Page 1

FANs 930, 930.5, 125

Product/Technical Bulletin Y350R

Issue Date 0598

System 350

The Y350R is a rectified Class 2, 24 VAC power

supply module designed specific ally for use with

System 350™ Modular Control Systems.

As with all System 350 products, the Y350R is housed

in a compact NEMA 1, high-impact plastic enclosure.

The modular design provides eas y , plug-in

connections for quic k ins tallation and future

expandability.

Y350R Power M odule

Figure 1: Y350R Power Module

❑

Modular De s ign

❑

Plug-in Connect or s a nd

35 mm D IN R a il M ounting

❑

Accepts Input Voltages of

120 or 240 VAC, 50/60 Hz

© 1998 Johnson Controls, Inc.

Part No. 24-7664-214, Rev. D

Code No. LIT-930090

Features and Benefits

Enables stage, display, and power modules to be

purchased and installed as necessary

Eliminates wiring between modules and reduces

installation costs

Reduces inventory by encompassing the primary

voltage requirements

1

Page 2

pplication

A

The Y350R Power Module provides the power

necessary to operate all System 350 controls and

add-on modules. For system capabilities, see T able 1.

Table 1: Maximum Number of A dd-on

Modules when Powered by a Y350R

Control

Module

A350A

A350B

A350E

A350P

A350R

A350S

W351A

W351P

P352A

P352P

R353

Stage Module

9 S350A’s or S350C’s

6 S350A’s or S350C’s with

1 S350P

4 S350A’s or S350C’s with

2 S350P’s

4 S350A’s or S350C’s

2 S350A’s or S350C’s with

1 S350P

9 S350A’s or S350C’s

6 S350A’s or S350C’s with

1 S350P

4 S350A’s or S350C’s with

2 S350P’s

5 S351’s 1 D351

4 S351’s 1 D351

5 S352’s 1 D352

No additional stages available 1 D352

5 S353’s No

All System 350 add-on modules snap on to a DIN rail

and plug into the control and to each other via 5-pin

connectors. A dd- on m odules c an be ar r anged in any

order and there is no wiring requir ed to interconnect

the System 350 components.

Display

Module

1 D350

1 D350

2 D350

display

available

IMPORTA NT: All Series Y350R Power Modules

are designed for use only in

conjunction with operat ing

controls. W her e an oper ating

control failure would res ult in

personal injury and/or loss of

property, it is the responsibility of

the installer to add dev ic es

(safety, lim it controls) t hat protect

against, or systems (alarm,

supervisory systems) that warn

of, control failure.

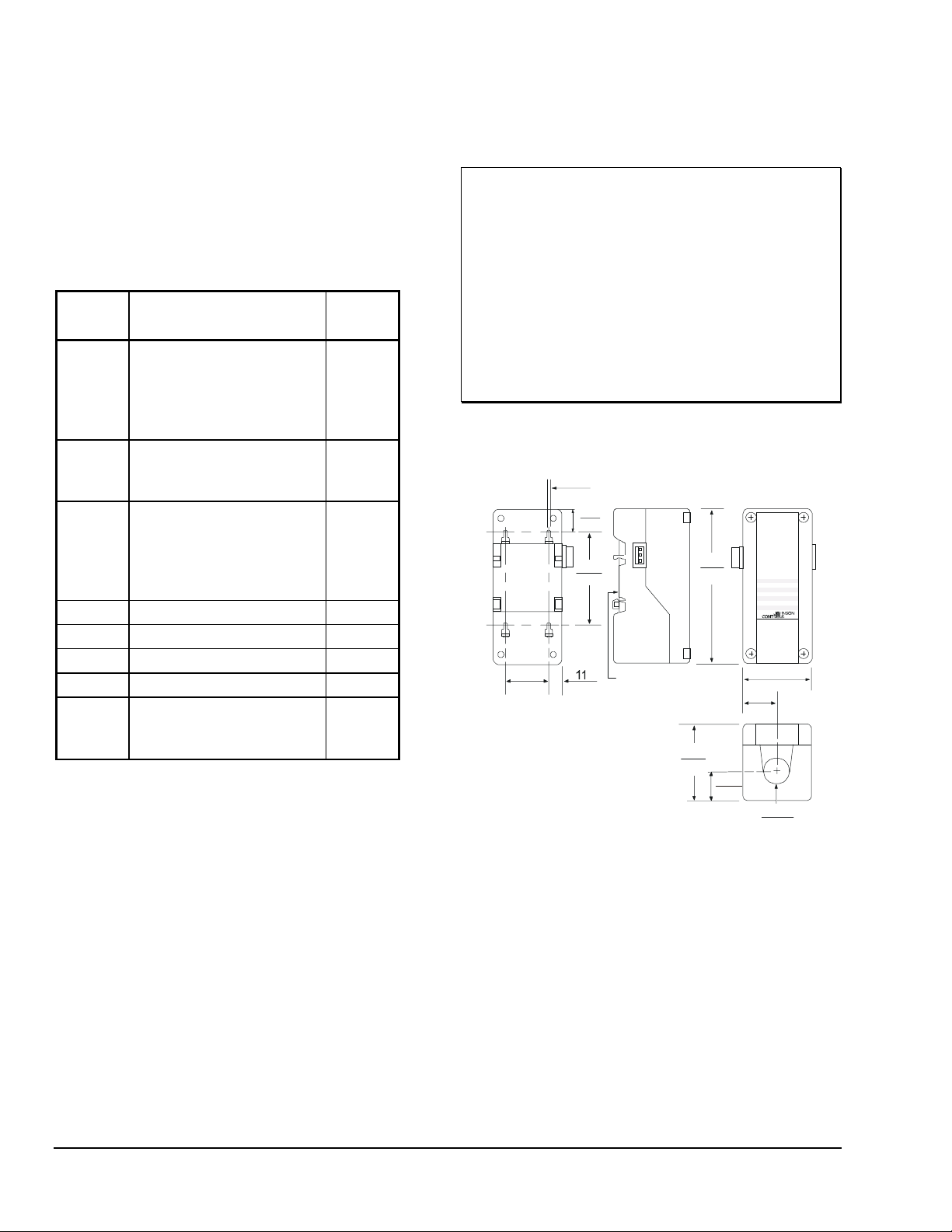

imensions

D

3.68

Mounting Slot (4)

for No . 6 Sc rews

0.145

13

0.5

61

2.40

127

5.00

21.6

0.85

Cond uit

Hole

31

1.20

Y350

61

2.40

22

0.875

40

1.56

75

2.94

0.42

DIN Rail

Mount

Figure 2: Y350R Dimensions, mm /in.

peration

O

The Y350R operates f r om 240 V A C or 120 V A C

power. A 24 VAC, Clas s 2, step-down trans former

brings the voltage to a level which the Syst em 350

modules will accept. There are no adjustment s for the

power module.

2 Y350R Power Module Product/Technical Bu l l e ti n

nstallation and Wir ing

I

The Y350R case has provis ions for mounting to a

standard 35 mm DIN r ail, or can be mounted using t he

four key slot m ounting holes located in the rear of the

case.

Mount System 350 modules in any convenient location

using either the DIN r ail m ounts or the mounting holes

located on the back of the control case. The

components are not pos ition sensitive, but should be

mounted so they can be eas ily wir ed and adjus ted.

Page 3

heckout Procedure

C

IMPORTA NT: All wiring must be inst alled to

conform to t he National Electrical

Code and local regulations.

1. Secure the module to the DIN rail, wall, or panel.

!

WARNING: Electrical S hock Hazard.

Disconnect power supply before

modules are interconnected and

wiring connections are made to

avoid possible electrical s hoc k or

damage to the equipment.

2. Connect input wiring to the Y350R power module.

Strip approximat ely 3/8 inch from the wir e

insulation, insert the wire under each terminal

screw, and tight en. (See Figure 3.)

Note: If conduit is used when installing Syst em 350

components, be sur e to connect the hub t o the

conduit before the hub is s ec ur ed to the

enclosure.

Before applying power, m ak e s ur e ins tallation and

wiring connections are acc or ding to job specifications .

After necess ar y adjus tments and electr ic al

connections have been made, put the syst em in

operation and observe at leas t three complete

operating cycles before leaving the installation.

roubleshooting

T

If the control syst em does not function properly and

the Y350R is suspect , proceed as follows:

1. Connect a Digital Voltmeter (DVM) between the

24V (+) and COM (-) terminals located on the

control module’s left-side connector. (Terminal

designations are marked on the control module.)

2. Select DC volts on the DVM and verify that the

voltage is between 16 and 38 VDC. If the DVM

reading is within range, t he Y 350R is functioning

properly.

Note: Consult the

appropriate control bulletin for a complete

system troubleshooting procedure.

Troubleshooting

section of the

Module

Conn ector

240 VAC CO M 120 VA C

P owe r Input Terminals

Figure 3: Inte r ior of the Y 350R Power

Module

rdering Information

O

Table 2: Product Availa ble

Item Product Code Description

Power Module

Y350R-1C Rectified, Class 2, 24 VAC Power Supply

Module

Conn ector

3. If the DVM r eading is not within the indicated

voltage range, check wir ing and c or r ec t if

necessary. I f the wiring is correc t and the reading

remains out of range, replace the Y350R.

epairs and Replacement

R

Field repairs or calibration must not be made.

Replacement modules are available through the

nearest Johnson Contr ols r epr es entative. (See Table

2.)

Y350R Power Module Product/Technical Bu l l e ti n 3

Page 4

pecifications

S

Product

Input Voltage

Output Vo lta g e

Material

Ambient Temperature

Ambient Humidity

Mounting

Agency Listing

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications,

consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.

Y350R Power Module

120/240 VAC, 50/60 Hz

Rectified 24 VAC, 10 VA, Class 2

Case and cover: NEMA 1 high-impact plastic

Operating: -34 to 66°C (-30 to 150°F)

Shipping: -40 to 85°C (-40 to 185°F)

0 to 95% RH non-condensing

Wall or DIN rail

UL Guide No. XAPX, File E27734

CUL Guide No. XAPX7, File E27734

CSA Class No. 4813 02, File LR948

Controls Group

507 E. Michigan Street

P.O. Box 423

Milwaukee, WI 53201 Printed in U.S.A.

4 Y350R Power Module Product/Technical Bu l l e ti n

Loading...

Loading...