Page 1

INSTALLATION

SUNLINE 2000™

MANUAL

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . 4

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REFERENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . 4

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

START-UP (COOLING) . . . . . . . . . . . . . . . . . . . . 35

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . 35

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SINGLE PACKAGE HEAT PUMP

BQ 036, 048 & 060

EXPORT ONLY

See the following page for a complete Table of Contents.

NOTES, CAUTIONS AND WARNINGS

The installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. Notes

clarify or make the installation easier. Cautions

to prevent equipment damage. Warnings

alert installer that personal injury and/or equipment damage may result if installation procedure is not handled

properly.

CAUTION: READ ALL SAFETY GUIDES BEFORE YOU

BEGIN TO INSTALL YOUR UNIT.

are intended to

are given

are given to

ISO 9001

Certified Quality

Management System

SAVE THIS MANUAL

364985-XIM-B-0508

Page 2

TABLE OF CONTENTS

364985-XIM-B-0508

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . 4

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . 4

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION SAFETY INFORMATION: . . . . . . . . 6

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RIGGING AND HANDLING . . . . . . . . . . . . . . . . . . . . 7

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . 7

COMPRESSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SERVICE ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . 8

THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

POWER AND CONTROL WIRING . . . . . . . . . . . . . . 10

OPTIONS/ACCESSORIES . . . . . . . . . . . . . . . . . . . . 10

ELECTRIC HEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ECONOMIZER/MOTORIZED DAMPER AND

RAIN HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

POWER EXHAUST/BAROMETRIC RELIEF

DAMPER AND RAIN HOOD . . . . . . . . . . . . . . . . . . .11

ECONOMIZER AND POWER EXHAUST DAMPER

SET POINT ADJUSTMENTS AND

INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MINIMUM POSITION ADJUSTMENT . . . . . . . . . . . .12

ENTHALPY SET POINT ADJUSTMENT . . . . . . . . . .12

POWER EXHAUST DAMPER SETPOINT (WITH

OR WITHOUT POWER EXHAUST) . . . . . . . . . . . . .12

INDOOR AIR QUALITY . . . . . . . . . . . . . . . . . . . . . . .1 2

PHASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SUPPLY AIR BLOWERS . . . . . . . . . . . . . . . . . . . . . 30

CHECKING SUPPLY AIR CFM . . . . . . . . . . . . . . . . 30

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SEQUENCE OF OPERATIONS OVERVIEW . . . . . . 31

COOLING SEQUENCE OF OPERATION . . . . . . . . 31

CONTINUOUS BLOWER . . . . . . . . . . . . . . . . . . . . . . 31

INTERMITTENT BLOWER . . . . . . . . . . . . . . . . . . . . 31

NO OUTDOOR AIR OPTIONS . . . . . . . . . . . . . . . . . 31

ECONOMIZER WITH SINGLE ENTHALPY

SENSOR - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ECONOMIZER WITH DUAL ENTHALPY

SENSORS - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ECONOMIZER (SINGLE OR DUAL) WITH POWER

EXHAUST - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MOTORIZED OUTDOOR AIR DAMPERS - . . . . . . . 32

COOLING OPERATION ERRORS . . . . . . . . . . . . . 32

HIGH-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . 32

LOW-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . 32

FREEZESTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

LOW AMBIENT COOLING . . . . . . . . . . . . . . . . . . . . . 33

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . 33

COMPRESSOR PROTECTION . . . . . . . . . . . . . . . 33

FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

HEATING SEQUENCE OF OPERATIONS . . . . . . . 33

WITH OR WITHOUT ELECTRIC HEAT . . . . . . . . . . . 33

DEFROST MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

FORCED DEFROST . . . . . . . . . . . . . . . . . . . . . . . . . 34

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . 34

HEAT ANTICIPATOR SETPOINTS . . . . . . . . . . . . . 34

START-UP (COOLING) . . . . . . . . . . . . . . . . . . . . . 35

PRESTART CHECK LIST . . . . . . . . . . . . . . . . . . . . 35

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . 35

POST START CHECK LIST . . . . . . . . . . . . . . . . . . 35

SHUT DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . 35

COOLING TROUBLESHOOTING GUIDE . . . . . . . . 35

UNIT FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . 37

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

NORMAL MAINTENANCE . . . . . . . . . . . . . . . . . . . 38

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

OUTDOOR COIL . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2 Johnson Controls Unitary Products

Page 3

364985-XIM-B-0508

LIST OF FIGURES

Fig. # Pg. #

1 RECOMMENDED DRAIN PIPING . . . . . . . . . . . . . . . . 7

2 COMPRESSOR RESTRAINING BRACKET . . . . . . . . 8

3 TYPICAL FIELD POWER & CONTROL WIRING . . . . 9

4 ENTHALPY SETPOINT ADJUSTMENT . . . . . . . . . . 13

5 HONEYWELL ECONOMIZER CONTROL W7212 . . . 13

6 FOUR AND SIX POINT LOADING . . . . . . . . . . . . . . . 14

7 UNIT DIMENSIONS (3 - 5 TON HEAT PUMP)

FRONT VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 UNIT WITH ECONOMIZER RAINHOOD . . . . . . . . . . 23

9 UNIT WITH FIXED OUTDOOR AIR/MOTORIZED

DAMPER RAINHOOD . . . . . . . . . . . . . . . . . . . . . . . . 23

10 UNIT DIMENSIONS (REAR VIEW) . . . . . . . . . . . . . . 24

11 DISCONNECT/BLOWER ACCESS LOCATION . . . . 24

12 BELT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . 30

13 PRESSURE DROP ACROSS COIL . . . . . . . . . . . . . . 31

LIST OF TABLES

Tbl. # Pg. #

1 UNIT APPLICATION DATA (BQ) . . . . . . . . . . . . . . . . . 6

2 CONTROL WIRE SIZES . . . . . . . . . . . . . . . . . . . . . . 10

3 ELECTRIC HEATER CFM LIMITATIONS . . . . . . . . . 11

4 CENTER OF GRAVITY (ALL MODELS) . . . . . . . . . . 14

5 BQ 4 POINT LOADS WEIGHT DISTRIBUTION . . . . 14

6 BQ 6 POINT LOADS WEIGHT DISTRIBUTION . . . . 14

7 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 OPERATING WEIGHTS (LBS.) . . . . . . . . . . . . . . . . . 15

9 ELECTRICAL DATA - BQ036-060 DIRECT DRIVE

W/O POWERED CONVENIENCE OUTLET . . . . . . . 16

10 ELECTRICAL DATA - BQ036-060 BELT DRIVE

W/O POWERED CONVENIENCE OUTLET . . . . . . . 17

11 ELECTRICAL DATA - BQ036-060 BELT DRIVE

HIGH STATIC W/O POWERED CONVENIENCE

OUTLET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tbl. #

12 ELECTRICAL DATA - BQ036-060 DIRECT DRIVE

W/POWERED CONVENIENCE OUTLET . . . . . . . . . 19

13 ELECTRICAL DATA - BQ036-060 BELT DRIVE

W/POWERED CONVENIENCE OUTLET . . . . . . . . . 20

14 ELECTRICAL DATA - BQ036-060 BELT DRIVE

HIGH STATIC W/POWERED CONVENIENCE

OUTLET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

15 ELECTRIC HEAT CORRECTION FACTORS . . . . . . 22

16 VOLTAGE LIMITATIONS . . . . . . . . . . . . . . . . . . . . . 22

17 UTILITIES ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

18 MINIMUM CLEARANCES . . . . . . . . . . . . . . . . . . . . . 24

19 SUPPLY AIR BLOWER PERFORMANCE (BQ036

BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . 25

20 SUPPLY AIR BLOWER PERFORMANCE (BQ036

BELT DRIVE) - BOTTOM DUCT APPLICATION . . . 25

21 SUPPLY AIR BLOWER PERFORMANCE (BQ048

BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . 25

22 SUPPLY AIR BLOWER PERFORMANCE (BQ048

BELT DRIVE) - BOTTOM DUCT APPLICATION . . . 25

23 SUPPLY AIR BLOWER PERFORMANCE (BQ060

BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . 26

24 SUPPLY AIR BLOWER PERFORMANCE (BQ060

BELT DRIVE) - BOTTOM DUCT APPLICATION . . . 26

25 SUPPLY AIR BLOWER PERFORMANCE (BQ036,

048 & 060 DIRECT DRIVE) - SIDE DUCT

APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

26 SUPPLY AIR BLOWER PERFORMANCE (BQ036,

048 & 060 DIRECT DRIVE) - BOTTOM DUCT

APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

27 BELT DRIVE RPM SELECTION . . . . . . . . . . . . . . . . 27

28 BELT DRIVE BLOWER MOTOR AND DRIVE

DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

29 STATIC RESISTANCES . . . . . . . . . . . . . . . . . . . . . . 27

30 ELECTRIC HEAT LIMIT CONTROL SETTING . . . . . 34

31 ELECTRIC HEAT ANTICIPATOR SETPOINTS . . . . 35

32 UNIT CONTROL BOARD FLASH CODES . . . . . . . . 37

Pg. #

Johnson Controls Unitary Products 3

Page 4

364985-XIM-B-0508

GENERAL

YORK Model BQ units are single package heat pumps

equipped with optional factory installed electric heaters. These are designed for outdoor installation on a

rooftop or slab.

The units are completely assembled on rigid, permanently attached base rails. All piping, refrigerant

charge, and electrical wiring is factory installed and

tested. The units require electric power, gas connection, duct connections, installation of combustion air

inlet hood, flue gas outlet hoods and fixed outdoor air

intake damper (units without ec onomizer or motorized

damper option only) at the point of installation.

The supplemental electric heaters have nickel-chrome

elements and utilize single point power connection.

SAFETY CONSIDERATIONS

Due to system pressure, moving parts and electrical

components, installation and servicing of air conditioning equipment can be hazardous. Only qualified,

trained, service personnel should install, repair, maintain or service this equipment.

Observe all precautions in the literature, on labels and

tags accompanying the equipment whenever working

on air conditioning equipment. Be sure to follow all

other safety precautions that apply.

• 530.18-N1.14V -Man. Outdoor Air Damper Accy

0 - 100%

• 035-07364-000 -Motorized Outdoor Air Damper

Accy.

• 035-19422-000 –Electric Heat Accessory

• 035-19405-000 -Barometric Relief Damper

• 530.46-N1.1V -Dual Enthalpy Accessory

• 530.18-N1.10V -Power Exhaust Accessory

RENEWAL PARTS

Contact your local York® parts distribution center for

authorized replacement parts.

APPROVALS

Design listed by CSA as follows:

• For use as a heat pump only with or without

optional electric heat.

• For outdoor installation only.

• For installation on combustible material.

Wear safety glasses and work gloves, and follow all

safety codes. Use a quenching cloth and have a fire

extinguisher available for all brazing operations.

INSPECTION

As soon as a unit is received, it should be inspected for

possible damage during transit. If damage is evident,

the extent of the damage should be noted on the carrier's freight bill. A separate request for inspection by

the carrier's agent should be made in writing. Refer to

Form 50.15-NM for additional information.

REFERENCE

Additional information on the design, installation, operation and service of this equipment is available in the

following reference forms:

• 364985 -General Installation

• 035-19404-000 -Economizer Accessory

• 530.18-N1.13V -Man. Outdoor Air Damper

Accessory 0 - 35%

This product must be installed in strict compliance with the enclosed installation instructions

and any applicable local, state, and national

codes including, but not limited to, building,

electrical, and mechanical codes.

Improper installation may create a condition

where the operation of the product could cause

personal injury or property damage.

The installer should pay particular attention to the

words: NOTE, CAUTION and WARNING. Notes are

intended to clarify or make the installation easier. Cautions are given to prevent equipment damage. Warnings are given to alert installer that personal injury and/

or equipment damage may result if installation procedure is not handled properly.

4 Johnson Controls Unitary Products

Page 5

364985-XIM-B-0508

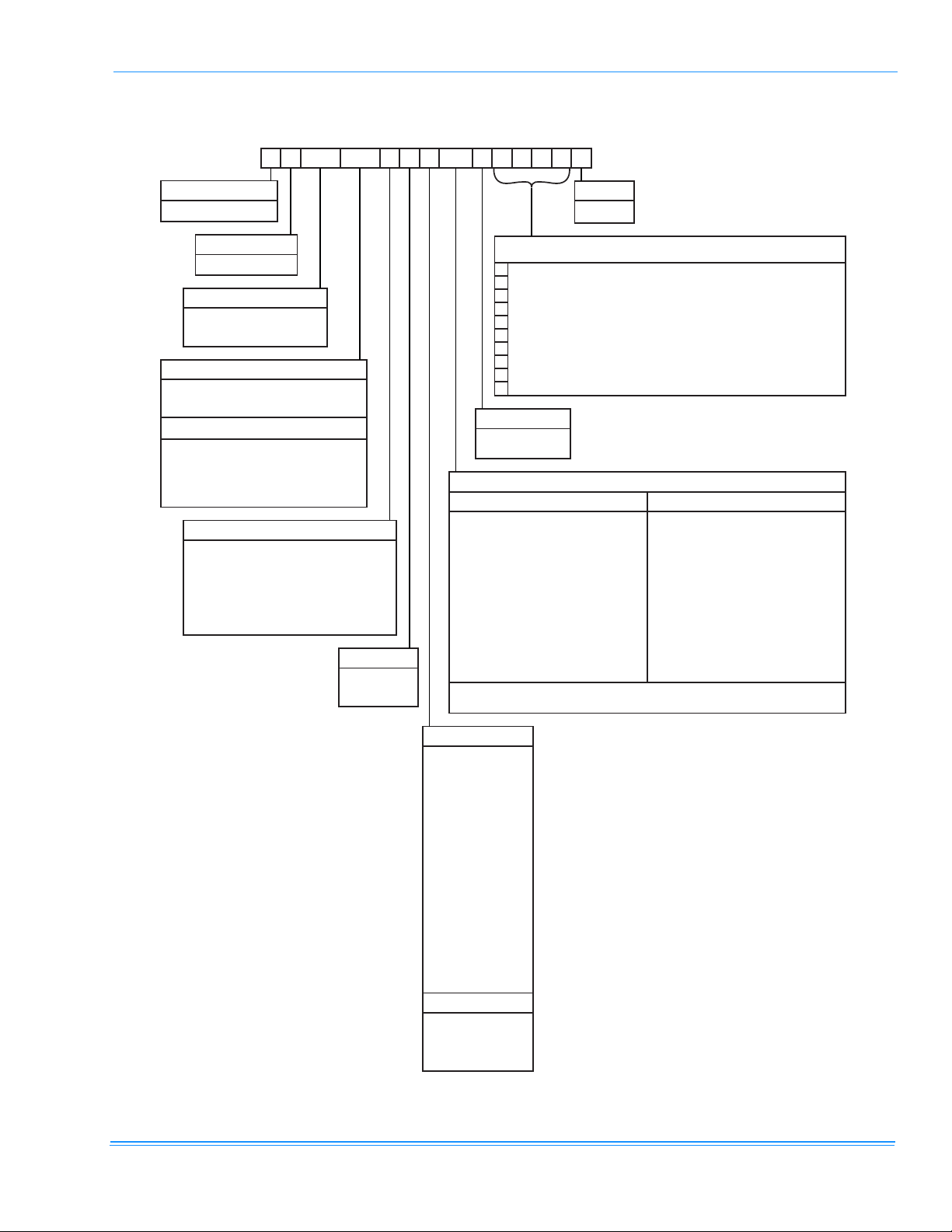

PRODUCT NOMENCLATURE

3-5 Ton Sunline Simplicity Model Number Nomenclature

B Q 048 N04 A 2 A AA 1 0 1 2 4 A

Product Category

B = HP, Single Pkg., R-22

Product Identifier

Q = 10.0 SEER HP

Nominal Cooling Capacity

036 = 3.0 Ton

048 = 4.0 Ton

060 = 5.0 Ton

Heat Type and Nominal Heat Capacity

C00 = Cooling Only. Suitable for Field

Installed Electric Heat

Electric Heat Options

E05 = 5 KW

E07 = 7 KW

E10 = 10 KW

E15 = 15 KW

E20 = 20 KW

E30 = 30 KW

Airflow

A = Direct Drive

B = Direct Drive/Single Input Economizer

D = Direct Drive/Motorized Damper

N = Belt Drive

P = Belt Drive/Single Input Economizer

R = Belt Drive/Motorized Damper

T = Belt Drive High Static

U = Belt Drive High Static/Single Input Economizer

V = Belt Drive High Static/Motorized Damper

Voltage

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

Product Style

A = Style A

These four digits will not be assigned until a quote is requested, or an order placed.

SS Drain Pan

CPC Controller, DFS, APS

Johnson Controller, DFS, APS

Honeywell Controller, DFS, APS

Novar Controller, DFS, APS

Simplicity IntelliComfort Controller

Simplicity IntelliComfort Controller w/ModLinc

2" Pleated Filters

BAS Ready Economizer (2-10 V. D. C. Actuator without a Controller)

Any Combination of Additional Options that Don’t Have an Option Code Pre-assigned

Product Generation

1 = First Generation

2 = Second Generation

Standard Cabinet

AA = None

AB = Phase Monitor

AC = Coil Guard

AD = Dirty Filter Switch

AE = Phase Monitor & Coil Guard

AF = Phase Monitor & Dirty Filter Switch

AG = Coil Guard & Dirty Filter Switch

AH = Phase Monitor, Coil Guard & Dirty Filter Switch

AS = Bottom Drain Connection

RC = Coil Guard & American Flag

TA = Technicoat Condenser Coil

TJ = Technicoat Evaporator Coil

TS = Technicoat Evaporator and Condenser Coil

ZZ = If desired option combination is not listed above, ZZ will be assigned and configuration options will be

located in digits 15-18.

Configuration Options (not required for all units)

Additional Options

Hinged Filter Door & Toolless Access Cabinet

BA = Hinged Filter Door & Toolless Access Panels

BA = Hinged Filter Door & Toolless Access Panels

BA = Hinged Filter Door & Toolless Access Panels

BB = Phase Monitor, Hinged Filter Door & Toolless

Access Panels

BC = Coil Guard, Hinged Filter Door & Toolless

Access Panels

BD = Dirty Filter Switch, Hinged Filter Door &

Toolless Access Panels

BE = Phase Monitor & Coil Guard, Hinged Filter

Door & Toolless Access Panels

BF = Phase Monitor & Dirty Filter Switch, Hinged

Filter Door & Toolless Access Panels

BG = Coil Guard & Dirty Filter Switch, Hinged Filter

Door & Toolless Access Panels

BH = Phase Monitor, Coil Guard & Dirty Filter Switch,

Hinged Filter Door & Toolless Access Panels

Installation Options

A = No Options Installed

B = Option 1

C = Option 2

D = Options 1 & 2

E = Option 3

F = Option 4

G = Options 1 & 3

H = Options 1 & 4

J = Options 1, 2 & 3

K = Options 1, 2, & 4

L = Options 1,3 & 4

M = Options 1, 2, 3, & 4

N = Options 2 & 3

P = Options 2 & 4

Q = Options 2, 3, & 4

R = Options 3 & 4

S = Option 5

T = Options 1 & 5

U = Options 1, 3, & 5

V = Options 1, 4, & 5

W = Options 1, 3, 4, & 5

X = Options 3 & 5

Y = Options 4 & 5

Z = Options 3, 4 & 5

Options

1 = Disconnect

2 = Non-Pwr'd Conv. Outlet

3 = Smoke Detector S.A.

4 = Smoke Detector R.A.

5 = Pwr'd Conv. Outlet

Johnson Controls Unitary Products 5

Page 6

364985-XIM-B-0508

INSTALLATION

INSTALLATION SAFETY INFORMATION:

Read these instructions before continuing this appliance installation. This is an outdoor combination heating and cooling unit. The installer must assure that

these instructions are made available to the consumer

and with instructions to retain them for future reference.

1. Install this unit only in a location and position as

specified on page 6 of these instructions.

2. This equipment is not to be used for temporary

heating of buildings or structures under construction.

LIMITATIONS

These units must be installed in accordance with the

following national and local safety codes:

In U.S.A

• National Electrical Code ANSI/NFPA No. 70.

.:

In Canada

:

• Current Canadian Electrical Code C22.1.

• Local plumbing and waste water codes.

• Other applicable local codes.

Refer to the Unit Application Data Table 1 and the

Electrical Data table for the unit.

If components are to be added to a unit to meet local

codes, they are to be installed at the dealer's and/or

the customer's expense.

Size of unit for proposed installation should be based

on heat loss/heat gain calculation made according to

the methods of the Air Conditioning Contractors of

America (ACCA).

This unit is not to be used for temporary heating of

buildings or structures under construction.

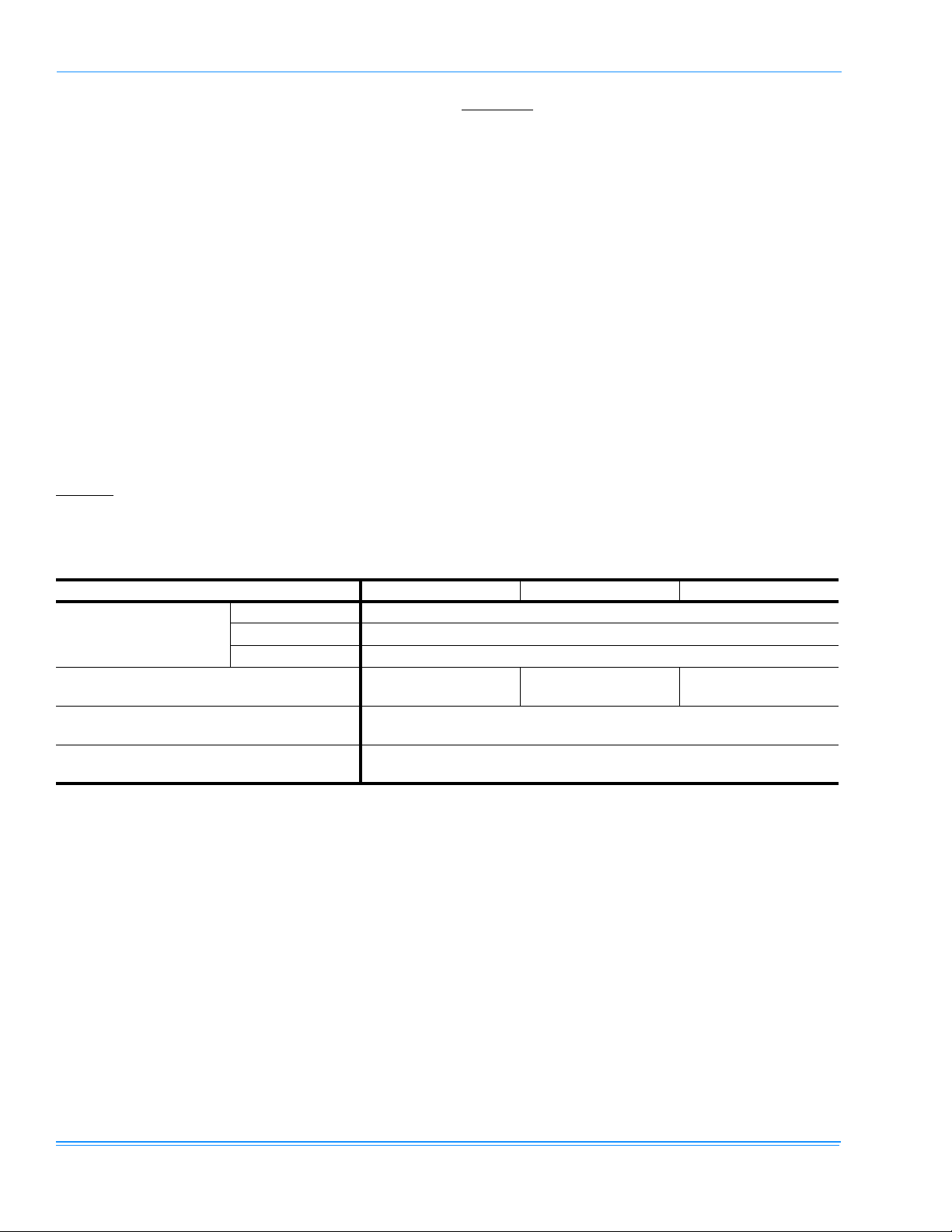

TABLE 1: UNIT APPLICATION DATA (BQ)

UNIT MODEL NUMBER 036 048 060

Voltage Variation,

Min. / Max.

Wet Bulb Temper ature (ºF) of Air on

Evaporator Coil, Min. / Max

Dry Bulb Temperature (ºF) of Air on

Condenser Coil, Min. / Max.

1. Utilization range “A” in accordance with ARI Standard 110.

1

Supply Air CFM, Nom. 1200 1600 2000

208/230 187 / 253

460 414 / 506

575 518 / 630

LOCATION

Use the following guidelines to select a suitable location for these units.

1. Unit is designed for outdoor installation only.

2. Condenser coils must have an unlimited supply of

air.

3. Where a choice of location is possible, position the

unit on either north or east side of building.

4. For ground level installation, use a level concrete

slab with a minimum thickness of 4 inches. The

length and width should be at least 6 inches

57 / 72

0 / 120

greater than the unit base rails. Do not tie slab to

the building foundation.

5. Roof structures must be able to support the weight

of the unit and its options and/or accessories. Unit

must be installed on a solid level roof curb or

appropriate angle iron frame.

6. Maintain level tolerance to 1/2 inch maximum

across the entire length or width of the unit.

If a unit is to be installed on a roof curb or special frame

other than a YORK roof curb, gasketing must be

applied to all surfaces that come in contact with the unit

underside.

6 Johnson Controls Unitary Products

Page 7

364985-XIM-B-0508

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove

any packaging until the unit is near the place of installation. Rig the unit by attaching chain or cable slings to

the lifting holes provided in the base rails. Spreader

bars, whose length exceeds the largest dimension

across the unit, MUST BE USED.

Units may also be moved or lifted with a forklift. Slotted

openings in the base rails are provided for this purpose. Fork lengths must be a minimum of 42 inches.

Remove the nesting brackets from the four corners on

the top of the unit. All screws that are removed when

removing the brackets must be replaced on the unit.

Refer to Table 8 for unit weights and to the Figure 6 for

approximate center of gravity.

Before lifting a unit, make sure that all panels

are in place and that its weight is distributed

equally on all cables so it will lift evenly.

CLEARANCES

A closed return duct system shall be used. This shall

not preclude use of economizers or outdoor fresh air

intake. The supply and return air duct connections at

the unit should be made with flexible joints to minimize

noise.

The supply and return air duct systems should be

designed for the CFM and static requirements of the

job. They should NOT be sized to match the dimensions of the duct connections on the unit.

When fastening ductwork to side duct flanges

on unit, insert screws through duct flanges

only. DO NOT insert screws through casing.

Outdoor ductwork must be insulated and

waterproofed.

Refer to Figures 7 and 10 for information concerning

side and bottom supply and return air duct openings.

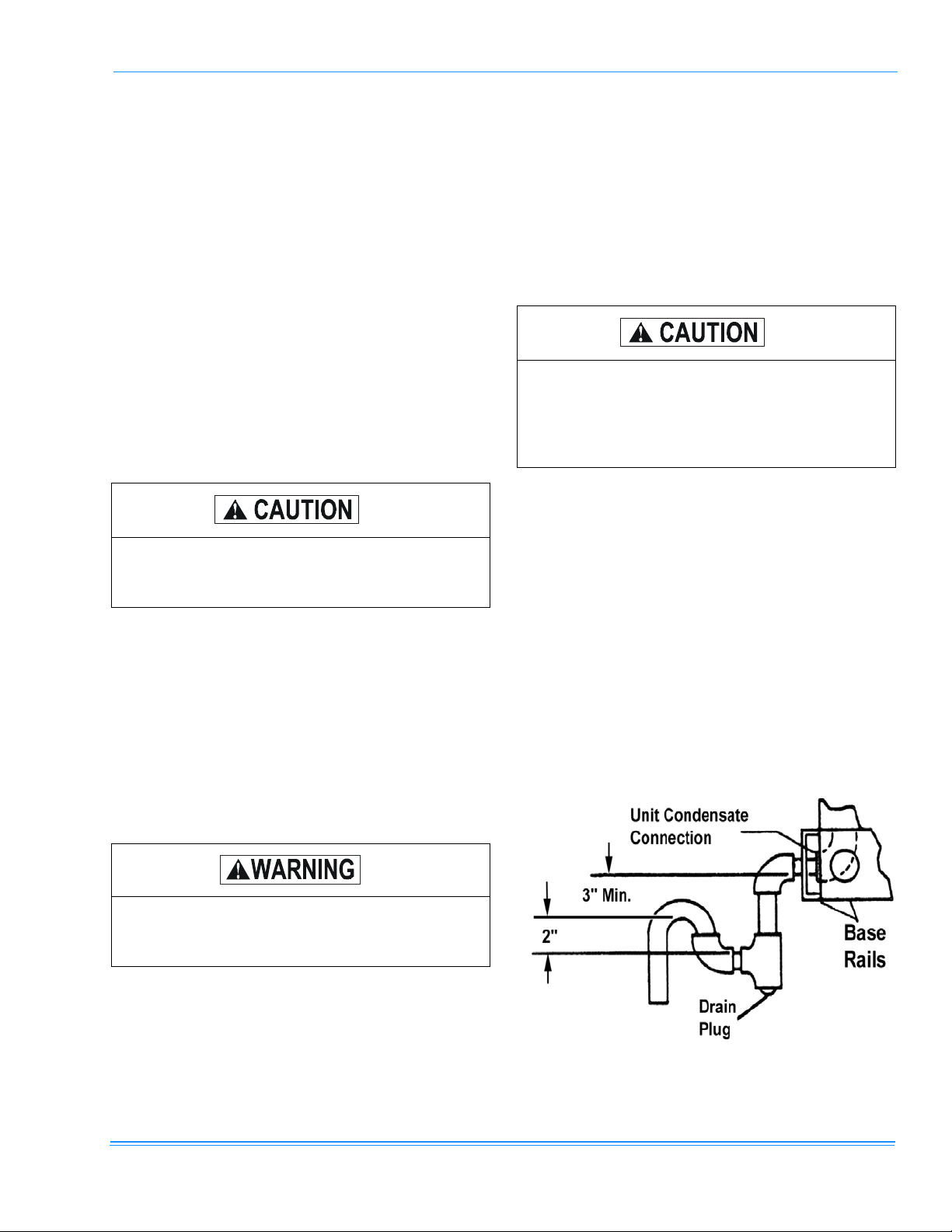

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate

drain line from the 3/4" NPT female con nection on the

unit to an open drain.

All units require certain clearances for proper operation

and service. Installer must make provisions for adequate ventilation air. Refer to Dimensions and Clearances shown in Figures 7 thr ough 10 and T able 18 for

the clearances required for combustible construction,

servicing, and proper unit operation.

Do not permit overhanging structures or shrubs

to obstruct outdoor air discharge outlet, combustion air inlet or vent outlets.

DUCTWORK

Ductwork should be designed and sized according to

the methods in Manual Q of the A ir Conditioning Contractors of America (ACCA).

NOTE: The condensate drain operates in a negative

pressure in the cabinet. The condensate drain

line MUST be trapped to provide proper drainage. See Figure 1.

FIGURE 1 - RECOMMENDED DRAIN PIPING

Johnson Controls Unitary Products 7

Page 8

364985-XIM-B-0508

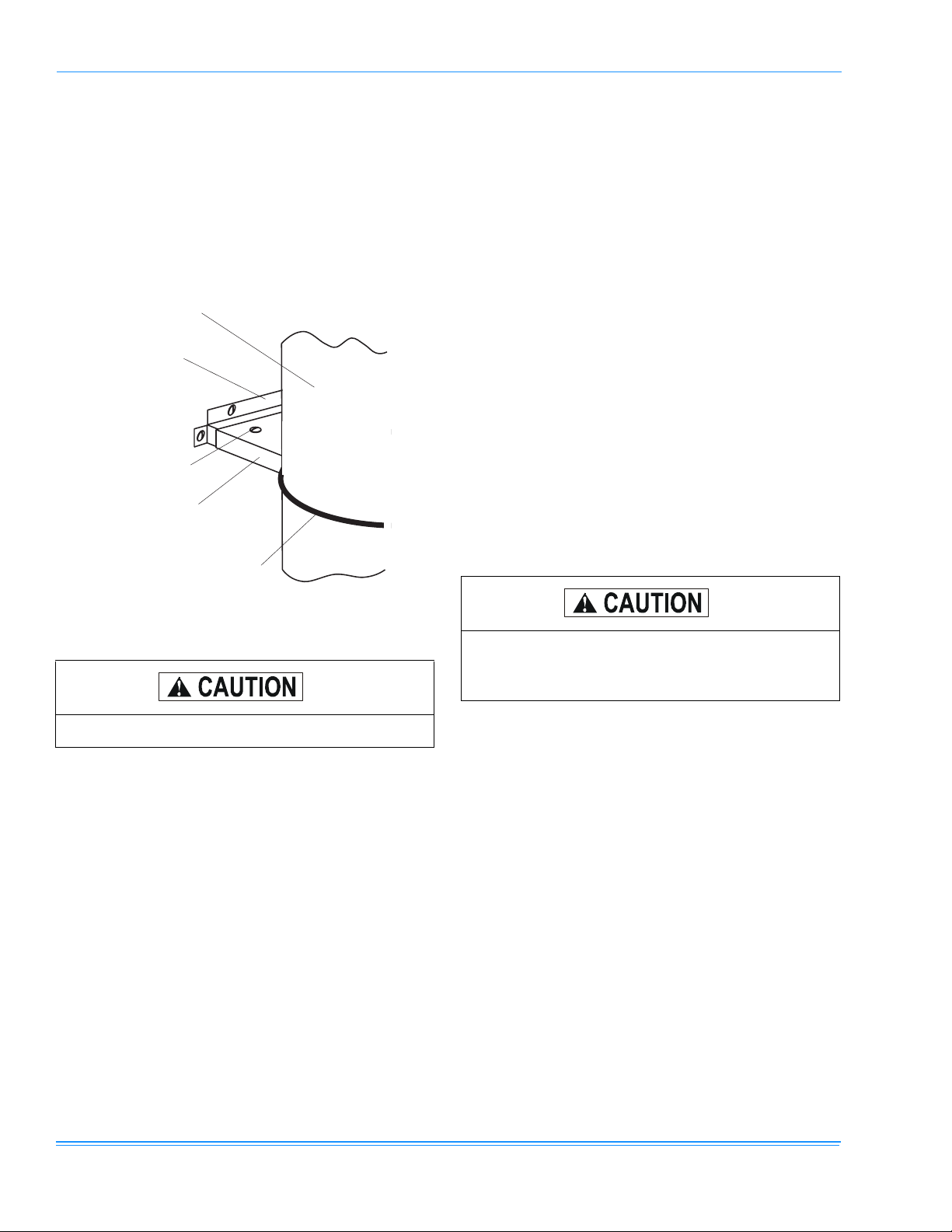

COMPRESSORS

Units are shipped with compressor mountings factoryadjusted and ready for operation.

Units with scroll compressors have a shipping bracket

which must be removed after the unit is set in place.

See Figure 2.

COMPRESSOR

MOUNTING

BRACKET BASE

REMOVE THESE

SCREWS (2)

MOUNTING

BRACKET TOP

(REMOVE)

FILTERS

One-inch or two-inch filters can be supplied with each

unit. Filters must always be installed ahead of the

evaporator coil and must be kept clean or replaced with

same size and type. Dirty filters will reduce the capacity

of the unit and will result in frosted coils or safety shutdown. Minimum filter area and required sizes are

shown in Physical Data Table 7.

SERVICE ACCESS

The following removable panels provide access to all

serviceable components:

• Compressor compartment

• Electric Heat compartment

• Blower compartment

• Main control box

• Filter compartment

Refer to the Dimensions and Clearances shown in Figures 7 and 11 for location of these access panels.

WIRE TIE (CUT AND REMOVE)

FIGURE 2 - COMPRESSOR RESTRAINING

BRACKET

Do not loosen compressor mounting bolts.

Make sure that all screws and panel latches

are replaced and properly positioned on the

unit to maintain an airtight seal.

8 Johnson Controls Unitary Products

Page 9

364985-XIM-B-0508

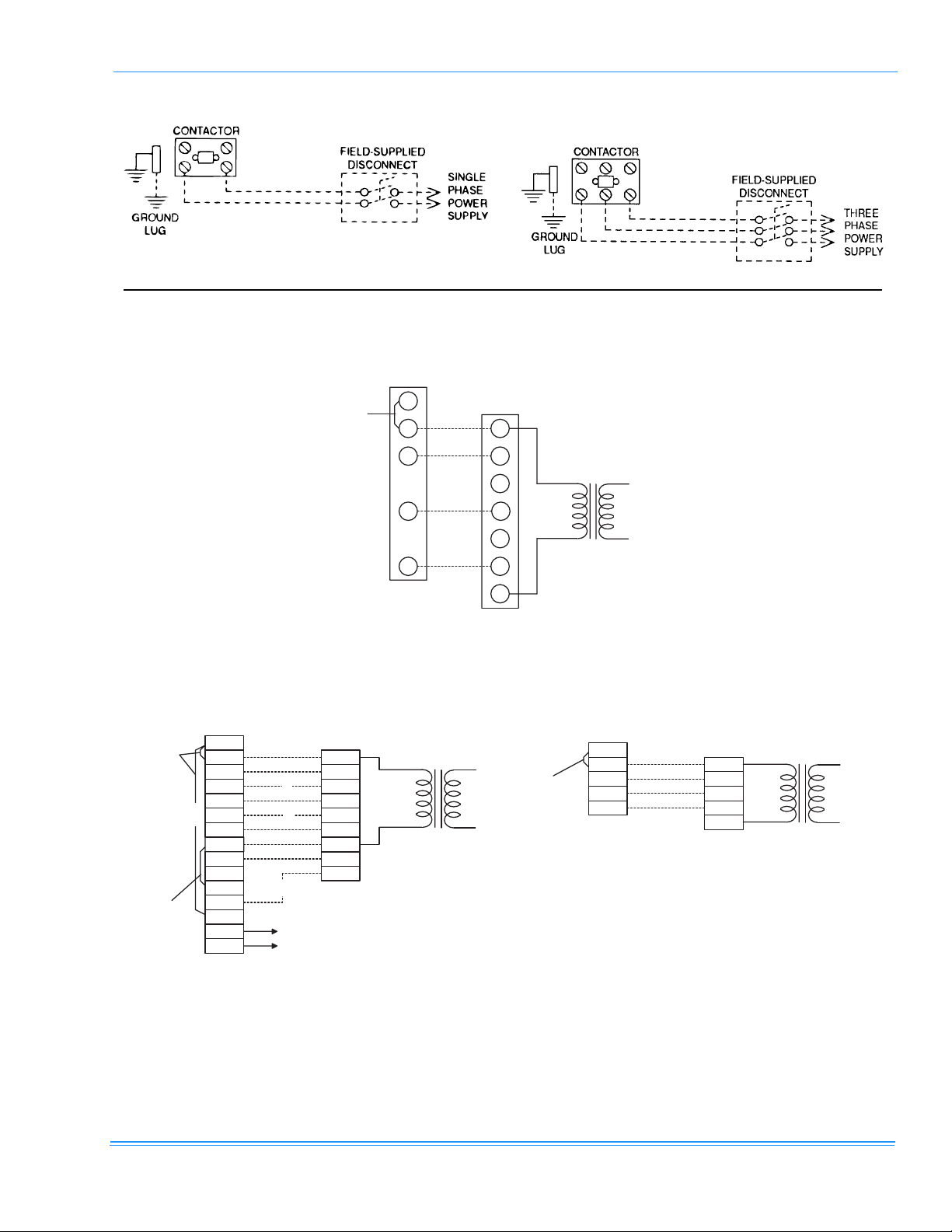

TYPICAL POWER WIRING

REFER TO THE ELECTRICAL DATA

TABLES TO SIZE THE DISCONNECT

SWITCH, OVERCURRENT PROTECTION AND WIRING.

TYPICAL CONTROL WIRING

COOLING / HEATING (24 VOLT THERMOSTAT)

THERMOSTAT

TERMINALS

ADD

JUMPER

1

RH

RC

UNIT TERMINAL

STRIP TB1

R

Y

W

G

1

24 VOLT THERMOSTAT 2ET07701024. TO CONTROL THE ECONOMIZER ON THE SECOND

STAGE COOLING OR TO HAVE AN ELECTRIC HEAT ACCESSORY WITH TWO STAGES OF

HEAT, USE THERMOSTAT 2TH0471024.

COOLING / HEATING (ELECTRONIC THERMOSTAT)

MULTI STAGE

RC

RH

Y1

Y2

W1

W2

A1

A2

1

UNIT TERMINAL

STRIP TB1

R

2

3

G

B

NOT

USED

4

T

T

TO REMOTE SENSOR

2TH040702224 IF USED

Y1

Y2

W1

W2

G

C

X

OCC

24 VOLT

TRANSFORMER

THERMOSTAT

TERMINALS

ADD

JUMPER

4

LED 1

LED 2

COM

ADD

JUMPER

1

ELECTRONIC PROGRAMMABLE THERMOSTAT 2ET04700224 (INCLUDES SUBBASE).

2

SECOND STAGE COOLING IS NOT REQUIRED ON UNITS LESS ECONOMIZER.

3

SECOND STAGE HEATING IS ONLY REQUIRED ON UNITS WITH A TWO STAGE

ELECTRIC HEATER OR 2 STAGE GAS HEAT.

4

REMOVE JUMPER J2 FROM TERMINALS 4 AND 9 ON JUMPER PLUG CONNECTOR

P6 ON UNITS WITH ECONOMIZER. TERMINALS A1 AND A2 PROVIDE A RELAY

OUT-PUT TO CLOSE THE OUTDOOR ECONOMIZER DAMPERS WHEN THE

THERMOSTAT SWITCHES TO THE SET-BACK POSITION.

Y1

Y2

W1

W2

G

C

24 VOLT

TRANSFORMER

COOLING / HEATING (ELECTRONIC THERMOSTAT)

SINGLE STAGE

THERMOSTAT

TERMINALS

ADD

JUMPER

1

ELECTRONIC PROGRAMMABLE THERMOSTAT 2ET07701024 (INCLUDES SUBBASE).

TO CONTROL THE ECONOMIZER ON SECOND STAGE COOLING, USE THERMOSTAT

2TH04700224.

1

UNIT TERMINAL

RH

RC

Y

W

G

STRIP TB1

R

Y1

W1

G

C

24 VOLT

TRANSFORMER

FIGURE 3 - TYPICAL FIELD POWER & CONTROL WIRING

Johnson Controls Unitary Products 9

Page 10

THERMOSTAT

The room thermostat should be located on an inside

wall approximately 56 inches above the floor where it

will not be subject to drafts, sun exposure or heat from

electrical fixtures or appliances. Follow the manufacturer's instructions enclosed with the thermostat for

general installation procedure. A minimum of seven

color-coded insulated wires (#18 AWG) should be used

to connect the thermostat to the unit.

POWER AND CONTROL WIRING

Field wiring to the unit must conform to provisions of

the National Electrical Code, ANSI / NFPA No. 70 (in

U.S.A.), current Canadian Electrical Code C22.1 (in

Canada) and/or local ordinances. The unit must be

electrically grounded in accordance with NEC and CEC

(as specified above) and/or local codes. Voltage tolerances, which must be maintained at the compressor

terminals, during starting and running conditions, are

indicated on the unit Rating Plate and the Unit Application Data table.

The internal wiring harness furnished with this unit is

an integral part of a CSA design certified unit. Field

alteration to comply with electrical codes should not be

required.

A fused disconnect switch should be field provided for

the unit. The switch must be separate from all other circuits. Wire entry at knockout openings require conduit

fittings to comply with NEC (in U.S.A.), CEC (in Canada) and/or local codes. If any of the wire supplied with

the unit must be replaced, replacement wire must be of

the type shown on the wiring diagram and the same

minimum gauge as the replaced wire.

Use copper conductors properly sized to carry the load.

Each unit must be wired with a separate branch circuit

fed directly from the meter panel and properly fused.

364985-XIM-B-0508

When connecting electrical power and control

wiring to the unit, waterproof type connectors

MUST BE USED so that water or moisture

cannot be drawn into the unit during normal

operation. The above waterproofing conditions

will also apply when installing a field-supplied

disconnect switch.

Refer to the Typical Field Wiring Figure 3 and to the

appropriate unit wiring diagram for control circuit and

power wiring information.

TABLE 2: CONTROL WIRE SIZES

Wire Size

18 AWG 150 Feet

1. From the unit to the thermostat and back to the unit.

Maximum Length

1

OPTIONS/ACCESSORIES

ELECTRIC HEAT

The factory- or field-installed heaters are wired for single point power supply. Power supply need only be

brought into the single point terminal block and thermostat wiring to the low voltage terminal strip located in

the upper portion of the unit control box.

These CSA approved heaters are located within the

central compartment of the unit with the heater elements extending into the supply air chamber. Refer to

Figure 7 for access panel location.

Fuses are supplied, where required, by the factory.

Some KW sizes require fuses and others do not. Refer

to Table 3 for minimum CFM limitations and to Tables

9 through 14 for electrical data.

10 Johnson Controls Unitary Products

Page 11

364985-XIM-B-0508

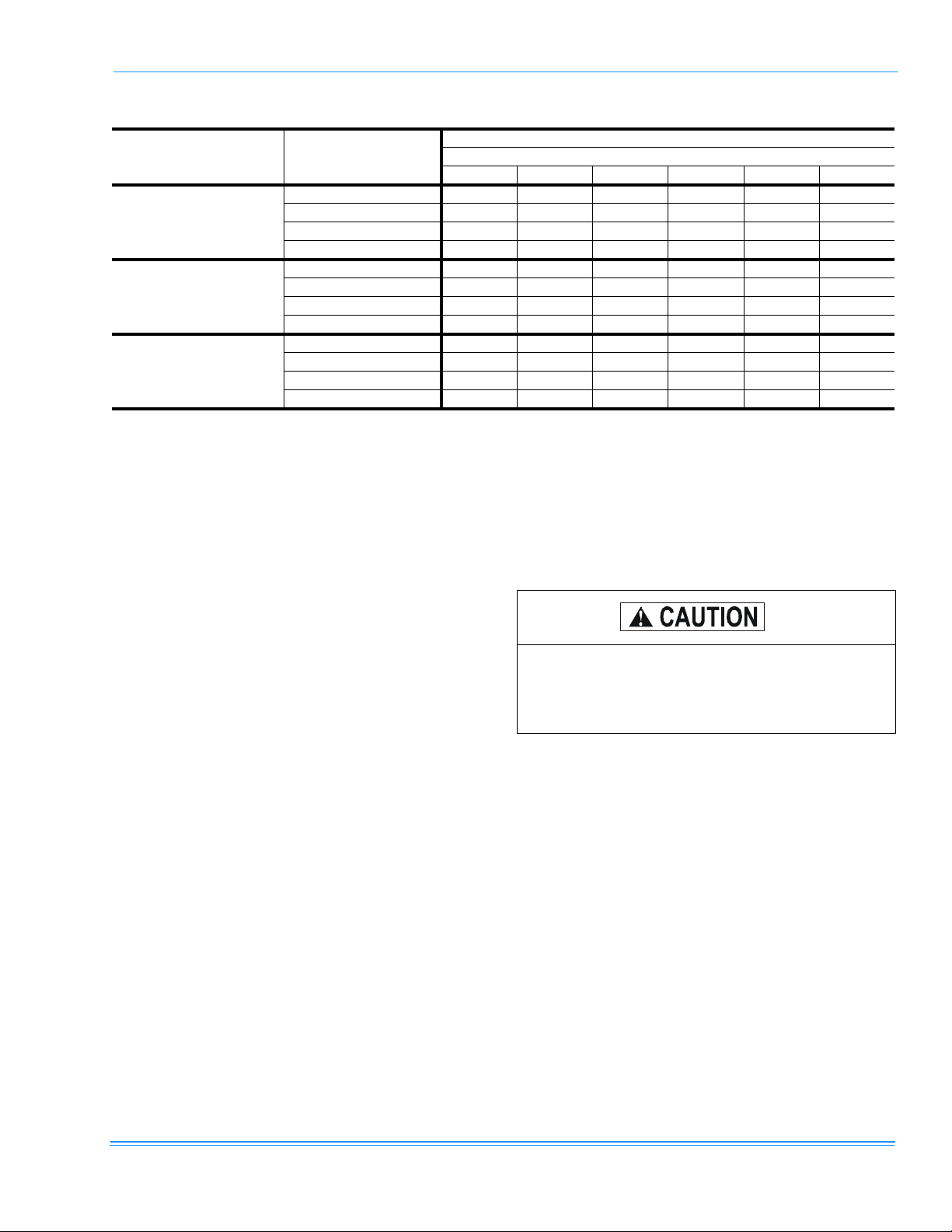

TABLE 3: ELECTRIC HEATER CFM LIMITATIONS

UNIT MODEL SIZE

NOMINAL TONS

036

(3)

048

(4)

060

(5)

ECONOMIZER/MOTORIZED DAMPER AND RAIN HOOD

VOLTAGE

5 7 10 15 20 30

208/230-1-60 900 900 900 900 900 208/230-3-60 900 900 900 900 900 -

460-3-60 - 900 900 900 900 -

600-3-60 - - 900 900 900 208/230-1-60 1200 1200 1200 1200 1200 208/230-3-60 1200 1200 1200 1200 1200 -

460-3-60 - 1200 1200 1200 1200 -

600-3-60 - - 1200 1200 1200 208/230-1-60 1500 1500 1500 1500 1500 1500

208/230-3-60 1500 1500 1500 1500 1500 1500

460-3-60 - 1500 1500 1500 1500 1500

600-3-60 - - 1500 1500 1500 1500

The instruction for the optional economizer/motorized

damper and rain hood can be found in form 03507364-000. Use these instructions when field assembling an economizer rain hood onto a unit. The outdoor

and return air dampers, the damper actuator, the

damper linkage, the outdoor and return air divider baffles, and all the control sensors are factory mounted as

part of the “Factory installed” economizer/motorized

damper options.

MINIMUM SUPPLY AIR CFM

HEATER SIZE NOMINAL KW

ECONOMIZER AND POWER EXHAUST DAMPER

SET POINT ADJUSTMENTS AND INFORMATION

Remove the economizer access panel from the unit.

Loosen but do not remove the two panel latches.

Locate the economizer control module, where the following adjustments will be made.

POWER EXHAUST/BAROMETRIC RELIEF DAMPER AND RAIN HOOD

The instructions for the power exhaust/barometric relief

damper and rain hood can be found in form 530.18N1.10V.

All of the components, including the dampers, hardware, and mounting instructions are shipped in a single

package external from the unit and must be field

assembled and installed.

Power exhaust is only available as a field installed

accessory.

Extreme care must be exercised in turning all

setpoint, maximum, and minimum damper

positioning adjustment screws to prevent twisting them off.

Check that the damper blades move smoothly without

binding; carefully turn the Minimum Position Adjusting

screw (found on the damper control module) fully

clockwise and then set the thermostat indoor fan switch

to the on position and then off, or energize and deenergize terminals “R” to “G”.

Johnson Controls Unitary Products 11

Page 12

364985-XIM-B-0508

MINIMUM POSITION ADJUSTMENT

With thermostat set to indoor fan on position, or terminals “R” to “G” energized, turn the Minimum Position

Adjusting screw (located on the damper control module) counterclockwise until the desired minimum

damper position has been attained.

ENTHALPY SET POINT ADJUSTMENT

The enthalpy setpoint may now be set by selecting the

desired setpoint shown in the Enthalpy Setpoint Adjustment Figure 4. Adjust as follows:

• For a single enthalpy operation carefully turn the

setpoint adjusting screw (found on the damper

control module) to the “A”, “B”, “C” or “D” setting

corresponding to the lettered curve of the Enthalpy

Setpoint Adjustment Figure 4.

• For a dual enthalpy operation, carefully turn the

setpoint adjusting screw fully clockwise past the

“D” setting.

POWER EXHAUST DAMPER SETPOINT (WITH OR WITHOUT POWER EXHAUST)

• With no power exhaust option, adjust the Exha u st

Air Adjustment Screw fully clockwise.

• With power exhaust option, each building pressurization requirement will be different. The point at

which the power exhaust comes on is determined

by the economizer damper position (Percent

Open). The Exhaust Air Adjustment Screw should

be set at the Percent Open of the economizer

damper at which the power exhaust is needed. It

can be set from 0 to 100% damper open.

INDOOR AIR QUALITY

Indoor air quality (indoor sensor input): Terminal AQ

accepts a +2 to +10 Vdc signal with respect to the

(AQ1) terminal. When the signal is below it's setpoint,

the actuator is allowed to modulate normally in accordance with the enthalpy and mixed air sensor inputs.

When the AQ signal exceeds it's setpoint setting and

there is no call for free cooling, the actuator is proportionately modulated from the 2 to 10 Vdc signal, with 2

Vdc corresponding to full closed and 10 Vdc corresponding to full open. When there is no call for free

cooling, the damper position is limited by the IAQ Max

damper position setting. When the signal exceeds it's

setpoint (Demand Control Ventilation Setpoint) setting

and there is a call for free cooling, the actuator modulates from the minimum position to the full open position based on the highest call from either the mixed air

sensor input or the AQ voltage input.

• Optional CO

Space Sensor Kit Part #

2

2AQ04700324

• Optional CO

Unit Sensor Kit Part # 2AQ04700424

2

Replace the economizer access panel.

12 Johnson Controls Unitary Products

Page 13

364985-XIM-B-0508

CONTROL

CURVE

A

B

C

D

CONTROL POINT

APPROX.

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

40

(4)

35

(2)

0

F (0C)

45

(7)

50

(10)

105

(41)

110

(43)

85

(32)

(29)

80

(27)

75

(24)

70

(21)

65

(18)

60

(16)

55

A

(13)

B

C

D

A

B

C

D

(35)

(38)

100

95

90

40

35

(2)

(4)45(7)

50

(10)55(13)

APPROXIMATE DRY BULB TEMPERATURE - 0F (0C)

FIGURE 4 - ENTHALPY SETPOINT ADJUSTMENT

Exhaust Air

Adjustment

Screw

Exhaust Air LED

Damper Min.

Position

Screw

Indoor Air Quality

Max. Adjustment

Screw

Indoor Air Quality

LED

Indoor Air Quality

Min. Adjustment

Screw

Free Cooling LED

Economizer Enthalpy

Set Point Adjustment

Screw

N1

P1

T1

AQ1 AQ

SO+ SO

SR+

65

60

(18)

EXH

EXH

Min

Pos

IAQ

Max

(21)

Set

(16)

N

P

T

IAQ

IAQ

Min

Free

Cool

SR

BC

A

D

70

75

(24)80(27)

85

(29)

Vac

HOT

95

90

(32)

(35)

TR TR1

24

Vac

COM

+

1

3

EF EF1

100

(38)

24

105

110

(41)

(43)

2

5

4

FIGURE 5 - HONEYWELL ECONOMIZER CONTROL W7212

Johnson Controls Unitary Products 13

Page 14

364985-XIM-B-0508

447/

8

A

BACK OF UNIT

821/

4

D

X

APPROXIMATE

CENTER OF GRAVITY

FRONT OF UNIT

C

B

CONDENSER COIL

Y

END OF UNIT

FIGURE 6 - FOUR AND SIX POINT LOADING

TABLE 4: CENTER OF GRAVITY (ALL MODELS)

DIMENSION 3 - 5 TON

X 40-¾”

Y 19-¾”

TABLE 5: BQ 4 POINT LOADS WEIGHT DISTRIBUTION

UNIT TOTALABCD

BQ036

BQ048

BQ060

628 139 137 174 177

668 148 146 185 189

693 154 151 192 196

447/

8

F

X

APPROXIMATE

CENTER OF GRAVITY

A

FRONT OF UNIT

BACK OF UNIT

821/

4

B

E

D

C

CONDENSER COIL

Y

END OF UNIT

TABLE 6: BQ 6 POINT LOADS WEIGHT DISTRIBUTION

UNIT TOTAL A B C D E F

BQ036

BQ048

BQ060

14 Johnson Controls Unitary Products

628939291116117119

668 99 98 97 123 125 126

693 103 102 100 128 129 131

Page 15

364985-XIM-B-0508

TABLE 7: PHYSICAL DATA

EVAPORATOR

BLOWER

EVAPORATOR

COIL

CONDENSER

FANS

CONDENSER

COILS

COMPRESSOR

(Qty. Per Unit)

AIR

FILTERS

CHARGE

MODELS

Centrifugal Blower (Dia. x Wd. in.) 12 X 10 12 X 10 12 X 10

Fan Motor HP (Direct Drive) 1/2 3/4 1

Fan Motor HP (Belt Drive) 1 1/2 1 1/2 1 1/2

Fan Motor HP (Belt Drive High Static) 1 1/2 1 1/2 2

Rows Deep 4 3 3

Fins Per Inch 16 15 15

Face Area (Sq. Ft.) 4.3 5.1 5.1

Propeller Dia. (in.) 22 22 24

Fan Motor Hp 1/3 1/2 1/2

Nom. CFM 4300 4200 4500

Rows Deep 1 1 1

Fins Per Inch 20 20 20

Face Area (Sq. Ft.) 17.1 17.1 17.1

Reciprocating Type 1 1 1

Quantity Per Unit (15” X 20” X 1” or 2“) 2 2 2

Quantity Per Unit (14” X 25” X 1” or 2“) 1 1 1

Total Face Area (sq. ft.) 6.6 6.6 6.6

Refrigerant 22

(lbs./oz.)

036 048 060

7/12 9/2 8/4

BQ

TABLE 8: OPERATING WEIGHTS (LBS.)

MODEL SIZE 3 TON 4 TON 5 TON

BASIC UNIT

OPTIONS

Electric Heater

ACCY.

Barometric Relief / Fixed Air Damper 10

BQ 628 668 693

Economizer 50

Motorized Damper 26

5 - 7 kW 18

10 - 15 kW 23

20 - 30 kW 28

Roof Curb 92

Belt-Drive Blower 5

Johnson Controls Unitary Products 15

Page 16

364985-XIM-B-0508

TABLE 9: ELECTRICAL DATA - BQ036-060 DIRECT DRIVE W/O POWERED CONVENIENCE OUTLET

Size

(Tons)

(3.0)

(4.0)

(5.0)

Volt

208-3-60 11.9 85.0 16.7 1.7 4.4 0.0

230-3-60 11.9 85.0 16.7 1.7 4.4 0.0

036

460-3-60 5.9 42.0 8.2 1.0 2.2 0.0

575-3-60 4.8 34.0 6.7 1.0 2.2 0.0

208-3-60 14.7 130.0 23.0 2.3 5.0 0.0

230-3-60 14.7 130.0 23.0 2.3 5.0 0.0

048

460-3-60 7.7 64.0 12.0 1.3 2.2 0.0

575-3-60 6.4 52.0 10.0 1.3 2.2 0.0

208-3-60 19.3 137.0 27.0 2.3 6.6 0.0

230-3-60 19.3 137.0 27.0 2.3 6.6 0.0

060

460-3-60 10.0 62.0 14.0 1.3 3.3 0.0

575-3-60 7.9 50.0 11.0 1.3 3.3 0.0

Compressors

(each)

RLA LRA MCC FLA FLA FLA Model kW Stages Amps

OD Fan

Motors

(each)

1. Minimum Circuit Ampacity.

2. Dual Element, Time Delay Type.

3. HACR type per NEC.

Supply

Blower

Motor

Pwr

Conv

Outlet

Max

Electric Heat Option

None - - - 21.0 30

E05 4.0 1 11.1 34.9 40

E07 5.6 1 15.5 40.4 45

E10 8.0 1 22.2 48.7 50

E15 11.9 2 33.0 62.3 70

E20 15.9 2 44.1 76.1 80

None - - - 21.0 30

E05 5.3 1 13.3 36.9 45

E07 7.5 1 18.8 43.5 50

E10 10.6 1 26.6 52.8 60

E15 15.9 2 39.9 68.8 70

E20 21.2 2 53.2 84.7 90

None - - - 10.6 15

E07 6.8 1 8.5 20.8 25

E10 10.1 1 12.7 25.8 30

E15 13.6 2 17.1 31.0 35

E20 19.5 2 24.5 39.9 40

None - - - 8.6 15

E10 10.6 1 10.6 21.3 25

E15 15.9 1 16.0 27.7 30

E20 21.2 2 21.3 34.1 35

None - - - 25.7 35

E05 4.0 1 11.1 39.6 50

E07 5.6 1 15.5 45.1 50

E10 8.0 1 22.2 53.4 60

E15 11.9 2 33.0 67.0 70

E20 15.9 2 44.1 80.8 90

None - - - 25.7 35

E05 5.3 1 13.3 41.6 50

E07 7.5 1 18.8 48.2 50

E10 10.6 1 26.6 57.5 60

E15 15.9 2 39.9 73.5 80

E20 21.2 2 53.2 89.4 90

None - - - 13.1 20

E07 6.8 1 8.5 23.3 25

E10 10.1 1 12.7 28.3 30

E15 13.6 2 17.1 33.6 35

E20 19.5 2 24.5 42.4 45

None - - - 10.8 15

E10 10.6 1 10.6 23.5 25

E15 15.9 1 16.0 29.9 30

E20 21.2 2 21.3 36.3 40

None - - - 33.0 45

E05 4.0 1 11.1 46.9 60

E07 5.6 1 15.5 52.5 60

E10 8.0 1 22.2 60.8 70

E15 11.9 2 33.0 74.3 80

E20 15.9 2 44.1 88.2 90

E30 22.2 2 61.6 110.1 125

None - - - 33.0 45

E05 5.3 1 13.3 49.0 60

E07 7.5 1 18.8 55.6 70

E10 10.6 1 26.6 64.9 70

E15 15.9 2 39.9 80.8 90

E20 21.2 2 53.2 96.8 100

E30 29.6 2 74.3 122.0 125

None - - - 17.1 25

E07 6.8 1 8.5 27.3 35

E10 10.1 1 12.7 32.3 35

E15 13.6 2 17.1 37.5 40

E20 19.5 2 24.5 46.4 50

E30 28.8 2 36.1 60.4 70

None - - - 13.5 20

E10 10.6 1 10.6 26.2 30

E15 15.9 1 16.0 32.6 35

E20 21.2 2 21.3 39.0 40

E30 30.4 2 30.5 50.1 60

MCA

(Amps)

1

Fuse

Breaker

Size

(Amps)

2

/

3

16 Johnson Controls Unitary Products

Page 17

364985-XIM-B-0508

TABLE 10: ELECTRICAL DATA - BQ036-060 BELT DRIVE W/O POWERED CONVENIENCE OUTLET

Size

(Tons)

(3.0)

(4.0)

(5.0)

Volt

208-3-60 11.9 85.0 16.7 1.7 5.2 0.0

230-3-60 11.9 85.0 16.7 1.7 5.2 0.0

036

460-3-60 5.9 42.0 8.2 1.0 2.6 0.0

575-3-60 4.8 34.0 6.7 1.0 2.0 0.0

208-3-60 14.7 130.0 23.0 2.3 5.2 0.0

230-3-60 14.7 130.0 23.0 2.3 5.2 0.0

048

460-3-60 7.7 64.0 12.0 1.3 2.6 0.0

575-3-60 6.4 52.0 10.0 1.3 2.0 0.0

208-3-60 19.3 137.0 27.0 2.3 5.2 0.0

230-3-60 19.3 137.0 27.0 2.3 5.2 0.0

060

460-3-60 10.0 62.0 14.0 1.3 2.6 0.0

575-3-60 7.9 50.0 11.0 1.3 2.0 0.0

Compressors

(each)

RLA LRA MCC FLA FLA FLA Model kW Stages Amps

OD Fan

Motors

(each)

1. Minimum Circuit Ampacity.

2. Dual Element, Time Delay Type.

3. HACR type per NEC.

Supply

Blower

Motor

Pwr

Conv

Outlet

Max

Electric Heat Option

None - - - 21.8 30

E05 4.0 1 11.1 35.7 40

E07 5.6 1 15.5 41.2 45

E10 8.0 1 22.2 49.5 50

E15 11.9 2 33.0 63.1 70

E20 15.9 2 44.1 76.9 80

None - - - 21.8 30

E05 5.3 1 13.3 37.7 45

E07 7.5 1 18.8 44.3 50

E10 10.6 1 26.6 53.6 60

E15 15.9 2 39.9 69.6 70

E20 21.2 2 53.2 85.5 90

None - - - 11.0 15

E07 6.8 1 8.5 21.2 25

E10 10.1 1 12.7 26.2 30

E15 13.6 2 17.1 31.4 35

E20 19.5 2 24.5 40.3 45

None - - - 8.8 15

E10 10.6 1 10.6 21.5 25

E15 15.9 1 16.0 27.9 30

E20 21.2 2 21.3 34.3 35

None - - - 25.9 35

E05 4.0 1 11.1 39.8 50

E07 5.6 1 15.5 45.3 50

E10 8.0 1 22.2 53.6 60

E15 11.9 2 33.0 67.2 70

E20 15.9 2 44.1 81.0 90

None - - - 25.9 35

E05 5.3 1 13.3 41.8 50

E07 7.5 1 18.8 48.4 50

E10 10.6 1 26.6 57.7 60

E15 15.9 2 39.9 73.7 80

E20 21.2 2 53.2 89.6 90

None - - - 13.5 20

E07 6.8 1 8.5 23.7 25

E10 10.1 1 12.7 28.7 30

E15 13.6 2 17.1 34.0 35

E20 19.5 2 24.5 42.8 45

None - - - 11.0 15

E10 10.6 1 10.6 23.8 25

E15 15.9 1 16.0 30.2 35

E20 21.2 2 21.3 36.5 40

None - - - 31.6 40

E05 4.0 1 11.1 45.5 60

E07 5.6 1 15.5 51.1 60

E10 8.0 1 22.2 59.4 70

E15 11.9 2 33.0 72.9 80

E20 15.9 2 44.1 86.8 90

E30 22.2 2 61.6 108.7 110

None - - - 31.6 40

E05 5.3 1 13.3 47.6 60

E07 7.5 1 18.8 54.2 60

E10 10.6 1 26.6 63.5 70

E15 15.9 2 39.9 79.4 80

E20 21.2 2 53.2 95.4 100

E30 29.6 2 74.3 120.6 125

None - - - 16.4 25

E07 6.8 1 8.5 26.6 30

E10 10.1 1 12.7 31.6 35

E15 13.6 2 17.1 36.8 40

E20 19.5 2 24.5 45.7 50

E30 28.8 2 36.1 59.7 60

None - - - 12.9 20

E10 10.6 1 10.6 25.6 30

E15 15.9 1 16.0 32.0 35

E20 21.2 2 21.3 38.4 40

E30 30.4 2 30.5 49.4 50

MCA

(Amps)

1

Fuse

Breaker

Size

(Amps)

2

/

3

Johnson Controls Unitary Products 17

Page 18

364985-XIM-B-0508

T ABLE 11: ELECTRICAL DA TA - BQ036-060 BELT DRIVE HIGH ST ATIC W/O POWERED CONVENIENCE OUTLET

Size

(Tons)

(3.0)

(4.0)

(5.0)

Volt

208-3-60 11.9 85.0 16.7 1.7 5.2 0.0

230-3-60 11.9 85.0 16.7 1.7 5.2 0.0

036

460-3-60 5.9 42.0 8.2 1.0 2.6 0.0

575-3-60 4.8 34.0 6.7 1.0 2.0 0.0

208-3-60 14.7 130.0 23.0 2.3 5.2 0.0

230-3-60 14.7 130.0 23.0 2.3 5.2 0.0

048

460-3-60 7.7 64.0 12.0 1.3 2.6 0.0

575-3-60 6.4 52.0 10.0 1.3 2.0 0.0

208-3-60 19.3 137.0 27.0 2.3 8.2 0.0

230-3-60 19.3 137.0 27.0 2.3 8.2 0.0

060

460-3-60 10.0 62.0 14.0 1.3 4.1 0.0

575-3-60 7.9 50.0 11.0 1.3 3.6 0.0

Compressors

(each)

RLA LRA MCC FLA FLA FLA Model kW Stages Amps

OD Fan

Motors

(each)

1. Minimum Circuit Ampacity.

2. Dual Element, Time Delay Type.

3. HACR type per NEC.

Supply

Blower

Motor

Pwr

Conv

Outlet

Max

Electric Heat Option

None - - - 21.8 30

E05 4.0 1 11.1 35.7 40

E07 5.6 1 15.5 41.2 45

E10 8.0 1 22.2 49.5 50

E15 11.9 2 33.0 63.1 70

E20 15.9 2 44.1 76.9 80

None - - - 21.8 30

E05 5.3 1 13.3 37.7 45

E07 7.5 1 18.8 44.3 50

E10 10.6 1 26.6 53.6 60

E15 15.9 2 39.9 69.6 70

E20 21.2 2 53.2 85.5 90

None - - - 11.0 15

E07 6.8 1 8.5 21.2 25

E10 10.1 1 12.7 26.2 30

E15 13.6 2 17.1 31.4 35

E20 19.5 2 24.5 40.3 45

None - - - 8.8 15

E10 10.6 1 10.6 21.5 25

E15 15.9 1 16.0 27.9 30

E20 21.2 2 21.3 34.3 35

None - - - 25.9 35

E05 4.0 1 11.1 39.8 50

E07 5.6 1 15.5 45.3 50

E10 8.0 1 22.2 53.6 60

E15 11.9 2 33.0 67.2 70

E20 15.9 2 44.1 81.0 90

None - - - 25.9 35

E05 5.3 1 13.3 41.8 50

E07 7.5 1 18.8 48.4 50

E10 10.6 1 26.6 57.7 60

E15 15.9 2 39.9 73.7 80

E20 21.2 2 53.2 89.6 90

None - - - 13.5 20

E07 6.8 1 8.5 23.7 25

E10 10.1 1 12.7 28.7 30

E15 13.6 2 17.1 34.0 35

E20 19.5 2 24.5 42.8 45

None - - - 11.0 15

E10 10.6 1 10.6 23.8 25

E15 15.9 1 16.0 30.2 35

E20 21.2 2 21.3 36.5 40

None - - - 34.6 45

E05 4.0 1 11.1 48.5 60

E07 5.6 1 15.5 54.1 60

E10 8.0 1 22.2 62.4 70

E15 11.9 2 33.0 75.9 80

E20 15.9 2 44.1 89.8 90

E30 22.2 2 61.6 111.7 125

None - - - 34.6 45

E05 5.3 1 13.3 50.6 60

E07 7.5 1 18.8 57.2 70

E10 10.6 1 26.6 66.5 70

E15 15.9 2 39.9 82.4 90

E20 21.2 2 53.2 98.4 100

E30 29.6 2 74.3 123.6 125

None - - - 17.9 25

E07 6.8 1 8.5 28.1 35

E10 10.1 1 12.7 33.1 40

E15 13.6 2 17.1 38.3 40

E20 19.5 2 24.5 47.2 50

E30 28.8 2 36.1 61.2 70

None - - - 14.5 20

E10 10.6 1 10.6 27.2 30

E15 15.9 1 16.0 33.6 35

E20 21.2 2 21.3 40.0 40

E30 30.4 2 30.5 51.0 60

MCA

(Amps)

1

Fuse

Breaker

Size

(Amps)

2

/

3

18 Johnson Controls Unitary Products

Page 19

364985-XIM-B-0508

TABLE 12: ELECTRICAL DATA - BQ036-060 DIRECT DRIVE W/POWERED CONVENIENCE OUTLET

Size

(Tons)

(3.0)

(4.0)

(5.0)

Volt

208-3-60 11.9 85.0 16.7 1.7 4.4 10.0

230-3-60 11.9 85.0 16.7 1.7 4.4 10.0

036

460-3-60 5.9 42.0 8.2 1.0 2.2 5.0

575-3-60 4.8 34.0 6.7 1.0 2.2 4.0

208-3-60 14.7 130.0 23.0 2.3 5.0 10.0

230-3-60 14.7 130.0 23.0 2.3 5.0 10.0

048

460-3-60 7.7 64.0 12.0 1.3 2.2 5.0

575-3-60 6.4 52.0 10.0 1.3 2.2 4.0

208-3-60 19.3 137.0 27.0 2.3 6.6 10.0

230-3-60 19.3 137.0 27.0 2.3 6.6 10.0

060

460-3-60 10.0 62.0 14.0 1.3 3.3 5.0

575-3-60 7.9 50.0 11.0 1.3 3.3 4.0

Compressors

(each)

RLA LRA MCC FLA FLA FLA Model kW Stages Amps

OD Fan

Motors

(each)

1. Minimum Circuit Ampacity.

2. Dual Element, Time Delay Type.

3. HACR type per NEC.

Supply

Blower

Motor

Pwr

Conv

Outlet

Max

Electric Heat Option

None - - - 31.0 40

E05 4.0 1 11.1 44.9 50

E07 5.6 1 15.5 50.4 60

E10 8.0 1 22.2 58.7 60

E15 11.9 2 33.0 72.3 80

E20 15.9 2 44.1 86.1 90

None - - - 31.0 40

E05 5.3 1 13.3 46.9 50

E07 7.5 1 18.8 53.5 60

E10 10.6 1 26.6 62.8 70

E15 15.9 2 39.9 78.8 80

E20 21.2 2 53.2 94.7 100

None - - - 15.6 20

E07 6.8 1 8.5 25.8 30

E10 10.1 1 12.7 30.8 35

E15 13.6 2 17.1 36.0 40

E20 19.5 2 24.5 44.9 45

None - - - 12.6 15

E10 10.6 1 10.6 25.3 30

E15 15.9 1 16.0 31.7 35

E20 21.2 2 21.3 38.1 40

None - - - 35.7 45

E05 4.0 1 11.1 49.6 60

E07 5.6 1 15.5 55.1 60

E10 8.0 1 22.2 63.4 70

E15 11.9 2 33.0 77.0 80

E20 15.9 2 44.1 90.8 100

None - - - 35.7 45

E05 5.3 1 13.3 51.6 60

E07 7.5 1 18.8 58.2 60

E10 10.6 1 26.6 67.5 70

E15 15.9 2 39.9 83.5 90

E20 21.2 2 53.2 99.4 100

None - - - 18.1 25

E07 6.8 1 8.5 28.3 30

E10 10.1 1 12.7 33.3 35

E15 13.6 2 17.1 38.6 40

E20 19.5 2 24.5 47.4 50

None - - - 14.8 20

E10 10.6 1 10.6 27.5 30

E15 15.9 1 16.0 33.9 35

E20 21.2 2 21.3 40.3 45

None - - - 43.0 60

E05 4.0 1 11.1 56.9 70

E07 5.6 1 15.5 62.5 70

E10 8.0 1 22.2 70.8 80

E15 11.9 2 33.0 84.3 90

E20 15.9 2 44.1 98.2 100

E30 22.2 2 61.6 120.1 125

None - - - 43.0 60

E05 5.3 1 13.3 59.0 70

E07 7.5 1 18.8 65.6 80

E10 10.6 1 26.6 74.9 80

E15 15.9 2 39.9 90.8 100

E20 21.2 2 53.2 106.8 110

E30 29.6 2 74.3 132.0 150

None - - - 22.1 30

E07 6.8 1 8.5 32.3 40

E10 10.1 1 12.7 37.3 40

E15 13.6 2 17.1 42.5 45

E20 19.5 2 24.5 51.4 60

E30 28.8 2 36.1 65.4 70

None - - - 17.5 25

E10 10.6 1 10.6 30.2 35

E15 15.9 1 16.0 36.6 40

E20 21.2 2 21.3 43.0 45

E30 30.4 2 30.5 54.1 60

MCA

(Amps)

1

Fuse

Breaker

Size

(Amps)

2

/

3

Johnson Controls Unitary Products 19

Page 20

364985-XIM-B-0508

TABLE 13: ELECTRICAL DATA - BQ036-060 BELT DRIVE W/POWERED CONVENIENCE OUTLET

Size

(Tons)

(3.0)

(4.0)

(5.0)

Volt

208-3-60 11.9 85.0 16.7 1.7 5.2 10.0

230-3-60 11.9 85.0 16.7 1.7 5.2 10.0

036

460-3-60 5.9 42.0 8.2 1.0 2.6 5.0

575-3-60 4.8 34.0 6.7 1.0 2.0 4.0

208-3-60 14.7 130.0 23.0 2.3 5.2 10.0

230-3-60 14.7 130.0 23.0 2.3 5.2 10.0

048

460-3-60 7.7 64.0 12.0 1.3 2.6 5.0

575-3-60 6.4 52.0 10.0 1.3 2.0 4.0

208-3-60 19.3 137.0 27.0 2.3 5.2 10.0

230-3-60 19.3 137.0 27.0 2.3 5.2 10.0

060

460-3-60 10.0 62.0 14.0 1.3 2.6 5.0

575-3-60 7.9 50.0 11.0 1.3 2.0 4.0

Compressors

(each)

RLA LRA MCC FLA FLA FLA Model kW Stages Amps

OD Fan

Motors

(each)

1. Minimum Circuit Ampacity.

2. Dual Element, Time Delay Type.

3. HACR type per NEC.

Supply

Blower

Motor

Pwr

Conv

Outlet

Max

Electric Heat Option

None - - - 31.8 40

E05 4.0 1 11.1 45.7 50

E07 5.6 1 15.5 51.2 60

E10 8.0 1 22.2 59.5 60

E15 11.9 2 33.0 73.1 80

E20 15.9 2 44.1 86.9 90

None - - - 31.8 40

E05 5.3 1 13.3 47.7 50

E07 7.5 1 18.8 54.3 60

E10 10.6 1 26.6 63.6 70

E15 15.9 2 39.9 79.6 80

E20 21.2 2 53.2 95.5 100

None - - - 16.0 20

E07 6.8 1 8.5 26.2 30

E10 10.1 1 12.7 31.2 35

E15 13.6 2 17.1 36.4 40

E20 19.5 2 24.5 45.3 50

None - - - 12.8 15

E10 10.6 1 10.6 25.5 30

E15 15.9 1 16.0 31.9 35

E20 21.2 2 21.3 38.3 40

None - - - 35.9 50

E05 4.0 1 11.1 49.8 60

E07 5.6 1 15.5 55.3 60

E10 8.0 1 22.2 63.6 70

E15 11.9 2 33.0 77.2 80

E20 15.9 2 44.1 91.0 100

None - - - 35.9 50

E05 5.3 1 13.3 51.8 60

E07 7.5 1 18.8 58.4 60

E10 10.6 1 26.6 67.7 70

E15 15.9 2 39.9 83.7 90

E20 21.2 2 53.2 99.6 100

None - - - 18.5 25

E07 6.8 1 8.5 28.7 30

E10 10.1 1 12.7 33.7 35

E15 13.6 2 17.1 39.0 40

E20 19.5 2 24.5 47.8 50

None - - - 15.0 20

E10 10.6 1 10.6 27.8 30

E15 15.9 1 16.0 34.2 35

E20 21.2 2 21.3 40.5 45

None - - - 41.6 60

E05 4.0 1 11.1 55.5 70

E07 5.6 1 15.5 61.1 70

E10 8.0 1 22.2 69.4 80

E15 11.9 2 33.0 82.9 90

E20 15.9 2 44.1 96.8 100

E30 22.2 2 61.6 118.7 125

None - - - 41.6 60

E05 5.3 1 13.3 57.6 70

E07 7.5 1 18.8 64.2 70

E10 10.6 1 26.6 73.5 80

E15 15.9 2 39.9 89.4 90

E20 21.2 2 53.2 105.4 110

E30 29.6 2 74.3 130.6 150

None - - - 21.4 30

E07 6.8 1 8.5 31.6 35

E10 10.1 1 12.7 36.6 40

E15 13.6 2 17.1 41.8 45

E20 19.5 2 24.5 50.7 60

E30 28.8 2 36.1 64.7 70

None - - - 16.9 20

E10 10.6 1 10.6 29.6 30

E15 15.9 1 16.0 36.0 40

E20 21.2 2 21.3 42.4 45

E30 30.4 2 30.5 53.4 60

MCA

(Amps)

1

Fuse

Breaker

Size

(Amps)

2

/

3

20 Johnson Controls Unitary Products

Page 21

364985-XIM-B-0508

T ABLE 14: ELECTRICAL DATA - BQ036-060 BELT DRIVE HIGH STA T IC W/POWERED CONVENIENCE OUTLET

Size

(Tons)

(3.0)

(4.0)

(5.0)

Volt

208-3-60 11.9 85.0 16.7 1.7 5.2 10.0

230-3-60 11.9 85.0 16.7 1.7 5.2 10.0

036

460-3-60 5.9 42.0 8.2 1.0 2.6 5.0

575-3-60 4.8 34.0 6.7 1.0 2.0 4.0

208-3-60 14.7 130.0 23.0 2.3 5.2 10.0

230-3-60 14.7 130.0 23.0 2.3 5.2 10.0

048

460-3-60 7.7 64.0 12.0 1.3 2.6 5.0

575-3-60 6.4 52.0 10.0 1.3 2.0 4.0

208-3-60 19.3 137.0 27.0 2.3 8.2 10.0

230-3-60 19.3 137.0 27.0 2.3 8.2 10.0

060

460-3-60 10.0 62.0 14.0 1.3 4.1 5.0

575-3-60 7.9 50.0 11.0 1.3 3.6 4.0

Compressors

(each)

RLA LRA MCC FLA FLA FLA Model kW Stages Amps

OD Fan

Motors

(each)

1. Minimum Circuit Ampacity.

2. Dual Element, Time Delay Type.

3. HACR type per NEC.

Supply

Blower

Motor

Pwr

Conv

Outlet

Max

Electric Heat Option

None - - - 31.8 40

E05 4.0 1 11.1 45.7 50

E07 5.6 1 15.5 51.2 60

E10 8.0 1 22.2 59.5 60

E15 11.9 2 33.0 73.1 80

E20 15.9 2 44.1 86.9 90

None - - - 31.8 40

E05 5.3 1 13.3 47.7 50

E07 7.5 1 18.8 54.3 60

E10 10.6 1 26.6 63.6 70

E15 15.9 2 39.9 79.6 80

E20 21.2 2 53.2 95.5 100

None - - - 16.0 20

E07 6.8 1 8.5 26.2 30

E10 10.1 1 12.7 31.2 35

E15 13.6 2 17.1 36.4 40

E20 19.5 2 24.5 45.3 50

None - - - 12.8 15

E10 10.6 1 10.6 25.5 30

E15 15.9 1 16.0 31.9 35

E20 21.2 2 21.3 38.3 40

None - - - 35.9 50

E05 4.0 1 11.1 49.8 60

E07 5.6 1 15.5 55.3 60

E10 8.0 1 22.2 63.6 70

E15 11.9 2 33.0 77.2 80

E20 15.9 2 44.1 91.0 100

None - - - 35.9 50

E05 5.3 1 13.3 51.8 60

E07 7.5 1 18.8 58.4 60

E10 10.6 1 26.6 67.7 70

E15 15.9 2 39.9 83.7 90

E20 21.2 2 53.2 99.6 100

None - - - 18.5 25

E07 6.8 1 8.5 28.7 30

E10 10.1 1 12.7 33.7 35

E15 13.6 2 17.1 39.0 40

E20 19.5 2 24.5 47.8 50

None - - - 15.0 20

E10 10.6 1 10.6 27.8 30

E15 15.9 1 16.0 34.2 35

E20 21.2 2 21.3 40.5 45

None - - - 44.6 60

E05 4.0 1 11.1 58.5 70

E07 5.6 1 15.5 64.1 70

E10 8.0 1 22.2 72.4 80

E15 11.9 2 33.0 85.9 90

E20 15.9 2 44.1 99.8 100

E30 22.2 2 61.6 121.7 125

None - - - 44.6 60

E05 5.3 1 13.3 60.6 70

E07 7.5 1 18.8 67.2 80

E10 10.6 1 26.6 76.5 80

E15 15.9 2 39.9 92.4 100

E20 21.2 2 53.2 108.4 110

E30 29.6 2 74.3 133.6 150

None - - - 22.9 30

E07 6.8 1 8.5 33.1 40

E10 10.1 1 12.7 38.1 45

E15 13.6 2 17.1 43.3 45

E20 19.5 2 24.5 52.2 60

E30 28.8 2 36.1 66.2 70

None - - - 18.5 25

E10 10.6 1 10.6 31.2 35

E15 15.9 1 16.0 37.6 40

E20 21.2 2 21.3 44.0 45

E30 30.4 2 30.5 55.0 60

MCA

(Amps)

1

Fuse

Breaker

Size

(Amps)

2

/

3

Johnson Controls Unitary Products 21

Page 22

364985-XIM-B-0508

TABLE 15: ELECTRIC HEAT CORRECTION

FACTORS

NOMINAL VOLTAGE VOLTAGE kW CAP. MULTIPLIER

208

240

480

600

208 0.75

230 0.92

460 0.92

575 0.92

TABLE 16: VOLTAGE LIMITATIONS

POWER SUPPLY

208/230-3-60

460-3-60

575-3-60

1. Utilization Range “A” in accordance with ARI Standard

110.

MIN. MAX.

187 253

414 506

518 630

1

VOLTAGE

FIGURE 7: UNIT DIMENSIONS (3 - 5 TON HEAT PUMP) FRONT VIEW

22 Johnson Controls Unitary Products

Page 23

364985-XIM-B-0508

FIGURE 8 - UNIT WITH ECONOMIZER RAINHOOD

DETAIL “A”

DETAIL “B”

FIGURE 9 - UNIT WITH FIXED OUTDOOR AIR/MOTORIZED DAMPER RAINHOOD

Johnson Controls Unitary Products 23

Page 24

FIGURE 10 - UNIT DIMENSIONS (REAR VIEW)

Filter Access

Blower Motor Access

Dot Plugs

Field -Supplied Disconnect

Switch Location

Mounting Bracket for

Disconnect Switch

(Field Supplied)

Disconnect Switch Location

and Motor Access Panel for

Unit with “Belt-Drive” Option

A,B

Wiring Entry

(See Detail “B”)

Control Box Access

FIGURE 11 - DISCONNECT/BLOWER ACCESS

LOCATION

364985-XIM-B-0508

TABLE 18: MINIMUM CLEARANCES

LOCATION

Front

Rear

Left Side (Filter Access)

Right Side (Cond. Coil)

Below Unit

Above Unit

1

2

1. Units may be installed on combustible floors made

from wood or class A, B, or C roof covering material.

2. Units must be installed outdoors. Overhanging structures or shrubs should not obstruct condenser air discharge outlet.

CLEARANCE

24” (Cooling/Electric Heat)

32” (Gas Heat)

12” (Less Economizer)

36” (With Economizer or Fixed

Air/Motorized Damper)

24” (Less Economizer)

36” (With Economizer)

72” (For

Condenser Air Discharge)

24”

0”

TABLE 17: UTILITIES ENTRY

HOLE OPENING SIZE (DIA.) USED FOR

A

B

C

D

1

7/8” KO

2” KO

1

Control Wiring

Power Wiring

1-5/8” KO Gas Piping (Front)

1-1/2” KO

Gas Piping (Bottom)

1. Opening in the bottom to the unit can be located by the

side in the insulation.

2. Do not remove the 2” knockout ring.

24 Johnson Controls Unitary Products

Side

2

Bottom

Side

Bottom

Page 25

364985-XIM-B-0508

TABLE 19: SUPPLY AIR BLOWER PERFORMANCE (BQ036 BELT DRIVE) - SIDE DUCT APPLICATION

Air

Flow

(CFM)

800 678 0.37 761 0.44 840 0.52 917 0.60 991 0.69 1062 0.77 1130 0.87 1195 0.96 1259 1.06 1320 1.17

1000 699 0.42 782 0.49 862 0.56 939 0.64 1012 0.73 1083 0.82 1151 0.91 1217 1.01 1280 1.11 1341 1.21

1200 727 0.45 810 0.52 889 0.60 966 0.68 1040 0.76 1110 0.85 1179 0.95 1244 1.04 1308 1.14 1369 1.24

1400 759 0.51 842 0.58 922 0.65 998 0.73 1072 0.82 1143 0.91 1211 1.00 1276 1.10 1340 1.20 1401 1.30

1600 795 0.60 878 0.67 958 0.74 1035 0.82 1108 0.91 1179 1.00 1247 1.09 1313 1.19 1376 1.28 1438 1.39

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Supplied Drive Standard Drive Option HIgh Static Drive Option

Available External Static Pressure - IWG

1

4

FS

1. Blower performance includes 1” filters. See STATIC RESISTANCE table for additional applications.

2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.932.

4. Field Supplied Drive.

TABLE 20: SUPPLY AIR BLOWER PERFORMANCE (BQ036 BELT DRIVE) - BOTTOM DUCT APPLICATION

Air

Flow

(CFM)

800 661 0.39 751 0.45 838 0.53 922 0.61 1002 0.69 1079 0.78 1153 0.87 1225 0.96 1294 1.06 1361 1.16

1000 685 0.43 775 0.50 862 0.57 945 0.65 1025 0.73 1103 0.82 1177 0.91 1248 1.00 1317 1.10 1384 1.20

1200 714 0.46 805 0.53 892 0.60 975 0.68 1055 0.76 1132 0.85 1207 0.94 1278 1.04 1347 1.13 1414 1.23

1400 749 0.52 840 0.58 927 0.66 1010 0.74 1090 0.82 1167 0.91 1242 1.00 1313 1.09 1382 1.19 1449 1.29

1600 789 0.60 880 0.67 967 0.74 1050 0.82 1130 0.91 1207 0.99 1282 1.08 1353 1.18 1422 1.27 1489 1.37

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Supplied Drive Standard Drive Option HIgh Static Drive Option

Available External Static Pressure - IWG

1. Blower performance includes 1” filters. See STATIC RESISTANCE table for additional applications.

2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.932.

1

Field Supplied Drive

TABLE 21: SUPPLY AIR BLOWER PERFORMANCE (BQ048 BELT DRIVE) - SIDE DUCT APPLICATION

Air

Flow

(CFM)

1000 656 0.41 757 0.46 851 0.52 937 0.58 1017 0.66 1092 0.73 1162 0.81 1228 0.90 1291 0.99 1351 1.08

1200 680 0.47 781 0.52 874 0.58 960 0.65 1041 0.72 1115 0.80 1185 0.88 1251 0.96 1314 1.05 1375 1.14

1400 706 0.56 807 0.61 901 0.67 987 0.73 1067 0.80 1142 0.88 1212 0.96 1278 1.05 1341 1.13 1401 1.22

1600 737 0.67 839 0.72 932 0.77 1018 0.84 1098 0.91 1173 0.99 1243 1.07 1309 1.15 1372 1.24 1433 1.33

1800 774 0.80 875 0.85 968 0.90 1055 0.97 1135 1.04 1209 1.12 1279 1.20 1345 1.28 1408 1.37 1469 1.46

2000 815 0.95 916 1.00 1010 1.06 1096 1.12 1176 1.19 1251 1.27 1321 1.35 1387 1.44 1450 1.52 1510 1.61

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Supplied Drive Standard Drive Option HIgh Static Drive Option

Available External Static Pressure - IWG

1. Blower performance includes 1” filters. See STATIC RESISTANCE table for additional applications.

2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.932.

1

TABLE 22: SUPPLY AIR BLOWER PERFORMANCE (BQ048 BELT DRIVE) - BOTTOM DUCT APPLICATION

Air

Flow

(CFM)

1000 638 0.42 748 0.47 849 0.53 944 0.59 1031 0.66 1112 0.74 1188 0.82 1260 0.90 1329 0.98 1395 1.07

1200 663 0.48 773 0.53 875 0.59 969 0.65 1056 0.72 1138 0.80 1214 0.88 1286 0.96 1354 1.04 1420 1.13

1400 692 0.57 802 0.61 904 0.67 998 0.73 1085 0.80 1167 0.88 1243 0.96 1315 1.04 1383 1.13 1449 1.21

1600 726 0.67 836 0.72 938 0.78 1032 0.84 1119 0.91 1201 0.98 1277 1.06 1349 1.15 1417 1.23 1483 1.32

1800 766 0.80 876 0.85 977 0.90 1072 0.97 1159 1.04 1240 1.11 1316 1.19 1388 1.27 1457 1.36 1523 1.45

2000 811 0.95 921 0.99 1023 1.05 1117 1.11 1204 1.18 1285 1.26 1362 1.34 1434 1.42 1502 1.51 1568 1.59

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Supplied Drive Standard Drive Option HIgh Static Drive Option

Available External Static Pressure - IWG

1. Blower performance includes 1” filters. See STATIC RESISTANCE table for additional applications.

2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.932.

4. Field Supplied Drive.

1

4

FS

Johnson Controls Unitary Products 25

Page 26

364985-XIM-B-0508

TABLE 23: SUPPLY AIR BLOWER PERFORMANCE (BQ060 BELT DRIVE) - SIDE DUCT APPLICATION

Air

Flow

(CFM)

1200 680 0.47 781 0.52 874 0.58 960 0.65 1041 0.72 1115 0.80 1185 0.88 1251 0.96 1314 1.05 1375 1.14

1400 706 0.56 807 0.61 901 0.67 987 0.73 1067 0.80 1142 0.88 1212 0.96 1278 1.05 1341 1.13 1401 1.22

1600 737 0.67 839 0.72 932 0.77 1018 0.84 1098 0.91 1173 0.99 1243 1.07 1309 1.15 1372 1.24 1433 1.33

1800 774 0.80 875 0.85 968 0.90 1055 0.97 1135 1.04 1209 1.12 1279 1.20 1345 1.28 1408 1.37 1469 1.46

2000 815 0.95 916 1.00 1010 1.06 1096 1.12 1176 1.19 1251 1.27 1321 1.35 1387 1.44 1450 1.52 1510 1.61

2200 862 1.12 963 1.17 1056 1.23 1142 1.29 1223 1.36 1297 1.44 1367 1.52 1433 1.61 1496 1.70 1557 1.78

2400 913 1.31 1014 1.36 1107 1.42 1194 1.49 1274 1.56 1349 1.63 1419 1.72 1485 1.80 1548 1.89 1608 1.98

2600 969 1.52 1070 1.57 1163 1.63 1250 1.70 1330 1.77 1405 1.84 1475 1.93 1541 2.01 1603 2.10 1664 2.19

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Supplied Drive Standard Drive Option HIgh Static Drive Option

Available External Static Pressure - IWG

1. Blower performance includes 1” filters. See STATIC RESISTANCE table for additional applications.

2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.932.

1

TABLE 24: SUPPLY AIR BLOWER PERFORMANCE (BQ060 BELT DRIVE) - BOTTOM DUCT APPLICATION

Air

Flow

(CFM)

1200 663 0.48 773 0.53 875 0.59 969 0.65 1056 0.72 1138 0.80 1214 0.88 1286 0.96 1354 1.04 1420 1.13

1400 692 0.57 802 0.61 904 0.67 998 0.73 1085 0.80 1167 0.88 1243 0.96 1315 1.04 1383 1.13 1449 1.21

1600 726 0.67 836 0.72 938 0.78 1032 0.84 1119 0.91 1201 0.98 1277 1.06 1349 1.15 1417 1.23 1483 1.32

1800 766 0.80 876 0.85 977 0.90 1072 0.97 1159 1.04 1240 1.11 1316 1.19 1388 1.27 1457 1.36 1523 1.45

2000 811 0.95 921 0.99 1023 1.05 1117 1.11 1204 1.18 1285 1.26 1362 1.34 1434 1.42 1502 1.51 1568 1.59

2200 861 1.11 971 1.16 1073 1.22 1167 1.28 1255 1.35 1336 1.43 1412 1.51 1484 1.59 1553 1.68 1619 1.76

2400 917 1.30 1027 1.35 1129 1.41 1223 1.47 1311 1.54 1392 1.62 1468 1.69 1540 1.78 1609 1.86 1675 1.95

2600 978 1.51 1088 1.56 1190 1.61 1284 1.68 1371 1.75 1453 1.82 1529 1.90 1601 1.98 1670 2.07 1736 2.15

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Supplied Drive Standard Drive Option HIgh Static Drive Option

Available External Static Pressure - IWG

1. Blower performance includes 1” filters. See STATIC RESISTANCE table for additional applications.

2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.932.

1

Field Supplied Drive

TABLE 25: SUPPLY AIR BLOWER PERFORMANCE (BQ036, 048 & 060 DIRECT DRIVE) -

SIDE DUCT APPLICATION

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

UNIT

TONNAGE

3

3

3

4

3

5

1. Factory set on medium speed tap.

2. Includes allowances for a wet evaporator coil, 1” filters. Refer to STATIC RESISTANCES Table for resistance values.

3. Side Flow application (230/460/575 Volts)

1

MOTOR

SPEED

CFM

HI - - - - - - 1720 825 1665 795 1600 765 1540 735 1490 700 1380 670

MED 1660 850 1630 820 1590 780 1550 750 1500 720 1450 690 1400 665 1360 650 1270 610

LOW 1470 750 1440 725 1410 700 1370 675 1330 650 1290 625 1250 610 1220 600 1130 560

HI - - - - 2000 1010 1950 975 1905 945 1840 910 1770 825 1660 825 1530 775

MED 1810 910 1780 880 1740 850 1700 825 1665 800 1620 775 1560 740 1480 700 1390 660

LOW 1635 810 1610 780 1580 760 1555 740 1540 730 1510 715 1460 690 1400 660 1300 615

HI - - - - 2500 1400 2420 1350 2340 1300 2260 1250 2160 1190 2060 1135 1925 1065

MED 2390 1350 2350 1300 2300 1255 2245 1210 2190 1165 2130 1120 2065 1075 1990 1030 1900 970

LOW 2270 1320 2230 1270 2190 1220 2145 1170 2090 1110 2030 1070 1960 1020 1890 970 1810 920

CFM

WATTS

WATTS

AVAILABLE EXTERNAL STATIC PRESSURE - IWG

CFM

CFM

WATTS

CFM

WATTS

WATTS

CFM

26 Johnson Controls Unitary Products

2

CFM

WATTS

CFM

WATTS

CFM

WATTS

WATTS

Page 27

364985-XIM-B-0508

TABLE 26: SUPPLY AIR BLOWER PERFORMANCE (BQ036, 048 & 060 DIRECT DRIVE) -

BOTTOM DUCT APPLICATION

WATTS

2

CFM

WATTS

AVAILABLE EXTERNAL STATIC PRESSURE - IWG

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

UNIT

TONNAGE

3

3

3

4

3

5

1. Factory set on medium speed tap.

2. Includes allowances for a wet evaporator coil, 1” filters. Refer to STATIC RESISTANCES Table for resistance values.

3. Side Flow application (230/460/575 Volts)

1

MOTOR

SPEED

CFM

HI - - - - - - 1661 825 1608 795 1545 765 1487 735 1439 700 1333 670

MED 1603 850 1574 820 1535 780 1497 750 1449 720 1401 690 1352 665 1314 650 1227 610

LOW 1420 750 1391 725 1362 700 1323 675 1285 650 1246 625 1208 610 1179 600 1092 560

HI - - - - 1931 1010 1882 975 1839 945 1776 910 1709 825 1603 825 1478 775

MED 1748 910 1719 880 1680 850 1641 825 1608 800 1564 775 1507 740 1429 700 1343 660

LOW 1579 810 1555 780 1526 760 1502 740 1487 730 1458 715 1410 690 1352 660 1256 615

HI - - - - 2412 1400 2335 1350 2258 1300 2181 1250 2085 1190 1988 1135 1858 1065

MED 2306 1350 2268 1300 2220 1255 2167 1210 2114 1165 2056 1120 1993 1075 1921 1030 1834 970

LOW 2191 1320 2152 1270 2114 1220 2070 1170 2017 1110 1960 1070 1892 1020 1825 970 1748 920

WATTS

CFM

WATTS

CFM

WATTS

CFM

WATTS

CFM

WATTS

CFM

TABLE 27: BELT DRIVE RPM SELECTION

CFM

WATTS

CFM

WATTS

Size

(Tons)

036

(3)

048

(4)

060

(5)

HP

Max

BHP

1.5 1.73 1VL44 AK64 805 865 920 980 1035 1095

1.5 1.73 1VP56 AK66 1115 1170 1225 1280 1335 1390

1.5 1.73 1VL44 AK56 930 995 1060 1130 1195 1260

1.5 1.73 1VP56 AK61 1210 1270 1330 1390 1455 1515

1.5 1.73 1VL44 AK56 930 995 1060 1130 1195 1260

2 2.3 1VP56 AK56 1325 1395 1460 1525 1590 1660

Motor

Sheave

Blower

Sheave

5 Turns

Open

4 Turns

Open

TABLE 28: BELT DRIVE BLOWER MOTOR AND DRIVE DATA

Size

(Tons)

036

(3.0)

048

(4.0)

060

(5.0)

HP RPM Eff. SF Frame

1-1/2 1725 0.8 1.15 56 2.8 - 3.8 7/8 1VL44 6.0 1 AK64 A37

1-1/2 1725 0.8 1.15 56 4.0 - 5.0 7/8 1VP56 6.2 1 AK66 A39

1-1/2 1725 0.8 1.15 56 2.8 - 3.8 7/8 1VL44 5.2 1 AK56 A36

1-1/2 1725 0.8 1.15 56 4.0 - 5.0 7/8 1VP56 5.7 1 AK61 A38

1-1/2 1725 0.8 1.15 56 2.8 - 3.8 7/8 1VL44 5.2 1 AK56 A36

2 1725 0.8 1.15 56 4.0 - 5.0 7/8 1VP56 5.2 1 AK56 A38

Motor Motor Sheave Blower Sheave

Datum Dia.

(in.)

Bore (in.) Model

TABLE 29: STATIC RESISTANCES

Description

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

Economizer

Electric

Heaters

1

Bottom Duct Connections

1 2

0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20 0.23 0.26 0.30

7 - 15 kW 0.04 0.05 0.06 0.07 0.08 0.10 0.12 0.14 0.16 0.19 0.22

20 - 30 kW 0.06 0.07 0.08 0.09 0. 11 0.13 0.15 0.17 0.20 0.23 0.26

1

0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.14 0.16 0.19 0.22

3 Turns

Open

2 Turns

Open

Datum Dia.

Resistance, IWG

CFM

(in.)

1 Turn

Open

Fully

Closed

Bore (in.) Model

Belt

1. Deduct these resistance values from the available external static pressure shown in SUPPLY AIR BLOWER PERFORMANCE Tables.

2. The pressure through the economizer is greater for 100% outdoor air than for 100% return air. If the resistance of the return air

duct system is less than 0.25 IWG, the unit will deliver less CFM during full economizer operation.

Johnson Controls Unitary Products 27

Page 28

364985-XIM-B-0508

Drive Selection

1. Determine desired airflow.

2. Calculate or measure the amount of external static pressure.

3. Using the operating point determined from steps 1 & 2, locate this point on the appropriate supply air blower performance table. (Linear

interpolation may be necessary.)

4. Noting the RPM and BHP from step 3, locate the appropriate model and drive on the RPM selection table.

5. Review the BHP compared to the motor options available. Select the appropriate motor.

6. Review the RPM range for the motor options available. Select the appropriate drive if multiple drives are available for the chosen motor.

7. Determine turns open to obtain the desired operation point.

Example

1. 19000 CFM

2. 5.4 iwg

3. Using the supply air blower performance table below, the following data point was located: 1150 RPM & 36 BHP.

4. Using the RPM selection table below, Size X and Model Y is found.

5. 36 BHP exceeds the maximum continuous BHP rating of the 30 HP motor. The 40 HP motor is required.

6. 1150 RPM is within the range of the 30 & 40 HP drives, but step 5 requires the 40 HP motor.

7. Using the 40 HP motor and drive, 5.5 turns open will achieve 1150 RPM.

Example Supply Air Blower Performance

Air

Flow

(CFM)

18000 800 10.00 850 14.00 900 18.00 950 22.00 1000 26.00 1050 30.00 1100 34.00 1150 38.00 1200 42.00 1250 46.00

19000 850 12.00 900 16.00 950 20.00 1000 24.00 1050 28.00 1100 32.00 1150 36.00 1200 40.00 1250 44.00 1300 48.00

20000 900 14.00 950 18.00 1000 22.00 1050 26.00 1100 30.00 1150 34.00 1200 38.00 1250 42.00 1300 46.00 1350 50.00

21000 950 16.00 1000 20.00 1050 24.00 1100 28.00 1150 32.00 1200 36.00 1250 40.00 1300 44.00 1350 48.00 1400 52.00

3.0 3.4 3.8 4.2 4.6 5.0 5.4 5.8 6.2 6.6