Page 1

System 450 Control System with a Control, Power,

and Expansion Module

System 450 Control Series

System 450™ Series Modular Controls

Description

System 450™ is a family of modular, digital electronic controls that is

easily assembled and set up to provide reliable temperature, pressure,

and humidity control for a wide variety of HVAC/R applications,

commercial process applications, and industrial process applications.

The System 450 control system is designed to replace System 350™

and System 27 control systems, and to provide many additional

features and benefits with fewer than twenty model variations.

System 450 control modules provide a field-configurable

out-of-the-box solution. Most System 450 control modules can control

temperature, pressure, and humidity systems simultaneously.

System 450 Control Modules with Communications enable you to

connect System 450 control systems to Modbus® or Ethernet

networks for remote monitoring and setup. The Modbus

communications control module is an RS485, RTU-compliant slave

device. The Ethernet communications control module has an integral

web server that can deliver web pages by means of a direct

connection, on your LAN, or across the Internet.

System 450 Reset Control Modules provide many of the features of the

standard models for temperature and humidity control. In addition,

these modules provide setpoint reset, real-time setback scheduling,

and run-time balancing (equal run time) capability.

The System 450 Control Module with Hybrid Analog Output has a

single self-selecting analog output to optimize and extend the

controlled speed range of variable speed electronically commutated

(EC) motors.

Refer to the following documents for important product application

information.

• System 450™ Series Modular Controls Product Bulletin

(LIT-12011458)

• System 450™ Series Modular Control Systems with Standard

Control Modules Technical Bulletin (LIT-12011459)

• System 450™ Series Modular Control Systems with Reset Control

Modules Technical Bulletin (LIT-12011842)

• System 450™ Series Modular Control Systems with

Communications Control Modules Technical Bulletin

(LIT-12011826)

Features

• durable, compact, interchangeable modular components with

plug-together connectors and DIN rail or direct wall mount capability

eliminate field wiring between modules and allow you to quickly and

easily design, assemble, install, and upgrade your control systems.

• versatile, multipurpose, field-configurable control modules and

expansion modules designed for global use allow you to create a

wide variety of application-specific control systems capable of

controlling temperature, pressure, or humidity, or all three

conditions simultaneously, with only a small suite of module

models.

• up to three hard-wired input sensors and up to ten relay or analog

outputs (in any combination) per control system allow you to build

complex custom control systems while reducing your control

system cost to only the cost of the required components.

• control Modules with bright backlit LCDs and four-button touch pad

user interfaces provide quick, clear, visual status of your

System 450 control system inputs and outputs with the touch of a

button and enable you to quickly and easily set up and adjust your

control system.

Code No. LIT-1900549

• multipurpose, all-in-one control modules enable simple

stand-alone, single-module control systems that are temperature,

pressure, and humidity capable out of the box and easy to set up in

the field to replace a wide variety of OEM HVAC/R and process

controls.

• an extensive suite of compatible temperature and humidity sensors,

and pressure transducers allows you to monitor and control a wide

range of HVAC/R and process conditions in a variety of standard

and global units of measurement.

• high input signal selection enables your control system to monitor a

temperature, pressure, or humidity condition with two or three

sensors (of the same type) and control your system outputs based

on the highest condition value sensed by the referenced sensors.

• differential control enables your control system to monitor and

maintain a temperature, pressure, or humidity differential between

two sensor points within a system, process, or space.

The Reset Control modules have additional features:

• adjustable minimum and maximum setpoint temperatures (reset

control modules only) enable compliance with the manufacturer’s

specifications for your controlled HVAC/R and process equipment.

• selectable shutdown-high and shutdown-low temperature settings

(reset control modules only) saves you energy by shutting down

controlled equipment when the ambient temperature either rises or

drops to a point where heating or cooling is no longer required.

• real time clock and adjustable setback temperature (reset control

modules only) save you energy by setting back heating, cooling, or

humidity setpoints during scheduled unoccupied periods (24-hour

day, 7-day week schedule).

• user-defined reset control capability (reset control modules only)

saves you energy in a wide variety of temperature and humidity

reset control applications by adjusting the temperature or humidity

control loop, based on changes in ambient outdoor temperature or

other uncontrolled condition.

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-192

Page 2

System 450 Control Series

System 450™ Series Modular Controls (Continued)

The Control Modules with Communications have additional

features:

• Ethernet communication capability through a built-in web server

(Ethernet Control Modules only) allows you to monitor your control

system status and set up or change the parameters by means of

a direct Ethernet cable connection, through a LAN connection, or

over the Internet. The built in web server delivers user-friendly web

pages to client browsers on a desktop, laptop, tablet, or smart

device.

• The Web page server on Ethernet communication modules

provides a simple, intuitive web interface for easy remote

monitoring, setup, adjustment and remote monitoring of your

control systems across Ethernet networks.

• RS485, RTU-compliant Modbus® network communication

capability (Modbus control modules only) enables a head-end

RS485 Modbus master controller to read and write control system

status and setup parameters to the System 450 Modbus

communication control module.

• Password protection for local access (Ethernet and Modbus

control modules only) and password protection for remote access

(Ethernet control module only) deters unauthorized changes to the

control system settings, but allows local and remote monitoring of

your control system status.

• Analog output signal limiting features (communication control

modules only) allow you to select the rate and condition range at

which the control updates the analog output signal, potentially

reducing wear on the controlled equipment.

• Binary input with time delay (communication control modules only)

allows you to use an external set of dry contacts and selectable

time delays to control relay outputs.

Applications

You can create a wide variety of custom, application-specific control

systems with System 450 modules. The following are some common

control application examples:

• Temperature control

• Pressure control

• Humidity control

• Multipurpose control

• Reset and setback control

• High input-signal selection

• Differential control

Temperature Control

• Temperature monitoring and alarming

• On/Off staged control of boilers and chillers

• Proportional stage control of boilers and chillers

• Boiler and chiller pump control

• Heating and cooling control with deadband

• Floating temperature control of damper and valve actuators

• Cooling tower fan speed/stage control based on water

temperature

• Supply, make-up, and mixed air temperature control

• Temperature actuated valve control

• Supply and make-up air damper and fan control

• Condenser fan staging or speed control based on condenser

temperature

Refrigerant Pressure Control

• Condenser fan cycling and stage control

• Multispeed condenser fan control

• Floating pressure control of damper and valve actuators

• Condenser fan speed and damper control

• High and low pressure cutout control

• Staged compressor control

• Cooling tower fan speed control based on high-side pressure

• Direct speed control of electronically commutated (EC) condenser

fan motors (C450CPW-100 model)

Other Pressure Control

• Relief damper and fan control for building pressurization

• Constant static pressure control

Humidity Control

• On/Off humidification and dehumidification control

• Proportional humidification and dehumidification control

• Multistage humidification and dehumidification control

• Humidity monitoring and alarming

Multipurpose Control

• Temperature and pressure based refrigeration rack control

• Temperature and humidity control of wine cellars and greenhouses

• Temperature, humidity, and static pressure control of clean rooms

and greenhouses

• Dehumidification with reheat control

Reset Control

• Boiler supply water temperature reset control based on outside air

temperature

• Chiller supply water temperature reset control based on outside air

temperature

• VAV zone temperature control based on outside air temperature

• Humidity reset based on outside air temperature

• Staged applications with runtime balancing

• Real-time Occupied/Unoccupied Setback

High Input Signal Selection

• Pressure-based fan speed or fan cycling control on multi-circuit

condensers

• Temperature-based fan speed or fan cycling control on

multi-circuit condensers

Differential Control

• Air and fluid pump-flow monitoring and alarming

• Air and fluid filter status monitoring and alarming

• Chiller barrel flow monitoring, control, and alarming

• Solar air and water heating applications

Note: Communications modules add network communication to any

application of your choosing, except those requiring reset, setback, or

EC motor control.

Repair Information

If a System 450 module fails to operate within its specifications,

replace the module. For a replacement module, contact your

Johnson Controls® representative.

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-193

Page 3

System 450 Control Series

System 450™ Series Modular Controls (Continued)

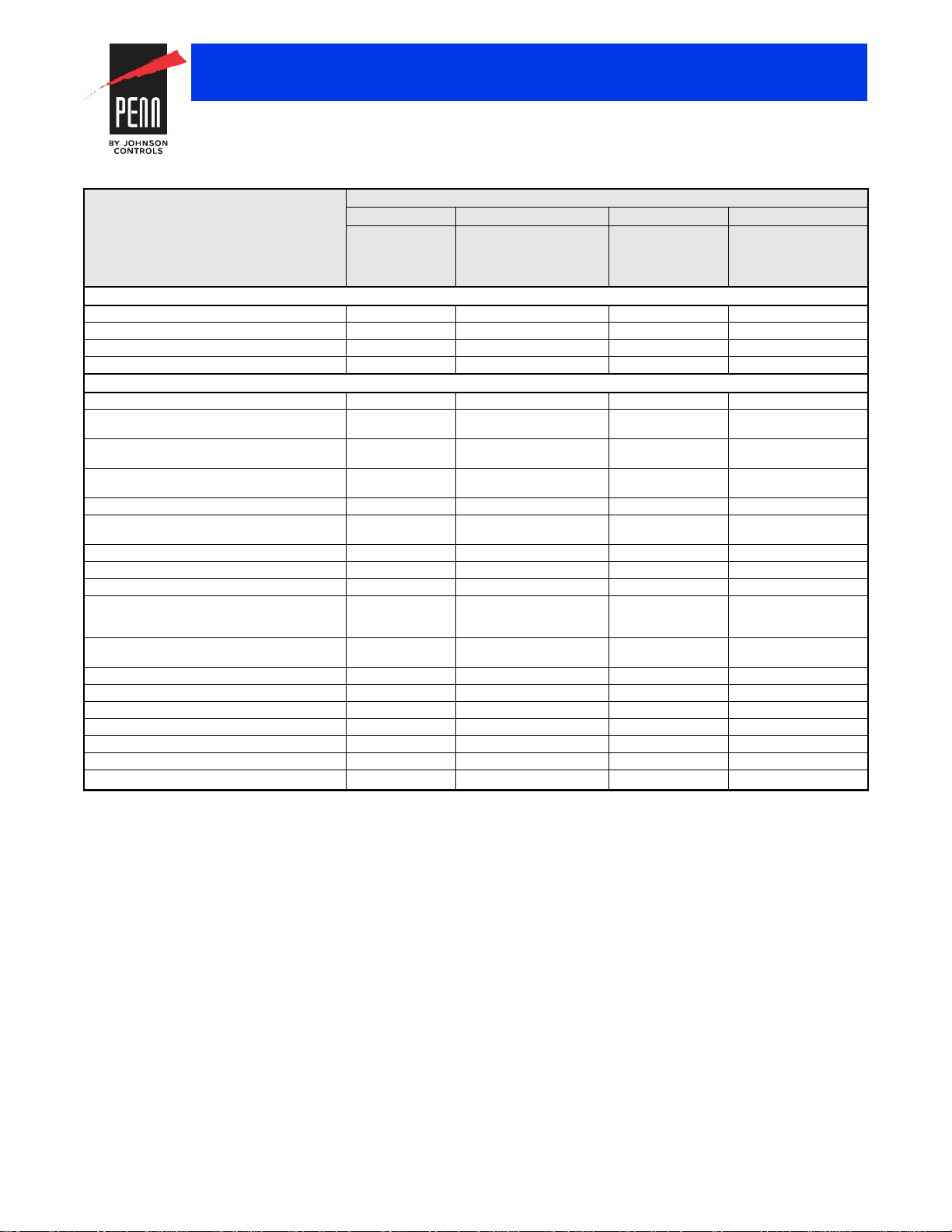

System 450 Control Module Capabilities

Control by ________ System 450 Control Modules

Standard Communications Reset Hybrid

C450CPN-3C

C450CQN-3C

C450CBN-3C

C450CCN-3C

Temperature

Pressure -

Humidity

Combination of Conditions

On/Off Relay Control

Analog Proportional Control

(Direct and Reverse Action)

Analog Proportional Plus Integral Control (Direct

and Reverse Action)

Combination of On/Off Relay and Analog Output

Control

Stand-Alone Control -

Multi-Stage Control

(Relay or Analog)

Network Communications - -High Input Signal Selection -

Differential Control -

Output Signal Limiting

Output Signal Update Rate

Output Signal Deadband

Binary Input Control for

Relay Outputs

On/Off Duration Time Control - -Temperature and Humidity Reset Control -- -

Scheduling and Temperature Setback Control -- -

Reset Setpoint Control -- -

Setback Scheduling -- -

Run-Time Balancing -- -

Hybrid Analog Output Control -- -

1. Only on output OUTA1.

- --

- --

C450CEN-1C

C450CRN-1C

Controlled Condition

Control Capabilities

C450RBN-3C

C450RCN-3C

C450CPW-100C

1

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-194

Page 4

System 450 Control Series

System 450™ Series Modular Controls (Continued)

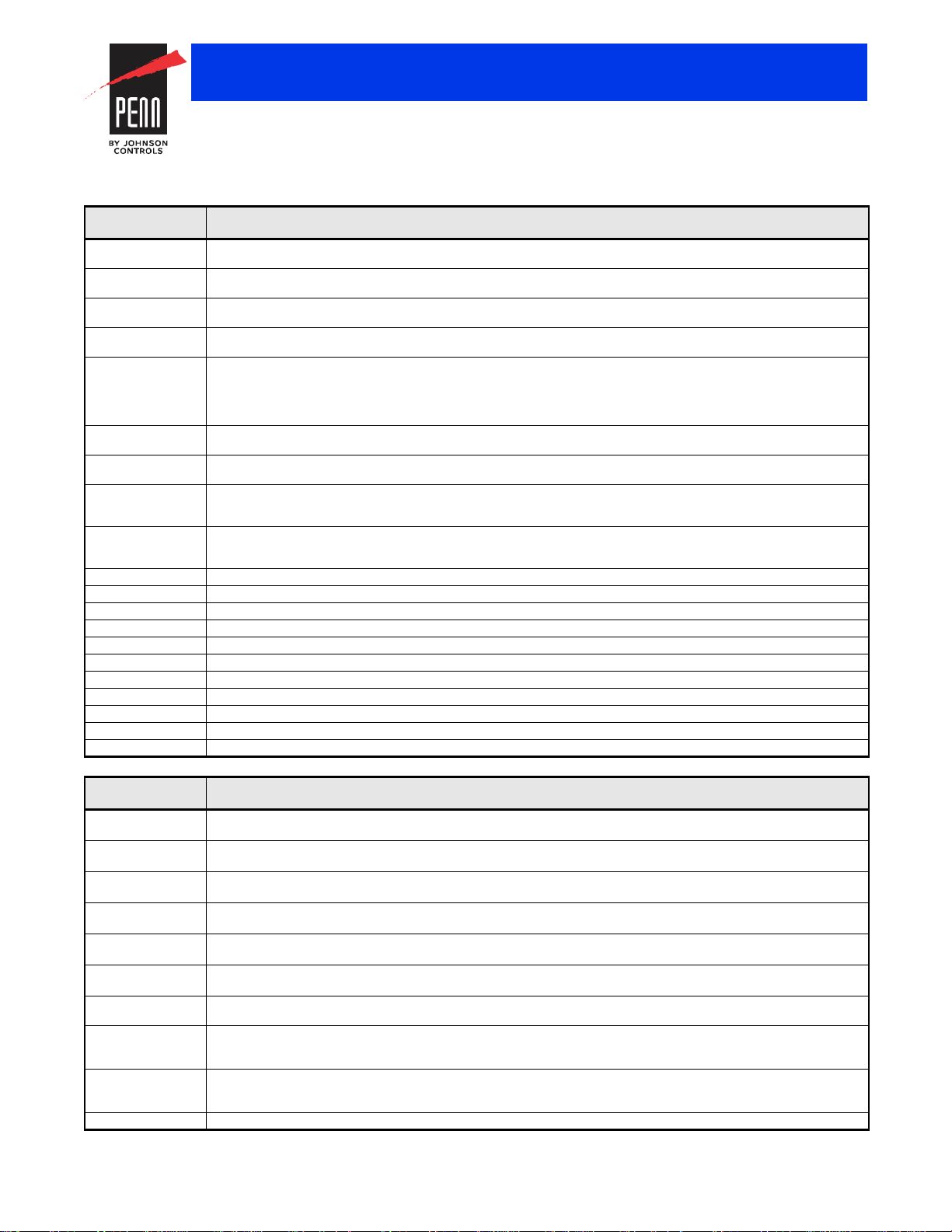

Selection Charts

System 450 Modules and Accessories Ordering Information

Product Code

Product Description

Number

C450CBN-3C Standard Control Module with LCD, Four-Button Touchpad UI, and Relay Output; provides one relay output (SPDT line-voltage relay) for

C450CCN-3C Standard Control Module

C450CEN-1C Control Module with Ethernet Communications, LCD, and Four-Button Touchpad UI. (No onboard outputs available on control modules

C450CPN-3C Standard Control Module with LCD, Four-Button Touchpad UI, and Analog Output; provides one analog output (0 to 10 VDC or 4 to

C450CPW-100C Hybrid Analog Output Control Module with LCD, Four-Button Touchpad UI, Hybrid Analog Output and Optional High Input Signal Select;

C450CQN-3C Standard Control Module with LCD and Four-Button Touchpad UI, and Analog Output; provides two analog outputs (0 to 10 VDC or

C450CRN-1C Control Module with RS485 Modbus Communications, LCD, and Four-Button Touchpad UI. (No onboard outputs available on control

C450RBN-3C Reset Control Module with LCD, Four-Button Touchpad UI, and SPDT relay output; provides one SPDT output relay. One A99BC-25C

C450RCN-3C Reset Control Module with LCD, Four-Button Touchpad UI, and SPDT relay output; provides two SPDT output relays. One A99BC-25C

C450SBN-3C Relay Output Expansion Module; provides one SPDT line-voltage relay output.

C450SCN-3C Relay Output Expansion Module; provides two SPDT line-voltage relay outputs.

C450SPN-1C Analog Output Expansion Module; provides one analog output (0 to 10 VDC or 4 to 20 mA self-selecting signal) for proportional control.

C450SQN-1C Analog Output Expansion Module; provides two analog outputs (0 to 10 VDC or 4 to 20 mA self-selecting signals) for proportional control .

C450YNN-1C Power Module; provides 24 V to System 450 Module Assembly; 120 VAC or 240 VAC supply power input terminals.

BKT287-1R DIN Rail; 0.30 m (12 in.) long

BKT287-2R DIN Rail; 1 m (39-1/3 in.) long

BKT287-3R DIN Rail; 0.61 m (24 in.) long

BKT287-4R DIN Rail; 0.36 m (14 in.) long

PLT344-1R DIN Rail End Clamps (2 clamps)

WHA-C450-100C System 450 module connection extension cable, 100 cm (3.3 ft) long

SPDT control.

for SPDT control.

with network communications capabilities.)

20 mA self-selecting signal) for proportional control.

provides one hybrid analog output and optional high input signal select primarily used for variable-speed EC motor speed control.

Only Analog Output 1 (OUTA1) can be configured as a hybrid analog output and/or use the High Input Signal Selection feature. These

features are not available for any of the other outputs in a System 450 control system that uses the C450CPW-100C as the control

module.

4 to 20 mA self-selecting signals) for proportional control.

modules with network communications capabilities.)

temperature sensor with 0.25 m (9-1/4 in.) silicon leads and one A99BC-300C temperature sensor with 3 m (9 ft 10 in.) silicon leads are

included in the box with the Reset Control Module.

temperature sensor with 0.25 m (9-1/4 in.) silicon leads and one A99BC-300C temperature sensor with 3 m (9 ft 10 in.) silicon leads are

included in the box with the Reset Control Module.

with LCD, Four-Button Touchpad UI, and Relay Output; provides two relay outputs (SPDT line-voltage relays)

System 450 Compatible A99B Temperature Sensors and Accessories Ordering Information1 (Part 1 of 2)

Product Code

Product Description

Number

A99BA-200C PTC Silicon Sensor with Shielded Cable; Cable Length 2 m (6-1/2 ft); Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

A99BB-25C PTC Silicon Sensor with PVC Cable; Cable Length 0.25 m (9-3/4 in.); Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

A99BB-200C PTC Silicon Sensor with PVC Cable; Cable Length 2 m (6-1/2 ft); Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

A99BB-300C PTC Silicon Sensor with PVC Cable; Cable Length 3 m (9-3/4 ft); Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

A99BB-500C PTC Silicon Sensor with PVC Cable; Cable Length 5 m (16-3/8 ft); Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

A99BB-600C PTC Silicon Sensor with PVC Cable; Cable Length 6 m (19-1/2 ft); Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

A99BC-25C PTC Silicon Sensor with High Temperature Silicon Cable; Cable Length 0.25 m (9-3/4 in.);

A99BC-300C PTC Silicon Sensor with High Temperature Silicon Cabl e; Cable Length 3 m (9-3/4 ft)

A99BC-1500C PTC Silicon Sensor with High Temperature Silicon Cable; Cable Length 15 m (49 ft)

BOX10A-600R PVC Enclosure for A99 Sensor; Includes Wire Nuts and Conduit Connector (for Outdoor Sensor)

Cable Jacket Temperature Range: -40 to 100°C (-40 to 212°F)

Cable Jacket Temperature Range: -40 to 100°C (-40 to 212°F)

Cable Jacket Temperature Range: -40 to 100°C (-40 to 212°F)

Cable Jacket Temperature Range: -40 to 100°C (-40 to 212°F)

Cable Jacket Temperature Range: -40 to 100°C (-40 to 212°F)

Cable Jacket Temperature Range: -40 to 100°C (-40 to 212°F)

Sensor Temperature Range: -40 to 120°C (-40 to 250°F) Cable Jacket Rated for Full Sensor Temperature Range.

Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

Cable Jacket Rated for Full Sensor Temperature Range.

Sensor Temperature Range: -40 to 120°C (-40 to 250°F)

Cable Jacket Rated for Full Sensor Temperature Range.

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-195

Page 5

System 450 Control Series

System 450™ Series Modular Controls (Continued)

System 450 Compatible A99B Temperature Sensors and Accessories Ordering Information1 (Part 2 of 2)

Product Code

Number

WEL11A-601R Immersion Well for A99 Sensor Liquid Sensing Applications

A99-CLP-1 Mounting Clip for A99 Temperature Sensor

ADP11A-600R Conduit Adaptor, 1/2 in. Snap-Fit EMT Conduit Adaptor (box of 10)

TE-6001-1 Duct Mounting Hardware with Handy Box for A99 Sensor

TE-6001-11 Duct Mounting Hardware without Handy Box for A99 Sensor

SHL10A-603R Sun Shield (for Use with Outside A99 Sensors in Sunny Locations)

1. Refer to the A99B Series Temperature Sensors Product/Technical Bulletin (LIT-125186) on the Johnson Controls® Product Literature website for more

information.

System 450 Compatible TE-6000 Series 1,000 Ohm Nickel Temperature Sensors and Accessories Ordering Information

Product Code

Number

TE-6000-x TE6000 Series 1,000 oh m at 70F nickel temp erature sensors (only). On ly the TE- 6000-6 sensor can be used for the ent ire HIC and HIF

System 450 Compatible TE-6300 Series 1,000 Ohm Nickel Temperature Sensors and Accessories Ordering Information

Product Code

Number

TE-631xx-x TE6300 Series 1,000 ohm at 70F nickel averaging and 1,000 ohm thin-film nickel temperature sensors (only). For a complete list of

System 450 Compatible TE-68NT-0N00S 1,000 Ohm Nickel Temperature Sensor Ordering Information

Product Code

Number

TE-68NT-0N00S TE6800 Series 1,000 ohm nickel temperature sensor for wall-mount applications. For more information, including sensor description,

System 450 Compatible HE67S3 Type Humidity Sensors with Integral A99B Temperature Sensor Ordering Information

Product Code

Number

HE-67S3-0N0BT Wall Mount Humidity Sensor with A99B Type Temperature Sensor: 10 to 90% RH; 0 to 60C (32 to 140F)

HE-67S3-0N00P Duct Mount Humidity Sensor with A99B Type Temperature Sensor: 10 to 90% RH; 0 to 60C (32 to 140F)

1. The HE-67S3 sensors require 24 VAC input and must use the 0–5 VDC output. Refer to the TrueRH Series HE-67xx Humidity Element with Temperature

Sensors Product Bulletin (LIT-216245) on the Johnson Controls Product Literature website for more information, including tech nical specif icati ons and mounti ng

accessories.

System 450 Compatible HE6800 Series Humidity Transmitters with Temperature Sensor Ordering Information

Product Code

Number

HE-68N2-0N00WS Wall Mount Humidity Transmitter with Nickel Temperature Sensor: 10 to 90 ±2% RH; 0 to 55C (32 to 131F)

HE-68N3-0N00WS Wall Mount Humidity Transmitter with Nickel Temperature Sensor: 10 to 90 ±3% RH; 0 to 55C (32 to 131F)

1. The HE-6800 transmitters require 24 V AC input and must use t he 0–5 VDC outp ut. Refer to the HE-6800 Series Humidity Transmitters with Temperature Sensor

Product Bulletin (LIT-12011625) on the Johnson Controls Product Literature website for more information, including technical specifications and mounting

accessories.

System 450 Compatible Low Pressure Differential Transducer Ordering Information1

Product Code

Number

DPT2650-R25B-AB Low Pressure Differential Transducer: -0.25 to 0.25 in. W.C. (System 450 Sensor Type: P 0.25)

DPT2650-0R5D-AB Low Pressure Differential Transducer: 0 to 0.5 in. W.C. (System 450 Sensor Type: P 0.5)

DPT2650-2R5D-AB Low Pressure Differential Transducer: 0 to 2.5 in. W.C. (System 450 Sensor Type: P 2.5)

DPT2650-005D-AB Low Pressure Differential Transducer: 0 to 5.0 in. W.C. (System 450 Sensor Type: P 5)

DPT2650-10D-AB Low Pressure Differential Transducer: 0 to 10 in. W.C. (System 450 Sensor Type: P 10)

1. Refer to the Setra Systems Model DPT265 Very Low Differential Pressure Transducer Catalog Page on the Johnson Controls Product Literature website for

more information.

2. The DPT265 sensors require 24 VAC input and must use the 0–5 VDC output. Refer to the Setra Systems Model DPT265 Very Low Differential Pressure

Transducer Catalog Page on the Johnson Controls Product Literature website for more information.

3. Used only with Communications Control Modules.

Product Description

Product Description

temperature range. Different sensing element packages are available for various applications. For a complete list of compatible 1,000

ohm nickel sensors, including sensor descriptions, technical specifications, and mounting accessories, refer to the

TE-6000 Series Temperature Sensing Elements Product Bulletin (LIT-216288). (System 450 Sensor Types HIC and HIF)

Product Description

compatible 1,000 ohm nickel averaging an d thin -fil m ni ckel sens ors, in cl uding sensor descri pti ons, technical specif ications, and mounting

accessories, refer to the TE-6300 Series Temperature Sensors Product Bulletin (LIT-216320). (System 450 Sensor Types HIC and HIF)

Product Description

technical specifications, and mounting accessories, refer to the TE-6800 Series Temperature Sensors Product Bulletin (LIT-12011542).

(System 450 Sensor Types HIC and HIF)

1

Product Description

1

Product Description

2

Product Description

3

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-196

Page 6

System 450 Control Series

System 450™ Series Modular Controls (Continued)

System 450 Compatible P499 Series Transducers with 1/4 in. SAE 45 Flare Internal Thread with Depressor (Style 47) Ordering

Information

Product Code

1

Product Description

Number

P499RCP-401C -1 to 8 bar; order WHA-PKD3 typ e wi r e ha r n e ss s epara t e ly

P499RCP-402C -1 to 15 bar; order WH A-PKD3 type wire harness separately

P499RCP-404C 0 to 30 bar; order WHA-PKD3 type wire harness separately

P499RCP-405C 0 to 50 bar; order WHA-PKD3 type wire harness separately

P499RCPS100C -10 to 100 psis (sealed for wet and freeze/thaw applications); order WHA-PKD3 type wire harness separately

P499RCPS100K -10 to 100 psis (sealed for wet and freeze/thaw applications); WHA-PKD3-200C wire harness included

P499RCPS102C 0 to 200 psis (sealed for wet and freeze/thaw applications); order WHA-PKD3 type wire harness separately

P499RCPS102K 0 to 200 psis (sealed for wet and freeze/thaw applications); WHA-PKD3-200C wire harness included

P499RCP-101C 0 to 100 psi; order WHA-PKD3 type wire harness separately

P499RCP-101K 0 to 100 psi; WHA-PKD3-200C wire harness included

P499RCP-105C 0 to 500 psi; order WHA-PKD3 type wire harness separately

P499RCP-105K 0 to 500 psi; WHA-PKD3-200C wire harness included

P499RCP-107C 0 to 750 psi; order WHA-PKD3 type wire harness separately

P499RCP-107K 0 to 750 psi; WHA-PKD3-200C wire harness included

1. The P499 sensors must be powered with the +5 VDC and C terminals and the output is 0.5 to 4.5 VDC. Refer to the P499 Series Electronic Pressure

Transducers Product/Technical Bulletin (LIT-12011190) on the Johnson Controls Product Literature website for more information.

System 450 Compatible P499 Series Transducers with 1/8 in. 27 NPT External Thread (Style 49) Ordering Information1

Product Code

Product Description

Number

P499RAPS100C -10 to 100 p s is (sealed for wet and freeze/thaw applications); order WHA-PKD3 type wire harness separately

P499RAPS100K -10 to 100 psis (sealed for wet and freeze/thaw applications); WHA-PKD3-200C wire harness included

P499RAPS102C 0 to 200 psis (sealed for wet and freeze/thaw applications); order WHA-PKD3 type wire harness separately

P499RAPS102K 0 to 200 psis (sealed for wet and freeze/thaw applications); WHA-PKD3-200C wire harness included

P499RAP-101C 0 to 100 psi; order WHA-PKD3 type wire harness separately

P499RAP-101K 0 to 100 psi; WHA-PKD3-200C wire harness included

P499RAP-102C 0 to 200 psi; order WHA-PKD3 type wire harness separately

P499RAP-105C 0 to 500 psi; order WHA-PKD3 type wire harness separately

P499RAP-105K 0 to 500 psi; WHA-PKD3-200C wire harness included

P499RAP-107C 0 to 750 psi; order WHA-PKD3 type wire harness separately

P499RAP-107K 0 to 750 psi; WHA-PKD3-200C wire harness included

1. The P499 sensors must be powered with the +5 VDC and C terminals and the output is 0.5 to 4.5 VDC. Refer to the P499 Series Electronic Pressure

Transducers Product/Technical Bulletin (LIT-12011190) on the Johnson Controls Product Literature website for more information.

WHA-PKD3 Wire Harnesses Ordering Information

Product Code

Product Description

1

Number

WHA-PKD3-200C Plug and Three-Wire Harness for P499 Electronic Pressure Transducers: 2.0 m (6-1/2 ft) cable

WHA-PKD3-400C Plug and Three-Wire Harness for P499 Electronic Pressure Transducers: 4.0 m (13 ft) cable

WHA-PKD3-600C Plug and Three-Wire Harness for P499 Electronic Pressure Transducers: 6.0 m (19-5/8 ft) cable

1. Refer to the P499 Series Electronic Pressure Transducers Product/Technical Bulletin (LIT-12011190) on the Johnson Controls Product Literature website for

more information.

Technical Specifications

C450CPN-3C and C450CQN-3C Control Modules with Analog Output (Part 1 of 2)

Product C450CPN-3C and C450CQN-3C: System 450 Control Module models are sensing controls and oper ating controls with

Power Consumption C450CPN-3C: 1.3 VA maximum using 0 to 10 V out; 1.5 V A maximum using 4 to 20 mA out

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

LCD, four-button touchpad, and SPDT analog output

C450CPN-3C: Control Module with one analog output

C450CQN-3C: Control Module with two analog outputs

C450CQN-3C: 2.0 VA maximum using 0 to 10 V out; 2.4 VA maximum using 4 to 20 mA out

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

R-197

Page 7

System 450 Control Series

System 450™ Series Modular Controls (Continued)

C450CPN-3C and C450CQN-3C Control Modules with Analog Output (Part 2 of 2)

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F) when using 0–10 VDC outputs;

Ambient Shipping and Storage

Conditions

Input Signal 0 to 5 VDC for humidity sensors and static pressure transducers

Analog Output Voltage Mode (0–10 VDC):

Analog Input Accuracy Resolution: 14 bits

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450CPN-3C: 195 g (0.43 lb)

Compliance North America: cULus Listed; UL 60730, File E27734;

-40 to 40C (-40 to 104F) when using 4–20 mA outputs

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

0.5 to 4.5 VDC for ratiometric pressure transducers

1,035 ohms at 25C (77F) for A99 PTC temperature sensors

1,000 ohms at 21.1C (70F) for TE-6xxx Nickel temperature sensors

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohms or more

The AO operates in Volta ge Mode when connected to devices with impedance greater than 1,000 ohms. Devices that

fall below 1,000 ohms may not operate as intended with Voltage Mode applications.

Current Mode (4–20 mA):

Requires an external load between 0 to 300 ohms

The AO operates in Current Mode when connected to devices with impedance less than 300 ohms. Devices that rise

above 300 ohms may not operate as intended with Current Mode applications.

mounting to a hard, even surface.

C450CQN-3C: 195 g (0.43 lb)

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia: Mark: C-Tick Compliant (N1813)

C450CEN-1C Control Module with Ethernet Communications

Product C450CEN: System 450 control modules are sensing controls and operating controls with LCD and four-button

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F)

Ambient Shipping and Storage

Conditions

Input Signal 0 to 5 VDC; 1,035 ohms at 25C (77F) for an A99 PTC Temperature Sensor

Analog Input Accuracy Resolution: 16 bits

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 63 x 63 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450CEN-1C: 207 g (0.46 lb)

Compliance Nor th America: cULus Listed; UL 60730, File E27734;

touchpad UI, Ethernet communications capability, and no outputs.

C450CEN-1C: Control module with Ethernet communications capability

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

mounting to a hard, even surface.

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive; Low Voltage Directive; CISPR22, class B.

Australia: Mark: C-Tick Compliant (N1813)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-198

Page 8

System 450 Control Series

System 450™ Series Modular Controls (Continued)

C450CRN-1C Control Module with RS485 Modbus Communications

Product C450CRN-1C: System 450 control modules are sensing controls and operating controls with LCD and four-button

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F)

Ambient Shipping and Storage

Conditions

Input Signal 0 to 5 VDC; 1,035 ohms at 25C (77F) for an A99 PTC Temperature Sensor

Analog Input Accuracy Resolution: 16 bits

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 63 x 63 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450CRN-1C: 207 g (0.46 lb)

Compliance North America: cULus Listed; UL 60730, File E27734:

touchpad UI and no outputs. This control module is an RS485, RTU compliant Modbus slave device.

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

mounting to a hard, even surface.

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive; Low Voltage Directive; CISPR22, class B

Australia: Mark: C-Tick Compliant (N1813)

C450CPW-100C Control Module with Hybrid Analog Output (Part 1 of 2)

Product C450CPW-100C System 450 control module is a sensing control and operating control with LCD, four-button

Power Consumption C450CPW-100C: 1.3 VA maximum using 0 to 10 V out; 1.5 VA maximum using 4 to 20 mA out

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F) when using 0 to 10 VDC outputs;

Ambient Shipping and Storage

Conditions

Input Signal 0 to 5 VDC for humidity sensors and static pressure transducers

Analog Output Voltage Mode (0–10 VDC):

Analog Input Accuracy Resolution: 14 bits

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450CPW-100C: 195 g (0.43 lb)

touchpad, and analog output with pulse-width modulation capability.

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

-40 to 40C (-40 to 104F) when using 4 to 20 mA outputs

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

0.5 to 4.5 VDC for ratiometric pressure transducers

1,035 ohms at 25C (77F) for A99 PTC temperature sensors

1,000 ohms at 21.1C (70F) for TE-6xxx Nickel temperature sensors

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohms or more

The AO operates in Voltage Mode when connected to devices with impedance greater than 1,000 ohms. Devices that

fall below 1,000 ohms may not operate as intended with Voltage Mode applications.

Current Mode (4–20 mA):

Requires an external load between 0 to 300 ohms

The AO operates in Current Mode when connected to devices with impedance less than 300 ohms. Devices that rise

above 300 ohms may not operate as intended with Current Mode applications.

mounting to a hard, even surface.

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-199

Page 9

System 450 Control Series

System 450™ Series Modular Controls (Continued)

C450CPW-100C Control Module with Hybrid Analog Output (Part 2 of 2)

Compliance North America: cULus Listed; UL 60730, File E27734;

Product C450CBN-3C and C450CCN-3C: System 450 Control Module models are sensing controls and operating co ntrols with

Power Consumption C450CBN-3C: 0.9 VA maximum

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F)

Ambient Shipping and Storage

Conditions

Input Signal 0 to 5 VDC for humidity sensors and static pressure transducers

Output Relay Contacts General: 1/2 HP at 120/240 VAC, SPDT

Analog Input Accuracy Resolution: 14 bits

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450CBN-3C: 209 g (0.46 lb)

Compliance North America: cULus Listed; UL 60730, File E27734;

C450RBN-3C and C450RCN-3C Reset Control Modules with Real-Time Clock and Relay Output (Part 1 of 2)

Product C450RBN-3C and C450RCN-3C: System 450 Reset Control Module models are sensing controls and operating

Power Consumption C450RBN-3C: 0.9 VA maximum

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F)

Ambient Shipping and Storage

Conditions

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia: Mark: C-Tick Compliant (N1813)

C450CBN-3C and C450CCN-3C Control Modules with Relay Output

LCD, four-button touchpad, and SPDT relay output

C450CBN-3C: Control Module with one SPDT output relay

C450CCN-3C: Control Module with two SPDT output relays

C450CCN-3C: 1.3 VA maximum

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

0.5 to 4.5 VDC for ratiometric pressure transducers

1,035 ohms at 25C (77F) for A99 PTC temperature sensors

1,000 ohms at 21.1C (70F) for TE-6xxx Nickel temperature sensors

Specific: AC Motor Ratings 120 VAC 208/240 VAC

AC Full-load Amperes: 9.8 A 4.9 A

Locked-Rotor Amperes: 58.8 A 29.4 A

_____________________________________

10 Amperes AC Non-inductive at 24/240 VAC

Pilot Duty: 125 VA at 24/240 VAC

mounting to a hard, even surface.

C450CCN-3C: 222 g (0.49 lb)

FCC Compliant to CFR47, Part 15, Subpart B, Class B;

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia: Mark: C-Tick Compliant (N1813)

controls with LCD, four-button touchpad, and SPDT relay output

C450RBN-3C: Control Module with one SPDT output relay

C450RCN-3C: Control Module with two SPDT output relays

C450RCN-3C: 1.3 VA maximum

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-200

Page 10

System 450 Control Series

System 450™ Series Modular Controls (Continued)

C450RBN-3C and C450RCN-3C Reset Control Modules with Real-Time Clock and Relay Output (Part 2 of 2)

Input Signal 0 to 5 VDC for humidity sensors

Output Relay Contacts General: 1/2 HP at 120/240 VAC, SPDT

Clock Accuracy ±4 minutes per year

Clock Backup Power 12 hours (capacitor reserve)

Setback Events One occupied and one unoccupied event per day; 7 day schedule

Analog Input Accuracy Resolution: 14 bits

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450RBN-3C: 209 g (0.46 lb)

Compliance North America: cULus Listed; UL 60730, File E27734;

Product C450SPN-1C: System 450 Expansion Module with one Analog output

Power Consumption C450SPN-1C: 1.1 VA max using 0 to 10 V out; 1.3 VA maximum using 4 to 20 mA out

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F) when using 0 to 10 VDC outputs;

Ambient Shipping and Storage

Conditions

Analog Output Voltage Mode (0 to 10 VDC):

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450SPN-1C: 150 g (0.33 lb)

Compliance North America: cULus Listed; UL 60730, File E27734, Vol. 1; FCC Compliant to CFR47, Part 15, Subpart B, Class B

1,035 ohms at 25C (77F) for A99 PTC temperature sensors

Specific: AC Motor Ratings 120 VAC 208/240 VAC

AC Full-load Amperes: 9.8 A 4.9 A

AC Locked-Rotor Amperes: 58.8 A 29.4 A

_____________________________________

10 Amperes AC Non-inductive at 24/240 VAC

Pilot Duty: 125 VA at 24/240 VAC

mounting to a hard, even surface.

C450RCN-3C: 222 g (0.49 lb)

FCC Compliant to CFR47, Part 15, Subpart B, Class B;

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia: Mark: C-Tick Compliant (N1813)

C450SPN-1C and C450SQN-1C Expansion Modules with Analog Output

C450SQN-1C: System 450 Expansion Module with two Analog outputs

C450SQN-1C: 1.8 VA max using 0 to 10 V out; 2.2 VA maximum using 4 to 20 mA out

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

-40 to 40C (-40 to 104F) when using 4 to 20 mA outputs

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohms or more

The AO operates in Volt age Mode when connect ed to devi ce s with i mpeda nce great er than 1, 000 oh ms. De vi ce s that

drop below 1,000 ohms may not operate as intended with Voltage Mode applications.

Current Mode (4 to 20 mA):

Requires an external load between 0 to 300 ohms

The AO operates in Current Mode when connected to devices with impedances less than 300 ohms. Devices that

exceed 300 ohms may not operate as intended with Current Mode applications.

mounting to a hard, even surface.

C450SQN-1C: 150 g (0.33 lb)

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark - Johnson Controls, Inc., declares that this product is in complian ce with the e ssential req uire ment s

and other relevant provisions of the Low Voltage Directive and the EMC Directive.

Australia: Mark: C-Tick Compliant (N1813)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-201

Page 11

System 450 Control Series

System 450™ Series Modular Controls (Continued)

C450SBN-3C and C450SCN-3C Expansion Modules with Relay Output

Product C450SBN-3C: System 450 Expansion Module with one SPDT output rela y

Power Consumption C450SBN-3C: 0.8 VA maximum

Supply Power Internal Supply Power: C450YNN-1C Power Supply Module

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F)

Ambient Shipping and Storage

Conditions

Output Relay Contacts General: 1/2 HP at 120/240 VAC, SPDT

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN rail mounting or direct

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450SBN-3C: 172 g (0.38 lb)

Compliance North America: cULus Listed; UL 60730, File E27734;

Product C450YNN-1C: System 450 Power Supply Module; 120 or 240 VAC stepdown to 24 VAC Class 2 (North America) or

Supply Power 110/120 VAC or 220/240 VAC at 50/60 Hz (100 mA maximum)

Secondary Power 24 VAC , 10 VA

Ambient Operating Conditions Temperature: -40 to 66C (-40 to 150F)

Ambient Shipping and Storage

Conditions

Control Construction Independently mount ed control, surface mounted with Lexan

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450YNN-1C: 390 gm (0.86 lb)

Compliance North America: cULus Listed; UL 60730, File E27734:

C450SCN-3C: System 450 Expansion Module with two SPDT output relays

C450SCN-3C: 1.2 VA maximum

External Supply Power: 24 VAC (20 to 30 VAC) Safety Extra-Low Voltage (SELV) (Europe), Class 2 (North America),

50/60 Hz, 10 VA minimum

Note: A System 450 control module or module assembly can use an internal or an external supply power source, but

must not be connected to both simultaneously.

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Specific: AC Motor Ratings 120 VAC 208/240 VAC

AC Full-Load Amperes: 9.8 A 4.9 A

AC Locked-Rotor Amperes: 58.8 A 29.4 A

_____________________________________

10 Amperes AC Noninductive at 24/240 VAC

Pilot Duty: 125 VA at 24/240 VAC

mounting to a hard, even surface.

C450SCN-3C: 186 g (0.41 lb)

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia: Mark: C-Tick Compliant (N1813)

C450YNN-1C Power Supply Module

SELV (Europe)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH noncondensing; maximum dew point 29C (85F)

® 950 enclosure suitable for DIN rail mounting or direct

mounting to a hard, even surface.

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

and other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia: Mark: C-Tick Compliant (N1813)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-202

Loading...

Loading...