Page 1

Features and Benefits

FANs 930, 930.5, 125, 121

Product/Technical Bulletin A350P

Issue Date 0414

System 350

TM

A350P Electronic Proportional Plus Integral

Temperature Control

The A350P is an electronic, proportional plus int egral

temperature control with analog 0 to 10 VDC and

0 to 20 mA outputs. The control is equipped with

three user-selectable time integration constants and

an adjustable throttling range of 2 to 30F° (1 to 17C°).

Two models cover a setpoint range of -30 to 130°F

(-35 to 55°C) and 90 to 250°F (32 to 121°C).

As are all System 350™ products, the A350P control

is housed in a NEMA 1, high-impact plastic enclosure.

The modular design provides easy, plug-together

connections for quick installation and fut ure

expandability.

Modular Design Enables stage, display, and power modul es to

be purchased and installed a s needed

Plug-Together Connectors

and 35 mm DIN Rail

Mounting

Eliminates wiring between m odules, whi ch

reduces installation costs

Figure 1: A350P Electronic Proportional Plus

Integral Temperature Control

Two Models Cover a Wide

Setpoint Range of -30 to

250°F (-35 to 121°C)

Minimum Output Adjustable

from 0 to 60%

Adjustable Throttling

Range of 2 to 30F° ( 1 to 17C°)

Field-selectable Rev erse

or Direct Acting Mode

Three User-Selectable

Integration Time Constants

Interchangeable

Temperature Sensors

Reduces inventory by encom passing

temperature ranges requi red to suppo rt the

majority of Heating, Ventilat ion, Air C onditioni ng,

and Refrigeration (HVAC/R) applications

Tailors the output to the req uirements of the

controlled device; can be us ed to set m inimum

valve or damper position

Enables the user to tune the system for optimum

stable performance

Works in heating or cooling applications

Provides selection of the int egration constant fo r

applications requiring propo rtional pl us integral

control

Increase versatility and serviceability

© 2014 Johnson Controls, Inc. 1

Part No. 24-7664-192, Rev. G www.johnsoncontrols.com

Code No. LIT-930020

Page 2

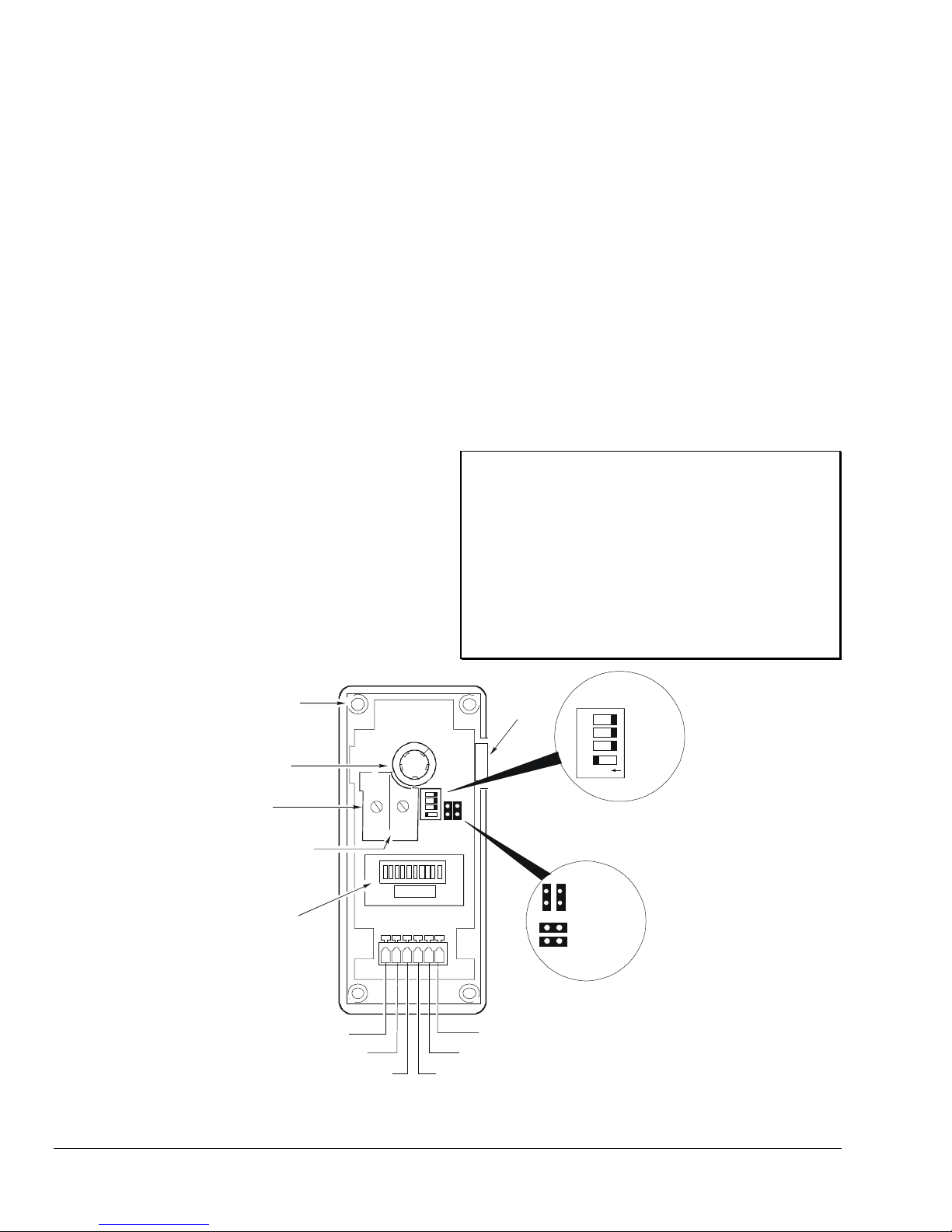

Cover Screw

(One of Four)

Setpoint

Dial

Throttling Range

Potentiometer

Minimum Output

Potentiometer

LED Indicator

(Percent of Output)

V: 0-10 VDC Ou tp ut

I: 0-20 mA Output

SN: Sensor Input

24V: 24 VAC (+)

C: Common (-)

VDC: +5 VDC (not used)

Operation Mode

Jumper Positions

Reverse

Acting (RA)

Direct

Acting (DA)

Module

Connector

Integration DIP switch is

shown in proportional-only position.

THROT

RANGE

MIN

OUTPUT

VIS

NVD

C

C

2

4

V

Fast

Medium

Slow

Off

On

1 2 3 4

Integration

DIP Switch

pplication

A

The A350P Temperature Control can be used as a

standalone device or in conjunction with plug-together

accessory modules. The addition of S350 Stage

Modules allows for the control of multiple stage

HVAC/R applications. Typical application for the

A350P includes:

• proportional heating control with staged direct

expansion cooling

• simple temperature control for air handling units

• modulating damper actuators for mixed air control

• simple proportional mixed air control

A typical System 350 Temperature Control setu p

includes the following:

• A350P Temperature Control

• A99B Series Temperature Sensor

• Y350R Power Module (or 24 VAC Class 2

transformer)

• S350 Stage Modules

• D350 Digital Temperature Display Module

peration

O

The A350P control operates on 24 VAC/VDC and

provides two simultaneous analog outputs:

0 to 10 VDC and 0 to 20 mA. A cover-mounted,

10-segment Light-Emitting Diode (LED) bar graph

indicates percentage of output.

Features include:

• adjustable setpoint

• adjustable minimum output

• adjustable throttling range (proportional b and)

• selectable integration time constant

• selectable Reverse Acting (RA) or Direct Act ing

(DA) mode of operation

IMPORTANT: All System 350 controls are

designed for use only as

operating controls. Where an

operating control failure would

result in personal injury and/or

loss of property, it is the

responsibility of the installer to

add devices (safety, limit controls)

or systems (alarm, supervisory

systems) that protect against, or

warn of, control failure.

Figure 2: Interior View Showing A350P Control’s Featur es

2 System 350 A350P Electronic Proportional Plus Integ ral Temper ature Cont rol Prod uct/Tech nical Bulleti n

Page 3

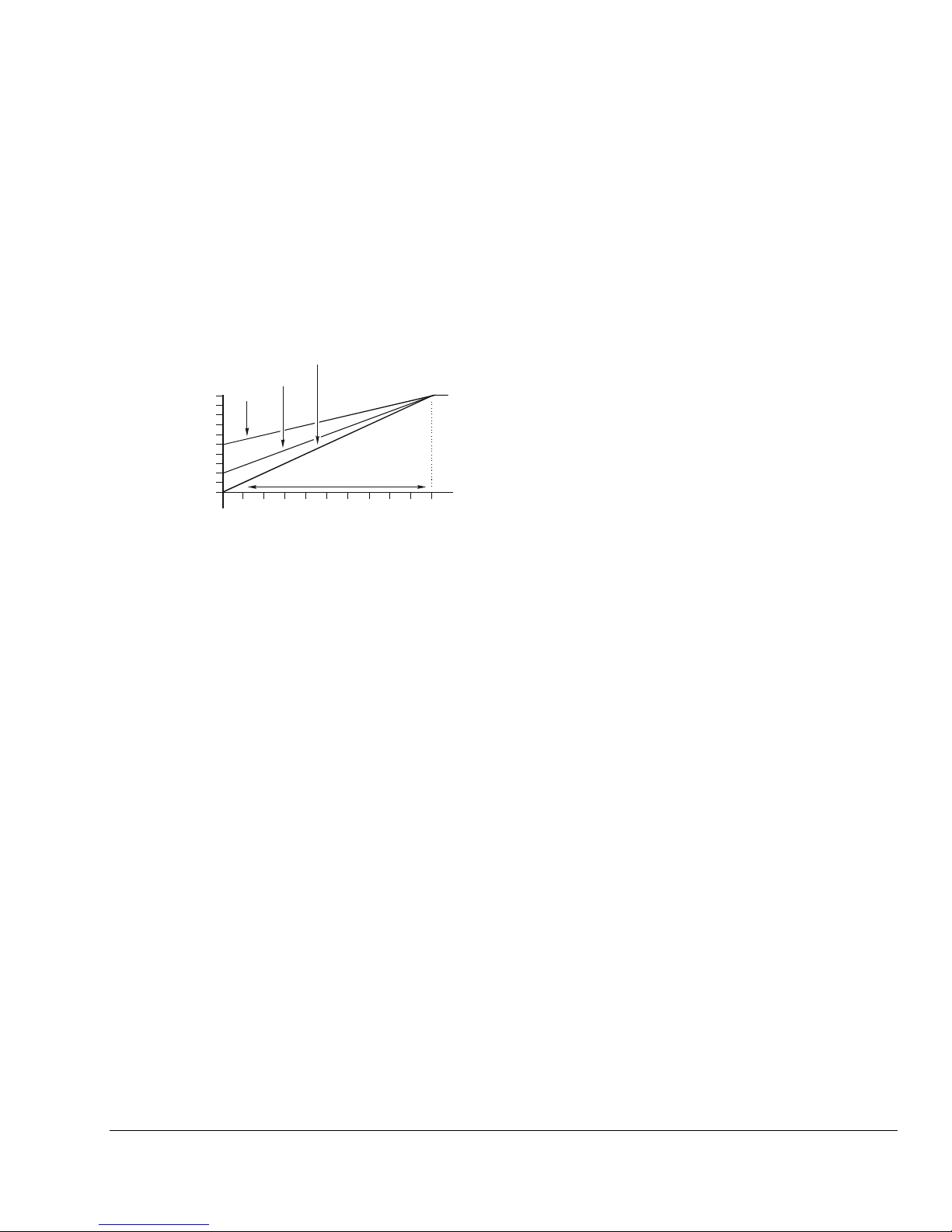

Deviation Above Setpoint (F°)

Output

(mA)

0

2 4 6 8 10 12 14 16 18 20

0

4

10

20

50%

20%

0%

Throttling Range

Minimum Output Adjustment

The minimum output adjustment sets the minimum

voltage or milliampere output provided by t he A 350P

control. It can be adjusted from 0 to 60% (0 t o 6 V DC

or 0 to 12 mA) of the output range.

Example:

A controlled device responding to a 4-20 mA out put

would require the minimum output to be adjusted t o

20% or 4 mA. (See Figure 3.) The minimum output

adjustment may also be used to set valves or dam pers

to minimum positions.

Throttling Range (Proportional Band)

The throttling range is the range over which a control

is active. Throttling range for the A350P control can be

adjusted from 2 to 30F° (1 to 17C°). Make the

adjustment at the throttling range potentiometer

marked THROT RANGE (see Figure 2).

Integration Function

Proportional-only controls cannot hold a process at the

exact setpoint. A proportional offset is alway s present

because the control output is 0% at setpoint. Any load

on the system will cause the control point to be offset

from the setpoint. The greater the load on the system,

the further the control point will be offset from the

setpoint. (This is commonly referred to as proportional

offset, and under maximum load this error will

approach the throttling range.)

Some proportional-only controls are designed with

their setpoint located midway through the proporti onal

band to help compensate for this offset. This results in

a plus/minus error from the setpoint rather t han a

single-ended error. Refer to Figure 4.

Figure 3: Output vs. Deviation from

Setpoint for: Minimum Output = 0, 20, and

50%, Throttling Range = 20°F (DA)

Make the adjustment at the minimum output

potentiometer marked as MIN OUTPUT.

(See Figure 2.) For each 10% increase in output, the

next bar on the LED indicator will light (only one bar is

lit at any time).

Note: Before setting the minimum output

potentiometer, verify that the control reads

zero output (that is, no LEDs are lit).

System 350 A350P Electron ic Proportio nal Plus Int egral Tempe rature Control Prod uct/Tec hnical Bullet in 3

Page 4

Proportional

Offset

Setpoint

Load Change

System Load

Contr ol Point

Follo ws the Load

Temperature

Time

Throttling

Range

Proportional Only Control

Temperature

Proportional

Offset = 0

Setpoint

Load Change

System Load

Integration adjusts the

proportional output to

bring the process to

setpoint regardless of load.

Time

Proportional Plus Integral Control

Figure 4: Comparison Between Proport ional Only and Proportional Plus Integral Control

The A350P control has an integration feature that

forces the control point to match the setpoint . Over

time, the A350P will control the heating/cooling

equipment to balance the system load at t he cont rol

setpoint. (See Figure 4.)

On traditional proportional plus integral controls, the

amount of correction will become too large if the

system load exceeds the capacity of the equipment.

When the actuated device (valve or damper) is ful l y

open or closed and the setpoint still cannot be

reached, the integration error continues to grow. The

result is called integral windup.

The A350P control avoids integral windup with a

patented circuit that puts a dynamic ceiling on the

integrator. This resets the integration error when the

sensor goes just above the setpoint plus the throttling

range (in DA mode) or just below the setpoint minus

the throttling range (in RA mode). This allows the

process to recover from an out-of-range condition

without a large overshoot.

The A350P control has three field-selectable

integration constants and an off position. The

integration DIP switch selects the integration constant.

(See Figure 2 for location.)

The field-selectable integration constant s i nclude:

• OFF: Switch 1 to On position, all others Off

provides proportional-only operation.

Note: In open-loop (without feedback) applications,

select OFF (proportional-only) operation.

Slow (C3): Switch 2 to On position, all others

•

Off is the slowest integration constant (26 minut e),

and is suitable for most proportional plus integral

applications. Slow is the recommended init i al

setting.

Medium (C2): Switch 3 to On position, all

•

others Off selects a 13-minute integration

constant. If the rate of system recovery to set point

is sluggish with the control set to slow, and if the

system has enough capacity to drive the process

to setpoint at a faster rate, the medium sett i ng

may be used.

Fast (C1): Switch 4 in On position, all

•

others Off is the fastest integration constant

(6.5 minutes). Use fast only in instances where the

rate of change at the sensor is extremely rapid

and system capacity can compensate for that

rapid change.

4 System 350 A350P Electronic Proportional Plus Integ ral Temper ature Cont rol Prod uct/Tech nical Bulleti n

Page 5

Note: Dashed areas show throttling range possibilities

from mi nimum to maximum.

VDC

Throttling Range

Setpoint

10

0

RA

20

10

0

mA

Setpoint

Throttling Range

10

0

VDC

DA

20

10

0

mA

5F°

5 10

15 202530F°

+

1015

20

2530

Reverse Acting Direct Acting

Power

Number

Number of

Allowed

Number of

Allowed

Y350R

4 2 0

Transformer

Reverse or Direct Acting Operation

With the operation jumpers in the Reverse Act ing (RA)

position, the analog output increases as t he

temperature drops below setpoint. (See Figure 5.)

With the operation jumpers in the Direct Act ing (DA)

position, the analog output will increase as t he

temperature rises above the setpoint.

Select the RA/DA mode by positioning the operat i on

jumpers vertically or horizontally. (See Figur e 2.)

Position the operation jumpers vertically for RA and

horizontally for DA.

The RA/DA operation jumpers are installed in t he RA

mode at the factory.

S350A On-Off Stage M odules

S350A On-Off stage modules receive power, setpoint,

and sensor input from the A350P control. S350A st age

modules perform switching functions based on the

control’s setpoint and sensor information , as well as

the offset and differential selected at the S 350A st age

module.

For more information on these modules, refer to the

System 350

TM

S350 Temperature, S351 Humidity,

and S352 Pressure On/Off Stage Modules

Product/Technical Bulletin (LIT-930080).

S350C Slave Stage Module

S350C slave stage modules receive power and sensor

input from the A350P control. S350C slave stage

modules perform switching functions based upon the

control’s sensor information, as well as the setpoint

and differential selected at the S350C stage mod ul e.

For more information on these modules, refer to the

System 350

TM

S350C Temperature Slave Stage

Module Product/Technical Bulletin (LIT-930084).

Figure 5: RA and DA Proportional Bands Sho wn in

Proportional-Only Mode

dd-on Modules

A

The maximum number of add-on modules is listed in

Table 1.

Table 1: Maximum Number of S350 Stage

Modules per A350P

Source

External

Class 2

of S350A

or S350C

Stage

Modules

Allowed

9 8 7

S350A or

S350C

Modules

(with

One S350P)

S350A or

S350C

Modules

(with

Two S350Ps)

S350P Proportional Stage Modules

S350P proportional stage modules receiv e power,

setpoint, and sensor input from the A350P control. T he

S350P stage module responds with an analog 0 to

10 VDC and 0 to 20 mA output signal. This is based

upon the control’s setpoint and sensor information, as

well as the offset, throttling range, and minimum output

selected at the S350P stage module.

For more information on these modules, refer to the

System 350

TM

S350P Proportional Plus Integral

Temperature Stage Module Product/Technical Bulletin

(LIT-930086).

System 350 A350P Electron ic Proportio nal Plus Int egral Tempe rature Control Prod uct/Tec hnical Bullet in 5

Page 6

imensions

Mounting Slots

for No. 6 S c rews

DIN

Rail Mount

A350P

Conduit

Hole

3/16 (4)

2 3/8 (61)

1 3/16 (31)

7/8

(22)

7/8 (22)

1 9/16

(40)

7/16 (11)

1

/

4

(

6

)

2 (50)

Sensor

1/2 (13)

2 15/16

(75)

9 3/4 (248)

3 (76)

2 3/8 (61)

4 (102)

5 (127)

!

D

Figure 6: A350P Control and Sensor Dimensi ons, in. (mm)

nstallation and Wiring

I

Celsius Scale Conversion

A Celsius scale throttling range decal is included with

the A350P control. If the Celsius scale is desired:

1. Locate the throttling range and minimum output

potentiometers on the main PC board.

(See Figure 2.) Carefully remove the knobs and

the existing decal.

2. Apply the Celsius scale decal in the same place as

the original decal.

3. Rotate both knob stems completely

counterclockwise (CCW).

4. Reinstall the potentiometer knobs so the arro ws

point to the minimum values.

The A350P Temperature Control is housed in a

compact NEMA 1 plastic enclosure designed for

standard 35 mm DIN rail mounting. Four key-slot

mounting holes on the back of the control case ar e

provided should surface mounting be required. If a

Y350R is used, it should be mounted immediately to

the right of the control. Any S350 modules would

follow on the right, with the D350 being the last module

mounted, also on the right.

Note: When mounting any System 350 module to

rigid conduit, attach the hub to the conduit

before securing the hub to the control

enclosure.

WARNING: Risk of Electrical Shock.

Disconnect the power supply before making

electrical connections. Contact with com ponents

carrying hazardous voltage can cause electric shock

and may result in severe personal injury or death.

AVERTISSEMENT: Risque de décharge

électrique.

Débrancher l'alimentation avant de réaliser tout

branchement électrique. Tout contact avec des

composants conducteurs de tensions dangereuses

risque d'entraîner une décharge électrique et de

provoquer des blessures graves, voire mortelles.

6 System 350 A350P Electronic Proportional Plus Integ ral Temper ature Cont rol Prod uct/Tech nical Bulleti n

Page 7

VISN

VDC

Terminal

Description

I

VDC

C

Wire

Shielded Cable Length

Gauge

16 AWG

22 AWG

(-40 to 100°C)

A350PS-2C

(-40 to 120°C)

A350PT-1C

A350BA-2C

Wiring Terminals

Install all wiring to conform to the National Electrical

Code and local regulations. For maximum el ect rical

rating of control, refer to the label inside the control

cover. Terminals will accept 12 to 26 AWG wire. Us e

only copper conductors.

1. Use a 1/8 in. (3 mm) flat-blade screwdriver to push

the clamp arm down.

2. Insert the appropriate wire into the opening.

Refer to Table 2 for terminal designations.

3. Release the clamp arm to secure the wire.

See Figure 7.

Sensor Connection

Shielded cable is not generally required for sensor

wiring on runs of less than 50 feet. When using

shielded cable, isolate and tape the shield at the

sensor. Connect the shield to Terminal C on the

A350P control.

Refer to Table 3 for the maximum recommended cable

lengths for particular sizes of wire.

Table 3: Maximum Recommended

Sensor Cable Lengths

Feet Meters

14 AWG

18 AWG

20 AWG

• Various A99B Series Temperature Sensors and

mounting hardware are available for use with

A350P Series controls.

800 244

500 152

310 94

200 61

124 38

Figure 7: Cage Clamp Terminal Block

Table 2: Terminal Designations

V

SN

24V

Note: Output signals from the A350P control vary

from 0 to 10 VDC and 0 to 20 mA. (Both

outputs can be used simultaneously.)

Connections can be made to both the V and

I terminals, allowing the control to drive

two outputs from the same RA or DA ramp

simultaneously. This feature can be used to

drive motor actuators of different types i n a

single application.

0 to 10 VDC output

0 to 20 mA output

Temperature sensor input

5 VDC power supply (not used)

Common for power supply,

temperature sensor, and outputs

24 Volts AC

The sensor must be connected to Terminals SN

and C. (See Figure 2.) The sensors are not

polarity sensitive.

• The sensor must be mounted so that it can

accurately sense the temperature of the controlled

medium.

Table 4: A350P Controls And Sensors

Control Sensor Included

Sensor Lead Length is 9-3/4 in.

(0.25 m)

A350PS-1C

A350PS-1CM

A99BB-25C; Range: -40 to 212°F

A99BB-25C; Range: -40 to 212°F

(-40 to 100°C)

A99BC-25; Range: -40 to 248°F

(-40 to 120°C)

A350PS-2CM

A99BC-25; Range: -40 to 248°F

No Sensor Included

A99BC-25; Range: -40 to 248°F

(-40 to 120°C)

• For more information regarding sensor options

and installation, refer to the A99B Series

Temperature Sensors Product/Technical Bulletin

(LIT-125186).

System 350 A350P Electron ic Proportio nal Plus Int egral Tempe rature Control Prod uct/Tec hnical Bullet in 7

Page 8

djustments

A

Follow this procedure to set up the A350P control f or

the types of operation desired.

1. Remove its cover by loosening the four captive

cover screws. (See Figure 2.)

2. Set the RA/DA operation jumpers to the desired

mode of operation. Position the operation j um pers

vertically for RA (Reverse Acting) or hor i zont all y

for DA (Direct Acting). (See Figure 2.)

3. Adjust the throttling range potentiometer to desired

setting. Rotate Clockwise (CW) to increase t he

throttling range.

Notes: Included with the control is a Celsius scale

throttling range decal. If the Celsius scale i s

desired, refer to the Celsius Scale Conv ersion

section for decal installation instructions .

If the A350P is to be used in proportional plus

integral control, the initial throttling range

adjustment is seldom set below 6F° (3C°).

A narrow proportional band used in

conjunction with the integration may result i n

unstable control.

4. If minimum output is required, set the minimum

output potentiometer (see Figure 2) to the desired

position. The 10-segment front LED panel or a

voltmeter can be used to read the minimum

output. (The minimum setting for the control is

designated by the 0 on the decal.)

Notes: Before adjusting the minimum output

potentiometer, verify that the control reads

zero output (that is, no LEDs are lit).

For each 10% increase in output, the next

bar will light on the LED bar graph (only

one bar is lit at anytime). In a milliampere

application, each bar equals 2 mA. In a

voltage application, each bar equals 1 VDC.

(Refer to Figure 3.)

Example:

To set the control for a minimum output of

4 mA, turn the minimum output potentiometer

clockwise until the second LED segment just

lights.

If the control system does not function properl y, verify

that the proper operation mode is selected on ea ch

module (DA or RA), and perform the following

procedures to determine the cause of the problem:

1. Check for proper voltages on the A350P control.

5. Make sure the system is stable in the proportional

mode before selecting integration. Refer t o the

Checkout Procedure section.

6. Reinstall the cover and secure in pl ace with the

four captive cover screws.

7. Adjust the setpoint dial to the desired setpoint.

If using the D350 Display Module, press and hol d

the setpoint button on the D350 while rotating t he

setpoint dial.

Note: The control’s setpoint is factory calibrated at

midscale to a tolerance of ±1F° (0.6C°). The

setpoint tolerance at the extreme ends of the

setpoint scale may be ± 4F° (2.2C°). The

D350 Display Module is unaffected by this

tolerance shift. Use the D350 for the most

accurate setpoint selection.

heckout Procedure

C

Follow this procedure to verify the A350P control is

connected and functioning properly.

1. Before applying power, make sure that the

installation and wiring connections are acc ording

to job specifications.

2. Set up the system for proportional mode

(Integration = OFF), and make any necessary

adjustments to the setpoint, throttling range, and

minimum output. Then select Reverse or Direct

Acting mode.

3. After making adjustments and electrical

connections, apply power to the system, and

observe it for stable operation.

4. If integration is required, select the fast (C1),

medium (C2), or slow (C3) integration constant.

Slow is the recommended initial setting. (Ref er to

the Integration Function section.)

5. Put the system back into operation. If instability

occurs, consider increasing the throttling range.

roubleshooting

T

a. Connect a digital voltmeter (DVM) between

Terminals 24V (+) and C (-) located on the

A350P’s terminal block. (See Figure 2.)

If an external transformer is used, select AC

volts on the DVM. Verify that the voltage is

between 20 and 30 VAC.

8 System 350 A350P Electronic Proportional Plus Integ ral Temper ature Cont rol Prod uct/Tech nical Bulleti n

Page 9

°F

Temperature

260

240

220

200

180

160

140

120

100

80

60

40

20

0

-20

-40

500

700 900

1100

Resistance (Ohms)

1300 1500

1700 1900

2100

°C

120

100

80

60

40

20

0

-20

-40

If a Y350R Power Module is used, select DC

volts on the DVM. Verify that the voltage is

between 16 and 38 VDC.

If an external DC power supply is used, select

DC volts on the DVM. Verify that the voltage is

between 22 and 29 VDC.

b. If the DVM reading is within the indicated

voltage range, select DC volts on the DVM

(DVM must be accurate to +/-0.01 VDC), and

connect the (+) lead to Terminal VDC and the

(-) lead to Terminal C.

If the DVM voltage is between 4.9 and

5.1 VDC, proceed to Step 2.

If the DVM voltage is above 5.1 VDC, replace

the A350P.

c. If the DVM voltage is below 4.9 VDC, check

the control using the following procedure.

Disconnect all loads from the A350P control.

(If in Direct Acting mode with power on, the

system will go to full output when the sensor is

disconnected. Thus, ensure that any loads are

disconnected before disconnecting the

temperature sensor.)

Disconnect the temperature sensor

completely, and recheck the DVM voltage.

2. Check sensor for proper resistance at a given

temperature. (The resistance across the sensor

changes with the temperature of the sensor. )

a. Disconnect power from the A350P control.

b. Disconnect the sensor from the control and

measure the resistance across sensor leads.

c. When measuring the sensor’s resistance, use

an accurate thermometer to measure the

temperature at the sensor.

d. Refer to Figure 8 to determine the optimal

resistance for the measured temperature.

e. If the measured resistance varies substantially

from the optimal resistance for that

temperature, the sensor or wiring must be

replaced.

f. If the sensor’s resistance conforms to the

chart in Figure 8, reconnect the sensor to the

control.

g. Reconnect power to the control.

Note: The sensor reading indicated by the D350

may differ somewhat from thermometer

readings due to sensor tolerances, time

constants, thermometer accuracy, and ot her

factors.

If the DVM voltage rises to a value between

4.9 and 5.1 VDC, replace the sensor.

If the DVM voltage is still below 4.9 VDC,

replace the A350P control.

System 350 A350P Electron ic Proportio nal Plus Int egral Tempe rature Control Prod uct/Tec hnical Bullet in 9

Figure 8: Temperature vs. Resistance Chart for the

A99B Series Sensor

Page 10

3. Check the A350P control for proper operation.

Note: Perform Steps 1 and 2 first.

a. Reconnect the sensor to the control and

re-apply power.

b. Turn the throttling range and the minimum

output to minimum by turning both

potentiometers counterclockwise.

c. Switch off the integration.

d. Select the RA mode.

e. Connect the DVM (+) lead to the A350P

control’s Terminal SN and the (-) lead to

Terminal C.

If the sensor voltage is less than 1.8 VDC on

model A350PS-1C or less than 2.3 VDC on

model A350PS-2C, go to Step 3g.

f. If the voltage is greater than 1.8 VDC on

model A350PS 1C or greater than 2.3 VDC on

model A350PS-2C, adjust the setpoint to

120°F (49°C) on model A350PS-1C or 240°F

(116°C) on model A350PS-2C.

The output Terminal V should be less than

0.1 VDC, and all LEDs in the bar graph display

should be off. If not, replace the A350P.

g. If the sensor voltage is above 1.1 VDC

on A350PS-1C or above 1.6 VDC on

A350PS-2C, adjust the setpoint to match t he

actual temperature (Ts). The output Terminal

V should be less than 0.1 VDC, and all LEDs

in the bar graph should be off.

Note: Some tolerance error is present betwee n the

setpoint scale and the setpoint knob pointer.

Refer to the Adjustments section.

1. Make sure the A350P control is in RA

mode.

2. Increase the setpoint in increments of 2F°

(1C°).

3. As the setpoint is increased, the control’s

Terminal V output voltage should go from

0 to 10 VDC, the Terminal I output current

should go from 0 to 20 mA, and the LEDs

should turn on, one at a time from left to

right.

4. If the LEDs do not turn on and if the

outputs of terminals V and I do not change

as described above, replace the control.

h. Readjust the A350P control to the desired

control settings.

1. Adjust the minimum output to the

maximum by turning the potentiometer

CW. As the potentiometer is turned CW,

the LEDs in the bar graph should turn on

from left to right until the fifth or sixth bar is

on. If not, replace the A350P control.

2. Adjust the minimum output to zero again,

and select the DA mode.

3. If the right most LED in the bar graph is on

(Terminal V = 10 VDC, Terminal I = 20 mA),

go to Step 3h. If the LED is not on, replace

the A350P.

epairs and Replacement

R

Do not make field repairs or perform calibrati on.

A99B Temperature Sensors and replacement controls

are available through the nearest Johnson Controls

representative. (See Tables 5 and 6 for orderin g

information.)

10 System 350 A350P Electroni c Proport ional Plus I ntegral Te mperat ure Control P roduct/T echnical Bulletin

Page 11

rdering Information

Item

Product Code Number

Description

(Sensor not included)

Display Modules

D350BA-1C

Digital Temperature Display Module (Celsius Scale)

On/Off Stage Modules

S350AB-1C

Celsius Scale

Slave Stage Module

Proportional Stage Modu le

24 VAC Output

Item

Product Code Number

Description

Wall Mount Plate

Duct Mounting

Conduit Adaptor

Immersion Well

WEL11A-601R

For liquid sensing applications

DIN Rail Sections

DIN Rail End Clamp

PLT344-1R

Consists of two end clamps

O

Table 5: System 350 Products

A350P Proportional Plus Inte gral

Temperature Controls

Power Module

A350PS-1C

A350PS-2C

A350PT-1C

D350AA-1C

S350AA-1C

S350CC-1C Dual Scale (°F and °C)

S350PQ-1C Dual Scale (°F and °C)

Y350R-1C 120 or 240 VAC, 50/60 Hz Input, Rectified Class 2,

Table 6: System 350 Accessories

Range: -30 to 130°F (-35 to 55°C)

Throttling Range: 2 to 30 F° (1 to 17C°)

(Includes the A99BC-25C Temperature Sensor)

Range: 90 to 250°F (30 to 120°C)

Throttling Range: 2 to 30 F° (1 to 17C°)

(Includes the A99BC-25C Temperature Sensor)

Range: -30 to 130°F (-35 to 55°C)

Throttling Range: 2 to 30F° (1 to 17C°)

Digital Temperature Display Module (Fahrenheit Scale)

Fahrenheit Scale

TE-6001-4 Includes sensor mounting clip

Cover

Mounting Clip

Duct Mounting

Sun Shield

Cables for Remote Mounting of

D350 Display Module

T-4000-2644 For wall mount plate

A99-CLP-1 Surface mounting clip for the A99B Temperature Sensor

TE-6001-1 Duct-mounting hardware with handy box

TE-6001-11 Duct-mounting hardware without handy box

ADP11A-600R 1/2 in. snap-fit EMT conduit adaptor (box of 10)

SHL10A-603R For use with outside sensors in sunny locations

BKT287-1R

BKT287-2R

WHA29A-600R*

WHA29A-603R

WHA29A-604R

12 in. (0.3 m) long

39-1/3 in. (1.0 m) long

3 ft (0.9 m)

25 ft (7.6 m)

50 ft (15.2 m)

*WHA29A-600R may be used to daisy chain S350 modules together.

System 350 A350P Electron ic Proportio nal Plus Int egral Tempe rature Control Prod uct/Tec hnical Bullet in 11

Page 12

Product

A350P Proportional Plus Time Integral Temperature Control

Note: Only one supply voltage source may be used.

Power Consumption

3.2 VA maximum

Shipping: -40 to 185°F (-40 to 85°C)

Humidity (all modules)

0 to 95% RH non-condensing; maximum dew point 85°F (29°C)

A350PT-1C: -30 to 130°F (-35 to 55°C)

Range

Analog Outputs

0 to 10 VDC (550 ohm load minimum) and 0 to 20 mA (600 ohm load maximum)

Minimum Output

Adjustable from 0 to 60% of the output

Output Indication

A ten segment LED bar graph indicates percentage of output.

Control Action

Direct or reverse action is jumper selectable.

Integration Constant

Four selectable rates: fast, medium, slow, and off

Reference resistance 1035 ohms at 77°F (25°C)

Material

Case and cover: NEMA 1 high-impact thermoplastic

UL Listed for Canada, CCN XAPX7, File E27734

Building Efficiency

pecifications

S

Supply Voltage Y350R Power Module: Input: 120/240 VAC 50/60 Hz

Output: 24 VDC, unfiltered, 10 VA

External Source: 24 VAC, 50/60 Hz, Class 2 (20-30 VAC)

Ambient Temperature Operating: -30 to 150°F (-34 to 66°C)

Setpoint Adjustment Ra nge A350PS-1C: -30 to 130°F (-35 to 55°C)

A350PS-2C: 90 to 250°F (30 to 120°C)

Throttling Adjustm ent

Sensor Replaceable positive temperature coefficient sensor

Agency Listing UL Listed, CCN XAPX, File E27734

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications,

consult Johnson Controls Application Engineering at (414) 274-5535. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication

or misuse of its products.

2 to 30F° (1 to 17C°)

® Johnson Controls and PENN are regi s tered trademarks of Johnson Controls, Inc. in the

United States of America and/or ot her countries. All other trademarks used herein are the property

of their respective owners. © Copyright 2014 by Johnson Controls, Inc. All rights res er ved.

12 System 350 A350P Electroni c Proport ional Plus I ntegral Te mperat ure Control P roduct/T echnical Bulletin

507 E. Michigan Street, Milwaukee, WI 53202

Loading...

Loading...