Page 1

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 1

Smart Equipment Controls

Installation, Operation, and Maintenance

Manual

Johnson Contr ols

SE-ZEC500-1 and SE-ZEC510-1 Controllers

Page 2

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 2

Table of Contents

Initial Setup .............................................................................................................................................................................. 3

Mounting .............................................................................................................................................................................. 3

Networking .......................................................................................................................................................................... 4

Field Controller (FC) Bus ................................................................................................................................................ 4

SE-ZEC Controller Address ............................................................................................................................................ 4

End-of-line (EOL) Switch ................................................................................................................................................. 5

Optional Components ......................................................................................................................................................... 5

Sensor Actuator (SA) Bus ............................................................................................................................................... 5

Supply Air Temp. Sensor ................................................................................................................................................ 5

Discharge Air Temp. Sensor ........................................................................................................................................... 6

Occupancy Sensor .......................................................................................................................................................... 6

Control Sequences .................................................................................................................................................................. 7

Controller Parameters ............................................................................................................................................................. 7

Parameter Descriptions ....................................................................................................................................................... 7

Static Parameters (All Applications) ................................................................................................................................ 7

Application Specific Parameters ................................................................................................................................... 11

Factory Programmed Parameters ..................................................................................................................................... 12

Default Parameters ....................................................................................................................................................... 12

Size Dependent Parameters ......................................................................................................................................... 13

Sequence Dependent Parameters ................................................................................................................................ 14

Commissioning ...................................................................................................................................................................... 16

Mobile Access Portal (MAP) Gateway .............................................................................................................................. 16

VAV Handheld Balancing Tool .......................................................................................................................................... 17

Troubleshooting .................................................................................................................................................................... 17

er Status LED ............................................................................................................................................................. 18

Pow

Communication Bus Problems .......................................................................................................................................... 18

I/O Wiring ...................................................................................................................................................................... 18

Duplicate Addresses ..................................................................................................................................................... 18

Correcting Physical Communication Bus Problems ...................................................................................................... 18

Parts and Accessories .......................................................................................................................................................... 18

Additional Information ........................................................................................................................................................... 19

Page 3

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 3

Initial Setup

Mounting

To mount the SE-ZEC Controllers:

1. Ensure that you have the appropriate personal protective equipment (PPE), such as a hard hat, safety glasses,

steel toe boots, and gloves.

2. Disconnect power to the VAV unit.

3. Set the MS/TP address, and ensure the end of line (EOL) switch is set to off. Instructions on setting the VAV

address and EOL are in the sections below.

4. Place the SE-ZEC Controller in the proper mounting position on the actuator shaft so that the wiring connections

are easily accessible. Make sure the SE-ZEC Controller base is parallel to the VAV box (perpendicular to the

damper shaft). If needed, use a spacer to offset tipping of the SE-ZEC Controller caused by the shaft bushings.

5. Use the alignment marks to center the captive spacer to ensure sufficient movement in either direction.

Fig

. 1: Captive Spacer Alignment Marks

Alignment

guide

6. Sec

7. Locate the damper position using the typical marking on the end of the damper shaft.

8. Note the direction, clockwise (CW) or counterclockwise (CCW), required to close the damper. The actuator setup

9. Push down and hold the manual override button and turn the SE-ZEC Controller until it contacts the mechanical

10. Ti

11. Put a loop in the pneumatic tubing, to trap condensation, when you attach the tubing to the SE-ZEC Controller

ure the self-drilling #10 screw through the captive spacer with a power screwdriver and 4” (100 mm) extension

socket. Otherwise, use a punch to mark the position of the shoulder washer, and then drill a hole into the VAV box

using a 5/16” drill bit. Insert the mounting screw and tighten against the spacer.

depends on the necessary amount of rotation required for the damper to go from full-open to full-closed. For 90°

rotation, install the damper full-closed.

end-stop at either the full-closed or full-open position.

. 2: Manual Override and Coupler

Fig

ghten the square coupler bolt to the shaft using a 5/16” (8 mm) wrench or a 3/8” (10 mm) 12-point socket.

Tighten to 95 to 105 lb·in (10.5 to 11.5 N·m)

pressure transducer ports. Loop the tubing before you make the final connections.

Page 4

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 4

12. Push the manual override button, and turn the actuator coupling manually to ensure the actuator can rotate from

full-closed to full-open positions without bindi ng.

13. Complete the mounting by rotating the damper to the full-open position.

Networking

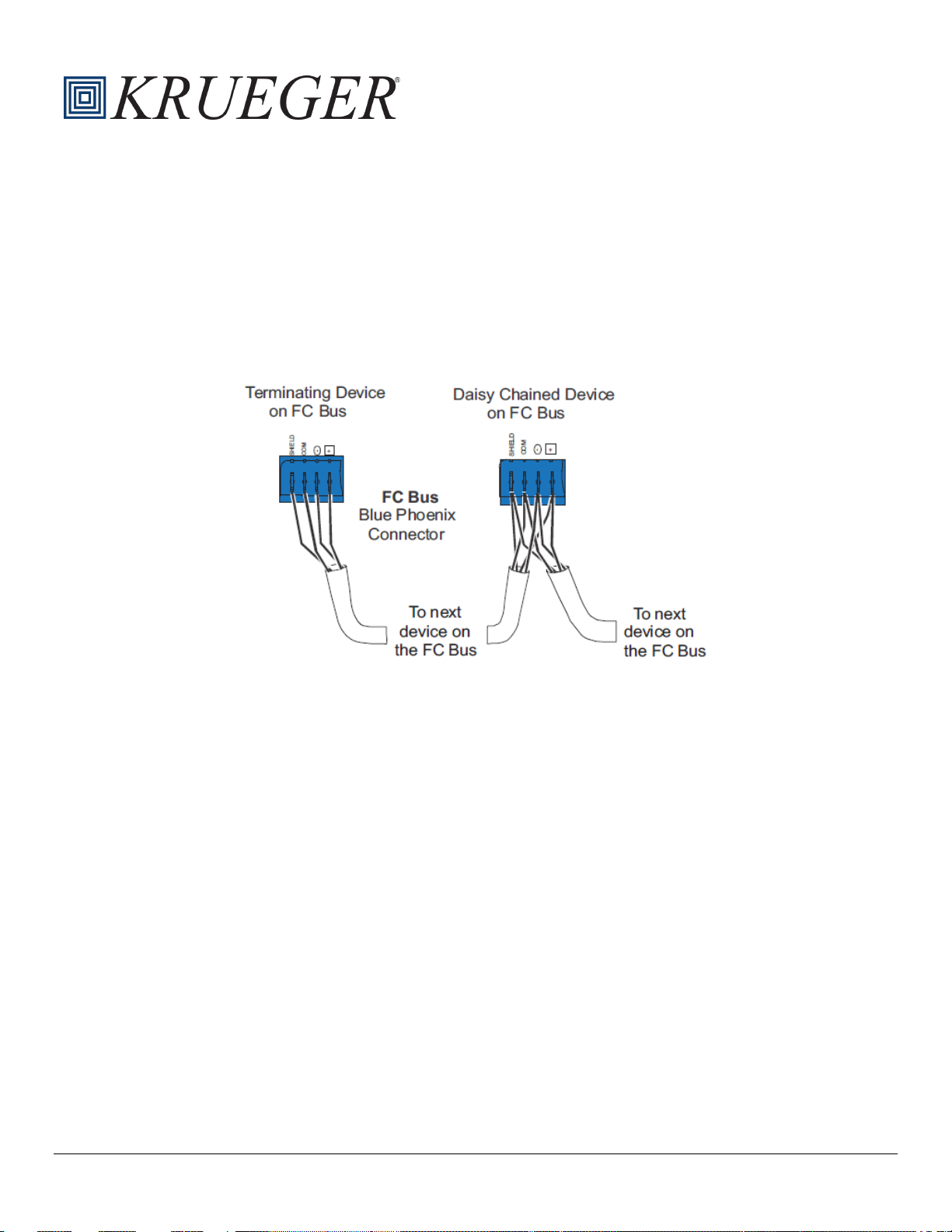

Field Controller (FC) Bus

The field controller (FC) Bus terminal block is a blue, removable, 4-terminal plug that is keyed to only fit in to the boardmounted, gray FC Bus jack. Wire the removable FC Bus terminal block plugs on the SE-ZEC Controller and other FC Bus

controllers in a daisy-chain configuration usin g 3-wire twisted, shielded cable.

Fig. 3: FC Bus Connections

SE-ZEC Controller Address

SE-ZEC Controllers are master devices on BACnet MS/TP (SA or FC) Buses. Before operating field controllers on a Bus,

you must set a valid and unique device address for each controller on the Bus. You set a field controller’s device address

by setting the positions of the switches on the devise address DIP switch block at the top of the controller. Device

addresses 4-127 are the valid addresses for the SE-ZEC controller. SE-ZEC Controllers ship with all address switches set

to ON. Set a valid and unique device address on the field controller before applying power to the controller on the Bus.

The DIP switch block has eight switches numbered 128, 64, 32, 16, 8, 4, 2, and 1.

To set the device addresses on a ZEC field controller:

1. Set all of the switches on the field controller’s device address DIP switch block (128 through 1) to OFF.

2. Set one or more of the seven address switches from 64 to 1 to ON, so that the sum of the switch numbers set to ON

equals the intended device address. Set the highest number switch that is less than or equal to the intended device

address to ON. Then continue setting lower numbered switches until the total equals the intended address.

For example: If the intended device address is 21, set the switches so that 16 + 4 + 1 = 21.

a. Set switch 16 to ON

b. Set switch 4 to ON

c. Set switch 1 to ON

3. Set a unique and sequential device address for each of the field controllers connected on the FC Bus, starting with

device address 4. To ensure the best Bus performance, set sequential device address es with no gaps in the de vice

Page 5

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 5

address range (4, 5, 6, and so on). The field controllers do not need to be physically connected on the Bus in their

numerical device address order.

4. Write each field controller’s device address on the white label below the DIP switch block on the controller’s cover.

End-of-line (EOL) Switch

The EOL switch must be set to ON for the two devices located at either end of each bus segment on an FC bus. The EOL

switches must be set to OFF for all other devices on the bus segment on an FC bus.

Optional Components

Sensor Actuator (SA) Bus

Factory or field supplied zone sensors are wired to the SA bus on the SE-ZEC Controller. The SA Bus is a brown,

removable 4-terminal plug that is keyed to only fit into the board mounted SA bus. Wire the removable SA bus terminal

block plugs on the SE-ZEC Controller and other field devices in a daisy-chain configuration using 4-wire, shielded cable.

Fig. 4: SA Bus Connections

Supply Air Temp. Sensor

Factory or field-supplied supply air temperature sensors can be used to measure the supply air temperature at the inlet of

the VAV box. The supply air temperature is wired between terminals ICOM3 and IN3 on the SE-ZEC Controller. The

sensor should be mounted in the inlet duct centered in the side of the ductwork. Avoid installing the sensor near an elbow,

take off or transition. Avoid blocking air to the primary airflow sensor.

Factory provided nickel (1k ohm) temperature sensors have 4” long probes and stainless steel mounting flanges with (2)

provided hex-head self-drilling mounting screws. Sensors come equipped with 10 ft. plenum rated cables with ¼” internal

thread insulated quick-connect terminations on leads. Install sensor by drilling a hole into the ductwork, inserting the

sensor, and securing with provided screws. The sensor tip should not touch any part of the ductwork.

With the supply air temperature sensor installed, the SE-ZEC controller will change its control sequence based on the

measured supply air temperature. When parameter Heating Limit Enable is TRUE the controller will not allow re-heat to

engage when the supply air temperature is greater than the value set in Heating Supply Air Limit.

Additionally, the controller will switch to warmup mode when warmup conditions are present. Warmup conditions are

present when the supply air temperature (SAT) sensor value exceeds the zone temperature (ZNT) sensor in unoccupied

mode or exceeds it by the Warmup Differential in occupied mode. While in Warmup mode the minimum flow will be set to

the Warmup Min Flow.

Page 6

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 6

SE-ZEC Occupancy Determination

Controller Type

ZEC500 (Standalone)

ZEC510 (Networked)

The controller will switch from

Setpoint the state is set to Occupied

The controller will read the occupancy

between Occupied and Unoccupied

The building automation system

and Unoccupied states. A room

Discharge Air Temp. Sensor

Factory or field supplied discharge air temperature sensors can be used to measure the temperature of the air being

discharged from the VAV box. The discharge air temperature sensor is wired between terminals ICOM1 and IN1 on the

SE-ZEC controller. The sensor should be mounted a minimum of 36” from the discharge of the unit and be centered in the

side of the ductwork. Avoid installing the sensor near an elbow, take off, or transition.

Factory provided nickel (1k ohm) temperature sensors have 4” long probes and stainless steel mounting flanges with (2)

provided hex-head self-drilling mounting screws. Sensors come equipped with 10 ft. plenum rated cables with ¼” internal

thread insulated quick-connect terminations on leads. Install sensor by drilling a hole into the ductwork, inserting the

sensor, and securing with provided screws. The sensor tip should not touch any part of the ductwork.

Occupancy Sensor

The SE-ZEC Controllers adjust the heating and cooling temperature setpoints, as well as the airflow setpoints based on

the zone occupancy. There are three different states of zone occupancy:

• Occupied Mode

o Uses Occupied Heating (68°F) and Occupied Cooling (72°F) temperature setpoints as well as Occupi

eating and Occupied Cooling Airflow setpoints

H

o For Series Fan Powered Terminals the Fan is always on

o For Parallel Fan Powered Terminals the Fan is only on during a call for heating

• Standby Mode

o Uses Standby Heating (66°F) and Standby Cooling (77°F) temperature setpoints as well as Unoccupi

H

eating and Unoccupied Cooling Airflow setpoints

o For Series Fan Powered Terminals the Fan is always on

o For Parallel Fan Powered Terminals the Fan is only on during a call for heating

• Unoccupied Mode

o Uses Unoccupied Heating (55°F) and Unoccupied Cooling (85°F) temperature setpoints as well as

Unoccupied Heating and Unoccupied Cooling Airflow setpoints

o For Series Fan Powered Terminals the Fan is only on during a call for heating or cooling

o For Parallel Fan Powered Terminals the Fan is only on during a call for heating

ed

ed

Table 1 below shows how occupancy states are determined for the SE-ZEC Controllers.

Terminal Unit Type

Single Duct Terminal Unit

Fan Powered Terminal Unit

Table 1: SE-ZEC Occupancy Determination

Occupied to Unoccupied states by

comparing the measured airflow to

the Occupancy Determination Flow

Setpoint. When the measured airflow

is below the Occupancy

Determination Flow Setpoint the state

is set to Unoccupied. When the

measured airflow is above the

Occupancy Determination Flow

sensor wired between IN2 and

ICOM2 on the controller to switch

The building automation system

(BAS) will schedule when t he

controller will switch from Occupied

and Unoccupied states. A room

occupancy sensor (wired to IN2 and

ICOM2 on the controller) can be used

to temporarily set the VAV box to

Standby mode when occupancy is not

sensed.

(BAS) will schedule when the

controller will switch from Occupied

Page 7

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 7

states. The occupancy sensor can be

always be in Occupied mode.

occupancy sensor (wired to IN2 and

Smart Equipment Controls - Control Sequences

Single Duct

Series Fan Powered

Parallel Fan Powered

ZEC500

ZEC510

ZEC500

ZEC510

ZEC500

ZEC510

Cooling Only

6101

7101

6201

7201

6301

7301

1-Stage Electric Heat

6102

7102

6202

7202

6302

7302

2-Stage Electric Heat

6103

7103

6203

7203

6303

7303

3-Stage Electric Heat

6104

7104

6204

7204

6304

7304

Proportional Electric Heat

6105

7105

6205

7205

6305

7305

On/Off Hot Water Heat

6106

7106

6206

7206

6306

7306

Floating Hot Water Heat

6107

7107

6207

7207

6307

7307

Proportional Hot Water Heat

6108

7108

6208

7208

6308

7308

Supplemental Heat

6109

7109

6209

7209

6309

7309

Menu 1

Menu 2

Parameter Name

Parameter Description

Parameter Values

Displays the active baud rate used for network

communication.

a room occupancy sensor or another

kind of occupancy detection (such as

a duct pressure switch*). Without an

occupancy sensor, the controller will

n optional factory provided occupancy pressure switch is available for standalone fan powered terminal units t

*A

det

ermine occupancy by measuring duct pressure to determine whether the air handler is on (zone is occupied) or off

(zone is unoccupied).

ICOM2 on the controller) can be used

to temporarily set the VAV box to

Standby mode when occupancy is not

sensed.

o

Control Sequences

VAV boxes with Smart Equipment Controls will be factory mounted and wired according to the selected control sequence.

Links to each individual control submittal are shown below:

Table 2: Control Sequences

Description

Controller Parameters

Parameter Descriptions

This section provides information on the SE-ZEC Controller Parameters.

Static Parameters (All Applications)

The list of available SE-ZEC Controller Parameters changes depending on the application type that is selected

(Staged/Incremental/SCR). Table 2 shows the SE-ZEC Controller parameters that are available for every application

(Staged/Incremental/SCR).

Table 3: Default SE-ZEC Controller Parameters

Home Page Setup Active Baud Rate

Read Only

Page 8

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 8

Menu 1

Menu 2

Parameter Name

Parameter Description

Parameter Values

Adjustable:

Proportional SCR

Allows PRAC+ auto tuning algorithm to

Setting this to Disable turns off this feature.

This feature drives the VAV box damper shut and

so it reads zero.

Sets the BACnet ID for the BACnet MS/TP

system.

Read Only:

0-4194302

Box Heating

Installed

Adjustable:

False/True

Read Only: No

Stage Electric

Discharge Air

Offset

Adjustable:

None/Parallel/Series

Enables/Disables the activation of re-hea t when

temperature is too high.

Determines whether box or supplemental heat is

turned on first.

Adjustable:

Supplemental/Box

Sets the highest inlet air temperature at which re-

cannot engage.

Sets airflow threshold for determining occupancy

the unoccupied mode.

Occupancy

Polarity

Sets input polarity of occupancy sensor when

Occupancy Sensor Enable is T rue. Open =

Adjustable:

Close/Open

Home Page Setup

Home Page Setup Application Type Set the type of application for the VAV Box.

Home Page Setup

Home Page Setup

Home Page Setup BACnet Id

Home Page Setup

Home Page Setup Box Heating Type Displays the type of heat installed.

Home Page Setup Damper Mode

Home Page Setup

Actuator Stroke

Time

Auto Tune

Enable

Autocalibration

Command

Temperature

Sets the damper actuator stroke time. Note: The

SE-ZEC5X0-1 actuator is a 60 second motor.

continuously tune the loops in the controller.

once shut offsets the differential pressure sensor

Specifies if box re-heat is installed (local re-heat).

Defines the direction of the damper rotation.

(Normal = CCW to close, Reverse = CW to close)

Used to calibrate the supply air temperature

sensor.

Adjustable:

30-120 seconds

Incremental/Staged/

Adjustable:

Enable/Disable

Adjustable:

False/True

Heat/1 Stage

Electric /2 Stage

Electric/Modulating

Hot Water Valve/3

Adjustable:

Normal/Reverse

Adjustable:

-5°F to 5°F

Home Page Setup Fan Control Type Set the type of fan for the VAV Box.

Home Page Setup

Home Page Setup Heating Priority

Home Page Setup

Home Page Setup

Home Page Setup

Heating Limit

Enable

Heating Supply

Air Limit

Occupancy

Determination

Flow Setpoint

the incoming air temperature exceeds the

temperature set in Heating Supply Air Limit. This

is to avoid engaging re-heat when the inlet

heat can be engaged when Heating Limit Enable

is set to True. When the inlet air temperature is

higher than Heating Supply Air Limit, re-heat

when Occupancy Sensor Enable is false.

Whenever the measured flow exceeds the

Occupancy Determination Flow Setpoint, the

system will be in the occupied mode. Whenever

the measured flow is less than the Occupancy

Determination Flow Setpoint, the system will be in

Adjustable:

False/True

Adjustable

Adjustable:

0 cfm to 10000 cfm

Page 9

Smart Equipment Controls

Form No. SECIOM.A

Effective Date: 07/05/19

Page 9

Menu 1

Menu 2

Parameter Name

Parameter Description

Parameter Values

Unoccupied when open, Closed = Unoc c upie d

when closed.

Home Page Setup

Enables determining occupancy by reading IN2

Flow Setpoint.

Resets the PRAC+ tuning parameters of the PID

controllers to the factory defaults.

Adjustable:

Enable/Disable

Sets the amount of time the controller waits to

when power is restored.

After switching to occupied mode, the box will stay

mode.

Enables Standalone Mode. This mode is intended

Enable is True.

Supplemental

Heating Installed

Specifies if re-heat is installed in the zone/space

(non box re-heat).

Adjustable:

False/True

Supply Air

Offset

Supply Airflow

Pickup Gain

Amplification provided by the pitot tube for supply

flow.

Shows the supply inlet area used to calculate the

supply flow.

Adjustable:

0 sq. ft. to 8.0 sq. ft.

The flow setpoint the damper is controlling the

morning warmup conditions, etc.)

Warmer/Cooler

Adjust Enable

Enables the warmer/cooler adjustment to offset

the current setpoint.

Adjustable:

False/True

Zone

Offset

Effective Cooling

Setpoint

Home Page Setup PID Tuning Reset

Home Page Setup

Occupancy

Sensor Enable

Power Fail

Restart Time

Installation, Operation and Maintenance Manual

and ICOM2 on the controller via an occupancy

sensor. When Occupancy Sensor Enable is

disabled, occupancy is determined by comparing

measured airflow to the Occupancy Determination

operate the unit after power is restored when

Power Fail Restart Enable is True. This is to avoid

a power surge with lights, computers, and other

electrical loads that come back on immediately

Adjustable:

Enable/Disable

Adjustable

Home Page Setup

Home Page Setup Standalone Mode

Home Page Setup

Home Page Setup

Home Page Setup

Home Page Setup Supply Area

Home Page Setup Supply Flow The supply airflow measured by the VAV box. Read Only

Standalone Min

Occupied Time

Temperature

in occupied mode for at least the amount of time

specified in Standalone Min Occupied Time,

before being able to switch back to unoccupied

to allow the controller to utilize unoccupied

setpoints when there is no connection to a

building automation system. When Standalone

Mode is enabled, occupancy is determ ined b y

comparing the measured flow against the

Occupancy Determinati on Flo w Setpoi nt when

Occupancy Sensor Enable if False, or by using

the Occupancy Sensor when Occ upanc y Sens or

Used to calibrate the supply air temperature

sensor.

Adjustable:

0-360 minutes

Adjustable: Off/On

Adjustable:

-5°F to 5°F

Adjustable

Home Page Setup

Home Page Setup

Home Page Setup

Home Page Setpoints

Supply Flow

Setpoint

Temperature

supply air flow to. This will be based on the unit

conditions (occupancy, temperature setpoint,

Used to calibrate the zone temperature sensor.

Effective Cooling Setpoint Read Only

Read Only

Adjustable:

-5°F to 5°F

Page 10

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 10

Menu 1

Menu 2

Parameter Name

Parameter Description

Parameter Values

Effective Heating

Setpoint

When occupied the thermostat controls cooling to

Defaults to 72°F.

When occupied the thermostat controls heating to

Defaults to 68°F.

In order for the Standby Cooling Setpoint to

unit is occupied. Defaults to 74°F.

In order for the Standby Heating Setpoint to

unit is occupied. Defaults to 66°F.

Unoccupied

Cooling Setpoint

When unoccupied the thermostat controls cooling

to this level. Defaults to 80°F.

Adjustable:

46°F to 99°F

When unoccupied the thermostat controls heating

Setpoint. Defaults to 60°F.

This is the range that the warmer cooler

adjustment at the sensor. Defaults to 5°F.

Sets the required differential between the supply

Flow.

Sets the maximum supply air flow of the VAV box

when cooling.

Adjustable:

0 cfm to 10000 cfm

Occupied Cooling

Min Flow

Sets the minimum supply air flow of the VAV box

when cooling.

Adjustable:

0 cfm to 10000 cfm

Sets the minimum supply air flow of the VAV box

heat to energize.

Sets the minimum heating flow for electric reheat

per kW of electric heat.

Sets the minimum supply air flow of the VAV box

mode.

Home Page Setpoints

Home Page Setpoints

Home Page Setpoints

Home Page Setpoints

Home Page Setpoints

Home Page Setpoints

Home Page Setpoints

Home Page Setpoints

Occupied Cooling

Setpoint

Occupied Heating

Setpoint

Standby Cooling

Setpoint

Standby Heating

Setpoint

Unoccupied

Heating Setpoint

Warmer/Cooler

Adjust Range

Effective Heating Setpoint Read Only

this level. Set above Occupied Heating Setpoint.

this level. Set below Occupied Cooling Setpoint.

appear, set the Occupancy Schedule to external.

When set to external the zone switches to this

setpoint when motion is no longer sensed and the

appear, set the Occupancy Schedule to external.

When set to external, the zone switches to this

setpoint when motion is no longer sensed and the

to this level. Set below Unoccupied Cooli ng

adjustment on the sensor can affect the setpoint.

Setting it to zero (0) means the user has no

Adjustable:

46°F to 99°F

Adjustable:

45°F to 98°F

Adjustable:

46°F to 99°F

Adjustable:

45°F to 98°F

Adjustable:

45°F to 98°F

Adjustable:

0°F to 5°F

Home Page Setpoints

Home Page Commissioning Cooling Max Flow

Home Page Commissioning

Home Page Commissioning

Home Page Commissioning

Home Page Commissioning

Warmup

Differential

Occupied Heating

Min Flow

Staged Device

Min Flow

Unoccupied

Cooling Min Flow

air temperature (SAT) sensor and the zone

temperature (ZNT) sensor in occupied mode to

notify the controller that warmup conditions are

present. When warmup conditions are present the

minimum supply airflow will be set to Warmup Min

when heating. Note: When the zone is in heating

mode, the supply air flow is constant. Thus, no

maximum heating air flow. This value must

exceed Staged Device Min Flow to allow electric

control. This parameter serves an additional

control safety to the high-limit switches in the box.

It is best practice to set this parameter to 70 cfm

when unoccupied cooling and in the cooling

Adjustable:

0 cfm to 10000 cfm

Adjustable:

0 cfm to 10000 cfm

Adjustable:

0 cfm to 10000 cfm

Page 11

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 11

Menu 1

Menu 2

Parameter Name

Parameter Description

Parameter Values

Sets the minimum supply air flow of the VAV box

mode.

Sets the minimum supply airflow when warmup

by the Warmup Differential in occupied mode.

Discharge Air

Velocity Pressure

Displays differential pressure measured across

the airflow probe.

Occupancy

Status

Supply Air

Temperature

Supply air temperature reading from the supply air

temperature sensor (if included).

Zone

Temperature

Supply Air

Damper Output

Displays damper position (0% = Fully Clos ed,

100% = Fully Open).

Supply Fan

Command

Factory Use

Only

STG

INC

SCR

Reverses the direction of the incremental heating

wiring to the actuator.

Home

Page

Box Heating

Stroke Time

Sets the actuator stroke time for incremental

heating valve.

Adjustable:

30-120 seconds

Home

Page

Dual Max

Enable

Adjustable:

Enable/Disable

Home

Page

Number Of

Heating Stages

Reverses the direction of the incremental

this or reverse the wiring to the actuator.

Supplemental

Time

Home Page Commissioning

Home Page Commissioning

Inputs

Inputs

Inputs

Inputs

Inputs

Outputs

Outputs

Parameters

Unoccupied

Heating Min Flow

Warmup Min

Flow

D

ischarge Air

Temperature

when unoccupied heating and in the heating

conditions are present. Warmup conditions are

present when the supply air temperature (SAT)

sensor value exceeds the zone temperature

(ZNT) sensor in unoccupied mode or exceeds it

Discharge air temperature reading from the

discharge air temperature sensor (if included).

Displays state of occupancy input. Read Only

Displays temperature measured at zone sensor. Ready Only

Displays fan status. Read Only

Adjustable:

0 cfm to 10000 cfm

Adjustable:

0 cfm to 10000 cfm

Read Only

Read Only

Read Only

Read Only

Application Specific Parameters

Table 3 below shows application specific parameters for the staged, incremental, and SCR applications:

Table 4: Application Specific SE-ZEC Controller Parameters

Menu 1 Menu 2

Home

Page

Home

Page

Home

Page

Setup

Setup

Setup

Setup

Setup

Setup

Parameter

Name

Box Heating

Polarity

Supplemental

Heating Polarity

Heating Stroke

●

●

●

●

● ●

● ●

Parameter Description Parameter Values

valve. You can either switch this or reverse the

Enables the Dual Max Control Sequence

S

ets the number of box heating stages. Adjustable: 0 - 3

supplemental heating valve. You can either switch

ets the actuator stroke time for incremental

S

supplemental heating valve.

Adjustable:

Normal/Reverse

Adjustable:

Normal/Reverse

Adjustable:

30-120 seconds

Page 12

Smart Equipment Controls

Form No. SECIOM.A

Effective Date: 07/05/19

Page 12

Home

When the space temperature drops below the

maximum f low.

When the space temperature drops below the

maximum f low.

Heating

Command

Displays the heat command (on/off) of the heat

output to the proportional actuator or electric heat

Displays the heat command (0-100%) of the heat

output to the proportional actuator or electric heat

Heating Stage 1

Command

Heating Stage 2

Command

Heating Stage 3

Command

Displays the supplemental heat command (0actuator or electric heat

Supplemental

Command

Parameter Name

Value

Supplemental Heating Stroke Time

N/A

Supplemental Heating Polarity

N/A

BACnet ID

10000

BACnet Encoding Type

ISO10646

Power Fail Restart Time

180

Warmer/Cooler Adjust Range

3

Warmup Differential

10

Autocalibration Command

FALSE

Zone Temperature Offset

0

Page

Home

Page

Setpoints

Setpoints

Discharge Air

Setpoint

Heating Max

Discharge Air

Temperature

Setpoint

●

●

Installation, Operation and Maintenance Manual

heating setpoint the zone controller will start from

the supply air temperature setpoint and reset to the

supply air setpoint heating max. Once the heating

max setpoint is reached the supply air flow will be

reset from heating minimum flow to cooling

heating setpoint the zone controller will start from

the supply air temperature setpoint and reset to the

supply air setpoint heating max. Once the heating

max setpoint is reached the supply air flow will be

reset from heating minimum flow to cooling

Adjustable:

45°F to 140°F

Adjustable:

45°F to 130°F

Outputs

Outputs Heating Output

Outputs

Outputs

Outputs

S

Outputs

Outputs

upplemental

Heating Output

Heating Stage 1

●

●

●

●

●

● ●

● ●

Read Only

Read Only

D

isplays status of stage 1 heat. Read Only

D

isplays status of stage 2 heat. Read Only

D

isplays status of stage 3 heat. Read Only

100%) of the heat output to the proportional

D

isplays status of stage 1 supplemental heat. Read Only

Read Only

Factory Programmed Parameters

This section outlines how the SE-ZEC Controller parameters are programmed at the factory.

Default Parameters

The following table shows factory programming for SE-ZEC Controller parameters that are independent of inlet size and

control sequence.

Table 5: Factory Programmed Default Parameters

Page 13

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 13

Supply Air Temperature Offset

0

Discharge Air Temperature Offset

0

Heating Limit Enable

TRUE

Heating Supply Air Limit

75

Rotation

90

Warmup Min Flow

200

Occupied Cooling Setpoint

72

Occupied Heating Setpoint

68

Unoccupied Cooling Setpoint

85

Unoccupied Heating Setpoint

55

Standby Cooling Setpoint

77

Standby Heating Setpoint

66

Standalone Min Occupied Time

15

Actuator Stroke Time

60

Size

4 5 6 7 8 9 10

12

14

16

20

22

Size Dependent Parameters

The following table shows factory programming for SE-ZEC Controller parameters that are inlet size dependent.

Table 6: Factory Programmed Size Dependent Parameters

Supply Area 0.087 0.136 0.196 0.267 0.349 0.442 0.545 0.785 1.069 1.396 0.738 2.667

Supply

Airflow

Pickup Gain

Cooling

Maximum

Flow

Occupied

Cooling Min

Flow

Unoccupied

Cooling Min

Flow

Occupied

Heating Min

Flow

Unoccupied

Heating Min

Flow

Staged

Device Min

Flow

2.329 2.327 2.332 2.325 2.329 2.327 2.327 2.327 2.328 2.328 1.982 2.328

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

55 85 110 140 190 240 300 425 580 750 425 1800

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Per

Order

Page 14

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 14

6102, 7102,

6106, 7106

6105, 7105,

6108, 7108

6202, 7202,

6206, 7206

6205, 7205,

6208, 7208

Occupancy

Determination

29 46 66 89 117 148 182 262 357 466 267 891

Flow Setpoint

Sequence Dependent Par am eter s

The following section shows factory programming for SE-ZEC Controller parameters that are control sequence specific.

Table 7: Factory Programmed Sequence Specific Parameters

Control Code 6101, 7101

Heating Type Cooling Only Staged Staged Staged SCR Incremental Staged

FAN-TYPE None None None None None None None

Number of Heating

Stages

Damper Polarity Normal Normal Normal Normal Normal Normal Normal

Supplemental

Heating Installed

Box Heating Installed FALSE TRUE TRUE TRUE TRUE TRUE FALSE

Box Heating Stroke

Time

Box Heating Polarity N/A N/A N/A N/A N/A Normal N/A

Staged Device Min

Flow

No Heat 1 2 3 No Stages No Stages No Heat

FALSE FALSE FALSE FALSE FALSE FALSE TRUE

N/A N/A N/A N/A N/A 60 N/A

Per Size

Table

Per Size

Table

6103, 7103 6104, 7104

Per Size

Table

Per Size

Table

Per Size

Table

6107, 7107 6109, 7109

N/A

Per Size

Table

Occupancy

Determination Flow

Setpoint

Occupancy Polarity N/A N/A N/A N/A N/A N/A N/A

Occupancy Sensor

Enable

Standalone Mode TRUE,FALSE

Control Code 6201, 7201

Heating Type Cooling Only Staged Staged Staged SCR Incremental Staged

Per Size

Table

FALSE FALSE FALSE FALSE FALSE FALSE FALSE

Per Size

Table

TRUE,FALSE

TRUE,FALSE

Per Size

Table

TRUE,FALSE TRUE,FALSE

Per Size

Table

6203, 7203 6204, 7204

Per Size

Table

TRUE,FALSE

TRUE,FALSE

Per Size

Table

TRUE,FALSE TRUE,FALSE

6207, 7207 6209, 7209

Per Size

Table

Page 15

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 15

6302, 7302,

6306, 7306

6305, 7305,

6308, 7308

FAN-TYPE Series Series Series Series Series Series Series

Number of Heating

Stages

Damper Polarity Reverse Reverse Reverse Reverse Reverse Reverse Reverse

Supplemental

Heating Installed

Box Heating Installed TRUE TRUE TRUE TRUE TRUE TRUE TRUE

Box Heating Stroke

Time

Box Heating Polarity N/A N/A N/A N/A N/A Normal N/A

Staged Device Min

Flow

Occupancy

Determination Flow

Setpoint

Occupancy Polarity Close Close Close Close Close Close Close

No Heat 1 2 3 No Stages No Stages No Heat

FALSE FALSE FALSE FALSE FALSE FALSE TRUE

N/A N/A N/A N/A N/A 60 N/A

0 0 0 0 0 N/A 0

0 0 0 0 0 0 0

Occupancy Sensor

Enable

Standalone Mode TRUE,FALSE

Control Code 6301, 7301

Heating Type Cooling Only Staged Staged Staged SCR Incremental Staged

FAN-TYPE Parallel Parallel Parallel Parallel Parallel Parallel Parallel

Number of Heating

Stages

Damper Polarity Reverse Reverse Reverse Reverse Reverse Reverse Reverse

Supplemental

Heating Installed

Box Heating Installed TRUE TRUE TRUE TRUE TRUE TRUE TRUE

Box Heating Stroke

Time

TRUE TRUE TRUE TRUE TRUE TRUE TRUE

TRUE,FALSE

TRUE,FALSE

TRUE,FALSE TRUE,FALSE

6303, 7303 6304, 7304

No Heat 1 2 3 No Stages No Stages No Heat

FALSE FALSE FALSE FALSE FALSE FALSE TRUE

N/A N/A N/A N/A N/A 60 N/A

TRUE,FALSE

TRUE,FALSE

TRUE,FALSE TRUE,FALSE

6307, 7307 6309, 7309

Page 16

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 16

Box Heating Polarity N/A N/A N/A N/A N/A Normal N/A

Staged Device Min

Flow

Occupancy

Determination Flow

Setpoint

Occupancy Polarity Close Close Close Close Close Close Close

Occupancy Sensor

Enable

Standalone Mode TRUE,FALSE

0 0 0 0 0 N/A 0

0 0 0 0 0 0 0

TRUE TRUE TRUE TRUE TRUE TRUE TRUE

TRUE,FALSE

TRUE,FALSE

TRUE,FALSE TRUE,FALSE

TRUE,FALSE

TRUE,FALSE

TRUE,FALSE TRUE,FALSE

Commissioning

For networked units, SE-ZEC Controller parameters can be changed by the BAS. For stand-alone units, controller

parameters can only be changed using the optional MAP Tool. An optional VAV Handheld balancing tool is available to

aid in the balancing process.

Mobile Access Portal (MAP) Gateway

The Mobile Access Portal (MAP) Gateway is an alternate local display solution or a temporary portable commissioning

device that enables users to leverage the power of mobility using smart phones, tablets, or laptop computers to interact

with building automation equipment controls. The MAP Gateway serves up web pages through a built-in Wi-Fi access

point or tethered Ethernet connection, which allows users to view and edit equipment controller configuration parameters,

setpoints, schedules, and alarms through a browser. A mobile application is not required to use the MAP Gateway with

your mobile device.

The MAP Gateway can be used to see field bus devices on Metasys® systems, Facility Explorer systems, and Smart

Equipment rooftop units (RTUs) with unit control boards (UCBs). The MAP Gateway supports Johnson Controls® branded

Field Controllers, including FEC, FAC, VMA, PCA, PCG, and PCV Series devices. MAP Gateway also supports the

TEC3000 Series Thermostats.

The MAP Gateway comes in two configurations: a portable configuration and a stationary configuration. The portable

configuration is an optional f ac tor y provided acces s ory (Part # PC-01-0206). PC-01-0206 includes the MAP Gateway, RJ12 cable, bumper guard, and lanyard. To use the MAP Gateway:

1. Connect the MAP Gateway to Equipment

a. Use the supplied RJ-12 cable to connect the RS-485 port of the MAP Gateway to the sensor bus or field

bus port of the equipment controller, or to the zone sensor connected to the equipment controller

b. T

he MAP Gateway LEDs flash, indicating that the device is initializing. When the fault LED turns off

.

and

the Wi-Fi LEDs flash in succession, the MAP Gateway is ready to use.

2. Connect to the MAP Gateway Wi-Fi Network

a. In the Wi-Fi settings of your mobile device or laptop, connect to the MAP Gateway Wi-Fi network usi

he credentials found in the MAP Gateway Quick Start Guide that is provided with the MAP Gateway (Part

t

ng

No. 24-10737-16)

3. Open a Web Browser

a. On your mobile device or laptop navigate to www.mapgwy.com on your internet browser.

Page 17

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 17

4. Log in to the MAP Gateway

a. Log in to the MAP Gateway using the default Admin login credentials found in the MAP Gateway Quick

Start Guide that is provided with the MAP Gateway (Part No. 24-10737-16)

5. Change Passwords

a. The first time you log in to the MAP Gateway, the Change Password and Passphrase web page appears.

You must change the Admin password and Wi-Fi passphrase.

SSID, the web server restarts and you must rejoin the MAP Gateway Wi-Fi network using the new

passphrase. On some mobile devices, you must select and forget the original MAP Gateway Wi-F

network before rejoining the network with the new passphrase.

6. Use the MAP Gateway

a. Select a device from the equipment list and use the web pages from the MAP Gateway to view,

commission and configure devices as needed.

For more information on the MAP Gateway reference the following Johnson Controls documents:

After you change the Wi-Fi passphrase or

i

Installation Instructions: LIT-24-10737-8

Catalog Page: LIT-1900869

User’s Guide: LIT-12011999

Product Bulletin: LIT-12011884

Technical Bulletin: LIT-12012015

VAV Handheld Balancing Tool

A Handheld Balancing Tool (Part # 15037701) can be used to aid in balancing units with SE-ZEC Controllers.

1. Connect the VAV Balancing Tool to the Network Zone Sensor ass oc iated w ith the control ler you want to bala nc e.

2. Press and hold the Enter and Cancel buttons on the VAV Balancing Tool for 5 seconds to enter balancing mode.

3. Balance the unit. Reference the Metasys Balancing Sensor User Guide that comes with the VAV Handheld

alancing Tool.

B

Parameters that can be balanced include:

Cooling Ma

Cooling Min Flow [CMIN]

eating Flow [HTG]

H

Differential Flow [DIFF]

Box Area [AREA]

Pickup Gain – K Factor [K]

dP Offset [DPO]

4. T

x Flow [CMAX]

o Exit, Press the enter button when Exit appears on the screen at the highest sub menu.

For more information on the VAV Handheld Balancing Tool reference the following Johnson Controls documents:

Catalog Page: LIT-1900348

Installation Instructions: LIT-24-10211-2

User Guide: LIT-24-10159-5

Troubleshooting

Use the following information to troubleshoot the SE-ZEC Controllers. *NOTE: Please use the appropriate personal

protective equipment when troubl es ho oti ng.

Page 18

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 18

Part Number

Part Description

PC-01-0189

SE-ZEC500-1 Standa lon e Contr o ller (Un-programmed)

PC-01-0190

SE-ZEC510-1 BACnet Controller (Un-programmed)

PC-01-0159

TE-631GV-2 Supply Air or Discharge Air Temperatur e Sensor

PC-01-0206

TL-MAP1810-0P Mobile Access Portal Gateway

15037701

NS-ATV7003-0 VAV Handheld Balancing Tool

15037501

NSB8BTN241-0 Network Sensor (LCD Display)

15037503

NSB8BTN141-0 Network Sensor (Warmer/Cooler Interface)

15037502

NSB8BTN041-0 Network Sensor (No Display)

Power Status LED

Ensure SE-ZEC Controller is receiving power. A green LED shows the power supply status to the SE-ZEC Controller.

LED OFF = No Power. LED ON = Power is supplied by primary voltage (normal operation)

Communication Bus Problems

Several factors may influence the behavior of the FC Communication Bus.

I/O Wiring

The SE-ZEC Controller must be wired properly. If the SE-ZEC Contr oller is wire d incor rec tly, communication problems

may occur. These problems include devices going online and offline, or devices not coming online at all.

Duplicate Addresses

Two or more devices on a communication Bus cannot have the same address. Two controllers on the FC Communication

Bus cannot both have an address of 18, for example. If two devices on the same Bus have the same address,

performance can degrade or serious communication problems may occur. These problems include the devices not

coming online and all communication stopping completely.

Check for duplicate addresses in the following ways:

• If a specific device is not communicating, remove the device with communication problems and check if devic

addr

ess remains online at the MAP Gateway to determine if the device address remains online.

• If the Bus communication problems are severe and no communication is present, or you cannot determ ine wher

communication is unreliable, partition (disconnect and isolate a portion of the Bus for testing purposes) and test

the Bus portion connected to the Zone Coordinator.

e

Correcting Physical Communication Bus Problems

The communication Bus is subject to a number of physical factors that can affect performance. Consider the follow ing lis t

of common physical problems that affect the communications Bus:

• Check status LED to verify power at the controller

• Check wires

o Verify that the wire is a 0.6 mm (22 AWG) three-conductor, twisted, shielded cable.

o Ensure the wires are not broken or frayed. Check wire connections.

Parts and Accessories

Table 8: SE-ZEC Controller Parts and Accessories

e

Page 19

Smart Equipment Controls

Installation, Operation and Maintenance Manual

Form No. SECIOM.A

Effective Date: 07/05/19

Page 19

Additional Information

Refer to Johnson Controls LIT-24-10143-01493 for more information on the SE-ZEC Controllers.

Refer to Johnson Controls LIT-1900217 for more information on the TE-631GV-2 supply air or discharge air temperature

sensors.

Refer to Johnson Controls LIT-1901099 for more information on NS8000 Series Network Sensors

Refer to Johnson Controls LIT-12012362 for more information on networking the SE-ZEC Controllers.

Loading...

Loading...