Page 1

System 350™

S350A Temperature, S351A Humidity,

and S352A Pressure Stage Modules

The S350A, S351A, and S352A Stage Modules are

intended to be used with System 350™ controls. Each

of these stage modules plugs into the respective

control module to add multiple-stage capability. These

stage modules have Single-Pole, Double-Throw

(SPDT) relay output with Light-Emitting Diode (LED)

indication.

As are all System 350 products, the stage modules are

housed in NEMA 1, high-impact thermoplastic

enclosures. The modular design provides easy,

plug-together connections for quick installation and

future expandability.

FANs 930, 125

Product/Technical Bulletin S350

Issue Date 0300

Modular Design

❑

Plug-together Connectors

❑

and 35 mm DIN Rail

Mounting

Selectable Mode of

❑

Operation

Adjustable Differential

❑

Adjustable Offset

❑

Figure 1: System 350 Stage Module

Features and Benefits

Permits system to be configured to

equipment, with convenient, future expansion

made easy

Eliminates wiring between modules and

reduces installation costs

Provides independent relay energization,

either above or below setpoint, for

cooling/heating (S350A),

dehumidification/humidification (S351A), or

direct acting/reverse acting (S352A)

Enables user to match the range of

temperature, humidity, or pressure stage

modules to specific application requirements

Allows multiple stage sequencing of 1-30F°

(0.5-17C°) (S350A), 2-30% RH (S351A), or

2-50 psi (S352AA-2)

© 2000 Johnson Controls, Inc.

Part No. 24-7664-1, Rev. D www.johnsoncontrols.com

Code No. LIT-930080

1

Page 2

pplication

A

The S350A, S351A, and S352A Stage Modules

receive power, setpoint, and sensor input from the

respective System 350 control modules. When

connected, the individual modules act as a multistage

control system.

The maximum number of stages that can be used in a

system varies with the control module type

(temperature, humidity, or pressure) and stage module

design.

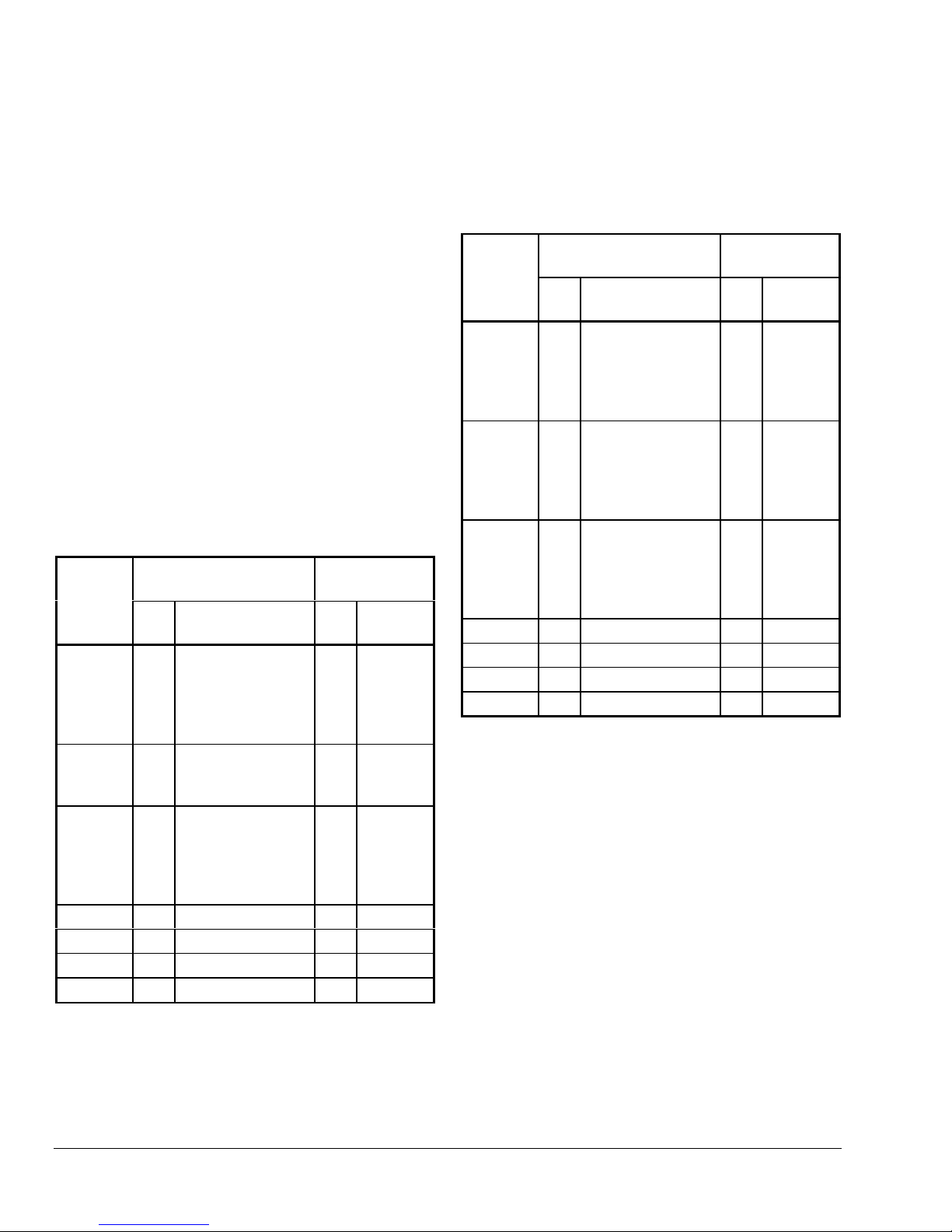

Refer to Table 1 or Table 2 to determine the maximum

number of stages that may be used with each control

module. When mixing stage module designs, always

use the lower number.

Note: When using an external transformer, the

Y65 Series or other 40 VA Class 2

transformers are recommended.

Table 1: Maximum Number of Add-on

Modules when Powered by a Y350R

Power Module

Control

Module

A350A

A350B

A350E

A350P

A350R

A350S

W351A

W351P

P352AB

P352PN

Stage

Module

No. Model

Numbers

9

S350As or S350Cs

6

S350As or S350Cs

with 1 S350P

S350As or S350Cs

4

with 2 S350Ps

42S350As or S350Cs

S350As or S350Cs

with 1 S350P

9

S350As or S350Cs

6

S350As or S350Cs

with 1 S350P

S350As or S350Cs

4

with 2 S350Ps

5 S351As 1 D351

4 S351As 1 D351

5 S352As 1 D352A

4 S352As 1 D352A

Display

Module

No. Model

Number

1 D350

1 D350

2 D350s

Table 2: Maximum Number of Add-on

Modules when Powered by an External

Transformer

Control

Module

Stage

Module

No. Model

Numbers

A350A

A350B

A350E

A350P

A350R

A350S

W351A

W351P

P352AB

P352PN

9

S350As or S350Cs

8

S350As or S350Cs

with 1 S350P

S350As or S350Cs

7

with 2 S350Ps

9

S350As or S350Cs

8

S350As or S350Cs

with 1 S350P

S350As or S350Cs

7

with 2 S350Ps

9

S350As or S350Cs

8

S350As or S350Cs

with 1 S350P

S350As or S350Cs

7

with 2 S350Ps

9 S351As 1 D351

9 S351As 1 D351

9 S352As 1 D352A

9 S352As 1 D352A

Notes: This bulletin only refers to the S350A, S351A,

and S352A Stage Modules.

For information on the S350C refer to the

System 350

TM

S350C Temperature Slave

Stage Module Product/Technical Bulletin

(LIT-930084).

For information on the S350P refer to the

System 350

TM

S350P Proportional Plus

Integral Temperature Stage Module

Product/Technical Bulletin (LIT-930086).

For information on the D350, D351 and D352

refer to the

System 350

TM

D350 Display

Modules Product/Technical Bulletin

(LIT-930070)

.

Display

Module

No. Model

Number

1 D350

1 D350

2 D350s

2

S350A Temperature, S351A Humidity, and S352A Pressure Stage Modules Product/Technical Bulletin

Page 3

O

peration

The S350A, S351A, and S352A Stage Modules

provide SPDT relay output. A front panel LED lights to

indicate when the relay is energized.

IMPORTANT: The System 350 Stage Modules

are intended to control

equipment under normal

operating conditions. Where

failure or malfunction of the

System 350 Stage Modules

could lead to an abnormal

operating condition that could

cause personal injury or damage

to the equipment or other

property, other devices (limit or

safety controls) or systems

(alarm or supervisory systems)

intended to warn of or protect

against failure or malfunction of

the System 350 Stage Modules

must be incorporated into and

maintained as part of the control

system.

Offset Adjustment

The offset adjustment determines the amount of offset

from the control module setpoint at which the stage

module relay de-energizes.

With the jumpers positioned vertically, the stage

module is set for Heating (S350A), Humidification

(S351A), or Reverse Acting (RA) (S352A) operation. In

this mode, the relay and LED indicator de-energize

when the sensed temperature, humidity, or pressure

rises to the setpoint

minus

offset value.

Note: The S350A, S351A, and S352A Stage

Modules are configured with the jumpers in

the horizontal position at the factory.

Refer to Figures 6, 7, and 8 for examples of S350A,

S351A, and S352A applications.

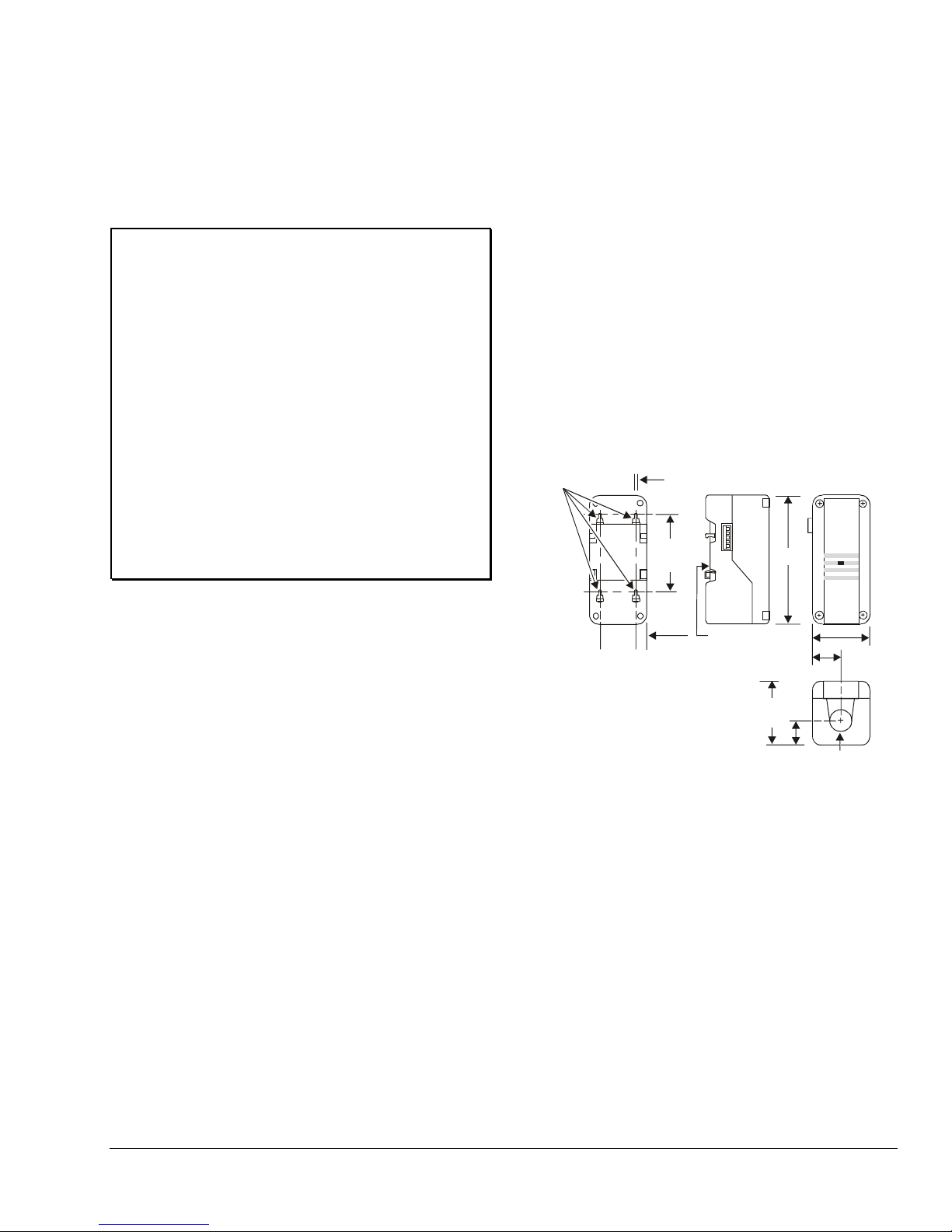

imensions

D

Mounting Slots

For No. 6 Screws

1-1/2

(40)

1/8 (4)

2-15/16

(75)

7/16

(11)

DIN Rail

Mount

5 (127)

1-3/16

(31)

ON

JOHNSON

CONTROLS

CONTROLS

2-3/8

(61)

S350

O

O

Differential Adjustment

Differential is defined as the difference in degrees,

% RH, or psi between energization and

de-energization of the stage module’s relay.

Operation Mode Selection

The S350A, S351A, and S352A utilize jumpers (at

jumper terminal J2) to select the operation mode. (See

Adjustments

With the jumpers positioned horizontally, the stage

module is set for Cooling (S350A), Dehumidification

(S351A), or Direct Acting (DA) (S352A) operation. In

this mode the relay and LED indicator de-energize

when the sensed temperature, humidity, or pressure

drops to the setpoint

section and Figures 3, 4, and 5.)

plus

offset value.

2-3/8

(61)

7/8 (22)

Conduit

Hole

7/8 (22)

Figure 2: System 350 Stage Module

Dimensions, in. (mm)

ounting

M

Each System 350 Stage Module is housed in a

compact NEMA 1 plastic enclosure designed for

standard 35 mm DIN rail mounting. Four key-slot

mounting holes on the back of the control case are

provided for surface mounting. (See Figure 2.) The

modules are not position sensitive, but should be

mounted for convenient access to wiring and

adjustments.

Note: When mounting any System 350 module to

rigid conduit, attach the hub to the conduit

before securing the hub to the control

enclosure.

S350A Temperature, S351A Humidity, and S352A Pressure Stage Modules Product/Technical Bulletin

3

Page 4

djustments

A

Refer to the following steps for adjusting stage module

settings. (See Figures 3, 4, and 5.)

!

WARNING:

Risk of Electrical Shock.

Disconnect power supply to

avoid possible electrical shock or

equipment damage. More than

one disconnect may be required

to completely de-energize

equipment.

1. Ensure all power to system is off.

Each stage module may be receiving separate

power sources. Make sure all power sources to

each stage module are off.

2. Remove the stage module cover by loosening the

four captive cover screws.

Set the mode of operation

3.

by positioning the

jumpers (at jumper terminal J2) for Cooling,

Dehumidification, or Direct Acting mode. Position

the jumpers vertically for Heating, Humidification,

or Reverse Acting mode.

Note: The S350A, S351A, and S352A Stage

Modules are configured with the jumpers in

the horizontal position at the factory.

Adjust the differential

4.

using the potentiometer

marked DIFF to the desired setting (the difference

in degrees, % RH, or psi between energization

and de-energization of the stage module’s relay).

Adjust the offset

5.

using the potentiometer marked

OFFSET to the number of degrees, % RH, or psi

from the System 350 control’s setpoint at which

the stage relay de-energizes (above setpoint with

Cooling, Dehumidification, or Direct Acting mode

selected, or below setpoint with Heating,

Humidification, or Reverse Acting mode selected).

6. Replace the cover on the stage module and fasten

in place with screws.

7. Restore power to system.

Potentiometer

Module

Connector

Relay Energized

LED Indicator

Cover Screw

1 of 4

Offset

N.C.

Relay

Relay

COM

Output

Differential

Potentiometer

Module

Connector

Jumper

Position at J2

Heating

Cooling

N.O.

Terminals

Figure 3: Interior View of S350A Stage Module

Offset

Potentiometer

Module

Connector

Relay Energized

LED Indicator

Cover Screw

1 of 4

N.C.

Relay

Relay

COM

Output

Differential

Potentiometer

Module

Connector

Jumper

Position at J2

Humidification

Dehumidification

N.O.

Terminals

Figure 4: Interior View of S351A Stage Module

Offset

Potentiometer

Module

Connector

Relay Energized

LED Indicator

Cover Screw

1 of 4

Relay

Differential

Potentiometer

Module

Connector

Jumper

Position at J2

Reverse

Acting

Direct

Acting

4

S350A Temperature, S351A Humidity, and S352A Pressure Stage Modules Product/Technical Bulletin

N.C.

Relay

COM

Output

N.O.

Terminals

Figure 5: Interior View of S352A Stage Module

Page 5

Higher

Temperature

Setpoi nt

Temperature

Lower

Temperature

ON

Differential

ON

Differential

OFF

OFFSET

OFF

OFF

ON = Energized

OFF = De-energized

A350

Stage 1

S350A

Stage 2

Cooling

OFFSET

Differential

S350A

Stage 3

ON

OFFSET

OFF

Differential

S350A

Stage 4

Heating

ON

S350A

Stage 5

OFFSET

OFF

Differential

ON

Higher

Pressure

Setpoint

Pressure

Lower

Pressure

Differential

ON

Differential

OFF

OFFSET

OFF

ON = Energized

OFF = De-energized

P352AB

Stage 1

S352A

Stage 2

Direct

ON

OFFSET

OFF

S352A

Stage 3

Reverse

Differential

ON

S352A

Stage 4

OFFSET

OFF

Differential

ON

Figure 6: Example of a Heating/Cooling

Application Using One A350 and Four S350As

Higher

Humidity

Setpoi nt

Relative

Humidity

Lower

Humidity

ON

Differential

OFF

ON = Energized

OFF = De-energized

W351

Stage 1

Dehumidify

OFF

OFFSET

S351

Stage 2

ON

Differential

OFFSET

OFF

S351

Stage 3

Humidify

Differential

ON

OFFSET

OFF

S351

Stage 4

Differential

ON

Figure 7: Example of a

Humidification/Dehumidification Application

Using One W351 and Three S351As

Figure 8: Example of a Reverse Acting/Direct

Acting Application Using One P352AB

and Three S352As

iring

W

Refer to the following guidelines and wiring diagrams

for proper wiring and terminal designations (See

Figures 9, 10, and 11.)

Note: For information on connecting to an external

transformer refer to the applicable control

bulletin.

!

WARNING:

Risk of Electrical Shock.

Disconnect power to avoid

possible electrical shock or

equipment damage. More than

one disconnect may be required

to completely de-energize

equipment.

IMPORTANT: Make all wiring connections in

accordance with the National

Electrical Code and all local

regulations. Use copper

conductors only. Do not exceed

the control’s electrical ratings.

S350A Temperature, S351A Humidity, and S352A Pressure Stage Modules Product/Technical Bulletin

The stage modules plug into the control and other

add-on modules via 5-pin connectors located on either

side of each module. Wiring is made at the Normally

Open (N.O.)/Normally Closed (N.C.) relay terminal

strip. (See Figures 3, 4, and 5.)

5

Page 6

Wire

Ter min al

Block

24V

COM

VDC

SEN

120 VAC

SEN

Shield (Connect

only to COM on A350)

A350

COM

Y350R

Sensor

Isolate and tape. (Do not ground

this end of cable shield.)

S350A D350

S350A S350A

Load

Load

Load

Load

Figure 9: Typical Multistage Temperature Control System Using 120 VAC Power Supply

Transmitter

Wire

Ter min al

Block

24V

COM

VDC

SEN

120 VAC

SEN

only to COM on W351)

W351 Y350R

VDC

Shield (Connect

Load Load

COM

S351A D351S351A S351A

Isolate and tape. (Do not ground

this end of cable shield.)

Load

Load

Figure 10: Typical Multistage Humidity Control System Using 120 VAC Power Supply

SEN

only to COM on P352AB)

P352AB

VDC

Shield (Connect

Y350R S352A S352A

COM

Wiring Harness

Isolat e and tape. (Do not ground

this end of cable shield.)

P399 Transducer

D352AS352A

Wire

Ter min al

Block

24V

COM

VDC

SEN

120 VAC

Figure 11: Typical Multistage Pressure Control System Using 120 VAC Power Supply

6

S350A Temperature, S351A Humidity, and S352A Pressure Stage Modules Product/Technical Bulletin

Load

Load

Load

Load

Page 7

heckout Procedure

C

Before applying power, make sure installation and

wiring connections are according to job specifications.

After necessary adjustments and electrical

connections have been made, put the system in

operation and observe at least three complete

operating cycles before leaving the installation.

roubleshooting

T

If the control system does not function properly, first

verify that the control, power, and display modules are

all operating correctly (refer to the respective

literature). Then inspect the stage modules for proper

operation.

Check that the proper operating mode

(Cooling/Heating, Dehumidification/Humidification, or

Direct Acting/Reverse Acting) has been selected on

each stage module. (See

Adjustments

section and

Figures 3, 4, and 5.) Then perform the following

procedures to determine the problem.

1. Verify the system has power.

2. Note the offset and differential settings on the

stage module.

3. Turn the setpoint dial on the control module to

minimum.

4. Increase the setpoint by slowly adjusting the

setpoint dial until the stage relay LEDs turn On

and Off as shown in Tables 3, 4, or 5.

Table 3: S350A Relay Troubleshooting

Operation

LED

Mode

Cooling

Cooling

Heating

Heating

*(Ts) = sensed temperature

On Closed

Off Open (Ts) – offset

On Closed

Off Open (Ts) + offset

N.O.

Relay

Status

Setpoint Dial

Setting

(Ts)* - offset

-

differential

(Ts) + offset

+

differential

Table 4: S351A Relay Troubleshooting

Operation

Mode

LED N.O.

Relay

Status

Dehumidify

Dehumidify

Humidify

Humidify

*(RHT) = actual relative humidity at transducer

On Closed (RHT)* -offset

Off Open (RH

On Closed (RH

Off Open (RHT) + offset

Setpoint Dial

Setting

-

differential

) - offset

T

) + offset

T

+

differential

Table 5: S352A Relay Troubleshooting

Operation

Mode

LED N.O.

Relay

Status

Direct

Direct

Reverse

Reverse

*(psiT) = actual pressure at transducer

On Closed (psiT)*- offset

Off Open (psi

On Closed (psi

Off Open (psiT) + offset

5. If the relays do not perform as indicated in

Tables 3, 4, or 5, adjust the stage module’s

differential and offset potentiometers to minimum

and repeat Steps 1 through 3.

6. If the relays still do not turn on and off, replace the

defective stage modules.

Note: There is the unlikely possibility that a defect in

one stage module could cause defective

symptoms in all modules. Plug each stage into

the control individually and check the

performance of each as explained above.

epairs and Replacement

R

Do not make field repairs or perform calibration.

Sensors and replacement controls are available

through your local Johnson Controls representative.

Setpoint Dial

Setting

differential

) - offset

T

) + offset

T

differential

-

+

S350A Temperature, S351A Humidity, and S352A Pressure Stage Modules Product/Technical Bulletin

7

Page 8

rdering Information

O

Table 6: Ordering Information

Item Product Code

Description

Number

S350A Temperature Stage

Module

S351A Humidity Stage Module

S352A Pressure Stage Module

pecifications

S

Product

Input Voltage

Power Consumption

Output Relay Electrical

Ratings

Differential Adjustment

Range

Offset Range

Ambient Temperature

Ambient Humidity

Material

Mounting

Agency Listing

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult Johnson Controls/Penn Application Engineering at (414) 274-5535. Johnson Controls, Inc. shall not be liable for

damages resulting from misapplication or misuse of its products.

S350AA-1C Temperature Stage Module with Fahrenheit Scale

S350AB-1C Temperature Stage Module with Celsius Scale

S351AA-1C Humidity Stage Module with percent RH Scale

S352AA-2C Pressure Stage Module with psi Scale

S350AA: Temperature Stage Module with Fahrenheit Scale

S350AB: Temperature Stage Module with Celsius Scale

S351AA: Humidity Stage Module with Percent RH Scale

S352AA-2: Pressure Stage Module with psi Scale

S350AA: Provided by the A350

S351AB: Provided by the W351

S352AA-2: Provided by the P352AB

1.0 VA maximun

SPDT Enclosed Relays

10 Ampere Non-inductive, 125 VA Pilot Duty, 24/240 VAC

1/2 hp 120/240 VAC

S350AA: 1 to 30F°

S350AB: 0.5 to 17C°

S351AA: 2 to 10% RH

S352AA-2: 2 to 50 psi

S350AA: 1 to 30F°

S350AB: 0.6 to 16.7C°

S351AA: 2 to 30% RH

S352AA-2: 2 to 50 psi

Operating: -30 to 150°F (-34 to 66°C)

Shipping: -40 to 185°F (-40 to 85°C)

0 to 95% RH (Non-condensing)

Case, Cover: NEMA 1 High Impact Thermoplastic

Wall or DIN Rail

UL Listed, CCN XAPX, File E27734

UL Listed for Canada, CCN XAPX7, File E27734

Controls Group

507 E. Michigan Street

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201 www.johnsoncontrols.com

8

S350A Temperature, S351A Humidity, and S352A Pressure Stage Modules Product/Technical Bulletin

Loading...

Loading...