Johnson Controls SE-SPU101 Series, SE-SPU1011-1, SE-SPU1012-1 Installation Instructions Manual

Page 1

CCS Smart Equipment Control Board for Single Packaged

Unit (SPU) Controller

Installation Instructions

SE-SPU1011-1, SE-SPU1012-1

Applications

The new SE-SPU101x controllers replace the

RTU-100x controllers. All the RTU100x controllers are

discontinued, including the RTU-1003-0 VAV SPU

controller. T he new SEC pr oduct offering provides new

controller options.

The SE-SPU101x-1 SEC Unit Control Board (UCB) is a

member of the Smart Equipment Controller (SEC)

product family. The controller is designed to run a preengineered HVAC zoning application and provide the

inputs and outputs required for this application.

North American Emissions Compliance

United States

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area

may cause harmful interference, in which case the

users will be required to correct the interference at

their own expense.

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Code No. LIT-12011479

Issued June 16, 2015

Installation

Special Tools Needed

• wire strippers

• small flat-head screwdriver

• 22 AWG (0.65 mm) 3-conductor, twisted,

e with a drain wire

cabl

Note: This drain wire is used only to group the

shielded cable. Do not use this drain wire

ection to the board.

conn

• wire nuts for 22 AWG drain wire

• electrical tape

shielded

as a

Mounting

The manufacturing facility mounts the controller. All of

the required power wiring, internal unit sensor wiring,

and output wiring is completed and tested at the

factory . The control application required for the specific

UCB is factory configured and ready for operation.

Wiring

Field Wiring Connections

In addition to power connections, the UCB requires a

communication bus connection. Address selection is

required for networking with a CCS Building

Automation System (BAS).

Power Wiring

The SEC UCB controller is factory wired for 24 VAC

power.

IMPORTANT: The 24 VAC power should not be

shared with other network devices. Sharing power to

other network devices may cause noise,

interference, and ground loop problems. You may

damage the controller by sharing power to other

devices.

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Inst allation

Instructions

1

Page 2

In certain cases, you may need to share a 24 V

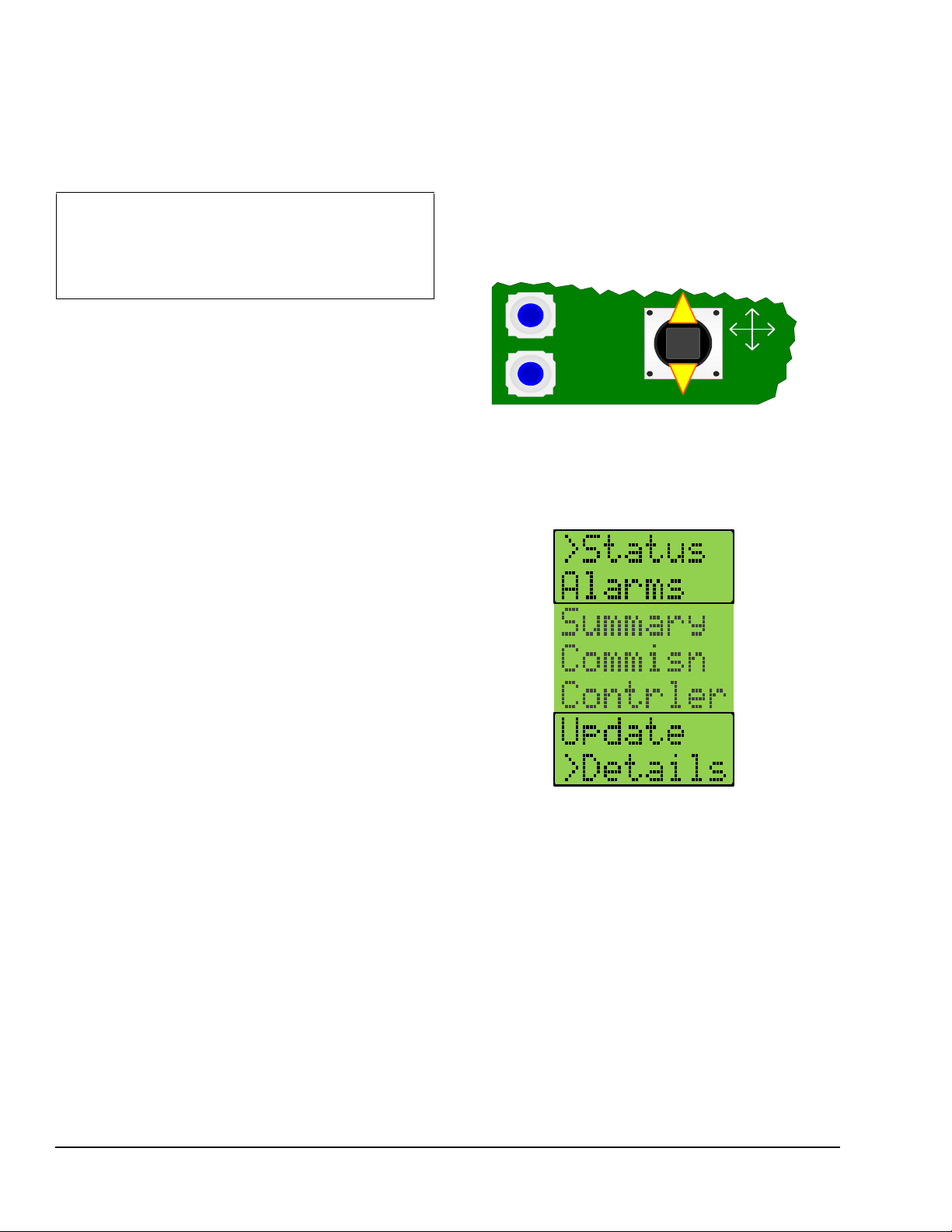

Figure 1: Joystick and Push Buttons on UCB

ENTER

CANCEL

JOY

Figure 2: UCB Top Level Menu

transformer with multiple CCS devices. Be sure that

you maintain consistent +, -, and common wiring

terminations on the shared CCS devices.

IMPORTANT: Do not interchange +, -, and

common 24 V terminations when sharing a

transformer with multiple CCS devices.

Interchanging these terminations can cause damage

to the controller.

Setup and Adjustments

To quickly set up your CCS network:

1. On each end of the 3-conductor cable, strip the

outside insulation back approximately 2 in.

(51 mm).

2. Tear off excess foil shield, leaving the bare drain

wire and the three insulated conductors.

3. On each end of the three insulated conductors in

the cable, strip the insulation back approximately

1/8 to 1/4 in. (4 to 7 mm).

4. Choose a color pattern to follow and insert each of

the three conductors into one each of the thr ee

terminals on the CCS board communication

connector.

Note: Be sure you observe polarity of each of the

conductors in the communication cable.

Communication Bus

The UCB default address is set to 4. The available

values range from 0 to 127. To view the UCB Network

Address, use the joystick and the two push buttons

below the LCD, to navigate through the menus to the

Commissioning menu (Figure 1).

Up and down movements of the joystick move the >

cursor and scroll through the selections in the active

section of the menu (Figure 2).

5. Tighten each terminal until the wire is secure.

6. Ground the drain wire at one end only of the

communication trunk. Do this on the last unit in

line.

Use an existing hole or drill a hole and insert a

sheet metal screw in the back plate below the

communication connector.

Wrap the bare drain wire around the screw and

tighten the screw. This is the only location where

the shield is grounded.

7. Daisy chain the three-conductor wire between the

remaining SPUs. Connect the drain wires together

with the wire nuts. Follow the stripping and

connecting procedure in Step 1 through Step .

8. Run the cable from the last unit to the location of

the System Manager or Zone Coordinator. Follow

the connection instructions for the System Manger

or Zone Coordinator . Figure 4 displays an example

communication riser.

9. Make sure all the SPUs are powered and operating

properly.

Each menu selection represents either a submenu or a

property. Press Enter to display the items in the

submenu or the values of the selected property.

Once you navigate to the Commissioning menu, use

the cursor to scroll to the Network submenu. From the

Address submenu, press Enter to display the current

network address. Move up or down with the joystick to

display the values of other properties.

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Installation Instructions2

Page 3

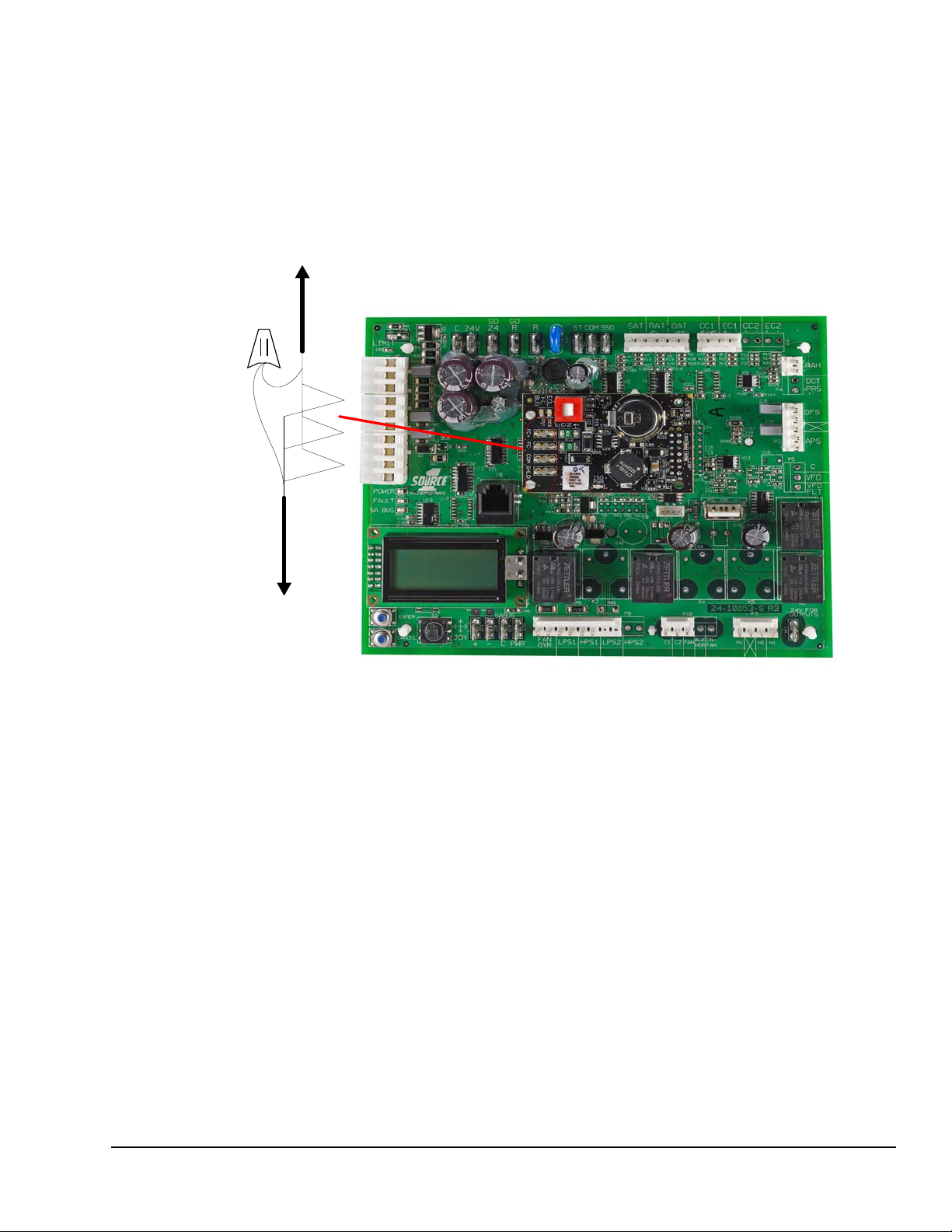

Control Board and Wiring Diagrams

Figure 3: VAV SPU Control Board Communication Terminations

Communication Cable to

Next VAV box*

Comm unication Cable to

Next VAV box, Zone

Dampers, and Bypass

Damper

* M o v e th e 4 -p ositio n te rmin al blo c k fro m th e T h e r mos ta t in pu ts

to the FC Bus connection of the communications card.

Figure 3 shows the location of the communication

cable terminations on the SPU controller board.

Figure 4 shows the VA V SPU contro ller communication

riser. .

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Installation Instructions 3

Page 4

Figure 4: VAV SPU Controller - Example System Communication Riser

Optional

Inte r ne t

Connection

+

–

S

H

L

D

R

E

F

A

Earth

Ground

The shield drain wire must be earth

grounded at one and only one point for

the entire comm unication bus segment.

(Preferably at the last device)

SHIELD GROUNDING

System M anager

COM

-

+

J2

COM

AI1

AI2

COM

AI3

AI4

1

64

32

16

8

4

2

128

O

N

24VCOM24VCOM

COM

-

+

J2

1

64

32

16

8

4

2

128

O

N

Address

Swit ch

24VCOM24VCO M

COM

AI1

COM

+5V

Wir e

Nut

Observe polarity

Drain

wire

Wire

Nut

Drai n

Wire

Wire

Nut

Drain

Wire

Tape back

drain wire

Wire

Nut

Wire

Nut

Wire

Nut

Tape back

drai n wire

SEC

COBP

RTU

Address 4

Bypass

Damper

Address 5

Zone Dam per

(Typical)

Address 6

IO M

Address 4

SEC

RTU

Single Zone

Address 18

SEC RTU

Single Zone

Address 19

To additional

units and/or

any IOM

expansion

modules

To

additional

zones

O p tional R e mo te OWS

OPTIONAL SWIT CH

ETHERNET

COMM UNICATION BUS WIR E

TO BE 22AWG, 3-CONDUCTOR

TWISTED SHIELDED W IR E

WITH DRAIN.

System

Communication Bus

Zone

Communication

Bus

S1 S2

J8 J7

J6

System

Bus

Zone

Bus

CO

M

-

+

CO

M

-

+

CO

M

24V

O

n

Of

f

24VAC

COM

COM

SB

-

SB

+

ZB

+

ZB

-

COM

EOL

O

N

Of

f

EOL

O

N

S1 S2

J8 J7

J6

System

Bus

Zone

Bus

CO

M

-

+

CO

M

-

+

CO

M

24 V

O

n

Of

f

24VAC

COM

COM

SB

-

SB

+

ZB

+

ZB

-

COM

EOL

O

N

Of

f

EOL

O

N

Termination Board

System Manager

Drai n

Wir e

S

1

S

2

J

8

J

7

J

6

System

Bus

Zone

Bus

C

O

M

-

+

C

O

M

-

+

C

O

M

2

4

V

O

n

O

ff

24VAC

COM

COM

SB -

SB +

ZB +

ZB COM

EOL

ON

O

ff

EOL

ON

System

Com m unication Bus

Terminal Strip

24VAC

Power

Input (10VA)

Zone Com m unication

Bus Terminal Strip

EOL Termination

S e t T o O N

COM

-

+

J2

COM

AI1

AI2

COM

AI3

AI4

1

64

32

16

8

4

2

128

O

N

24VCOM24VCO M

COM

-

+

J2

1

64

32

16

8

4

2

128

O

N

Address

Swit ch

24VCOM24VCOM

COM

AI1

COM

+5V

SEC

VAV RTU

Address 4

VAV Box

(Typical)

Address 7

Zone

Communication

Bus

+

Termination Board

VAV Zone C oordinator

S1 S2

J8 J7

J6

System

Bus

Zone

Bus

CO

M

-

+

CO

M

-

+

CO

M

24 V

O

n

Of

f

24VAC

COM

COM

SB

-

SB

+

ZB

+

ZB

-

COM

EOL

O

N

Of

f

EOL

O

N

Termin a tion Bo a r d

COB P Zone Coordinator

Drain

wire

Tape back

drain wire

VAV Box

(Ty p ica l)

Address 6

Drai n

Wire

Wire

Nut

Drain

Wire

To

additional

zones

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Installation Instructions4

Page 5

End-of-Line (EOL) Terminations

(Bounce Back and Noise)

No

EOL

EOL

Cushioning (No Bounce Back)

FIG:intrfrnc

Figure 5: Interference

Figure 6: CCS EOL Wiring Example

Input

Output

Module

24V

COM

COM-+

BI-1

COM

BI-2

COM

AI-3

COM

AI-4

Monitored Contact

To Temperature,

RH%, CO

2 Sensor,

Building Pres su re,

Light Sensor,

Refrigerant Sensor,

Common Flow

To 24VAC

BO-3

BO-2

BO-1

BO-4

COM

Monitored Contact

To Scheduled Item 1

To Scheduled Item 2

To Scheduled Item 3

To Scheduled Item 4

NonCCS

HVAC

System

Universal

CV Unit

Controller

24V

COM

Zone Sensor

COM-+

AI-1

COM

AI-2

123

4

BO-1

BO-2

BO-3

BO-4

BO-5

C

R

G

Y1

Y2

W1

W2

COM

AI-6

COM

AI-7

COM

AI-8

COM

AI-4

COM

AI-5

COM

BI-2

SAT Sensor

RAT Sensor

OAT Sensor

To Zone RH% Sensor

To Zone CO

2 Sensor

APS

COBP Zone Coordinator

System

Bus

COM

SB-

SB+

EOL

O

N

?

Zone

Bus

COM

ZB-

ZB+

EOL

O

N

?

COM

24V

LAN

To 24VAC

System Manager

System

Bus

COM

SB-

SB+

EOL

O

N

?

Zone

Bus

COM

ZB-

ZB+

EOL

O

N

?

COM

24V

Modem

LAN

To 24VAC

To Phone Line

To Ethernet Hub

VAV Zone Coordinator

System

Bus

COM

SB-

SB+

EOL

O

N

?

Zone

Bus

COM

ZB-

ZB+

EOL

O

N

?

COM

24V

LAN

To 24VAC

tape

off

SEC Unit Control Board

COM-+

This end of the Drain Wire

connected to cabinet ground

Other System Bus Devices

CCS System Bus Devices

Other System Bus Devices

Other System Bus Devices

To COBP Zone

Bus Devices

To VAV Zone

Bus Devices

Recommended ZC e nd-of-line for zone bus

Recommended S M end -of-line for system bus

Must be end of line for zone bus

TEC2601-4

TEC2602-4

TEC2603-4

Y2

Y1

G

RC

C

RH

W1

W2

Aux

DI1

DI2

RS

Scom

OS

MS

+

_

Ref

COM-+

Daisy-chained RS485 protocol networks require

end-of-line (EOL) termination to reduce interference.

Interference is caused by signal reflection that occurs

when data transmissions reach the end of a bus

segment and bounce back (Figure 5). The high baud

rates on Master-Slave/Token-Passing (MS/TP) bus

applications require robust EOL termination and strict

adherence to the EOL termination rules.

On a CCS System bus or Zone bus, only one EOL

termination is required due to the fewer number of

devices on one bus and the shorter wiring length.

Specifically, the System bus must always have a

System Manager as the EOL device, and the Zone bus

must always have a Zone Coordinator as the EOL

device. Figure 6 shows a CCS EOL wiring example.

No EOL = No Signal Cushioning

EOL Provides Signa l

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Installation Instructions 5

Page 6

Operation

Figure 7: Startup Countdown

The controllers are supplied in a pre-configured format.

Y ou do not n eed to configure the controller. Refer to the

Commercial Comfort System (CCS) Operation

Overview Technical Bulletin (LIT-12011617) or the

Smart Equipment Controls (SEC) Quick Start Guide

(LIT-12011938) for information on operating modes and

functionality.

Troubleshooting

Use the following information to troubleshoot the

System Manger and Zone Coordinator.

Power Status LED

The display backlight and green Power LED remain lit

as long as power is applied to the C and 24V terminals.

The red Fault LED lights, goes off briefly, and then

flashes throughout the startup sequence.

The green SA Bus LED lights briefly.

During the startup sequence, the joystick, the Enter

button, and the Cancel button are not functional.

The LCD shows a countdown on the top line.

After the startup sequence finishes, the display shows

XxXx on both lines if no alarm is active. The red Fault

LED stops flashing and turns off. The joystick, Enter,

and Cancel buttons are operational.

Communication Bus Problems

Several factors may influence the behavior of the

communication bus. In addition, certain proble ms can

affect the bus in multiple ways and have multiple

symptoms, which makes the exact diagnosis difficult.

For example, duplicate addresses on the bus can

degrade performance, make the device go offline, or

stop communication completely.

Incomplete Address

With the SEC controller for VAV, COBP must have the

address switch set to 4 on the zone communication

bus. Other settings prevent the SPU from

communicating on the System Communication bus.

Duplicate Addresses

Two or more devices on a communication bus cannot

have the same address. For example, two SPUs on the

System communication bus cannot both have the

address 4. If two devices on the same bus have the

same address, performance can degrade or serious

communication problems may occur. These problems

include the devices not coming online or all

communication stopping completely.

After approximately 15 seconds, the green SA Bus

LED does one of the following:

• Lights to indicate the UCB has not established

communication and is awaiting communication

from SA Bus devices

• Flashes to indicate the UCB established

communication with SA Bus devices

Check for duplicate addresses in the following ways

depending on the severity of the situation:

• If the bus performance is degraded, check the

address switch settings at the devices with

unreliable communications.

• If a specific device is not communicating, remove

the device with communication problems and

check if the device address remains online at the

System Manager or Zone Coordinator.

• If the bus communication problems are severe,

and no communication is present (or if you cannot

determine where communication is unreliable),

partition (disconnect and isolate a portion of the

bus for testing purposes) and test the bus portion

connected to the System Manager and Zone

Coordinator controllers.

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Installation Instructions6

Page 7

Correcting Physical Communication Bus Problems

The communication bus is subject to a number of

physical factors that can affect performance. Consider

the following list of common physical problems that

affect the communications bus:

• Check wires

- Verify that the wire is 22 AWG (0.65 mm) 3conductor, twisted, shielded cable.

- Verify that the shield is continuous and hardgrounded at one end.

• Check wiring

- Check for and eliminate T-Taps (wire

configurations that create a T shape) and star

configurations.

- Ensure that the bus is wired in daisy-chain

fashion.

- Verify that appropriate devices have three

wires entering and exiting each terminal.

(Devices at the ends of the trunk do not have

this wiring.)

• Check EOL switch settings

- Verify that the zone bus EOL switch on the

Zone Coordinator is set to ON and the Zone

Coordinator is located at the end of the zone

bus trunk.

- Verify that only the EOL switch at the end of

the system bus is set to ON and all other

system bus EOL switches are set to OFF.

• Check connections, polarity, and lengths

- Verify that communica tions loop s ar e less th an

approximately 304 m (1,000 ft) total in length

- If you are using one transformer to power

multiple devices, verify that the device 24 VAC

power connection follows the polarity of the

common and 24 V terminations (see Power

Wiring).

• Check for opens and shorts

• Check terminations

• Check addresses

- Check for duplicate addresses.

- Verify that the address range is sequential.

• Check for sources of interference

• Check the status LED to verify power at the

controller.

• Check bus voltages:

- (+) to COM must be within 2.0 to 3.0 VDC

- (-) to COM must be within 1.5 to 2.54 VDC

- (+) to (-) must be within 0.3 to 1.0 VDC

Note: Values may fluctuate due to ongoing

communications; this operation is normal provided

the voltage is within the defined range.

Repair Information

If the Unit Control Board (UCB) fails to operate within

its specifications, replace the unit. For a replacement

controller, co ntact the nearest Johnson Controls®

representative.

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Installation Instructions 7

Page 8

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2015 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Technical Specifications

Unit Control Board with BACnet® Communication

Product Code Number SE-SPU1011-1 – Single-stage Unit Control Board with Field Bus Expansion Module

SE-SPU1012-1 – Dual-stage Unit Control Board with Field Bus Expansion Module

Power Supply Requirement 24 VAC (nominal, 20 VAC minimum/30 VAC maximum), 50/60 Hz, Power Supply

Class 2 (North America), Safety

Power Consumption 15 VA maximum

Note: VA ratings do not include any power supplied to the peripheral devices connected

to binary outputs (BOs)

Ambient Conditions Operating: -40 to 158°F (-40 to 70°C); 10 to 90% RH noncondensing

UI Operating: -4 to 158°F (-20 to 70°C); 10 to 90% RH noncondensing

Storage: -40 to 194°F (-40 to 85°C); 5 to 95% RH noncondensing

Processor RX631 Renesas® microcontroller

Memory 2 MB internal program flash, 32 KB internal E2Data flash, 4 MB external serial flash

Input and Output Capabilities SE-SPU1011-1:

Housing Unpackaged printed circuit board (PCB) with silkscreen labels

Mounting Mounted with Nylon Standoffs

Dimensions

(Height x Width x Depth)

Shipping Weight SE-SPU1011-1 – 3.6 lb (1.63 kg)

Compliance United States:

memory

9 AIs: 7: 10k RTD, 1: 0 to 10 VDC, 1: 24 VAC Voltage Monitor

13 BIs: 24 VAC input with contact cleaning circuits

5 BOs: 4: relay outputs, 1: Transistor output

SE-SPU1012-1:

12 AIs: 9: 10k RTD, 2: 0 to 10 VDC, 1: 24 VAC Voltage Monitor

1 AOs: 2 to 10 VDC, 10 mA maximum

16 BIs: 24 VAC input with contact cleaning circuits

8 BOs: 7: relay outputs, 1: transistor output

1.44 x 6.5 x 5.27 in. (36 x 165 x 133 mm)

SE-SPU1012-1 – 3.7 lb (1.68 kg)

UL Recognized, File E107041, UL 916, Energy Management Equipment, UL1995,

Heating and Cooling Equipment; FCC Compliant to CFR47, Part 15, Subpart B, Class B

Canada:

UL Recognized, File E107041, CSA 22.2 No. 236, Signal Equipment Industry Canada,

ICES-003 – Recognized

CCS Smart Equipment Control Board for Single Packaged Unit (SPU) Controller Installation Instructions8

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...