and Relay OFF Selection screens.

4. Press UP or DOWN to select the value at which output relay turns Off. Press NEXT to save

your selection and go to Minimum Relay ON TIme Selection Screen.

Example shows an OFF value of 75 (°F) selected for Relay Output 1.

Minimum Relay ON Time Selection Screen: Minimum ON Time range is 0 to 300 seconds.

5. Press UP or DOWN to select the minimum time that the output relay remains On after reaching

the Relay ON value. Press NEXT to save your selection and go to the Minimum Relay OFF Time

Selection Screen.

Example shows 0 (zero) seconds selected for the minimum ON-Time for Output 1.

Minimum Relay OFF Time Selection Screen: Minimum OFF Time range is 0 to 300 seconds.

6. Press UP or DOWN to select the minimum time that this output relay remains Off after reaching

the Relay OFF value. Press NEXT to save your selection and go to the Sensor Failu re Mode

Selection screen.

Example shows 120 seconds selected for the minimum OFF-Time for Output 1.

Sensor Failure Mode Selection Screen: Select this output’s mode of operation if the referenced sensor

or sensor wiring fails. The output operates in the selected mode until the failure is remedied.

Sensor Failure mode selections for Relay Outputs include:

• ON output relay remains On during sensor failure.

• OFF output relay remains Off during sensor failure.

7. Press UP or DOWN to select this output mode of operation if the sensor or sensor wiring fails.

Press NEXT to save your sensor failure mode selection and go to the Edit Sensor Screen.

Example shows OFF sensor failure mode selected for Output 1. This output relay is Off if the referenced

sensor or sensor wiring fails.

.)

System 450™ Series Control Modules with Analog Outputs Installation Instructions8

Page 9

Table 5: System 450 Relay Output Setup Screen Information, and User Actions (Continued)

SENS

OUTR

1

-- -

0%

100%

Less Greater

65

°F

10%

70

°F

SP > EP

SP = 70 ( )

EP = 65 ( )

OSP = 10 (%)

°F

°F

OSP < OEP

OEP

Band

Fig:sys450_cntrl_rmp_exmpl

Figure 6: Control Ramp Example for a Typical

Heating Application (SP > EP and OSP < OEP)

LCD Screen Name, Description/Function, User Action, and Example

Edit Sensor Screen: This screen displays the sensor that this output currently references. Typically, no

Sn-2

action is taken in this screen. But if you need to change the sensor that this output references, you can

select a different sensor for this output in this screen.

Note: Changing the sensor that an output references to a sensor with a different Sensor Type changes

the default setup values for the output, and requires setting up the output again.

8. To change this output’s sensor, Press UP or DOWN to select the sensor that this output will

reference. After you select a different sensor for this output, press NEXT to return to the Relay

ON Selection screen (Step 3 above) and repeat the output relay setup procedure for this output

and the new Sensor Type values associated with the new sensor selection.

If you do not need to change this output’s sensor, simply press NEXT to save the current

sensor selection and return to the Relay Output Setup Start screen.

This Relay Output is now set up in the System 450 UI.

Example shows input Sensor 2 selected for Output 1 (Output 1 references Sensor 2).

Relay Output Setup Start Screen

After you have set up this Relay Output, you can go to another Output Setup Start screen, the Sensor

Setup Start screen, or return to the Main screens.

9. Press MENU to scroll through the remaining Output Setup Start screens and return to the

Sensor Setup Start screen, or press UP and DOWN simultaneously and hold for 5 seconds to

return to the System 450 Main screens.

Example shows the Relay Output Setup-Start screen for Output 1.

Setting up an Analog Output (OUTA#)

Analog outputs provide an auto-selecting analog sign al

that is proportional to the sensed input condition. The

analog output circuit senses the impedance and

automatically selects 0-10 VDC or 4-20 mA operation.

The control action between the input signal and the

output signal can be set up four different ways,

depending on the values selected for the Setpoint (SP),

End Point (EP), %Output Signal Strength at Setpoint

(OSP), and %Output Signal Strength at End Point

(OEP). The LCD displays different Control Ramp icons

for the four control actions.

Figure 6 shows an example of the analog output setup

values and the resulting output signal in a typical sp ace

heating application (SP > EP and OSP < OEP).

Proportional

EP

SP

System Output

OSP

OEP = 10 0 ( % )

Table 6 shows the four Control Ramp icons and the

associated analog output setup value relationships.

Table 6: Analog Output Control Ramp Icons

Control Ramp

Displayed on

LCD

Analog

Output Value

Relationships

SP < EP

OSP < OEP

SP > EP

OSP < OEP

SP > EP

OSP > OEP

SP < EP

OSP > OEP

Output Signal

Strength at

Setpoint

Minimum

Minimum

Maximum

Maximum

See Table 7 for analog output setup information and

procedures.

Condition Value

System 450™ Series Control Modules with Analog Outputs Installation Instructions 9

Page 10

Table 7: System 450 Analog Output Setup Screens Information (Part 1 of 2)

OUTA

3

-- -

SENS

3

Sn-1

3

200

3

250

OSP

3

10

OEP

3

90

I-C

3

0

LCD Screen Name, Description/Function, User Action, Example

Analog Output Setup Start Screen: Output number and the output type (relay or analog) are

automatically assigned when you connect power to your control system’s module assembly.

Note: You must set up the system’s sensors before you can set up the outputs.

1. Press NEXT to go to this output’s Sensor Selection screen.

Example shows the Analog Output Setup-Start screen for Output 3.

Sensor Selection Screen: The Sensor you select here determines this output’s setup parameters and

values, including condition type, unit of measurement, minimum proportional band, default setup values,

and setup value ranges for several of the remaining output setup screens. If a sensor is not selected here,

this output’s remaining setup screens do not appear. If a sensor is already selected for this output, the

Sensor Selection screen does not appear here, instead the Setpoint Selection screen appears.

Note: You must select a sensor in this Sensor Selection screen and the selected sensor must be already

SP

EP

set up in the System 450 UI. (See Setting up System 450 Sensors

2. Press UP or DOWN to select the Sensor (Sn-1, Sn-2, or Sn-3) that this output references. Press

NEXT to save your sensor selection and go to the Setpoint Selection screen.

Example shows input Sensor 1 (Sn-1) selected for Output 3.

Setpoint Selection Screen: Setpoint is the target value that the controlled system drives towards and

along with End Point, defines this output’s proportional band.

Note: An output’s minimum proportional band (between Setpoint and End Point) is automatically

enforced in the output’s Setpoint and End Point Selection screens.

3. Press UP or DOWN to select this output’s Setpoint value. Press NEXT to save your Setpoint

value selection and go to the End Point Selection screen.

Example shows a Setpoint of 200 (psi) selected for Output 3.

End Point Selection Screen: End Point is the (condition) value that the controlled system drives away

from (towards Setpoint) and, along with Setpoint, defines this output’s proportional band.

Note: An output’s proportional band (between Setpoint and End Point) is automatically enforced in the

output’s Setpoint and End Point Selection screens.

4. Press UP or DOWN to select this output’s End Point value. Press NEXT to save your End Point

value selection and go to the %Output Signal Strength at Setpoint Selection screen.

Example shows a End Point of 250 (psi) selected for Output 3.

Output Signal Strength at Setpoint Selection Screen: Select the strength of the signal that this output

generates when the sensed condition is at the Setpoint value. The signal strength range is 0 to 100 (%).

5. Press UP or DOWN to select this output’s %Output Signal Strength at Setpoint value. Press

NEXT to save your selection and go to the %Output Signal Strength at End Point Selection

screen.

Example shows Analog Output 3 is setup to generate 10% of the total signal strength when the input is at

the Setpoint value (= 1 V or 5.6 mA).

Output Signal Strength at End Point Selection Screen: Select the strength of the signal that this output

generates when the sensed condition is at the End Point value. The signal strength range is

0 to 100 (%).

6. Press UP or DOWN to select this output’s %Output Signal Strength at End Point value. Press

NEXT to save your selection and go to the Integration Constant Selection screen.

Example shows Output 3 is set up to generate 90% of the total signal strength when the input is at the End

Point value (= 9 V or 18.4 mA).

Integration Constant Selection Screen: An integration constant allows you to set up proportional plus

integral control for this analog output. proportional plus integral control can drive the load closer to

Setpoint than proportional only control.

Note: Initially, you should select the I-C value of 0 (zero) for no integration constant. Refer to the System

450 Series Technical Bulletin (LIT-12011459) for more information on proportional plus integral control

and setting an integration constant in the System 450 UI.

7. Press UP or DOWN to select this output’s Integration Constant for proportional plus integral

control. Press NEXT to save your selection and go to the Sensor Failure Mode Selection

screen.

Example shows an Integration Constant of 0 (zero) selected for Output 3.

.)

System 450™ Series Control Modules with Analog Outputs Installation Instructions10

Page 11

Table 7: System 450 Analog Output Setup Screens Information (Part 2 of 2)

SNF

3

OFF

3

Sn-1

LCD Screen Name, Description/Function, User Action, Example

Sensor Failure Mode Selection Screen:

8. Press UP or DOWN to select this output’s mode of operation if the sensor or sensor wiring

fails. Press NEXT to save your selection and go to the Edit Sensor Selection screen.

Y ou can select this output’s mode of operation in the event of a sensor or sensor wiring failure. The output

operates in the selected mode until the failure is fixed. Sensor Failure Mode selections for Analog Outputs

include:

• ON - output generates maximum signal strength during sensor failure.

• OFF- output generates minimum signal strength during sensor failure.

Example shows the OFF Sensor Failure Mode selected for Output 3.

Edit Sensor Selection Screen: Press Up or Down to change the sensor that this output references (only

if required), then press Next to go to this output’s setup start screen.

Note: Changing the sensor that an output references to a sensor with a different Sensor Type changes

SENS

the default setup values for the output, and requires setting up the output again.

Example shows input Sensor 1 selected for Output 3.

Technical Specifications

C450CxN-1 (Part 1 of 2)

Product C450CxN-1: System 450 Control Module models are sensing controls and operating

controls with LCD, four-button touch pad, and analog output.

C450CPN-1: Control Module with One Analog Output

C450CQN-1: Control Module with Two Analog Outputs

Supply Power C450YNN-1 Power Supply Module or

24 (20-30) VAC Safety Extra-Low Voltage (SELV) (Europe) Class 2 (North America)

50/60 Hz, 10 VA minimum

Ambient Operating Conditions Temperature: -40 to 66°C (-40 to 150°F) when using 0-10 VDC outputs;

-40 to 40°C (-40 to 104°F) when using 4-20 mA outputs

Humidity: Up to 95% RH noncondensing; Maximum Dew Point 29°C (85°F)

Ambient Shipping and Storage

Conditions

Input Signal 0-5 VDC; 1035 ohms at 25°C (77°F) for an A99 PTC Temperature Sensor

Analog Output Voltage Mode (0–10 VDC):

Analog Input Accuracy Resolution: 14 bit

Control Construction Independently-mounted control, surface mounted with Lexan® 950 enclosure suitable

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450CPN-1: 195 g (0.43 lb)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing; Maximum Dew Point 29°C (85°F)

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohm or more

Note: The AO operates in Voltage Mode when connected to devices with

impedances greater than 1,000 ohm. Devices that drop below 1,000 ohm may not

operate as intended for Voltage Mode applications.

Current Mode (4–20 mA):

Requires an external load between 0–300 ohm

Note: The AO operates in Current Mode when connected to devices with

impedances greater than 1,000 ohm. Devices that drop below 1,000 ohm may not

operate as intended for Current Mode applications.

for DIN rail mounting or direct mounting to a hard, even surface.

C450CQN-1: 195 g (0.43 lb)

System 450™ Series Control Modules with Analog Outputs Installation Instructions 11

Page 12

C450CxN-1 (Part 2 of 2)

Compliance North America: cULus Listed; UL 60730, File E27734, Vol. 1; FCC Compliant to

CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: Mark: CE Compliant; Low Voltage Directive (2006/95/EC); EMC Directive

(2004/108/EC); RoHS Directive (2002/95/EC); WEEE Directive (2002/96/EC)

Australia: Mark: C-Tick Compliant (N1813)

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult Johnson Controls Application Engineering at (414) 524-5535. Johnson Controls, Inc. shall not be liable for damages

resulting from misapplication or misuse of its products.

United States Emissions Compliance

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Canadian Emissions Compliance

This Class (B) digital apparatus meets all the requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe (B) respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

System 450™ Series Control Modules with Analog Outputs Installation Instructions12

Page 13

Figure 7: System 450 Status Screens, Setup Screens, and Menu Flow Example

Relay Output

Setup Start

OUTR

1

-- -

Sensor 2 S elected.

(Displayed only when a

Sensor is selected.)

not

Up to

ten

Outputs

can be

connected

and

set up.

M

Relay

Output

1

OUTA

3

OutputAnalog

Setup Start

Analog

Output

3

Select Relay ON

Value

ON

1

78

Relay

at ºF

1ON

78

OFF

1

Select Relay OFF

Value

Relay

at ºF

1OFF

75

Select Mini

Relay ON

ONT

1

0

Relay

Seconds

(Minimum)

1ON

0

)

Select

Setpoin t Value

Prop. Band

SP

3

200

Analog Output

Prop. Band

Setpoint psi

3

200

Sele

End

Ana

End

FIG:menu_flw_chrt

M

232

PSI

1

Main Screen

Sensor 2 S t at us

74

2

F

Sensor 1 St at us

Up to ten Outp

can be set up

displayed.

Relay Output 2

Status

OFF

OUT

2

Output 2 Relay

OFF

Relay Output 1

Status

OUT

1

Output 1 Relay

On

Analog Output 3

Status

64

OUT

3

Output 3 Signal

at % of Range

64

Control Sensor 3

Status

----

3

Control Sens or 3

Not Set Up

Control Sensor 2

Status

74ºF

74

2

F

232

PSI

1

Control Sensor 1

Status

232 psi

Sensor Setup

Screens

System Status

Screens

Main Screens

(Sensor Status)

Relay Output

Setup Screens

Analog O utput

Setup Screens

M

Press and hold +

for 5 seconds to go to

the Setup Start screens.

Press to scroll through

Sensor Status screens and

Output S tatus screens.

Select

Control Se nsor

Sn-2

SENS

SENS

Sensor Type

Setup Start

-- -

Select Sensor 2

Type

°F

Sensor Type

(-40 to 250ºF)

ºF

Select Sensor 3

Type

--

No

Sensor Type

Selected

Select Sensor 1

Type

P500

Sn-1

Sn-2 Sn-3

3

Select

Control Sensor

SENS

3

Sensor 1 Selected

(Displayed only

when a Sensor

is selected.)

not

Sn-1

)

Select

Te mperature (on

Offset Degree

-3

OFFS

During norm al operation, the display autom at i c

for all sensor s s et up in th e UI.

After a 2 min ut e pause in any setup or stat us s

Main (Sen sor Status) screens.

Press in any Setup screen to go to the asso

Press + simultaneously in any Setup Star

M

On

2

M

-- -

Output 2

Setup Start

Screen

3

Edit

Control Sensor

1

1

Sn-2

2

SENS

Controls Relay

Sensor (Sn-2

1

1OFF

Failure Mode

Select Sensor

uts

and

Edit

Contr ol Sensor

OFF

Relay

Failure Mode

ally scro lls through the Sensor S t at us screens

Main Screen

ciated Setup Start screen.

creen (below), the display retur ns to the

t screen to return to the Main screen.

ly)

s

Select Sensor

Select Minimum

Relay OFF Time

mum

Time

SNF

1

120

OFFT

if Sensor 2 Fails

1OFF

Seconds

(Minimum

120

Relay

Constant Value

Select Integration

at End Point

Signal Value

Select % Output

at Setpoint

Signal Value

Select % Output

Point Value

ct Prop. Band

1

Sn-1

SENS

Sensor (Sn-1)

3

3

OFF

SNF

Analog Output

3

0

3

I-C

Analog Output

90

3

90

OEP

Output Signal %

10

3

10

OSP

Output S ig nal %

3

3

250

EP

log Output Prop. Band

Controls

if

OFF

Integration

No

of Range at

of Range at

Analog Out put

Sensor 1 Fails

Constant

Value

End Point

Value

Setpoint

250

Point psi

System 450™ Series Control Modules with Analog Outputs Installation Instructions 13

Page 14

System 450™ Series Control Modules with Analog Outputs Installation Instructions14

Page 15

System 450™ Series Control Modules with Analog Outputs Installation Instructions 15

Page 16

System 450™ Series Control Modules with Analog Outputs Installation Instructions16

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2009 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...